Professional Documents

Culture Documents

Atex - Solenoid Valve 2/2 Way With Pilot Control Explosion Proof 21X Ex M, Ex D N.C

Atex - Solenoid Valve 2/2 Way With Pilot Control Explosion Proof 21X Ex M, Ex D N.C

Uploaded by

betoplapaCopyright:

Available Formats

You might also like

- 21ih-In-Valv Solenoide InoxDocument1 page21ih-In-Valv Solenoide InoxMonica CarrenoNo ratings yet

- Port Size: DN 8, G3/8 High Pressure Solenoid Valve Manifold Further Customized Solutions Available Upon RequestDocument3 pagesPort Size: DN 8, G3/8 High Pressure Solenoid Valve Manifold Further Customized Solutions Available Upon RequestEnrique MurgiaNo ratings yet

- ICO4SDocument12 pagesICO4SGopinath SekarNo ratings yet

- Technical Data Sheet Ecotrol Rotary Control Valve TD 8CD 6HDDocument5 pagesTechnical Data Sheet Ecotrol Rotary Control Valve TD 8CD 6HDagus trionoNo ratings yet

- Series XPM Pushbutton Sampling ValveDocument1 pageSeries XPM Pushbutton Sampling ValvevangoetheNo ratings yet

- Operating Range Recommended Applications: Mechanical Seals - Agitator Seals - Liquid-Lubricated SealsDocument5 pagesOperating Range Recommended Applications: Mechanical Seals - Agitator Seals - Liquid-Lubricated SealsserdarNo ratings yet

- ICO3S 350B Hydraulic Valve Electromagnetically Actuated, Directly ControlledDocument3 pagesICO3S 350B Hydraulic Valve Electromagnetically Actuated, Directly ControlledUntoro Adi NugrohoNo ratings yet

- Wika Type M93X.D1 Pressure Gauge Data SheetDocument5 pagesWika Type M93X.D1 Pressure Gauge Data SheetTrEnD SeT vicky rioNo ratings yet

- PEGLER ValvesDocument8 pagesPEGLER Valveseng.abdullrahmanNo ratings yet

- Samson Axial Valve 3599Document6 pagesSamson Axial Valve 3599Shaheen HydrosNo ratings yet

- Valvula Accionamiento Directo Herion 96000Document2 pagesValvula Accionamiento Directo Herion 96000Base SistemasNo ratings yet

- Shell Heat Transfer Oil S4 X: Performance, Features & BenefitsDocument2 pagesShell Heat Transfer Oil S4 X: Performance, Features & Benefitsrodrigonicolasdiaz1No ratings yet

- _0000000020002400__IMI Herion Series 95000 2 way, 2 to 6mmDocument4 pages_0000000020002400__IMI Herion Series 95000 2 way, 2 to 6mmantony.ideharaNo ratings yet

- PMP Emco Wheaton D2000-Swivel-JointDocument2 pagesPMP Emco Wheaton D2000-Swivel-JointnarminaNo ratings yet

- 54 PNA enDocument2 pages54 PNA enArmin HajdarovićNo ratings yet

- 0536 A2ex 0.5Document2 pages0536 A2ex 0.5brianNo ratings yet

- ICO4S 2/2, 3/2 or 5/2 Poppet Valves Electromagnetic Actuated, Directly ControlledDocument12 pagesICO4S 2/2, 3/2 or 5/2 Poppet Valves Electromagnetic Actuated, Directly ControlledDur MuhammadNo ratings yet

- Datasheet t5500 t6500 Pressure GaugesDocument5 pagesDatasheet t5500 t6500 Pressure GaugesEdy WijayaNo ratings yet

- ENG - BD - TDS170-PN-S-GATE-PN Gate ActuatorsDocument9 pagesENG - BD - TDS170-PN-S-GATE-PN Gate Actuatorslungelo.dlaminiNo ratings yet

- B600 PDFDocument4 pagesB600 PDFzsmithNo ratings yet

- DB HDA4400ExiaATEXIECExH2 E 18.639.1 02.20Document4 pagesDB HDA4400ExiaATEXIECExH2 E 18.639.1 02.20Exinspection anoafpsoNo ratings yet

- 3521DHS BDocument4 pages3521DHS BDaniel SaucedaNo ratings yet

- Ramset rsc1045 - 2019120519315Document8 pagesRamset rsc1045 - 2019120519315sitirNo ratings yet

- Flgyt 3020 Technical SpecDocument16 pagesFlgyt 3020 Technical SpecdaniqoNo ratings yet

- Sealing Nipples GN PDF Catalogue ENG COELBO ItalyDocument1 pageSealing Nipples GN PDF Catalogue ENG COELBO Italycahyo sNo ratings yet

- 4130wog0913 - Rev14Document3 pages4130wog0913 - Rev14Quality controller100% (1)

- 250 ML Stirred Pressure Reactor Autoclaves Datasheet 1669874059Document3 pages250 ML Stirred Pressure Reactor Autoclaves Datasheet 1669874059Vamshika SutarNo ratings yet

- Diaphragm Valve, Metal: ConstructionDocument10 pagesDiaphragm Valve, Metal: ConstructionChemikal EngineerNo ratings yet

- 2520 - H Cat PumpDocument5 pages2520 - H Cat PumpRicardo RosasNo ratings yet

- Ventilador de Insuflação - SODECA CAS-ATEXDocument5 pagesVentilador de Insuflação - SODECA CAS-ATEXSandra Freire TabordaNo ratings yet

- TDS - Soudal Soudafix CA 1400Document2 pagesTDS - Soudal Soudafix CA 1400Hussein K. AliNo ratings yet

- UK SKX 12-15 - TdsDocument8 pagesUK SKX 12-15 - Tdsyarik.rguNo ratings yet

- Sika Anchorfix-2Document9 pagesSika Anchorfix-2Anonymous ELujOV3No ratings yet

- FT44 Carbon Steel Ball Float Steam Traps (DN15 To DN50)Document7 pagesFT44 Carbon Steel Ball Float Steam Traps (DN15 To DN50)Liêm HàNo ratings yet

- MOLYKOTE 165 LT Gearwheel Grease 71-0179D-01Document2 pagesMOLYKOTE 165 LT Gearwheel Grease 71-0179D-01bravindranath5768No ratings yet

- Pipe FittingsDocument5 pagesPipe FittingsAutieri AutieriNo ratings yet

- ICO4S Data SheetDocument13 pagesICO4S Data Sheetaxeaxeaxe544No ratings yet

- 2.6.5 Retro Lavado Del Sistema de Ultrafiltración (5450 - PP-008 A-B)Document2 pages2.6.5 Retro Lavado Del Sistema de Ultrafiltración (5450 - PP-008 A-B)Jennifer FigueroaNo ratings yet

- ISOVALVE Automatic ValveDocument4 pagesISOVALVE Automatic ValveDineshkumarNo ratings yet

- En5922 6 - Db16621e 10Document2 pagesEn5922 6 - Db16621e 10markoNo ratings yet

- 0589 TMCXQSTX Bg080623naDocument2 pages0589 TMCXQSTX Bg080623naranjith_007No ratings yet

- 20 ISO Tank Container enDocument5 pages20 ISO Tank Container enSmart LauNo ratings yet

- Ficha Tecnica Tapón Hexagonal de Polyamide Ex-E Draco, Marca. BimedDocument2 pagesFicha Tecnica Tapón Hexagonal de Polyamide Ex-E Draco, Marca. BimedGiancarloEleNo ratings yet

- 3xvx1wmf 2Document1 page3xvx1wmf 2recrutementee.2020No ratings yet

- Solenoid ValveDocument2 pagesSolenoid ValveHeru PurwantoNo ratings yet

- SNDocument12 pagesSNmsh16000No ratings yet

- Bartec CatalogoDocument3 pagesBartec CatalogoManuel PousaNo ratings yet

- E5906 Wk08c01Document2 pagesE5906 Wk08c01ardossantosNo ratings yet

- E1fw Metric PDFDocument1 pageE1fw Metric PDFari firmanNo ratings yet

- Mechanical Seals - Agitator Seals - Liquid-Lubricated Seals: Rely On ExcellenceDocument6 pagesMechanical Seals - Agitator Seals - Liquid-Lubricated Seals: Rely On ExcellenceVEZZ RIDE25No ratings yet

- 96000-Series Solenoid ValveDocument10 pages96000-Series Solenoid ValveBilal HussainNo ratings yet

- DK DIN Bite Type Tube FittingDocument62 pagesDK DIN Bite Type Tube FittingLuisFranciscoMarinMedranoNo ratings yet

- bite-type-tube-fittings-2015Document62 pagesbite-type-tube-fittings-2015Vaibhav KotnalaNo ratings yet

- Masoneilan Series: Complete Line of Rugged, Top Guided, Globe Valves With Lo-dB and Anti-Cavitation CapabilitiesDocument34 pagesMasoneilan Series: Complete Line of Rugged, Top Guided, Globe Valves With Lo-dB and Anti-Cavitation CapabilitiesIsrael Luna PenasNo ratings yet

- ISORIA 20 BrochureDocument16 pagesISORIA 20 BrochuremariodalNo ratings yet

- Data Sheet: 35 Frame Plunger PumpsDocument4 pagesData Sheet: 35 Frame Plunger PumpsrochdiNo ratings yet

- E5911 18 - PWK10120W 10Document4 pagesE5911 18 - PWK10120W 10Anonymous K3FaYFlNo ratings yet

- Sample QuestionsDocument3 pagesSample QuestionsRAJKUMARNo ratings yet

- 2532 EnuDocument2 pages2532 EnuAvinash AdhavNo ratings yet

- IM05805001K - LMR Electric, FDF Foam, FDM Medium Voltage Operation Manual - English - 2003Document38 pagesIM05805001K - LMR Electric, FDF Foam, FDM Medium Voltage Operation Manual - English - 2003betoplapaNo ratings yet

- Docu31797 - VNXe3100 Hardware Information GuideDocument52 pagesDocu31797 - VNXe3100 Hardware Information GuidebetoplapaNo ratings yet

- Push PullDocument50 pagesPush PullbetoplapaNo ratings yet

- Secure Socket LayerDocument14 pagesSecure Socket LayerbetoplapaNo ratings yet

- History of MEMS - PresentationDocument27 pagesHistory of MEMS - PresentationbetoplapaNo ratings yet

- Tesis QFBDocument101 pagesTesis QFBbetoplapaNo ratings yet

- X13 X15 X17 X19 X22 X25: Heriot WattDocument1 pageX13 X15 X17 X19 X22 X25: Heriot WattanishNo ratings yet

- Overload.: Nice Weld Shame About The FusionDocument5 pagesOverload.: Nice Weld Shame About The Fusionmangalraj900No ratings yet

- SP6 2Document191 pagesSP6 2RameshNo ratings yet

- CE401 Design of Steel StructuresDocument2 pagesCE401 Design of Steel Structuresrenjith037No ratings yet

- 3311 KV (1x5MVA) Sub-Staion - Tender BoQDocument10 pages3311 KV (1x5MVA) Sub-Staion - Tender BoQRicky ChangNo ratings yet

- Design of Vertical Pressure VesselDocument31 pagesDesign of Vertical Pressure Vesselshibabw worknehNo ratings yet

- Types 1808 and 1808A Pilot-Operated Relief Valves or Backpressure RegulatorsDocument8 pagesTypes 1808 and 1808A Pilot-Operated Relief Valves or Backpressure RegulatorsAlberto CastellanosNo ratings yet

- Tangki MinyakDocument6 pagesTangki MinyakcathlenNo ratings yet

- Pre-Engineered Building Solutions - FUXIN Steel Buildings Co., Ltd. 2015Document28 pagesPre-Engineered Building Solutions - FUXIN Steel Buildings Co., Ltd. 2015vannethny100% (2)

- Assessment of In-Situ Compressive Strength in Concrete Structures, Methods and CharacteristicsDocument8 pagesAssessment of In-Situ Compressive Strength in Concrete Structures, Methods and CharacteristicsAnonymous ELujOV3No ratings yet

- Bina Goodyear Berhad: Method Statement SubmittalDocument5 pagesBina Goodyear Berhad: Method Statement SubmittalGan Chin PhangNo ratings yet

- Catalogo de Pecas - Mx210 PTDocument134 pagesCatalogo de Pecas - Mx210 PTRafael de AlmeidaNo ratings yet

- Catalog Thermocouple CW ThermowellDocument2 pagesCatalog Thermocouple CW ThermowellFIRMANSYAHNo ratings yet

- Lintel Installation GuideDocument5 pagesLintel Installation GuideAnneBricklayer100% (1)

- 1.1.1 Global and National Situation in OSH - CEC 003-CEC32S6 - Construction Occupational Safety and Health (COSH)Document9 pages1.1.1 Global and National Situation in OSH - CEC 003-CEC32S6 - Construction Occupational Safety and Health (COSH)RYAN JOSEPH QUIMONo ratings yet

- Column & Shear Wall Shortening by Praveen MoragaspitiyaDocument157 pagesColumn & Shear Wall Shortening by Praveen Moragaspitiyasuman33100% (1)

- E 50B 4KG1 - Fire PDFDocument2 pagesE 50B 4KG1 - Fire PDFdocrafiNo ratings yet

- Architects Rules 1986Document24 pagesArchitects Rules 1986034039No ratings yet

- Material Submittal For IDEACUASTIC HIGH 16 PDFDocument81 pagesMaterial Submittal For IDEACUASTIC HIGH 16 PDFChris EnyinnayaNo ratings yet

- Cracking in Concrete LR R14 PDFDocument10 pagesCracking in Concrete LR R14 PDFValentin VrabieNo ratings yet

- Concrete Slump TestDocument4 pagesConcrete Slump TestyohanjNo ratings yet

- Body Safety Valve - KSB PDFDocument4 pagesBody Safety Valve - KSB PDFgm_revankar3942No ratings yet

- The Use and Interpretation of The Dynamic Cone Penetrometer (DCP) TestDocument11 pagesThe Use and Interpretation of The Dynamic Cone Penetrometer (DCP) TestRoddy TeeNo ratings yet

- COC BuildingDocument1 pageCOC Buildingrolando dionisioNo ratings yet

- 14-201-R1 Flange Insulating KitsDocument2 pages14-201-R1 Flange Insulating Kitssams1101No ratings yet

- An Introduction To Passive Solar Buildings: by J. Paul Guyer, P.E., R.A. Course No 0005466 2 PDH HoursDocument31 pagesAn Introduction To Passive Solar Buildings: by J. Paul Guyer, P.E., R.A. Course No 0005466 2 PDH HourspavanNo ratings yet

- Sewerage Code of Australia: Second EditionDocument26 pagesSewerage Code of Australia: Second Editionabhijithaval100% (1)

- 6381y Cable To bs6004 PDFDocument4 pages6381y Cable To bs6004 PDFbenNo ratings yet

- Asogravas Panorama de Los Agregados Reciclados en La Union Europea PDFDocument69 pagesAsogravas Panorama de Los Agregados Reciclados en La Union Europea PDFYazmin VargasNo ratings yet

- #4 VHB SGT G23F-B23F Data PageDocument3 pages#4 VHB SGT G23F-B23F Data PageSenthil KumarNo ratings yet

Atex - Solenoid Valve 2/2 Way With Pilot Control Explosion Proof 21X Ex M, Ex D N.C

Atex - Solenoid Valve 2/2 Way With Pilot Control Explosion Proof 21X Ex M, Ex D N.C

Uploaded by

betoplapaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Atex - Solenoid Valve 2/2 Way With Pilot Control Explosion Proof 21X Ex M, Ex D N.C

Atex - Solenoid Valve 2/2 Way With Pilot Control Explosion Proof 21X Ex M, Ex D N.C

Uploaded by

betoplapaCopyright:

Available Formats

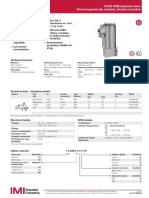

21X Ex m, Ex d N.C.

Atex - Solenoid valve 2/2 way With pilot control Explosion proof

FEATURES TECHNICAL SPECIFICATION 4 Switching time: 20-40 msec

(depending on pressure conditions)

4 Dedicate to CPT Market 4 Body material: Stainless Steel AISI 316 4 (Conforme to Atex Directive 94/9/CE ATEX)

4 Explosion proof rate 4 Armature tube: Stainless Steel AISI 300 series For S.V. 21X2Q..

4 Reliable construction 4 Plungers: Stainless Steel AISI 400 series II 2G Ex mb IIC Gb

4 Spring: Stainless Steel AISI 300 series II 2D Ex tb IIIC t130°C Db

4 Ex d Housing in Aluminium die cast

4 Media: mineral oils, gasoline, diesel, fuel oils, air For S.V. 21X2KI..

Ex d inert gases, water, 134 a, R 404a II 2G Ex d IIC t6 o t5 Gb

4 Ex m Ambient temperature: See coils catalogue page for its compatibility II 2D Ex bb IIIC T80°C o T95°C Db

4 Ex m Fluid temperature: -10°C +80°C with FKM seals (Tamb: -40°C ≤ +60°C)

4 Ex d Housing Ambient temperature: -40°C +60°C

4 Ex d Fluid temperature: -30°C +80°C with H-NBR seals

-10°C +140°C with FKM seals

4 Design pressure PS: 25 bar

Ex m 4 Protection class: Ex m IP65 (complete with electric plug)

Ex d IP 65 (with hosing fitted by cable gland Atex Ex d)

4 Electrical conformity: IEC 335

N.C.

21X 2 QD V 120 B D A 08 012 C S Section Section

2= G 1/2 012= 12V C= DC 1 REPAIR KIT 2 REPAIR KIT

QD= N.C. Ex m V= FKM For spare parts please For spare parts please

4= 1/2 NPT 024= 24V A= AC

120 consult our technical consult our technical

Model 3= G 3/4 Orefice B= 30mm D A= Class F 08= 8W department department

KI= N.C. Ex d F= H-NBR 190 048= 48V S= Without Approval(*)

valve 5= 3/4 NPT 10-1mm Ø 13 EN 175301-803

250 110= 110V

4= G 1 Coil P/N Ex mb II T 4 ACCESSORIES

6= 1 NPT 223= 220V-230V RTNA4X024D4 Code P992219 Cable Gland

(*) Ex d protection class when assembled with Ex housing RTNA5X110D4 (to be ordered separately)

RTNA05224DA

T N A 4X 024 D 4 RTNA10024C4

4X= 7,2V 024= 24V

T= 36mm N 5X= 9,13V 110= 110V D= AC

A= Class F 4= Ex m T4

Ø 14,5 3 cables cm 300 05= 7,7V-9,2V 224= 220V-240V

10= 10,1W 024= 24V C= DC

PRESSURE MAX MOPD (bar) INSTALLATION

4 The solenoid valves can be mounted in any position

Ø Kv MAX VISCOSITY PRESSURE COIL TYPE DRAWING 4 Maintenance and instruction sheet available in each solenoid valve box

PIPE (mm) (l/min) cSt (°E) min GAS CODE NPT CODE

AC DC REFERENCE 4 Attention: for fuse selection please refer to the “Instruction sheet

B T B T Atex products” delivered together with the valve

4 Holes and threaded connections for panel fixing

Normally Closed Ex m

1/2 12 35 12(2) - 16 - 16 21X2QDV120 21XN4QDV120 1 Drawing Reference Drawing Reference

3/4 19 130 12(2) 0,1 - 16 - 16 21X3QDV190 21XN5QDV190 1

1 2

1 25 160 12(2) - 16 - 16 21X4QDV250 21XN6QDV250 1

Normally Closed Ex d

1/2 12 35 12(2) 20 - 20 - 21X2KIV120 21XN2KIV120 2

3/4 19 130 12(2) 0,1 16 - 16 - 21X3KIV190 21XN3KIV190 2

1 25 160 12(2) 16 - 16 - 21X4KIV250 21XN4KIV250 2

Dimensionale Table

Figure Pipe Coil Type A mm B mm C mm D mm E mm F mm

G 1/2 B 120 36,5 -

40 73 71

1/2 NPT T 110 36 47

G 3/4 B 136 88,5 -

1-2 65 104 71

3/4 NPT T 120 36 47

G1 B 136 88,5 -

65 104 71

1 NPT T 120 36 47

92 93

You might also like

- 21ih-In-Valv Solenoide InoxDocument1 page21ih-In-Valv Solenoide InoxMonica CarrenoNo ratings yet

- Port Size: DN 8, G3/8 High Pressure Solenoid Valve Manifold Further Customized Solutions Available Upon RequestDocument3 pagesPort Size: DN 8, G3/8 High Pressure Solenoid Valve Manifold Further Customized Solutions Available Upon RequestEnrique MurgiaNo ratings yet

- ICO4SDocument12 pagesICO4SGopinath SekarNo ratings yet

- Technical Data Sheet Ecotrol Rotary Control Valve TD 8CD 6HDDocument5 pagesTechnical Data Sheet Ecotrol Rotary Control Valve TD 8CD 6HDagus trionoNo ratings yet

- Series XPM Pushbutton Sampling ValveDocument1 pageSeries XPM Pushbutton Sampling ValvevangoetheNo ratings yet

- Operating Range Recommended Applications: Mechanical Seals - Agitator Seals - Liquid-Lubricated SealsDocument5 pagesOperating Range Recommended Applications: Mechanical Seals - Agitator Seals - Liquid-Lubricated SealsserdarNo ratings yet

- ICO3S 350B Hydraulic Valve Electromagnetically Actuated, Directly ControlledDocument3 pagesICO3S 350B Hydraulic Valve Electromagnetically Actuated, Directly ControlledUntoro Adi NugrohoNo ratings yet

- Wika Type M93X.D1 Pressure Gauge Data SheetDocument5 pagesWika Type M93X.D1 Pressure Gauge Data SheetTrEnD SeT vicky rioNo ratings yet

- PEGLER ValvesDocument8 pagesPEGLER Valveseng.abdullrahmanNo ratings yet

- Samson Axial Valve 3599Document6 pagesSamson Axial Valve 3599Shaheen HydrosNo ratings yet

- Valvula Accionamiento Directo Herion 96000Document2 pagesValvula Accionamiento Directo Herion 96000Base SistemasNo ratings yet

- Shell Heat Transfer Oil S4 X: Performance, Features & BenefitsDocument2 pagesShell Heat Transfer Oil S4 X: Performance, Features & Benefitsrodrigonicolasdiaz1No ratings yet

- _0000000020002400__IMI Herion Series 95000 2 way, 2 to 6mmDocument4 pages_0000000020002400__IMI Herion Series 95000 2 way, 2 to 6mmantony.ideharaNo ratings yet

- PMP Emco Wheaton D2000-Swivel-JointDocument2 pagesPMP Emco Wheaton D2000-Swivel-JointnarminaNo ratings yet

- 54 PNA enDocument2 pages54 PNA enArmin HajdarovićNo ratings yet

- 0536 A2ex 0.5Document2 pages0536 A2ex 0.5brianNo ratings yet

- ICO4S 2/2, 3/2 or 5/2 Poppet Valves Electromagnetic Actuated, Directly ControlledDocument12 pagesICO4S 2/2, 3/2 or 5/2 Poppet Valves Electromagnetic Actuated, Directly ControlledDur MuhammadNo ratings yet

- Datasheet t5500 t6500 Pressure GaugesDocument5 pagesDatasheet t5500 t6500 Pressure GaugesEdy WijayaNo ratings yet

- ENG - BD - TDS170-PN-S-GATE-PN Gate ActuatorsDocument9 pagesENG - BD - TDS170-PN-S-GATE-PN Gate Actuatorslungelo.dlaminiNo ratings yet

- B600 PDFDocument4 pagesB600 PDFzsmithNo ratings yet

- DB HDA4400ExiaATEXIECExH2 E 18.639.1 02.20Document4 pagesDB HDA4400ExiaATEXIECExH2 E 18.639.1 02.20Exinspection anoafpsoNo ratings yet

- 3521DHS BDocument4 pages3521DHS BDaniel SaucedaNo ratings yet

- Ramset rsc1045 - 2019120519315Document8 pagesRamset rsc1045 - 2019120519315sitirNo ratings yet

- Flgyt 3020 Technical SpecDocument16 pagesFlgyt 3020 Technical SpecdaniqoNo ratings yet

- Sealing Nipples GN PDF Catalogue ENG COELBO ItalyDocument1 pageSealing Nipples GN PDF Catalogue ENG COELBO Italycahyo sNo ratings yet

- 4130wog0913 - Rev14Document3 pages4130wog0913 - Rev14Quality controller100% (1)

- 250 ML Stirred Pressure Reactor Autoclaves Datasheet 1669874059Document3 pages250 ML Stirred Pressure Reactor Autoclaves Datasheet 1669874059Vamshika SutarNo ratings yet

- Diaphragm Valve, Metal: ConstructionDocument10 pagesDiaphragm Valve, Metal: ConstructionChemikal EngineerNo ratings yet

- 2520 - H Cat PumpDocument5 pages2520 - H Cat PumpRicardo RosasNo ratings yet

- Ventilador de Insuflação - SODECA CAS-ATEXDocument5 pagesVentilador de Insuflação - SODECA CAS-ATEXSandra Freire TabordaNo ratings yet

- TDS - Soudal Soudafix CA 1400Document2 pagesTDS - Soudal Soudafix CA 1400Hussein K. AliNo ratings yet

- UK SKX 12-15 - TdsDocument8 pagesUK SKX 12-15 - Tdsyarik.rguNo ratings yet

- Sika Anchorfix-2Document9 pagesSika Anchorfix-2Anonymous ELujOV3No ratings yet

- FT44 Carbon Steel Ball Float Steam Traps (DN15 To DN50)Document7 pagesFT44 Carbon Steel Ball Float Steam Traps (DN15 To DN50)Liêm HàNo ratings yet

- MOLYKOTE 165 LT Gearwheel Grease 71-0179D-01Document2 pagesMOLYKOTE 165 LT Gearwheel Grease 71-0179D-01bravindranath5768No ratings yet

- Pipe FittingsDocument5 pagesPipe FittingsAutieri AutieriNo ratings yet

- ICO4S Data SheetDocument13 pagesICO4S Data Sheetaxeaxeaxe544No ratings yet

- 2.6.5 Retro Lavado Del Sistema de Ultrafiltración (5450 - PP-008 A-B)Document2 pages2.6.5 Retro Lavado Del Sistema de Ultrafiltración (5450 - PP-008 A-B)Jennifer FigueroaNo ratings yet

- ISOVALVE Automatic ValveDocument4 pagesISOVALVE Automatic ValveDineshkumarNo ratings yet

- En5922 6 - Db16621e 10Document2 pagesEn5922 6 - Db16621e 10markoNo ratings yet

- 0589 TMCXQSTX Bg080623naDocument2 pages0589 TMCXQSTX Bg080623naranjith_007No ratings yet

- 20 ISO Tank Container enDocument5 pages20 ISO Tank Container enSmart LauNo ratings yet

- Ficha Tecnica Tapón Hexagonal de Polyamide Ex-E Draco, Marca. BimedDocument2 pagesFicha Tecnica Tapón Hexagonal de Polyamide Ex-E Draco, Marca. BimedGiancarloEleNo ratings yet

- 3xvx1wmf 2Document1 page3xvx1wmf 2recrutementee.2020No ratings yet

- Solenoid ValveDocument2 pagesSolenoid ValveHeru PurwantoNo ratings yet

- SNDocument12 pagesSNmsh16000No ratings yet

- Bartec CatalogoDocument3 pagesBartec CatalogoManuel PousaNo ratings yet

- E5906 Wk08c01Document2 pagesE5906 Wk08c01ardossantosNo ratings yet

- E1fw Metric PDFDocument1 pageE1fw Metric PDFari firmanNo ratings yet

- Mechanical Seals - Agitator Seals - Liquid-Lubricated Seals: Rely On ExcellenceDocument6 pagesMechanical Seals - Agitator Seals - Liquid-Lubricated Seals: Rely On ExcellenceVEZZ RIDE25No ratings yet

- 96000-Series Solenoid ValveDocument10 pages96000-Series Solenoid ValveBilal HussainNo ratings yet

- DK DIN Bite Type Tube FittingDocument62 pagesDK DIN Bite Type Tube FittingLuisFranciscoMarinMedranoNo ratings yet

- bite-type-tube-fittings-2015Document62 pagesbite-type-tube-fittings-2015Vaibhav KotnalaNo ratings yet

- Masoneilan Series: Complete Line of Rugged, Top Guided, Globe Valves With Lo-dB and Anti-Cavitation CapabilitiesDocument34 pagesMasoneilan Series: Complete Line of Rugged, Top Guided, Globe Valves With Lo-dB and Anti-Cavitation CapabilitiesIsrael Luna PenasNo ratings yet

- ISORIA 20 BrochureDocument16 pagesISORIA 20 BrochuremariodalNo ratings yet

- Data Sheet: 35 Frame Plunger PumpsDocument4 pagesData Sheet: 35 Frame Plunger PumpsrochdiNo ratings yet

- E5911 18 - PWK10120W 10Document4 pagesE5911 18 - PWK10120W 10Anonymous K3FaYFlNo ratings yet

- Sample QuestionsDocument3 pagesSample QuestionsRAJKUMARNo ratings yet

- 2532 EnuDocument2 pages2532 EnuAvinash AdhavNo ratings yet

- IM05805001K - LMR Electric, FDF Foam, FDM Medium Voltage Operation Manual - English - 2003Document38 pagesIM05805001K - LMR Electric, FDF Foam, FDM Medium Voltage Operation Manual - English - 2003betoplapaNo ratings yet

- Docu31797 - VNXe3100 Hardware Information GuideDocument52 pagesDocu31797 - VNXe3100 Hardware Information GuidebetoplapaNo ratings yet

- Push PullDocument50 pagesPush PullbetoplapaNo ratings yet

- Secure Socket LayerDocument14 pagesSecure Socket LayerbetoplapaNo ratings yet

- History of MEMS - PresentationDocument27 pagesHistory of MEMS - PresentationbetoplapaNo ratings yet

- Tesis QFBDocument101 pagesTesis QFBbetoplapaNo ratings yet

- X13 X15 X17 X19 X22 X25: Heriot WattDocument1 pageX13 X15 X17 X19 X22 X25: Heriot WattanishNo ratings yet

- Overload.: Nice Weld Shame About The FusionDocument5 pagesOverload.: Nice Weld Shame About The Fusionmangalraj900No ratings yet

- SP6 2Document191 pagesSP6 2RameshNo ratings yet

- CE401 Design of Steel StructuresDocument2 pagesCE401 Design of Steel Structuresrenjith037No ratings yet

- 3311 KV (1x5MVA) Sub-Staion - Tender BoQDocument10 pages3311 KV (1x5MVA) Sub-Staion - Tender BoQRicky ChangNo ratings yet

- Design of Vertical Pressure VesselDocument31 pagesDesign of Vertical Pressure Vesselshibabw worknehNo ratings yet

- Types 1808 and 1808A Pilot-Operated Relief Valves or Backpressure RegulatorsDocument8 pagesTypes 1808 and 1808A Pilot-Operated Relief Valves or Backpressure RegulatorsAlberto CastellanosNo ratings yet

- Tangki MinyakDocument6 pagesTangki MinyakcathlenNo ratings yet

- Pre-Engineered Building Solutions - FUXIN Steel Buildings Co., Ltd. 2015Document28 pagesPre-Engineered Building Solutions - FUXIN Steel Buildings Co., Ltd. 2015vannethny100% (2)

- Assessment of In-Situ Compressive Strength in Concrete Structures, Methods and CharacteristicsDocument8 pagesAssessment of In-Situ Compressive Strength in Concrete Structures, Methods and CharacteristicsAnonymous ELujOV3No ratings yet

- Bina Goodyear Berhad: Method Statement SubmittalDocument5 pagesBina Goodyear Berhad: Method Statement SubmittalGan Chin PhangNo ratings yet

- Catalogo de Pecas - Mx210 PTDocument134 pagesCatalogo de Pecas - Mx210 PTRafael de AlmeidaNo ratings yet

- Catalog Thermocouple CW ThermowellDocument2 pagesCatalog Thermocouple CW ThermowellFIRMANSYAHNo ratings yet

- Lintel Installation GuideDocument5 pagesLintel Installation GuideAnneBricklayer100% (1)

- 1.1.1 Global and National Situation in OSH - CEC 003-CEC32S6 - Construction Occupational Safety and Health (COSH)Document9 pages1.1.1 Global and National Situation in OSH - CEC 003-CEC32S6 - Construction Occupational Safety and Health (COSH)RYAN JOSEPH QUIMONo ratings yet

- Column & Shear Wall Shortening by Praveen MoragaspitiyaDocument157 pagesColumn & Shear Wall Shortening by Praveen Moragaspitiyasuman33100% (1)

- E 50B 4KG1 - Fire PDFDocument2 pagesE 50B 4KG1 - Fire PDFdocrafiNo ratings yet

- Architects Rules 1986Document24 pagesArchitects Rules 1986034039No ratings yet

- Material Submittal For IDEACUASTIC HIGH 16 PDFDocument81 pagesMaterial Submittal For IDEACUASTIC HIGH 16 PDFChris EnyinnayaNo ratings yet

- Cracking in Concrete LR R14 PDFDocument10 pagesCracking in Concrete LR R14 PDFValentin VrabieNo ratings yet

- Concrete Slump TestDocument4 pagesConcrete Slump TestyohanjNo ratings yet

- Body Safety Valve - KSB PDFDocument4 pagesBody Safety Valve - KSB PDFgm_revankar3942No ratings yet

- The Use and Interpretation of The Dynamic Cone Penetrometer (DCP) TestDocument11 pagesThe Use and Interpretation of The Dynamic Cone Penetrometer (DCP) TestRoddy TeeNo ratings yet

- COC BuildingDocument1 pageCOC Buildingrolando dionisioNo ratings yet

- 14-201-R1 Flange Insulating KitsDocument2 pages14-201-R1 Flange Insulating Kitssams1101No ratings yet

- An Introduction To Passive Solar Buildings: by J. Paul Guyer, P.E., R.A. Course No 0005466 2 PDH HoursDocument31 pagesAn Introduction To Passive Solar Buildings: by J. Paul Guyer, P.E., R.A. Course No 0005466 2 PDH HourspavanNo ratings yet

- Sewerage Code of Australia: Second EditionDocument26 pagesSewerage Code of Australia: Second Editionabhijithaval100% (1)

- 6381y Cable To bs6004 PDFDocument4 pages6381y Cable To bs6004 PDFbenNo ratings yet

- Asogravas Panorama de Los Agregados Reciclados en La Union Europea PDFDocument69 pagesAsogravas Panorama de Los Agregados Reciclados en La Union Europea PDFYazmin VargasNo ratings yet

- #4 VHB SGT G23F-B23F Data PageDocument3 pages#4 VHB SGT G23F-B23F Data PageSenthil KumarNo ratings yet