Professional Documents

Culture Documents

DTL 1 BLDG 1 AUCU EE 102

DTL 1 BLDG 1 AUCU EE 102

Uploaded by

SYED RAIYAN HOSSAINCopyright:

Available Formats

You might also like

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Quick Ref Table For V-Notch Weir, 0 To 64 L/s oDocument3 pagesQuick Ref Table For V-Notch Weir, 0 To 64 L/s osultanbona99100% (1)

- 4700 Ofs - 6610239659Document2 pages4700 Ofs - 6610239659ALEJO100% (1)

- Fire Pump DiagramDocument1 pageFire Pump DiagrammarvinNo ratings yet

- AVC FAN Catalog 10 2017Document78 pagesAVC FAN Catalog 10 2017FRANCISCO JAVIER RODRIGUEZ LEAL0% (1)

- Electrical PlanDocument1 pageElectrical PlandeanNo ratings yet

- DesignDocument1 pageDesignSubhash SahuNo ratings yet

- Electrical Schematic Diagram For Lift Switch Board For Lift No. L3 (FPTV)Document1 pageElectrical Schematic Diagram For Lift Switch Board For Lift No. L3 (FPTV)Lukman IbrahimNo ratings yet

- 04 - SC-Exercise-ANSI PDFDocument7 pages04 - SC-Exercise-ANSI PDFEma Robertho NaniNo ratings yet

- 5721-Article Text-16024-1-10-20200328Document5 pages5721-Article Text-16024-1-10-20200328f20220331No ratings yet

- Mini Project Harmonisa SebelumDocument1 pageMini Project Harmonisa SebelumShohib FaseNo ratings yet

- Cunanan Exam 3Document1 pageCunanan Exam 3ELLAINE DE CLARONo ratings yet

- Fault Current 30 Cycle For Relay Co-Ordination ANSI Standard PDFDocument1 pageFault Current 30 Cycle For Relay Co-Ordination ANSI Standard PDFRAJANo ratings yet

- Medium Voltage Network Design Exercise BookDocument31 pagesMedium Voltage Network Design Exercise BookJennifer SimpsonNo ratings yet

- Performance Check Form Cooling Tower PDFDocument1 pagePerformance Check Form Cooling Tower PDFzar niNo ratings yet

- Assignment No 2Document16 pagesAssignment No 2morye.riyalNo ratings yet

- Annexure - IV (SLD)Document6 pagesAnnexure - IV (SLD)Gaurav SinghNo ratings yet

- SC Exercise ANSIDocument5 pagesSC Exercise ANSIdiogoufrn-1No ratings yet

- TUTORIAL 2 - Forces Acting On Particle and Rigid BodyDocument7 pagesTUTORIAL 2 - Forces Acting On Particle and Rigid BodybiasedmoldyNo ratings yet

- Webench Design Report: Electrical BOMDocument7 pagesWebench Design Report: Electrical BOMGuilhermeNo ratings yet

- 3 BJT-3Document3 pages3 BJT-3shilaNo ratings yet

- Aditional Examples For Entropy ProductionDocument4 pagesAditional Examples For Entropy ProductionPaola AguileraNo ratings yet

- 6.5 Proble MS: K K H TDocument8 pages6.5 Proble MS: K K H TanumnedNo ratings yet

- MB3773Document32 pagesMB3773chrisNo ratings yet

- Bat-Dwg-Dd-Me-00-Ep-6003 - R0 - Load Schedule Diagram of PP Chiller - PP - AhuDocument1 pageBat-Dwg-Dd-Me-00-Ep-6003 - R0 - Load Schedule Diagram of PP Chiller - PP - AhuCosphiiiNo ratings yet

- Annexure-B1 (Typical Plant SLD)Document4 pagesAnnexure-B1 (Typical Plant SLD)saurabhNo ratings yet

- One-Line Diagram - OLV1 (Edit Mode)Document1 pageOne-Line Diagram - OLV1 (Edit Mode)unedo parhusipNo ratings yet

- Contoh Soal Diagram ImpedansiDocument11 pagesContoh Soal Diagram ImpedansiJoseph67% (3)

- Local Media5650569760850960331Document3 pagesLocal Media5650569760850960331William JugalbotNo ratings yet

- Per Unit System Explanation With Solved ExampleDocument13 pagesPer Unit System Explanation With Solved ExampleMoudinet PassoretNo ratings yet

- One-Line Diagram - Olv1 (Edit Mode) : Page 1 19:29:39 Oct 01, 2017 Project File: HerdoloudryDocument1 pageOne-Line Diagram - Olv1 (Edit Mode) : Page 1 19:29:39 Oct 01, 2017 Project File: HerdoloudryAlfiana RamadhaniNo ratings yet

- One-Line Diagram - OLV1 (Edit Mode)Document1 pageOne-Line Diagram - OLV1 (Edit Mode)unedo parhusipNo ratings yet

- Controller and Mini-Programmer: Ascon Tecnologic S.R.L. 2.1 General Notes About WiringDocument35 pagesController and Mini-Programmer: Ascon Tecnologic S.R.L. 2.1 General Notes About WiringPetru GhineaNo ratings yet

- BEAM - MOMENT Ke 2Document45 pagesBEAM - MOMENT Ke 2azwanNo ratings yet

- Tutorial Topic 2 Unbalanced FaultDocument12 pagesTutorial Topic 2 Unbalanced Faultzeyn mzNo ratings yet

- T7 - 082 - Ni Made Ari SarasuandewiDocument1 pageT7 - 082 - Ni Made Ari SarasuandewisarasNo ratings yet

- D.B Loading - Unloading PumpsDocument1 pageD.B Loading - Unloading PumpsAhmed ShoaibNo ratings yet

- MGS & WipDocument2 pagesMGS & WipRoni HadyanNo ratings yet

- Hydraulic BlocksDocument2 pagesHydraulic BlocksSasko Dimitrov100% (1)

- Bta16 600BDocument5 pagesBta16 600Btwitcuenta00No ratings yet

- 4857-59 Cable Schedule Sending End Switchyard LRMP TRMP CT CVT MBDocument3 pages4857-59 Cable Schedule Sending End Switchyard LRMP TRMP CT CVT MBDev Dutt DwivediNo ratings yet

- Bts Site As-Built Documentation: Site Id: 18SPT165 Site Name: Kabuau - Parenggean - SPTDocument16 pagesBts Site As-Built Documentation: Site Id: 18SPT165 Site Name: Kabuau - Parenggean - SPTHaryo WNo ratings yet

- CB2 Cable2 Ampacity Cable4 Ampacity: Amps TAB TGS (Nom. KV 0.22, Plot Ref. KV 0.22)Document1 pageCB2 Cable2 Ampacity Cable4 Ampacity: Amps TAB TGS (Nom. KV 0.22, Plot Ref. KV 0.22)Eduardo DavilaNo ratings yet

- Dibujo1 Presentación3Document1 pageDibujo1 Presentación3giovanni.zemmaNo ratings yet

- 1.main SLDDocument1 page1.main SLDPratikSakharkarNo ratings yet

- Summary of The Simulation:: Name: Tayyab Mansoor Ch. SAP: 24166Document31 pagesSummary of The Simulation:: Name: Tayyab Mansoor Ch. SAP: 24166Xahid YousafNo ratings yet

- LP GHDocument2 pagesLP GHShofi FawahisNo ratings yet

- Lectures 9 - 10 Voltage Regulators 2019-2Document55 pagesLectures 9 - 10 Voltage Regulators 2019-2Vanderson Xavier vandilolNo ratings yet

- Webench Design Report: Electrical BOMDocument10 pagesWebench Design Report: Electrical BOMJurgen González LópezNo ratings yet

- BT EcodialDocument1 pageBT EcodialNgọc NômNo ratings yet

- Mps 8098Document6 pagesMps 8098freddyNo ratings yet

- One-Line Diagram - Study View (Edit Mode) : Network Feeder 500 Mvasc 33 KV Network Feeder 500 Mvasc 33 KVDocument1 pageOne-Line Diagram - Study View (Edit Mode) : Network Feeder 500 Mvasc 33 KV Network Feeder 500 Mvasc 33 KVBhavik PrajapatiNo ratings yet

- Wall Structural DesignDocument1 pageWall Structural DesignnurNo ratings yet

- FMMT3903 FMMT3904: Sot23 NPN Silicon Planar Switching TransistorsDocument2 pagesFMMT3903 FMMT3904: Sot23 NPN Silicon Planar Switching TransistorsSuper WhippedNo ratings yet

- Eas254 MDM Part 2 - ExampleDocument8 pagesEas254 MDM Part 2 - ExampleNasrulNo ratings yet

- Slab Design6 Edj ROOFDocument2 pagesSlab Design6 Edj ROOFhedayatullahNo ratings yet

- And The Power Supply Transformers As Well As Those of The Electrical Lines)Document15 pagesAnd The Power Supply Transformers As Well As Those of The Electrical Lines)JayagurunathanNo ratings yet

- Calculation of Short Circuit Current 1704367703Document4 pagesCalculation of Short Circuit Current 17043677035r9rp4jq5dNo ratings yet

- Bts Site As-Built Documentation: Site Id: 18SPT169 Site Name: Karang - Tunggal - SPTDocument16 pagesBts Site As-Built Documentation: Site Id: 18SPT169 Site Name: Karang - Tunggal - SPTHaryo WNo ratings yet

- CE-5013 Structure IIIDocument46 pagesCE-5013 Structure IIIKyaw Zin HeinNo ratings yet

- Low Voltage Circuit Breaker Designing: Compiled By: Er. SADIQ HUSSAIN - INDIADocument16 pagesLow Voltage Circuit Breaker Designing: Compiled By: Er. SADIQ HUSSAIN - INDIAsaleh gazi100% (1)

- Star1 (Star TCC) - Engg9 (Project Editor)Document1 pageStar1 (Star TCC) - Engg9 (Project Editor)Vishal PankhaniyaNo ratings yet

- Lecture # 23Document14 pagesLecture # 23VaridGuptaNo ratings yet

- IJCRT2006358Document6 pagesIJCRT2006358SYED RAIYAN HOSSAINNo ratings yet

- Environmental Assessment Report of Road and Drain (P-1) of KaliakoirDocument103 pagesEnvironmental Assessment Report of Road and Drain (P-1) of KaliakoirSYED RAIYAN HOSSAINNo ratings yet

- 0 Sense of Place PPDocument7 pages0 Sense of Place PPSYED RAIYAN HOSSAINNo ratings yet

- Bird Feeding GuideDocument2 pagesBird Feeding GuideSYED RAIYAN HOSSAINNo ratings yet

- DTL 1 BLDG 1 AUCU EE 103Document1 pageDTL 1 BLDG 1 AUCU EE 103SYED RAIYAN HOSSAINNo ratings yet

- SNDP CompressedDocument1 pageSNDP CompressedSYED RAIYAN HOSSAINNo ratings yet

- ARC 494 Lecture 03Document9 pagesARC 494 Lecture 03SYED RAIYAN HOSSAINNo ratings yet

- Solvency & Credit FacilitiesDocument2 pagesSolvency & Credit FacilitiesSYED RAIYAN HOSSAINNo ratings yet

- 30 ST Mary AxeDocument29 pages30 ST Mary AxeAkrame100% (1)

- Roll No. ...................... Total Pages: 3: GSM/D-21Document3 pagesRoll No. ...................... Total Pages: 3: GSM/D-21Pankaj KaushikNo ratings yet

- Operations & Production ManagementDocument33 pagesOperations & Production ManagementSaqlain AbbasNo ratings yet

- 6802 4301 Data AnalysisDocument31 pages6802 4301 Data AnalysisAnsuman PrasadNo ratings yet

- Common Lesson Plan 3 - Kelly SibrianDocument4 pagesCommon Lesson Plan 3 - Kelly Sibrianapi-510450123No ratings yet

- Psicothema 0214-9915: Issn: Psicothema@cop - EsDocument8 pagesPsicothema 0214-9915: Issn: Psicothema@cop - EsangeNo ratings yet

- A Report Writing (Amaco)Document9 pagesA Report Writing (Amaco)Stive AustineNo ratings yet

- Second Language Lexical Acquisition: The Case of Extrovert and Introvert ChildrenDocument10 pagesSecond Language Lexical Acquisition: The Case of Extrovert and Introvert ChildrenPsychology and Education: A Multidisciplinary JournalNo ratings yet

- Three Phase Induction MotorDocument6 pagesThree Phase Induction MotorCønstäh Van Der WüppertälärîanskíhNo ratings yet

- 3 s2.0 B9780124079144060012 MainDocument3 pages3 s2.0 B9780124079144060012 Mainsiintoolina tubeNo ratings yet

- Grade 5 Chapter 1 The Fish TaleDocument15 pagesGrade 5 Chapter 1 The Fish TaleThulirgalNo ratings yet

- Manpreet Et Al 2010Document12 pagesManpreet Et Al 2010manpreetNo ratings yet

- AI LandscapeDocument111 pagesAI LandscapeSuraj PatilNo ratings yet

- Evidence Giving AdviceDocument3 pagesEvidence Giving AdviceJessica Morales0% (1)

- EC100Document2 pagesEC100Esfan GaripNo ratings yet

- Excavadora 270 CLC John Deere 1719Document524 pagesExcavadora 270 CLC John Deere 1719Angel Rodriguez100% (1)

- Risk Adjustment of Health-Care Performance MeasureDocument12 pagesRisk Adjustment of Health-Care Performance MeasureAmbarNo ratings yet

- Improvement Effect of Vacuum Consolidation and Prefabricated Vertical Drain in Peat GroundDocument10 pagesImprovement Effect of Vacuum Consolidation and Prefabricated Vertical Drain in Peat GroundMark MengNo ratings yet

- Power Electronics: Eng. Ameen QuranDocument31 pagesPower Electronics: Eng. Ameen QuranFatima AgNo ratings yet

- Arcelormittal 4q 22 Esg PresentationDocument30 pagesArcelormittal 4q 22 Esg PresentationmukeshindpatiNo ratings yet

- R-KEM II ETA - Polyester Resin For ConcreteDocument16 pagesR-KEM II ETA - Polyester Resin For ConcreteLouis BirNo ratings yet

- Recruitment For The Post of Office AttendantDocument2 pagesRecruitment For The Post of Office AttendantrajnagpNo ratings yet

- Fluid McqsDocument10 pagesFluid Mcqsfloret leoNo ratings yet

- HL GR 12 Exam Guidelines 2015Document23 pagesHL GR 12 Exam Guidelines 2015ntandotwala201No ratings yet

- Roland Sh-201 - Guide Book EnGLISHDocument15 pagesRoland Sh-201 - Guide Book EnGLISHHURRYSTARNo ratings yet

- Twin Screw PumpsDocument56 pagesTwin Screw PumpsAyman MedaneyNo ratings yet

- Datatool Alarm ManualDocument20 pagesDatatool Alarm ManualMark AustinNo ratings yet

- Assignment 3Document7 pagesAssignment 3Midhun MNo ratings yet

DTL 1 BLDG 1 AUCU EE 102

DTL 1 BLDG 1 AUCU EE 102

Uploaded by

SYED RAIYAN HOSSAINOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DTL 1 BLDG 1 AUCU EE 102

DTL 1 BLDG 1 AUCU EE 102

Uploaded by

SYED RAIYAN HOSSAINCopyright:

Available Formats

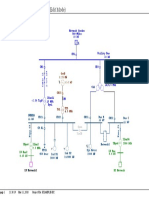

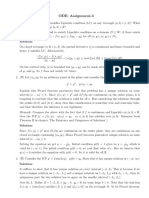

M12 = Heat Press M/C : 3.0kw, 1-phase Q1= A/C 2.

0kw,1-Phase C151= 20/25ATPN-E CU BBT

M13 = Heat Press M/C : 3.0kw, 3-phase Q2= Computer & Ploter = 1.50kw,1-Phase C152= 32ATPN-E CU BBT Cable Tray

M1 = Autocutting M/C : 3.80 kw, 1-phase M7 = Auto Spreading M/C : 3.0kw, 1-phase

M14 = Fusing M/C : 8.0kw, 3-phase Q3-Q10= Manual Cutter m/c = 0.59kw,1-Phase C153= 40ATPN-E CU BBT A Type = 18" BBT

M2 = Autocutting M/C : 30.0 kw, 3-phase M15 = Bend Knife M/C : 0.89kw, 1-phase Q11-16 For Cutter m/c = 0.59kw, 1 Phase C154= 50ATPN-E CU BBT BBT

M8 = Auto Spreading M/C : 13.0kw, 3-phase B Type = 12"

M16 = Rib Cutter M/C : 0.5kw, 1-phase Q17-Q18= Fabric Inspection m/c = 0.88kw,1-Phase C155= 63ATPN-E CU BBT

SDB-502(VX)

M3 = Auto Spreading M/C : 3.0kw , 1-phase M9 = Auto Spreading M/C 2.20kw , 3-phase C Type = 10" Trolly BBT

M17 = Steam platter M/C : 4.5kw, 3-phase C156= 100ATPN-E CU BBT`

SDB-501(L)

M4 = Auto Spreading M/C : 13.0kw , 3-phase M10 = Heat Press M/C : 3.0kw, 1-phase

M5 = Auto Spreading M/C : 3.0kw , 1-phase C157= 150ATPN-E CU BBT D Type = 8"

M11 = Heat Press M/C : 3.0kw, 3-phase

M6 = Auto Spreading M/C : 13.0kw, 3-phase C158= 200ATPN-E CU BBT

DB-501

C159= 250ATPN-E CU BBT

Cable Tray D-Type 3C11+C6 C11

C16 C17

C11 C11 C11 T4 C11

227'-3"

M14 T2 T1 T3 C11 T5 T6

Q1

C15 10 ASPN-E TOB C23 C154

Fusing 3C11+C6

M/C B- Type Cable Tray

STAIR

2C11+C6 C11 C11 250 ATPN-E Feed Unit

C152

25 ATPN-E Feed Unit

Q8 Q10

10 ASPN-E TOB

Q7 Q9

B- Type Cable Tray

C6+C11 32 ATPN-E TOB C159 Manual Spreading Table - 02

Q2 M15 M16 C11 C11 C11 C11 End Box

32 ATPN-E TOB 32 ATPN-E TOB

Band Rib Cutting Table

C6 OIC Office & Knife

& Plotter 25 ATPN-E

C15 32 ATPN-E Feed Unit

Travel BBT or Trolly BBT

Q3 Q4 Manual Spreading Table - 01 Q5 Q6

100ATPN-E TOB

C11 C11 C11 C11 End Box

P-504

Print Checking Area

Print Checking Area 32 ATPN-E Feed Unit 20ASPN-E TOB 25 ATPN-E

C156 Travel BBT or Trolly BBT

SDB-504(P) C159

LIFT

5'-10"X5'-10" Collar C11 Fabric Relaxation Fabric Stotage

T8 T7 Heat Press C19 & Cuff

100ATPN-E TOB

M13 M11 Fabric Relaxation

C11 T11 T12 B- Type Cable Tray

C11 C7 C7 C11

C11 Q11 15 ASPN-E TOB BBT Light (C154)

15 ASPN-E TOB M12 M10 40 ATPN-E TOB

C14 C14

C14+C18

C11

Input Area C157 250/150 ATPN-E BBT

20 ASPN-E TOB Reducing unit

Power Cable Riser (PCR)

10 ATPN-E TOB M9

Q12 C14 Auto Spreading Table - 04

110'

C7

M1 M2

Size- 4'x6"

Cable Rail terinal

C157

C153 C16

C11

Fabric Plating & Checking Area Q17 Q18

M8 Auto Spreading Table - 03

25 ASPN-E TOB 40 ATPN-E TOB

C24/C25 End Box

C18 C7+C16 Cable Duct in Floor C11

Q13 15 ASPN-E TOB 15 ASPN-E TOB C11

C14 C153

25 ASPN-E TOB 15 ATPN-E TOB 20 ASPN-E TOB

C11 M7

T9 BBT-POWER T15

T10 C153

40 ATPN-E TOB T16

Power Supply from MDB at Ground Floor.

C11 C11 T13 T14 C11 M17 20 ASPN-E TOB

40 ATPN-E TOB M6 C12

C24/C25

C11 C11

C11

Q14

15 ASPN-E TOB

Auto cutter

C16

C14 Auto Spreading Table - 02

C11 25 ASPN-E TOB M5 P-502

Cable Duct in Floor

Q15 C7+2C14+2C16

T23

M4

40 ATPN-E TOB C6

C16

20'-0"X24'-7"

C11 C157

STAIR

C14 Auto Spreading Table - 01

C154

C11 End Box Q16 25 ASPN-E TOB M3

STAIR

100 ATPN-E Feed Unit C11+2C6 2C6

P-503 40 ATPN-E TOB C19 P-501

C11 C7+3C14+3C16

C11+C6 T22 C11 T21 SDB-503(P) C11 T17 T18 C11 T19 C11 T20

C11

2C11+C6

D- Type Cable Tray 2C11+2C6 D- Type Cable Tray

TOB = Tap off Box

FU = Feed Unit Ref. Drg.:

1) For Legend : Pl. see drg. DTL-1-AUCU-EE-100 Communication Cable Riser (CCR)

Note: 3) Connection of M3, M4, M5, M6, M7, M8 & M9 will be done by Size- 3'x6"

Note: 1) Mounting height of BBT-Light= 2.3m 2) For light- fan layout: Pl. see drg. DTL-1-AUCU-EE-101

cable laid in cable duct inside floor from SDB-503(P).

2) Mounting height of BBT-Power = 2.5m 3) For Circuit dia of m/c & general power: Pl. see drg. DTL-1-AUCU-EE-105.

Project:..............-Autocut Drawing title :- Electrical Consultant: Architect: Mechanical Consultant: Note : Status Date

Proposed Development of Cutting Section at 5th

Power outlet [Machine & General], DB, Md. Shah Alam Talukder. PEng. ............................ 1. Earth terminals of all switch For Comments ..................

W

floor of Building - 1 ............................................. ............................................

BBT & Conduit layout-5th Floor. F-5507. DMI # 03/0001. boards and socket outlets must For Approval ................

Dhaka, Bamgladesh.

be provided with ECC

Fig. 9.03

OWNER: ....................

ENGINEERING SERVICE ASSOCIATES

ELECTRICAL SYSTEM DESIGN AND DOCUMENTATION

Structural Engineer:

N connection. R-1: For Approval ........07-17

S

Drawn by : (Changed DB

..................................................................................

Drg. no : ........................-AUCU-EE- 102-R1 House # 13 Road # 01, Block # G 2. No twisted joint shall be

..................................................................................... Banasree Housing Area, ......................................

Md. Harun-Ar-Rashid done throughout the wiring location & Power

....................................................................... Dhaka - 1219, Bangladesh.

Scale : Not to Scale. system. Supply System)

E

Date :..................................

You might also like

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Quick Ref Table For V-Notch Weir, 0 To 64 L/s oDocument3 pagesQuick Ref Table For V-Notch Weir, 0 To 64 L/s osultanbona99100% (1)

- 4700 Ofs - 6610239659Document2 pages4700 Ofs - 6610239659ALEJO100% (1)

- Fire Pump DiagramDocument1 pageFire Pump DiagrammarvinNo ratings yet

- AVC FAN Catalog 10 2017Document78 pagesAVC FAN Catalog 10 2017FRANCISCO JAVIER RODRIGUEZ LEAL0% (1)

- Electrical PlanDocument1 pageElectrical PlandeanNo ratings yet

- DesignDocument1 pageDesignSubhash SahuNo ratings yet

- Electrical Schematic Diagram For Lift Switch Board For Lift No. L3 (FPTV)Document1 pageElectrical Schematic Diagram For Lift Switch Board For Lift No. L3 (FPTV)Lukman IbrahimNo ratings yet

- 04 - SC-Exercise-ANSI PDFDocument7 pages04 - SC-Exercise-ANSI PDFEma Robertho NaniNo ratings yet

- 5721-Article Text-16024-1-10-20200328Document5 pages5721-Article Text-16024-1-10-20200328f20220331No ratings yet

- Mini Project Harmonisa SebelumDocument1 pageMini Project Harmonisa SebelumShohib FaseNo ratings yet

- Cunanan Exam 3Document1 pageCunanan Exam 3ELLAINE DE CLARONo ratings yet

- Fault Current 30 Cycle For Relay Co-Ordination ANSI Standard PDFDocument1 pageFault Current 30 Cycle For Relay Co-Ordination ANSI Standard PDFRAJANo ratings yet

- Medium Voltage Network Design Exercise BookDocument31 pagesMedium Voltage Network Design Exercise BookJennifer SimpsonNo ratings yet

- Performance Check Form Cooling Tower PDFDocument1 pagePerformance Check Form Cooling Tower PDFzar niNo ratings yet

- Assignment No 2Document16 pagesAssignment No 2morye.riyalNo ratings yet

- Annexure - IV (SLD)Document6 pagesAnnexure - IV (SLD)Gaurav SinghNo ratings yet

- SC Exercise ANSIDocument5 pagesSC Exercise ANSIdiogoufrn-1No ratings yet

- TUTORIAL 2 - Forces Acting On Particle and Rigid BodyDocument7 pagesTUTORIAL 2 - Forces Acting On Particle and Rigid BodybiasedmoldyNo ratings yet

- Webench Design Report: Electrical BOMDocument7 pagesWebench Design Report: Electrical BOMGuilhermeNo ratings yet

- 3 BJT-3Document3 pages3 BJT-3shilaNo ratings yet

- Aditional Examples For Entropy ProductionDocument4 pagesAditional Examples For Entropy ProductionPaola AguileraNo ratings yet

- 6.5 Proble MS: K K H TDocument8 pages6.5 Proble MS: K K H TanumnedNo ratings yet

- MB3773Document32 pagesMB3773chrisNo ratings yet

- Bat-Dwg-Dd-Me-00-Ep-6003 - R0 - Load Schedule Diagram of PP Chiller - PP - AhuDocument1 pageBat-Dwg-Dd-Me-00-Ep-6003 - R0 - Load Schedule Diagram of PP Chiller - PP - AhuCosphiiiNo ratings yet

- Annexure-B1 (Typical Plant SLD)Document4 pagesAnnexure-B1 (Typical Plant SLD)saurabhNo ratings yet

- One-Line Diagram - OLV1 (Edit Mode)Document1 pageOne-Line Diagram - OLV1 (Edit Mode)unedo parhusipNo ratings yet

- Contoh Soal Diagram ImpedansiDocument11 pagesContoh Soal Diagram ImpedansiJoseph67% (3)

- Local Media5650569760850960331Document3 pagesLocal Media5650569760850960331William JugalbotNo ratings yet

- Per Unit System Explanation With Solved ExampleDocument13 pagesPer Unit System Explanation With Solved ExampleMoudinet PassoretNo ratings yet

- One-Line Diagram - Olv1 (Edit Mode) : Page 1 19:29:39 Oct 01, 2017 Project File: HerdoloudryDocument1 pageOne-Line Diagram - Olv1 (Edit Mode) : Page 1 19:29:39 Oct 01, 2017 Project File: HerdoloudryAlfiana RamadhaniNo ratings yet

- One-Line Diagram - OLV1 (Edit Mode)Document1 pageOne-Line Diagram - OLV1 (Edit Mode)unedo parhusipNo ratings yet

- Controller and Mini-Programmer: Ascon Tecnologic S.R.L. 2.1 General Notes About WiringDocument35 pagesController and Mini-Programmer: Ascon Tecnologic S.R.L. 2.1 General Notes About WiringPetru GhineaNo ratings yet

- BEAM - MOMENT Ke 2Document45 pagesBEAM - MOMENT Ke 2azwanNo ratings yet

- Tutorial Topic 2 Unbalanced FaultDocument12 pagesTutorial Topic 2 Unbalanced Faultzeyn mzNo ratings yet

- T7 - 082 - Ni Made Ari SarasuandewiDocument1 pageT7 - 082 - Ni Made Ari SarasuandewisarasNo ratings yet

- D.B Loading - Unloading PumpsDocument1 pageD.B Loading - Unloading PumpsAhmed ShoaibNo ratings yet

- MGS & WipDocument2 pagesMGS & WipRoni HadyanNo ratings yet

- Hydraulic BlocksDocument2 pagesHydraulic BlocksSasko Dimitrov100% (1)

- Bta16 600BDocument5 pagesBta16 600Btwitcuenta00No ratings yet

- 4857-59 Cable Schedule Sending End Switchyard LRMP TRMP CT CVT MBDocument3 pages4857-59 Cable Schedule Sending End Switchyard LRMP TRMP CT CVT MBDev Dutt DwivediNo ratings yet

- Bts Site As-Built Documentation: Site Id: 18SPT165 Site Name: Kabuau - Parenggean - SPTDocument16 pagesBts Site As-Built Documentation: Site Id: 18SPT165 Site Name: Kabuau - Parenggean - SPTHaryo WNo ratings yet

- CB2 Cable2 Ampacity Cable4 Ampacity: Amps TAB TGS (Nom. KV 0.22, Plot Ref. KV 0.22)Document1 pageCB2 Cable2 Ampacity Cable4 Ampacity: Amps TAB TGS (Nom. KV 0.22, Plot Ref. KV 0.22)Eduardo DavilaNo ratings yet

- Dibujo1 Presentación3Document1 pageDibujo1 Presentación3giovanni.zemmaNo ratings yet

- 1.main SLDDocument1 page1.main SLDPratikSakharkarNo ratings yet

- Summary of The Simulation:: Name: Tayyab Mansoor Ch. SAP: 24166Document31 pagesSummary of The Simulation:: Name: Tayyab Mansoor Ch. SAP: 24166Xahid YousafNo ratings yet

- LP GHDocument2 pagesLP GHShofi FawahisNo ratings yet

- Lectures 9 - 10 Voltage Regulators 2019-2Document55 pagesLectures 9 - 10 Voltage Regulators 2019-2Vanderson Xavier vandilolNo ratings yet

- Webench Design Report: Electrical BOMDocument10 pagesWebench Design Report: Electrical BOMJurgen González LópezNo ratings yet

- BT EcodialDocument1 pageBT EcodialNgọc NômNo ratings yet

- Mps 8098Document6 pagesMps 8098freddyNo ratings yet

- One-Line Diagram - Study View (Edit Mode) : Network Feeder 500 Mvasc 33 KV Network Feeder 500 Mvasc 33 KVDocument1 pageOne-Line Diagram - Study View (Edit Mode) : Network Feeder 500 Mvasc 33 KV Network Feeder 500 Mvasc 33 KVBhavik PrajapatiNo ratings yet

- Wall Structural DesignDocument1 pageWall Structural DesignnurNo ratings yet

- FMMT3903 FMMT3904: Sot23 NPN Silicon Planar Switching TransistorsDocument2 pagesFMMT3903 FMMT3904: Sot23 NPN Silicon Planar Switching TransistorsSuper WhippedNo ratings yet

- Eas254 MDM Part 2 - ExampleDocument8 pagesEas254 MDM Part 2 - ExampleNasrulNo ratings yet

- Slab Design6 Edj ROOFDocument2 pagesSlab Design6 Edj ROOFhedayatullahNo ratings yet

- And The Power Supply Transformers As Well As Those of The Electrical Lines)Document15 pagesAnd The Power Supply Transformers As Well As Those of The Electrical Lines)JayagurunathanNo ratings yet

- Calculation of Short Circuit Current 1704367703Document4 pagesCalculation of Short Circuit Current 17043677035r9rp4jq5dNo ratings yet

- Bts Site As-Built Documentation: Site Id: 18SPT169 Site Name: Karang - Tunggal - SPTDocument16 pagesBts Site As-Built Documentation: Site Id: 18SPT169 Site Name: Karang - Tunggal - SPTHaryo WNo ratings yet

- CE-5013 Structure IIIDocument46 pagesCE-5013 Structure IIIKyaw Zin HeinNo ratings yet

- Low Voltage Circuit Breaker Designing: Compiled By: Er. SADIQ HUSSAIN - INDIADocument16 pagesLow Voltage Circuit Breaker Designing: Compiled By: Er. SADIQ HUSSAIN - INDIAsaleh gazi100% (1)

- Star1 (Star TCC) - Engg9 (Project Editor)Document1 pageStar1 (Star TCC) - Engg9 (Project Editor)Vishal PankhaniyaNo ratings yet

- Lecture # 23Document14 pagesLecture # 23VaridGuptaNo ratings yet

- IJCRT2006358Document6 pagesIJCRT2006358SYED RAIYAN HOSSAINNo ratings yet

- Environmental Assessment Report of Road and Drain (P-1) of KaliakoirDocument103 pagesEnvironmental Assessment Report of Road and Drain (P-1) of KaliakoirSYED RAIYAN HOSSAINNo ratings yet

- 0 Sense of Place PPDocument7 pages0 Sense of Place PPSYED RAIYAN HOSSAINNo ratings yet

- Bird Feeding GuideDocument2 pagesBird Feeding GuideSYED RAIYAN HOSSAINNo ratings yet

- DTL 1 BLDG 1 AUCU EE 103Document1 pageDTL 1 BLDG 1 AUCU EE 103SYED RAIYAN HOSSAINNo ratings yet

- SNDP CompressedDocument1 pageSNDP CompressedSYED RAIYAN HOSSAINNo ratings yet

- ARC 494 Lecture 03Document9 pagesARC 494 Lecture 03SYED RAIYAN HOSSAINNo ratings yet

- Solvency & Credit FacilitiesDocument2 pagesSolvency & Credit FacilitiesSYED RAIYAN HOSSAINNo ratings yet

- 30 ST Mary AxeDocument29 pages30 ST Mary AxeAkrame100% (1)

- Roll No. ...................... Total Pages: 3: GSM/D-21Document3 pagesRoll No. ...................... Total Pages: 3: GSM/D-21Pankaj KaushikNo ratings yet

- Operations & Production ManagementDocument33 pagesOperations & Production ManagementSaqlain AbbasNo ratings yet

- 6802 4301 Data AnalysisDocument31 pages6802 4301 Data AnalysisAnsuman PrasadNo ratings yet

- Common Lesson Plan 3 - Kelly SibrianDocument4 pagesCommon Lesson Plan 3 - Kelly Sibrianapi-510450123No ratings yet

- Psicothema 0214-9915: Issn: Psicothema@cop - EsDocument8 pagesPsicothema 0214-9915: Issn: Psicothema@cop - EsangeNo ratings yet

- A Report Writing (Amaco)Document9 pagesA Report Writing (Amaco)Stive AustineNo ratings yet

- Second Language Lexical Acquisition: The Case of Extrovert and Introvert ChildrenDocument10 pagesSecond Language Lexical Acquisition: The Case of Extrovert and Introvert ChildrenPsychology and Education: A Multidisciplinary JournalNo ratings yet

- Three Phase Induction MotorDocument6 pagesThree Phase Induction MotorCønstäh Van Der WüppertälärîanskíhNo ratings yet

- 3 s2.0 B9780124079144060012 MainDocument3 pages3 s2.0 B9780124079144060012 Mainsiintoolina tubeNo ratings yet

- Grade 5 Chapter 1 The Fish TaleDocument15 pagesGrade 5 Chapter 1 The Fish TaleThulirgalNo ratings yet

- Manpreet Et Al 2010Document12 pagesManpreet Et Al 2010manpreetNo ratings yet

- AI LandscapeDocument111 pagesAI LandscapeSuraj PatilNo ratings yet

- Evidence Giving AdviceDocument3 pagesEvidence Giving AdviceJessica Morales0% (1)

- EC100Document2 pagesEC100Esfan GaripNo ratings yet

- Excavadora 270 CLC John Deere 1719Document524 pagesExcavadora 270 CLC John Deere 1719Angel Rodriguez100% (1)

- Risk Adjustment of Health-Care Performance MeasureDocument12 pagesRisk Adjustment of Health-Care Performance MeasureAmbarNo ratings yet

- Improvement Effect of Vacuum Consolidation and Prefabricated Vertical Drain in Peat GroundDocument10 pagesImprovement Effect of Vacuum Consolidation and Prefabricated Vertical Drain in Peat GroundMark MengNo ratings yet

- Power Electronics: Eng. Ameen QuranDocument31 pagesPower Electronics: Eng. Ameen QuranFatima AgNo ratings yet

- Arcelormittal 4q 22 Esg PresentationDocument30 pagesArcelormittal 4q 22 Esg PresentationmukeshindpatiNo ratings yet

- R-KEM II ETA - Polyester Resin For ConcreteDocument16 pagesR-KEM II ETA - Polyester Resin For ConcreteLouis BirNo ratings yet

- Recruitment For The Post of Office AttendantDocument2 pagesRecruitment For The Post of Office AttendantrajnagpNo ratings yet

- Fluid McqsDocument10 pagesFluid Mcqsfloret leoNo ratings yet

- HL GR 12 Exam Guidelines 2015Document23 pagesHL GR 12 Exam Guidelines 2015ntandotwala201No ratings yet

- Roland Sh-201 - Guide Book EnGLISHDocument15 pagesRoland Sh-201 - Guide Book EnGLISHHURRYSTARNo ratings yet

- Twin Screw PumpsDocument56 pagesTwin Screw PumpsAyman MedaneyNo ratings yet

- Datatool Alarm ManualDocument20 pagesDatatool Alarm ManualMark AustinNo ratings yet

- Assignment 3Document7 pagesAssignment 3Midhun MNo ratings yet