Professional Documents

Culture Documents

K017 - OHSE Tower Crane Checklist

K017 - OHSE Tower Crane Checklist

Uploaded by

Rajib Mondal0 ratings0% found this document useful (0 votes)

47 views2 pagesThis checklist documents an inspection of a tower crane at the Syngene 1401 project site. The inspection covers eight sections: the foundation, mast section, cat head with swing unit, counter jib, main jib, hoist, swing, and trolley. Each section lists specific components to check for any issues like cracks, deformation, loose or missing parts. The inspection aims to ensure the crane is properly installed and functioning safely based on its condition and compliance with displayed safety information like load charts and signage. Signatures are required from contractor safety and engineering staff as well as the project management consultant to verify review and acceptance of the inspection results.

Original Description:

CRANE CHECKLIST

Original Title

27. K017- OHSE Tower Crane Checklist

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis checklist documents an inspection of a tower crane at the Syngene 1401 project site. The inspection covers eight sections: the foundation, mast section, cat head with swing unit, counter jib, main jib, hoist, swing, and trolley. Each section lists specific components to check for any issues like cracks, deformation, loose or missing parts. The inspection aims to ensure the crane is properly installed and functioning safely based on its condition and compliance with displayed safety information like load charts and signage. Signatures are required from contractor safety and engineering staff as well as the project management consultant to verify review and acceptance of the inspection results.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

47 views2 pagesK017 - OHSE Tower Crane Checklist

K017 - OHSE Tower Crane Checklist

Uploaded by

Rajib MondalThis checklist documents an inspection of a tower crane at the Syngene 1401 project site. The inspection covers eight sections: the foundation, mast section, cat head with swing unit, counter jib, main jib, hoist, swing, and trolley. Each section lists specific components to check for any issues like cracks, deformation, loose or missing parts. The inspection aims to ensure the crane is properly installed and functioning safely based on its condition and compliance with displayed safety information like load charts and signage. Signatures are required from contractor safety and engineering staff as well as the project management consultant to verify review and acceptance of the inspection results.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

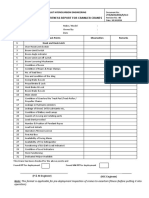

TOWER CRANE INSPECTION-CHECKLIST

PROJECT : Syngene 1401 CHECKLIST NO:

CLIENT : Syngene International Ltd. DATE & TIME:

PMC : CBRE South Asia Pvt. Ltd. MAKE & MODEL:

CONTRACTOR : HEIGHT:

LOCATION/AREA : JIB LENGTH:

INSPECTION CONDUCTED BY: YEAR & AGE:

Sl No Description Inspection Result Remarks

Ok/Yes Not

Ok/No

1. Foundation

2. Check for any cracks

3. Are the Crane rails grounded at 2 locations

4. Check fixing angles for any deformation

II Mast section

1. Check the Mast section for any deformation

2. Check the pins/Bolts of the Mast section

3. Check the climbing ladder mounting and platform

4. Check the tie-collar mounting and Pins

5. Check the climbing gauge mounting pins

6. Co-ordinates of mast centers displayed

7. Load Chart Displayed on crane mast

8. Is the Crane mast is vertical to plumb

9. Is the mast anchorages are intact

III Cat Head with Swing Unit

1. Check the revolving bolts for tightness

2. Check the Cabin Mounting Pin and Collar pins

3. Check the counter jib tie and main Jib tie Connecting Pin

and cottar Pins

4. Is the Cabin visibility through glass is ok

5. Is the Anemometer functional

6. Is the aviation lamp is functional (Reqd. for 30mt and

above)

7. Fire Extinguisher installed at operators cabin & ground

level

8. Emergency Stop button is functional

IV Counter Jib

1. Check the Counter Jib Mounting Pins and Cotter Pins

2. Check the Platform mounting pins of the panel, handrail,

sign board and working platform

3. Check the counter weight placement and pins

4. Check the mounting of the hoist winches

5. Check the Pins and cotter pins of the Tie Rod

6. Is the platform along jib & counter weight(jib) in

structurally sound & good condition

V Main Jib

1. Check the Mounting Pins and Cotter Pins

2. Check the Tie rod pins and cotter pins.

3. Check Jib Inserts connecting pins and cotter pins

4. Check the light fitting mounting for tightness

5. SWL displayed on main jib for various operating radius

6. SWL is calibrated once in a month for various operating

CBRE South Asia Pvt. Ltd Page 1 of 2

Format No. K017-OHS-TC-Ch-019/Rev02/Jan2016

radius.

VI Hoist

1. Check the condition of wire rope

2. Check over hoist limit switch

3. Check the break pads for excessive wear

4. Check the rope swiel for free rotation

5. Check the Moment Cut off Limit Switch

6. Check the break Cylinder for proper function and

leakage

VII Swing

1. Check the Swing Brake

2. Check Swing Limit Switch if applicable

3. Swing Alarm is functional

VIII Trolley

1. Check the Trolley rope condition and rope end arresting

2. Check the trolley brake

3. Check the trolley lock arrangement

4. Check the working platform pins and handrails attached

with trolley

5. Check the trolley in and out limit Switch

OHSE Incharge of Contractor signature/Name/Date: …………………./………………/……………

Discipline P&M Engineer of Contractor Signature/Name/Date: ……………………. /……………………../…………………

CBRE Reviewed and

Accepted □ Rejected □ Observation Incorporated & Closed □

Comments: ……………………………………………………………………………………………………………………………………………

PMC- CBRE Discipline Engineer Signature/Name/Date: ………………………/……….………………./……………………

CBRE OHSE Manager Signature/Name/Date: ………………………/…………………………. /…………………

CBRE South Asia Pvt. Ltd Page 2 of 2

Format No. K017-OHS-TC-Ch-019/Rev02/Jan2016

You might also like

- MKS SERVO57D - CAN User Manual V1.0.0Document45 pagesMKS SERVO57D - CAN User Manual V1.0.0EU100% (1)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- E021-Checklist LT PanelDocument1 pageE021-Checklist LT Panelaudiihussain67% (3)

- Checklist For Anchor Bolt FixingDocument1 pageChecklist For Anchor Bolt FixingGabriel Gabe100% (4)

- AL1 Programmer 2017Document34 pagesAL1 Programmer 2017Umer Farooq75% (4)

- Advanced Oilfield Technology Company LLC: Work ProcedureDocument6 pagesAdvanced Oilfield Technology Company LLC: Work ProcedureAhmed M. AbdelazizNo ratings yet

- Piping Field Inspection Checklist DikonversiDocument3 pagesPiping Field Inspection Checklist DikonversiJo Francesc100% (2)

- Form Checklist Pre Erection GirderDocument8 pagesForm Checklist Pre Erection GirderRoro Menna Ayu Aldilla67% (6)

- Method Statement - FinalDocument6 pagesMethod Statement - FinalJustin Joy0% (1)

- Imagining Constructions Digital FutureDocument14 pagesImagining Constructions Digital Futurekmandar99No ratings yet

- IpTIME Manual Wireless Router EngDocument9 pagesIpTIME Manual Wireless Router EngJinwookParkNo ratings yet

- Tower Crane Inspection ChecklistDocument1 pageTower Crane Inspection Checklistshakti123456789No ratings yet

- Tower Crane ChecklistDocument1 pageTower Crane ChecklistkardinyenduNo ratings yet

- IM-09-A9 Tower Crane Inspection Check ListDocument2 pagesIM-09-A9 Tower Crane Inspection Check ListVishnu SNo ratings yet

- Tower Crane Inspection Checklist ChecklistDocument1 pageTower Crane Inspection Checklist Checklistalok.singhNo ratings yet

- SGT - Le.014 Crane Inspection Type 1Document10 pagesSGT - Le.014 Crane Inspection Type 1ryangillespie100% (1)

- Crane Assembling Check ListDocument2 pagesCrane Assembling Check ListBaldev SinghNo ratings yet

- Draft Maintenance Check List For 220Mm Point Machine (Clamp Type) Installed at Thick Web Switch LayoutDocument5 pagesDraft Maintenance Check List For 220Mm Point Machine (Clamp Type) Installed at Thick Web Switch Layoutexam proNo ratings yet

- Intermediate Inspection Criteria, Well Control Equipment: Equipment Group: Shooting NippleDocument2 pagesIntermediate Inspection Criteria, Well Control Equipment: Equipment Group: Shooting NippleKaleem UllahNo ratings yet

- Boom Truck Instructors NotesDocument76 pagesBoom Truck Instructors NotesWill RodriguezNo ratings yet

- Crane ChecklistDocument1 pageCrane ChecklistArun RAAJASEKARNo ratings yet

- Material Handling Equipment Test Method Rev. 2 (Dood)Document8 pagesMaterial Handling Equipment Test Method Rev. 2 (Dood)ThomasNo ratings yet

- HookDocument5 pagesHookHarris ShehzadNo ratings yet

- Maintenance Schedules For BG Coaches of Icf DesignDocument6 pagesMaintenance Schedules For BG Coaches of Icf DesignParthaprotim NathNo ratings yet

- K018 - OHSE Crane ChecklistDocument1 pageK018 - OHSE Crane ChecklistRajib MondalNo ratings yet

- Cur Soar Condicion A Do AutoDocument37 pagesCur Soar Condicion A Do AutoFabio Adriana FláviaNo ratings yet

- Audit Report Century 14 Rev 1Document51 pagesAudit Report Century 14 Rev 1agusnurcahyo66100% (1)

- (B) Viewing Procedure of Crank Shaft AimDocument3 pages(B) Viewing Procedure of Crank Shaft Aimesakkimuthu100% (1)

- High Pressure Lines PDFDocument3 pagesHigh Pressure Lines PDFKaleem UllahNo ratings yet

- 05 Checklist C&S RC Work (General)Document6 pages05 Checklist C&S RC Work (General)Aldi mubaroq100% (1)

- Equipment Fitness Report For Crawler Cranes - Rev 00Document1 pageEquipment Fitness Report For Crawler Cranes - Rev 00okba labdiNo ratings yet

- TM 80 Daily and Weekly Inspection and Maintenance TasksDocument25 pagesTM 80 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoNo ratings yet

- Form Inspection Premob - Quarterly (1) - 2Document26 pagesForm Inspection Premob - Quarterly (1) - 2Ryan Rhamdhani100% (1)

- Overhead CranesDocument50 pagesOverhead CraneshamzanusratNo ratings yet

- TM 120 Daily and Weekly Inspection and Maintenance TasksDocument23 pagesTM 120 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoNo ratings yet

- Hoist Annual Inspection ChecklistDocument1 pageHoist Annual Inspection ChecklistMohamad Hairy Hafizal RosniNo ratings yet

- H-Type CBCDocument67 pagesH-Type CBCManohara BabuNo ratings yet

- Equipment Group:: Intermediate Inspection Criteria, Well Control EquipmentDocument2 pagesEquipment Group:: Intermediate Inspection Criteria, Well Control Equipmentkaleem ullah jan100% (2)

- Sub Structure NewDocument6 pagesSub Structure NewEkene NwachukwuNo ratings yet

- Crane ProceduresDocument67 pagesCrane ProceduresKen RanggaNo ratings yet

- Crawler Crane Checklist Rev 0Document2 pagesCrawler Crane Checklist Rev 0Maizatul Akmar Manshor100% (2)

- Check List Int DiaDocument2 pagesCheck List Int DiaCrazzy RamNo ratings yet

- SECL-CV210-A4 Pre-Pouring InspectionDocument1 pageSECL-CV210-A4 Pre-Pouring InspectionhadefNo ratings yet

- 01 QC Preventive Maintenance Checklist Drafted Q34 Q44 1Document153 pages01 QC Preventive Maintenance Checklist Drafted Q34 Q44 1shani5573No ratings yet

- Preventive Maintenance Checklist Drafted Q34 Q44 1Document152 pagesPreventive Maintenance Checklist Drafted Q34 Q44 1shani5573100% (1)

- Intermodal ChecklistDocument4 pagesIntermodal Checklistrogelio mezaNo ratings yet

- Chain Sling ChecklistDocument1 pageChain Sling Checklistswarnajit paulNo ratings yet

- SOP Mobile Crane-Rev.1Document7 pagesSOP Mobile Crane-Rev.1RonniNo ratings yet

- Kelly Hose PDFDocument2 pagesKelly Hose PDFKaleem UllahNo ratings yet

- Ex - No 1 Dismantling of Piston EngineDocument9 pagesEx - No 1 Dismantling of Piston EngineesakkimuthuNo ratings yet

- Qc-Qcr-Ele-24 Power CircuitDocument1 pageQc-Qcr-Ele-24 Power CircuitRoderick HipolNo ratings yet

- PrecommissioningSwitchgear GeneralDocument3 pagesPrecommissioningSwitchgear GeneralSatish ReddyNo ratings yet

- Crawler Crane Inspection ChecklistDocument8 pagesCrawler Crane Inspection ChecklistMD RASID FAKIRNo ratings yet

- Maintenance Y SERIESDocument10 pagesMaintenance Y SERIESStowartNo ratings yet

- Irata, NDT, Inspection EngineerDocument5 pagesIrata, NDT, Inspection EngineerryangillespieNo ratings yet

- Tank ProcedureDocument5 pagesTank ProcedurejacquesmayolNo ratings yet

- Guidance Inspection Crane RuiDocument34 pagesGuidance Inspection Crane RuiRonniNo ratings yet

- 24 Safety Checks Before Crane OperationDocument14 pages24 Safety Checks Before Crane OperationNeeta PatilNo ratings yet

- G Series Elevator Maintenance ManualDocument9 pagesG Series Elevator Maintenance ManualBahman MatouriNo ratings yet

- 11 5K 5K Annular BOPDocument4 pages11 5K 5K Annular BOPEdwin MP0% (1)

- Crane Inspection Checklist-RevDocument1 pageCrane Inspection Checklist-RevPradip Tapan BanerjeeNo ratings yet

- Boom Lift - Man Lift Inspection ChecklistsDocument3 pagesBoom Lift - Man Lift Inspection ChecklistsAgung Tri SugihartoNo ratings yet

- DDocking Survey ChecklistDocument3 pagesDDocking Survey ChecklistTammam HassanNo ratings yet

- K019 - OHSE Builder Hoist ChecklistDocument1 pageK019 - OHSE Builder Hoist ChecklistRajib MondalNo ratings yet

- L021 - OHSE Piling Work Permit Cum Checklist FormatDocument1 pageL021 - OHSE Piling Work Permit Cum Checklist FormatRajib MondalNo ratings yet

- K008 - OHSE Concrete Works ChecklistDocument1 pageK008 - OHSE Concrete Works ChecklistRajib MondalNo ratings yet

- L025 - OHSE Adhesive Application Work PermitDocument2 pagesL025 - OHSE Adhesive Application Work PermitRajib MondalNo ratings yet

- L019 - OHSE Shaft Work Permit FormatDocument1 pageL019 - OHSE Shaft Work Permit FormatRajib MondalNo ratings yet

- K018 - OHSE Crane ChecklistDocument1 pageK018 - OHSE Crane ChecklistRajib MondalNo ratings yet

- K013 - OHSE Welding Machine ChecklistDocument1 pageK013 - OHSE Welding Machine ChecklistRajib MondalNo ratings yet

- AHU Typical Manifold Arrangement Drawing PDFDocument1 pageAHU Typical Manifold Arrangement Drawing PDFRajib MondalNo ratings yet

- Scaffold Safety ProcedureDocument24 pagesScaffold Safety ProcedureRajib MondalNo ratings yet

- Aditya College of Technology & Science Satna Group PageDocument4 pagesAditya College of Technology & Science Satna Group PagePankaj soniNo ratings yet

- Chapter 5 Pen Testing AndroidDocument17 pagesChapter 5 Pen Testing AndroidBouslah YasserNo ratings yet

- Optimass 1400 Tech DatasheetDocument32 pagesOptimass 1400 Tech DatasheetAbid Hossain RupamNo ratings yet

- Reference Guide: March 02, 2012Document40 pagesReference Guide: March 02, 2012Lara SantoNo ratings yet

- 2.VSUN410 108MH BW Solar Module 182mm 30 1722 1134 30Document2 pages2.VSUN410 108MH BW Solar Module 182mm 30 1722 1134 30beydacaltu beydacaltuNo ratings yet

- Cpa Tcig Tin 000 Issue T 130722Document2 pagesCpa Tcig Tin 000 Issue T 130722Tarek HareedyNo ratings yet

- 1GT105DC PDFDocument4 pages1GT105DC PDFIsos CellNo ratings yet

- SynopsisDocument4 pagesSynopsisT-Series0% (1)

- Testing Equipment For The Construction Industry - CONTROLS PDFDocument2 pagesTesting Equipment For The Construction Industry - CONTROLS PDFMayaisjakaBlankNo ratings yet

- Css Cheat SheetDocument3 pagesCss Cheat SheetSyrine hammoudaNo ratings yet

- First Semester-NOTESDocument182 pagesFirst Semester-NOTESkalpanaNo ratings yet

- BITM Lesson 1 Class Notes - v1 0Document29 pagesBITM Lesson 1 Class Notes - v1 0Hawkins ChinNo ratings yet

- MS SQL DBA Course ContentDocument5 pagesMS SQL DBA Course ContenttejareddyNo ratings yet

- Case 5 2020 PDFDocument2 pagesCase 5 2020 PDFAhmadNo ratings yet

- Microsoft Azure Commercial Penetration Test Report 20190613Document47 pagesMicrosoft Azure Commercial Penetration Test Report 20190613cnbirdNo ratings yet

- D475a, D475asd 5e0Document18 pagesD475a, D475asd 5e0João MariaNo ratings yet

- Manual SF-C21Document126 pagesManual SF-C21AgnaldoNo ratings yet

- Dabur: Creating Efficient, Cost-Saving Shared Services With Sap® Document Access by OpentextDocument6 pagesDabur: Creating Efficient, Cost-Saving Shared Services With Sap® Document Access by OpentextAnkitaNo ratings yet

- DHIS2 Events and Tracker: Background and Introduction Part 1 of 3Document12 pagesDHIS2 Events and Tracker: Background and Introduction Part 1 of 3NeoGellinNo ratings yet

- Automobile Design (5051)Document4 pagesAutomobile Design (5051)Ziyad KprNo ratings yet

- Failure Analysis ExaminationDocument3 pagesFailure Analysis ExaminationNelbert SumalpongNo ratings yet

- Web Design Pre-ProposalDocument5 pagesWeb Design Pre-ProposalOmoniyi Lawson100% (1)

- Is Three Solutions in One - LucideaDocument5 pagesIs Three Solutions in One - Lucideafahmi1987No ratings yet

- Smart City Lahore Phase-1: A Collaboration Between PITB andDocument14 pagesSmart City Lahore Phase-1: A Collaboration Between PITB andHussain DanialNo ratings yet

- Fernandez, Ryan Kristoffer A.: Figure 1: Steam Power Plant DiagramDocument5 pagesFernandez, Ryan Kristoffer A.: Figure 1: Steam Power Plant DiagramBruce BannerNo ratings yet

- Systems Hardware System Storage Ts Data Sheet Tsd03174usen 20171122Document4 pagesSystems Hardware System Storage Ts Data Sheet Tsd03174usen 20171122Dean DjordjevicNo ratings yet