Professional Documents

Culture Documents

AHFs Vs AFEs White Paper

AHFs Vs AFEs White Paper

Uploaded by

Dinesh Kumar0 ratings0% found this document useful (0 votes)

11 views3 pagesActive front ends (AFE) replace diode rectifiers in variable frequency drives (VFDs) with active, IGBT-based rectifiers to cancel out harmonics created by VFDs. AFEs have very low THD below 5% and high power factor. Active harmonic filters inject corrective current into the power system to mitigate harmonics from non-linear loads. Both AFEs and active harmonic filters are effective solutions for meeting IEEE harmonic distortion standards, but each have advantages depending on the application characteristics and number of drives.

Original Description:

AHF and AFE comparaison

Original Title

AHFs vs AFEs White Paper

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentActive front ends (AFE) replace diode rectifiers in variable frequency drives (VFDs) with active, IGBT-based rectifiers to cancel out harmonics created by VFDs. AFEs have very low THD below 5% and high power factor. Active harmonic filters inject corrective current into the power system to mitigate harmonics from non-linear loads. Both AFEs and active harmonic filters are effective solutions for meeting IEEE harmonic distortion standards, but each have advantages depending on the application characteristics and number of drives.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

11 views3 pagesAHFs Vs AFEs White Paper

AHFs Vs AFEs White Paper

Uploaded by

Dinesh KumarActive front ends (AFE) replace diode rectifiers in variable frequency drives (VFDs) with active, IGBT-based rectifiers to cancel out harmonics created by VFDs. AFEs have very low THD below 5% and high power factor. Active harmonic filters inject corrective current into the power system to mitigate harmonics from non-linear loads. Both AFEs and active harmonic filters are effective solutions for meeting IEEE harmonic distortion standards, but each have advantages depending on the application characteristics and number of drives.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

Application Decision Making:

Active Harmonic Filters vs. Active Front Ends

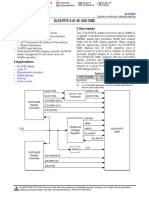

About Harmonics Active Front Ends (AFE)

There have been various solutions developed In a regular variable speed drive, the rectifier is controlled

for mitigating harmonic distortion over the past through diodes. With an AFE these are replaced with an

couple of decades. Harmonics became an increasingly active, generally IGBT based, controlled rectifier. This

important issue as more facilities have begun to active rectifier creates canceling harmonics that effectively

use variable frequency drives (VFDs) creating an eliminate those created in standard VFDs. In the figure

immense burden on our utility grid. Engineers will below, it shows the components of an AFE, including

attempt to specify the harmonic limits for bus loads, the active rectifier, DC energy storage, and the inverter.

which include switchgear and motor control centers Because of its series installation the active rectifier needs to

(MCC), in order to help to mitigate this problem. be able to transmit the full power of the load. In addition

to performing harmonic correction, the active front end

IEEE-519-2014 provides a guideline for Total

rectifier has the ability to feed electrical energy back to the

Harmonic Distortion (THD) limits that are being

utility during braking. AFE drives usually have very low

increasingly enforced by utility companies around the

current distortion (often down to 5% THD) and high power

United States, in an attempt to maintain power quality

factor. The ability to feedback braking energy is very useful

for their customers. IEEE-519 requires that each in applications; while in others, AFEs are only installed for

facility at the Point of Common Coupling (PCC) meet their effectiveness at reducing harmonic distortion.

certain THD levels. These levels are based on several

Active Front End Diagram

considerations within the facility and the utility that is

providing the power. The PCC is clearly defined as the

point where the utility power enters the facility, not at

each drive input.

These recommendations require facilities to

utilize active front ends, 18-pulse drives or use an

additional passive or active harmonic filter with a

12-pulse or 6-pulse drive, all of which can significantly

In order to make the AFE as light and compact as possible,

increase initial equipment installation costs.

the switching frequency of the active rectifier must be

relatively low. This lower switching frequency creates a

higher switching ripple, which can introduce harmonics

The following document will provide a comparison of above the 50th order; these higher-order harmonics can

drives equipped with an active front end with the use of negatively affect the performance of some equipment. In

6-pulse drives combined with an active harmonic filter. order to mitigate these concerns the switching frequency

These are both proven methods of decreasing harmonic must be increased. However, manufacturers do not

typically take this approach because the active rectifier

distortion to below IEEE-519 levels. However before we

becomes physically larger and more expensive. The rectifier

can compare these two systems we need to take time to

also creates a voltage boost on the DC bus voltage when

give an overview how both of these different solutions

compared to a conventional 6-pulse drive. This higher DC

work and can aid a facility with harmonic distortion

bus voltage creates a higher ripple on the motor side, which

issues.

may require a dv/dt filter be placed to protect to motor/load.

Mesta Electronics Inc. 11020 Parker Drive, North Huntingdon PA 15642

Phone: 412-754-3000 Fax: 412-754-3016 Email mesta@mesta.com Web: www.mesta.com Page 1

Active Harmonic Filters Comprehensive Comparison

Active harmonic filters use intelligent electronics

and IGBTs to inject corrective current into the power

Advantages of Active Front Ends

system to correct for the harmonics generated by

non-linear loads. Systems are installed in parallel to • Some cost savings can be realized in comparison

the utility line and sensors are used to monitor the to active harmonic filters if there is a single, large

line and determine the amount of corrective current drive present in the application

that must be injected to ensure the utility provides a • Provides increased input protection for a VFD

sinusoidal waveform. and its semiconductors from line transients

Active Harmonic Filter • Systems are insensitive to network imbalance

Installation Diagram present in the line

• Will be IEEE-519 compliant when active rectifier

is transmitting full load power

• Has a extremely high power factor going as high

as .99

• Able to feed energy back to the grid during

braking effectively reducing utility costs

Advantages of Active Harmonic Filters

Active Harmonic Filter

• While an AFE meets the harmonic limits specified

Active harmonic filters can be used to compensate

in the IEEE-519, an active harmonic filter, if sized

for both harmonic distortion and power factor, and

correctly, guarantees that the standard is met,

one unit can be used to compensate for multiple

making THD less than 5% regardless if the VFDs

non-linear loads. It is able to operate at its maximum

are not operating near maximum load.

current rating and not be overloaded, even if new

loads are installed. Multiple active harmonic filters • One Active Harmonic Filter can correct for

can be installed in parallel to supply corrective current multiple 6-pulse drive systems, while if using an

for larger applications. They are able to function AFE, the system is required for each drive product,

properly if voltage imbalances exist. Active harmonic which can become costly if the application has

filters can be a more costly solution for a single multipleVFDs.

drive application, but as one filter is used to correct • Active Harmonic Filters introduce significantly

for multiple loads, they clearly become a more cost less switching ripple than an AFE because of its

effective solution. use of a higher switching frequency and smaller

size in comparison to the load

Mesta Electronics Inc. 11020 Parker Drive, North Huntingdon PA 15642

Phone: 412-754-3000 Fax: 412-754-3016 Email mesta@mesta.com Web: www.mesta.com Page 2

Comprehensive Comparison Conclusions

Advantages of Active Harmonic Filters

• An Active Harmonic Filter, if appropriately sized, Both systems are effective at mitigating harmonic

can correct power factor and balance the line while distortion and meeting IEEE-519, and it often

simultaneously correcting the facilities/application depends on each individual facility to determine

harmonic distortion. which application to use. Certain situations where a

• Parallel installation of active harmonic filters single large VFD is present an Active Front End may

provides for easy installation with no major system be the more cost effective option, however active

rework, while the installation of a AFE requires harmonic filters can be more cost effective if there

complete replacement of each existing drive are multiple VFDs (non-linear loads) in the facility.

The Active Harmonic Filter is the only solution to

• Active Harmonic Filters can be integrated with

guarantee that IEEE-519 recommendations are met,

MCC’s switch gear, which dramatically save space

even when voltage unbalance exists or if a load is

and costs when compared to an AFE, whose

not expected to run at its maximum (which are both

footprints’ may be a concern, especially for retrofit

common).

projects.

• Active Harmonic Filters have less losses and

increased efficiency , which decreases electricity

and cooling costs when compared to series type References

AFE arrangements

1. D.J. Carnovale, “Applying Harmonic Solutions to

• Maintenance, repair, and replacement of 6-pulse Commercial Systems.” Globalcon, 2003, Boston, MA.

drives combined with an active harmonic filter are 2. IEEE Standard 519-1992-IEEE Recommended Practices and

significantly faster and less complicated than that Requirements for Harmonic Control in Electrical Power

of Active Front Ends. Systems

3. Kelly, Rob. “Active Front End Variable Frequency Drives.”

Pumps & Systems Magazine. Emerson Control Techniques,

2010. Web. 11 June 2014.

4. Singh, B.; Al-Haddad, K. and Chandra, A. (1999) A review

of active filters for power quality improvement”, IEEE Trans.

Industrial Electronics, vol. 46, no. 5, pp. 960-971.

5. “CDA Magazine – Reducing Harmonics with Filter or

Active Front-End Drives?”18 Sept. 2012. Web. 11 June 2014.

6. Nick Guskov, “Straight Talk about PWM AC Drive

Harmonic Problems and Solutions.” Rockwell Automation,

Mequon, WI.

7. Persson, Jonas. “Comparing Harmonics Mitigation

Techniques.” (2014): n. pag. Web. 10 June 014.

Mesta Electronics Inc. 11020 Parker Drive, North Huntingdon PA 15642

Phone: 412-754-3000 Fax: 412-754-3016 Email mesta@mesta.com Web: www.mesta.com Page 3

You might also like

- Omis 109 PresentationDocument15 pagesOmis 109 Presentationapi-471141379No ratings yet

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- Business Idea Feasibility Report: Electronicsaid (PVT.), LTDDocument11 pagesBusiness Idea Feasibility Report: Electronicsaid (PVT.), LTDOmair Mir50% (2)

- NI 40-41 ManualDocument47 pagesNI 40-41 ManualNikhil Singh100% (1)

- Lvd-Eotkn073u-En - RevaDocument5 pagesLvd-Eotkn073u-En - RevaAshen RavinduNo ratings yet

- Drives br011 - en P PDFDocument8 pagesDrives br011 - en P PDFreynhardsNo ratings yet

- Engineering Bulletin: Variable Frequency Drive/ Generator ApplicationDocument2 pagesEngineering Bulletin: Variable Frequency Drive/ Generator ApplicationMustafa A.WNo ratings yet

- Perfect PDFDocument15 pagesPerfect PDFPRECIOUS MUMBANo ratings yet

- Active Harmonic FilterDocument8 pagesActive Harmonic FilterKanai BanerjeeNo ratings yet

- Danfoss 3Document2 pagesDanfoss 3mavenplanningengineerNo ratings yet

- AF-6 Catalogue Ed02 (En)Document64 pagesAF-6 Catalogue Ed02 (En)NateshNo ratings yet

- Harmonics - A Costly Problem: Easily SolvedDocument10 pagesHarmonics - A Costly Problem: Easily SolvedBalan PalaniappanNo ratings yet

- FN 3410 Open FrameDocument6 pagesFN 3410 Open FrameVarun GuptaNo ratings yet

- Ecosine Max, 480 VAC 60 HZ Full Performance Passive Harmonic FiltersDocument5 pagesEcosine Max, 480 VAC 60 HZ Full Performance Passive Harmonic FiltersOmar Alfredo Del Castillo QuispeNo ratings yet

- Ineator Ineator: Advanced Universal Harmonic FilterDocument8 pagesIneator Ineator: Advanced Universal Harmonic FilterAhmed KotbNo ratings yet

- Clean Power Drive Solution To Harmonic DistortionDocument8 pagesClean Power Drive Solution To Harmonic DistortionBijuNo ratings yet

- Achieve Superior Product Performance and Reliability!: Application ProfileDocument2 pagesAchieve Superior Product Performance and Reliability!: Application ProfileAnonymous T0KltPNo ratings yet

- Eaton 9390 Datasheet Com5Document12 pagesEaton 9390 Datasheet Com5Ali IbrahimNo ratings yet

- Ijser: Simulation of Active Front End Converter Based VFD For Induction MotorsDocument6 pagesIjser: Simulation of Active Front End Converter Based VFD For Induction Motorsabdallah hosinNo ratings yet

- Highly Efficient Active Front End Enables Trouble-Free Operation of Low Harmonic DrivesDocument12 pagesHighly Efficient Active Front End Enables Trouble-Free Operation of Low Harmonic DrivesdavialacerdaNo ratings yet

- Meeting Ieee519Document4 pagesMeeting Ieee519rechtman1289No ratings yet

- Single-Tuned Passive Harmonic Filters Design With Uncertain Source and Load CharacteristicsDocument9 pagesSingle-Tuned Passive Harmonic Filters Design With Uncertain Source and Load CharacteristicsTuydocuNo ratings yet

- Schaffner Datasheet FN3471Document5 pagesSchaffner Datasheet FN3471thyago.rNo ratings yet

- HarmonicsDocument10 pagesHarmonicsPaul Andres Mantilla SolorzanoNo ratings yet

- WP Mitigating Harmonics 2014 Thought Leadership White Paper: Mitigating Data Center HarmonicDocument7 pagesWP Mitigating Harmonics 2014 Thought Leadership White Paper: Mitigating Data Center HarmonicMani SainiNo ratings yet

- Applying Low Voltage Harmonic Filters, Revisited: By: Brian Prokuda, P.E. Keweenaw Power Systems, Howell, MIDocument9 pagesApplying Low Voltage Harmonic Filters, Revisited: By: Brian Prokuda, P.E. Keweenaw Power Systems, Howell, MIMostafa ElSayedNo ratings yet

- Designing Power Factor Correction Equipment For Economic ReturnsDocument3 pagesDesigning Power Factor Correction Equipment For Economic ReturnsGenosNo ratings yet

- Three Phase OptionsDocument3 pagesThree Phase OptionsVineeth KrishnarajNo ratings yet

- Hybrid Active Power FilterDocument54 pagesHybrid Active Power FilterMadhu Mathi ErNo ratings yet

- Quote CT PT Isolator VCB AB Switch Drop Out Fuse Set TPMO SMC LT Distribution Box HT PanelDocument11 pagesQuote CT PT Isolator VCB AB Switch Drop Out Fuse Set TPMO SMC LT Distribution Box HT PanelSharafatNo ratings yet

- Power Quality Best Practices Part 2 Electrical Mirror 1673640158Document2 pagesPower Quality Best Practices Part 2 Electrical Mirror 1673640158Hitesh RaiNo ratings yet

- A Guide To Supply Harmonics and Other Low Frequency Disturbances Iss2x 0704 0002 02x PDFDocument32 pagesA Guide To Supply Harmonics and Other Low Frequency Disturbances Iss2x 0704 0002 02x PDFRichie ChicolNo ratings yet

- Project TransformersDocument2 pagesProject TransformersNikhil SinghNo ratings yet

- Transformer-Based Uneven Doherty Power Amplifier in 90 NM CMOS For WLAN ApplicationsDocument13 pagesTransformer-Based Uneven Doherty Power Amplifier in 90 NM CMOS For WLAN Applicationsreddy balajiNo ratings yet

- Harmonic Filtering TechniquesDocument5 pagesHarmonic Filtering TechniquesDarshan MNo ratings yet

- 1-PQF - Filtros Activos de ArmónicosDocument12 pages1-PQF - Filtros Activos de ArmónicosAnonymous cOYX3GRdRBNo ratings yet

- Power FactorDocument3 pagesPower FactorravisriramulNo ratings yet

- PG 000162Document6 pagesPG 000162voNo ratings yet

- Synchronous Transfer Control With SC9000 EP: Application Paper AP020001ENDocument8 pagesSynchronous Transfer Control With SC9000 EP: Application Paper AP020001ENLIU LINo ratings yet

- Switch Mode Power Supply Topologies Compared - Wurth Electronics MidcomDocument4 pagesSwitch Mode Power Supply Topologies Compared - Wurth Electronics Midcommayank shuklaNo ratings yet

- Panda, 2012Document6 pagesPanda, 2012EdsonNo ratings yet

- 04.26.24_Innomotics_WaterCooled_Brochure_200dpiDocument12 pages04.26.24_Innomotics_WaterCooled_Brochure_200dpieltripperNo ratings yet

- Active Harmonic Filter-PQF PamphletDocument12 pagesActive Harmonic Filter-PQF PamphletPercy GoitsemangNo ratings yet

- UE NeutralRatingsDocument6 pagesUE NeutralRatingssibashisdharNo ratings yet

- Current Transformer, Potential Transformer, LTCT, Low Tension CT, Combined CTPT Unit, Metering Unit, Metering Cubicle, Resin Cast CT, Cast Resin CT, Cast Resin PT, RVT, Residual Voltatge TransformerDocument12 pagesCurrent Transformer, Potential Transformer, LTCT, Low Tension CT, Combined CTPT Unit, Metering Unit, Metering Cubicle, Resin Cast CT, Cast Resin CT, Cast Resin PT, RVT, Residual Voltatge TransformerSharafatNo ratings yet

- Rockwell Multi - Pulse Transformer SolutionsDocument10 pagesRockwell Multi - Pulse Transformer Solutionsalex696No ratings yet

- A New Control Algorithm For Harmonics and Reactive Power Compensation Under Non-Ideal Mains VoltageDocument6 pagesA New Control Algorithm For Harmonics and Reactive Power Compensation Under Non-Ideal Mains VoltageAlfredo CordovaNo ratings yet

- Active Filter Solutions For Utility Interface of Industrial LoadsDocument7 pagesActive Filter Solutions For Utility Interface of Industrial LoadsPoorna ChandraNo ratings yet

- Passive Harmonic FilterDocument5 pagesPassive Harmonic FilterKanai BanerjeeNo ratings yet

- HPS TruWave Active Harmonic Filter BrochureDocument12 pagesHPS TruWave Active Harmonic Filter BrochureRafael Adrián CarrillonsNo ratings yet

- Power Factor CorrectionDocument2 pagesPower Factor CorrectionGeo ThaliathNo ratings yet

- A Transfer Function Approach To Harmonic Filter DesignDocument15 pagesA Transfer Function Approach To Harmonic Filter DesignvgarudaNo ratings yet

- Analysis of Harmonic Mitigation Using Hybrid Passive FilterDocument7 pagesAnalysis of Harmonic Mitigation Using Hybrid Passive FilterDinesh KumarNo ratings yet

- A 2.4-GHz - 27-DBm Asymmetric Multilevel Outphasing Power Amplifier in 65-Nm CMOSDocument13 pagesA 2.4-GHz - 27-DBm Asymmetric Multilevel Outphasing Power Amplifier in 65-Nm CMOSwangzengdaNo ratings yet

- Cost Considerations VFD FINALDocument9 pagesCost Considerations VFD FINALpatilshailesh123No ratings yet

- CT Afq enDocument12 pagesCT Afq enthulasiNo ratings yet

- 1141 F AC Line Load ReactorsDocument8 pages1141 F AC Line Load ReactorsAlejandro Olguin OlguinNo ratings yet

- IEEE519 Guide ToshibaDocument3 pagesIEEE519 Guide ToshibaVanshika MasandNo ratings yet

- Chapter 3.10-Energy Efficient Technologies EditDocument15 pagesChapter 3.10-Energy Efficient Technologies EditRahul KolheNo ratings yet

- Single-Tuned Filter Design For Harmonic Mitigation and Optimization With Capacitor BanksDocument7 pagesSingle-Tuned Filter Design For Harmonic Mitigation and Optimization With Capacitor BanksNelson ParijósNo ratings yet

- VF-S15 Toshiba DriveDocument13 pagesVF-S15 Toshiba DriveRebecca DangNo ratings yet

- Danfoss FC 301 302 newVLTbook PDFDocument20 pagesDanfoss FC 301 302 newVLTbook PDFzeljkoradaNo ratings yet

- HPS Solutions For Drive Applications BrochureDocument8 pagesHPS Solutions For Drive Applications BrochureGustavo PérezNo ratings yet

- IEEE SeFeTDocument6 pagesIEEE SeFeTDinesh KumarNo ratings yet

- CBSE Class 9 Science The Fundamental Unit of Life MCQsDocument3 pagesCBSE Class 9 Science The Fundamental Unit of Life MCQsDinesh Kumar0% (1)

- Programme For SEFET 2023 FinalDocument22 pagesProgramme For SEFET 2023 FinalDinesh KumarNo ratings yet

- Quadratic Functions and EquationsDocument23 pagesQuadratic Functions and EquationsDinesh KumarNo ratings yet

- Step-By-Step Design Procedure For A Grid-Connected Three-Phase PWM Voltage Source ConverterDocument17 pagesStep-By-Step Design Procedure For A Grid-Connected Three-Phase PWM Voltage Source ConverterDinesh KumarNo ratings yet

- MC34063 STmicroDocument23 pagesMC34063 STmicroFady HachemNo ratings yet

- Electrical 336F SYEDocument36 pagesElectrical 336F SYEhayamwuruk mantulNo ratings yet

- Transducers: by Er. Chandraveer Singh Assistant Professor School of Automation Banasthali VidyapithDocument55 pagesTransducers: by Er. Chandraveer Singh Assistant Professor School of Automation Banasthali VidyapithPOORVI LALWANINo ratings yet

- SkyAir R410 Inv Cooling EDMT281537 PDFDocument524 pagesSkyAir R410 Inv Cooling EDMT281537 PDFAnh Thu Mai100% (2)

- Transformer ManualDocument63 pagesTransformer Manualmohammed.omaraNo ratings yet

- Product Data Sheet: Miniature Circuit Breaker, Easy9, 3P, 40 A, C Curve, 4500 ADocument2 pagesProduct Data Sheet: Miniature Circuit Breaker, Easy9, 3P, 40 A, C Curve, 4500 ASunil LakhaniNo ratings yet

- Busbar ProtectionDocument42 pagesBusbar ProtectionShahzad Bhatti100% (2)

- ECE Syllabus - 2017 Batch PDFDocument314 pagesECE Syllabus - 2017 Batch PDFSrilakshmi DasariNo ratings yet

- EHVHV Cable Sheath EarthingDocument12 pagesEHVHV Cable Sheath EarthingHimdad Tahir100% (1)

- Manual Tecnico HLDocument77 pagesManual Tecnico HLEdisonGualpa100% (2)

- Design and Control of An LCL-Filter-Based Three-Phase Active RectifierDocument11 pagesDesign and Control of An LCL-Filter-Based Three-Phase Active RectifierFederico Wasonski BollutoNo ratings yet

- Hopple Battery MaintenanceDocument64 pagesHopple Battery Maintenancerup123No ratings yet

- Acti9 iPF K - A9L15688Document3 pagesActi9 iPF K - A9L15688VINOTHNo ratings yet

- Hardware Development Guide For The MIMXRT1020 Processor: Application NoteDocument24 pagesHardware Development Guide For The MIMXRT1020 Processor: Application NoteKaganovichNo ratings yet

- STR Se501Document48 pagesSTR Se501ironmike615646No ratings yet

- Manual de Uso RectificadorDocument33 pagesManual de Uso RectificadorLuis Luna CruzNo ratings yet

- 74HC4851 74HCT4851: 1. General DescriptionDocument20 pages74HC4851 74HCT4851: 1. General DescriptionYousaf KhanNo ratings yet

- Information Provided byDocument22 pagesInformation Provided byvico21hNo ratings yet

- HMC 1001 and HMC 1002Document15 pagesHMC 1001 and HMC 1002Không Có GìNo ratings yet

- Type MMCO Microprocessor Time Overcurrent Relay: ApplicationDocument4 pagesType MMCO Microprocessor Time Overcurrent Relay: ApplicationUrsula JohnsonNo ratings yet

- Line-3 (4) - Bay-403 (401) - 400KV - #Document12 pagesLine-3 (4) - Bay-403 (401) - 400KV - #1453hNo ratings yet

- Capacitor PanelDocument8 pagesCapacitor PanelPratik JangidNo ratings yet

- Pe - 1966-10Document134 pagesPe - 1966-10Anonymous kdqf49qbNo ratings yet

- 2022 Wassce Priv Physics Paper 1Document4 pages2022 Wassce Priv Physics Paper 1Reginald Da vinciNo ratings yet

- DLP470TE 0.47 4K UHD DMD: 1 Features 3 DescriptionDocument44 pagesDLP470TE 0.47 4K UHD DMD: 1 Features 3 DescriptionRojan SolelyNo ratings yet

- L 603 CDocument4 pagesL 603 CjemanuelvNo ratings yet

- A Little Legend - The BBC LS3Document6 pagesA Little Legend - The BBC LS3cubusberlin100% (2)