Professional Documents

Culture Documents

Dixell xw270k - Xw271k-En-Gb-3722952

Dixell xw270k - Xw271k-En-Gb-3722952

Uploaded by

filipko123Copyright:

Available Formats

You might also like

- St501-Ln1kv 04fs EnglishDocument12 pagesSt501-Ln1kv 04fs Englishsanthoshs241s0% (1)

- DCB31 Eng.Document15 pagesDCB31 Eng.Aimad ChamsaouiNo ratings yet

- AutoCAD VBA ProgrammingDocument59 pagesAutoCAD VBA ProgrammingZeljko Ristic100% (3)

- Live Code User GuideDocument625 pagesLive Code User GuideironickNo ratings yet

- Shield Traning ManualDocument50 pagesShield Traning ManualArith Krishnanandan88% (16)

- Controllers For Refrigerated Cabinets, Counters and Islands, With Energy-Saving Strategies and Compatible With The Evconnect AppDocument2 pagesControllers For Refrigerated Cabinets, Counters and Islands, With Energy-Saving Strategies and Compatible With The Evconnect AppMihai Lungu100% (1)

- Parameter List: To Unlock The KeyboardDocument2 pagesParameter List: To Unlock The KeyboardJennifer Eszter SárközyNo ratings yet

- HP11 Manual 4.0Document1 pageHP11 Manual 4.0Mauricio Plaza SalinasNo ratings yet

- At2-5 Instructions For Use: Range DescriptionDocument2 pagesAt2-5 Instructions For Use: Range DescriptionIulian DobrinNo ratings yet

- 53 Instruction ManualDocument2 pages53 Instruction ManualAlejandro Palomino AmaroNo ratings yet

- DeltaOhm 9785T Ve 9765T Online PHDocument4 pagesDeltaOhm 9785T Ve 9765T Online PHEnisNo ratings yet

- Auber Instruments SYL-1614 ManualDocument4 pagesAuber Instruments SYL-1614 ManualDNo ratings yet

- SD660 UserDocument10 pagesSD660 UserPhat Dat NguyenNo ratings yet

- XR10C - XR10D: Digital Controller With Cooling or Heating ActionDocument4 pagesXR10C - XR10D: Digital Controller With Cooling or Heating ActionJennifer Eszter SárközyNo ratings yet

- Operating Instructions SINGLE SBC - ControllerDocument12 pagesOperating Instructions SINGLE SBC - ControllerASCI MaintenanceNo ratings yet

- Procool Electronic Panel: Ako-17632, Ako-17633, Ako-17634, Ako-17635, Ako-17636, Ako-17637, Ako-17520, Ako-17521Document4 pagesProcool Electronic Panel: Ako-17632, Ako-17633, Ako-17634, Ako-17635, Ako-17636, Ako-17637, Ako-17520, Ako-17521Amic BanatNo ratings yet

- UsermanualREKA3 3Document8 pagesUsermanualREKA3 3David Lemos Sanchez100% (1)

- EWPX 190 (.E) 6.97 IngDocument4 pagesEWPX 190 (.E) 6.97 Ingroby72No ratings yet

- XW230K GB r1.0 04.08.2015Document2 pagesXW230K GB r1.0 04.08.2015Jennifer Eszter SárközyNo ratings yet

- Xwa11v v8 2 01-3110Document8 pagesXwa11v v8 2 01-3110lopez IvánNo ratings yet

- Operating Instructions: Scroll Through Parameters & Increases Parameter ValueDocument2 pagesOperating Instructions: Scroll Through Parameters & Increases Parameter ValuePradhish VNNo ratings yet

- Operating Instructions: SZ-7556-P-DDocument5 pagesOperating Instructions: SZ-7556-P-Djaganks100% (1)

- Ac1-5 Instruction For Use: PAR Range DescriptionDocument2 pagesAc1-5 Instruction For Use: PAR Range Descriptionnajdo1No ratings yet

- Digital Controler - Pizza de VerdadDocument5 pagesDigital Controler - Pizza de VerdadEdison EspinalNo ratings yet

- ST 710 KHJV 03Document13 pagesST 710 KHJV 03Saad rechamNo ratings yet

- Termostato Digital - SMP55Document88 pagesTermostato Digital - SMP55Julio Cesar T ProcopioNo ratings yet

- XR30C - XR30D: Digital Controller With Off Cycle DefrostDocument4 pagesXR30C - XR30D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNo ratings yet

- HP46 InstDocument2 pagesHP46 InstmahmudNo ratings yet

- Freezer&Fridge KeypadDocument21 pagesFreezer&Fridge Keypadjohnwayne314No ratings yet

- EN-ST129-JB1BV.10FP - DIN RailDocument11 pagesEN-ST129-JB1BV.10FP - DIN RailДмитий ЦымбалNo ratings yet

- Ac1-5 Instruction For Use: PAR Range DescriptionDocument2 pagesAc1-5 Instruction For Use: PAR Range Descriptionhisham falousNo ratings yet

- Ac1-5 Instruction For Use: PAR Range DescriptionDocument2 pagesAc1-5 Instruction For Use: PAR Range Descriptiondiab aliNo ratings yet

- AKO-14012 AKO-14023, AKO-14123,: 1411H210 Thermometers and Thermostats With 1 Probe and 1 Relay: AKO-140XX, AKO-141XXDocument2 pagesAKO-14012 AKO-14023, AKO-14123,: 1411H210 Thermometers and Thermostats With 1 Probe and 1 Relay: AKO-140XX, AKO-141XXmartinNo ratings yet

- CAUTION: Eye Damage May Result From Direct: Adjusting The Alarm Set Points) - Press and Hold ToDocument2 pagesCAUTION: Eye Damage May Result From Direct: Adjusting The Alarm Set Points) - Press and Hold ToSomkiat K. DonNo ratings yet

- Ir-Gun-S: Thermometer Operating InstructionsDocument2 pagesIr-Gun-S: Thermometer Operating InstructionsRamadhan FebriNo ratings yet

- Digital Relay E1200 PDFDocument5 pagesDigital Relay E1200 PDFMisdehRasmanNo ratings yet

- ST710-JB1BA.10: Wiring DiagramDocument11 pagesST710-JB1BA.10: Wiring DiagramAsd AsdNo ratings yet

- Nabertherm Controller R7Document3 pagesNabertherm Controller R7Diógenes Honorato PivaNo ratings yet

- 23.5 Eliwell Bedieing Ontdooithermostaat Id985-E-lx enDocument16 pages23.5 Eliwell Bedieing Ontdooithermostaat Id985-E-lx enjosepadilla1987No ratings yet

- Controller For DHW Heat Pump Heaters: EN EnglishDocument4 pagesController For DHW Heat Pump Heaters: EN EnglishToussaintNo ratings yet

- TR-42 TR-42: Orion ItaliaDocument4 pagesTR-42 TR-42: Orion ItaliaCAMILONo ratings yet

- Termostato UMA CasablancaDocument3 pagesTermostato UMA CasablancaCris YañezNo ratings yet

- SZ 7521Document3 pagesSZ 7521Praveen RajNo ratings yet

- Manual Display Bomba NM076BYDocument1 pageManual Display Bomba NM076BYzuriqueNo ratings yet

- XR30C - XR30D: Installing and Operating InstructionsDocument4 pagesXR30C - XR30D: Installing and Operating InstructionsJennifer Eszter SárközyNo ratings yet

- Im Ec 50154 20180813Document28 pagesIm Ec 50154 20180813Jeff BaumanNo ratings yet

- Thermostat InstructionsDocument8 pagesThermostat InstructionswdreilingNo ratings yet

- 9400 Thermostat Manual - 110-1039Document11 pages9400 Thermostat Manual - 110-1039andrewh3No ratings yet

- Keld KLT11Document1 pageKeld KLT11user userNo ratings yet

- HL2027 (Luna) Only Cooling User Manual (2017.2.16)Document2 pagesHL2027 (Luna) Only Cooling User Manual (2017.2.16)carmen hernandezNo ratings yet

- FTC100D Panel Interface AT052610Document8 pagesFTC100D Panel Interface AT052610Azahra Bintang DyahNo ratings yet

- EWPC 901/A: Temperature Controller With Alarm OutputDocument5 pagesEWPC 901/A: Temperature Controller With Alarm OutputOswaldo Rengifo MuozNo ratings yet

- Shenzhen Willhi Electronics Co., Ltd. Tel:0755 - 29539385 Fax:86-0755 - 2953 9395 Technical Support: Engineer TianDocument6 pagesShenzhen Willhi Electronics Co., Ltd. Tel:0755 - 29539385 Fax:86-0755 - 2953 9395 Technical Support: Engineer TianHoney GibraltarNo ratings yet

- Thermo-Hygrostat Controller: InstallationDocument2 pagesThermo-Hygrostat Controller: Installationeurotunnels100% (1)

- Eliwell EWPC905ManualDocument3 pagesEliwell EWPC905ManualvitapabloNo ratings yet

- EWPC 901/AR: Temperature Controller With Alarm OutputDocument3 pagesEWPC 901/AR: Temperature Controller With Alarm OutputOswaldo Rengifo MuozNo ratings yet

- Zanotti Parameter SP SplitaggregatDocument17 pagesZanotti Parameter SP SplitaggregatSinan BulutNo ratings yet

- Thermostat Honeywell RLV3100Document4 pagesThermostat Honeywell RLV3100LSNo ratings yet

- Temperature Controller, Ad2-5Document2 pagesTemperature Controller, Ad2-5bartosz15023No ratings yet

- Flag Alarm Relay: Description For D.C. or A.C. Supply Operating On "Pick-Up" or "Reset"Document2 pagesFlag Alarm Relay: Description For D.C. or A.C. Supply Operating On "Pick-Up" or "Reset"hendranafiat.aisNo ratings yet

- TACm Instruction Obs Ver 560Document4 pagesTACm Instruction Obs Ver 560Aidan PitsisNo ratings yet

- XT110C - XT111C - XT110D - XT111D: Single Stage Digital Controller With Multi Probe InputDocument4 pagesXT110C - XT111C - XT110D - XT111D: Single Stage Digital Controller With Multi Probe InputJennifer Eszter SárközyNo ratings yet

- Esquema Frigorifico Multi FujitsuDocument1 pageEsquema Frigorifico Multi Fujitsufilipko123No ratings yet

- Ev Aoyg14kbta2 MLDocument6 pagesEv Aoyg14kbta2 MLfilipko123No ratings yet

- Herald Spitfire VitesseDocument417 pagesHerald Spitfire Vitessefilipko123100% (1)

- Carpigiani MINIWIP:GDocument7 pagesCarpigiani MINIWIP:Gfilipko123100% (1)

- Release Notes Csi Bridge 2017 V 1900Document9 pagesRelease Notes Csi Bridge 2017 V 1900Ihab El AghouryNo ratings yet

- 3BSE020926-510 en S800 I O Fieldbus Communication Interface For PROFIBUS DP DPV1Document130 pages3BSE020926-510 en S800 I O Fieldbus Communication Interface For PROFIBUS DP DPV1Format_CNo ratings yet

- 09 SlideDocument54 pages09 SlideMem MemNo ratings yet

- Tutorial ModefrontierDocument8 pagesTutorial ModefrontierOsmar Francisco Reis SilvaNo ratings yet

- XDXL Instruction ManualDocument381 pagesXDXL Instruction ManualeversonsolomaoNo ratings yet

- Digital Input 6ES7521 1BH00 0AB0Document64 pagesDigital Input 6ES7521 1BH00 0AB0najiruddinshaikNo ratings yet

- C++ Programming: From Problem Analysis To Program Design, Fourth Edition (Chapter 3: Input/Output)Document26 pagesC++ Programming: From Problem Analysis To Program Design, Fourth Edition (Chapter 3: Input/Output)Jaid HedrianaNo ratings yet

- 3-Migrating and DataLoading Into ADBDocument9 pages3-Migrating and DataLoading Into ADBAndersonLondoñoNo ratings yet

- Eps 2 PGFDocument6 pagesEps 2 PGFziddasyNo ratings yet

- Semester 1 FinalDocument29 pagesSemester 1 FinalBudi NugrohoNo ratings yet

- Polygon PyDocument18 pagesPolygon Pyheriegeo99No ratings yet

- 3BSE042835R5001 CIO LibObjDesignDocument90 pages3BSE042835R5001 CIO LibObjDesignCristi CrseNo ratings yet

- Standard BASIC LanguageDocument140 pagesStandard BASIC LanguageedhanaaNo ratings yet

- Fx-82sx 220plus Etc enDocument2 pagesFx-82sx 220plus Etc enMegan Graciela IceMintzNo ratings yet

- Unit V Files, Modules, Packages File and Its Operation: Format (I.e .0's and 1's)Document16 pagesUnit V Files, Modules, Packages File and Its Operation: Format (I.e .0's and 1's)nancypeterNo ratings yet

- Simulation Optimization Research On Logistics Distribution Center Picking OperationDocument5 pagesSimulation Optimization Research On Logistics Distribution Center Picking OperationMiguel PeñaNo ratings yet

- IBM Content Manager OnDemand and FileNet-4Document88 pagesIBM Content Manager OnDemand and FileNet-4David ResendizNo ratings yet

- The Evolution of LispDocument109 pagesThe Evolution of LispJeff Pratt100% (2)

- UntitledDocument76 pagesUntitledPankaj MaryeNo ratings yet

- IT104 Discrete StructuresDocument31 pagesIT104 Discrete StructuresAina Maree Eusebio SiasonNo ratings yet

- 2009 06Document350 pages2009 06Venkateswara RaoNo ratings yet

- C++ Function (With Examples)Document13 pagesC++ Function (With Examples)DegageNo ratings yet

- Core Java Question Bank (Set-1)Document22 pagesCore Java Question Bank (Set-1)Amitav BiswasNo ratings yet

- How To Create An Exit ProgramDocument7 pagesHow To Create An Exit Programrachmat99No ratings yet

- Documentation QDDDocument14 pagesDocumentation QDDcistron77No ratings yet

- Lopez 2019 ADocument7 pagesLopez 2019 ARenev UP2B Jawa BaratNo ratings yet

- Math - The Commons Math User Guide - Numerical AnalysisDocument13 pagesMath - The Commons Math User Guide - Numerical AnalysisJean claude onanaNo ratings yet

Dixell xw270k - Xw271k-En-Gb-3722952

Dixell xw270k - Xw271k-En-Gb-3722952

Uploaded by

filipko123Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dixell xw270k - Xw271k-En-Gb-3722952

Dixell xw270k - Xw271k-En-Gb-3722952

Uploaded by

filipko123Copyright:

Available Formats

3.5 AUXILIARY OUTPUT 4.2 HOW TO SEE THE MIN TEMPERATURE 4.

12 TO SEE THE PROBE VALUES ALARMS

The auxiliary output is switch ON and OFF by means of the corresponding button 1. Press and release the n key. 1. Enter in “Pr2” level. ALC Temperature alarm configuration

WING on the keyboard.

The auxiliary output of the XW271K model controls the anti-condensing heater and

2. The “Lo” message will be displayed followed by the minimum

temperature recorded.

2.

3.

Select “Prd” parameter with o or n.

Press the “SET” key to display “Pb1” label alternate with Pb1 value.

rE = High and Low alarms related to Set Point

Ab = High and low alarms related to the absolute temperature.

it is automatically activated if the room temperature is lower than the “SAA” ALU High temperature alarm setting:

parameter. 3. By pressing the n key or waiting for 5s the normal display will 4. Use o and n keys to display the other probe values. ALC= rE, 0 50°C or 90°F

be restored. 5. Press “SET” to move to the following parameter. ALC= Ab, ALL 110°C or 230°F

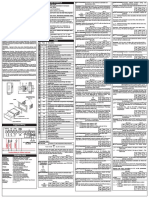

XW270K - XW271K 4. KEYBOARD

4.3 HOW TO SEE THE MAX TEMPERATURE

when this temperature is reached and after the ALd delay time the HA alarm

5. PARAMETER LIST is enabled.

1. Press and release the o key. ALL Low temperature alarm setting:

REGULATION

1. GENERAL WARNING 2. The “Hi” message will be displayed followed by the maximum ALC = rE , 0 50 °C or 90°F

Hy Differential: (0,1÷25,5°C; 1÷45°F): Intervention differential for set point, ALC = Ab , - 50°C or -58°F ALU

temperature recorded.

always positive. Compressor Cut IN is Set Point Plus Differential (Hy). when this temperature is reached and after the ALd delay time, the LA alarm

3. By pressing the o key or waiting for 5s the normal display will Compressor Cut OUT is when the temperature reaches the set point. is enabled,.

be restored. LS Minimum set point limit: (-50,0°CSET; -58°F÷SET) Sets the minimum

1.1 PLEASE READ BEFORE USING THIS MANUAL AFH Temperature alarm and fan differential: (0,1÷25,5°C; 1÷45°F) Intervention

acceptable value for the set point. differential for temperature alarm set point and fan regulation set point, always

This manual is part of the product and should be kept near the instrument for 4.4 HOW TO RESET THE MAX AND MIN TEMPERATURE RECORDED US Maximum set point limit: (SET110°C; SET÷230°F) Set the maximum positive.

easy and quick reference. To display and modify target set point; in programming mode it To reset the stored temperature, when max or min temperature is displayed : acceptable value for set point. ALd Temperature alarm delay: (0÷255 min) time interval between the detection

The instrument shall not be used for purposes different from those described selects a parameter or confirm an operation. 1. Press SET key until “rST” label starts blinking. OdS Outputs activation delay at start up: (0÷255 min) This function is enabled of an alarm condition and the corresponding alarm signalling.

hereunder. It cannot be used as a safety device. By holding it pressed for 3s when max or min temperature is at the initial start up of the instrument and inhibits any output activation for the dAO Delay of temperature alarm at start-up: (0min÷23h 50min) time interval

Check the application limits before proceeding. displayed it will be erased. N.B. After the installation RESET the temperature stored . period of time set in the parameter. (AUX and Light can work) between the detection of the temperature alarm condition after the instrument

Dixell Srl reserves the right to change the composition of its products, even AC Anti-short cycle delay: (0÷30 min) interval between the compressor stop power on and the alarm signalling.

without notice, ensuring the same and unchanged functionality. To see the max. stored temperature; in programming mode it 4.5 HOW TO SEE AND MODIFY THE SET POINT and the following restart. EdA Alarm delay at the end of defrost: (0255 min) Time interval between the

browses the parameter codes or increases the displayed value. By 1. Push and immediately release the SET key: the display will CCt Thermostat override: (0min ÷23h 50min) allows to set the length of the detection of the temperature alarm condition at the end of defrost and the

holding it pressed for 3s the fast freezing cycle is started. show the Set point value; continuous cycle. Can be used, for instance, when the room is filled with new alarm signalling.

To see the min stored temperature; in programming mode it browses 2. The SET LED start blinking; products. dot Delay of temperature alarm after closing the door : (0255 min) Time

1.2 SAFETY PRECAUTIONS

the parameter codes or decreases the displayed value. 3. To change the Set value push the o or n arrows within Con Compressor ON time with faulty probe: (0÷255 min) time during which the delay to signal the temperature alarm condition after closing the door.

Check the supply voltage is correct before connecting the instrument. compressor is active in case of faulty thermostat probe. With COn=0 doA Open door alarm delay:(0÷255 min) delay between the detection of the

10s.

Do not expose to water or moisture: use the controller only within the 4. To memorise the new set point value push the SET key again compressor is always OFF. open door condition and its alarm signalling: the flashing message “dA” is

operating limits avoiding sudden temperature changes with high atmospheric By holding it pressed for 3s the defrost is started. or wait 10s. COF Compressor OFF time with faulty probe: (0÷255 min) time during which the displayed.

humidity to prevent formation of condensation compressor is off in case of faulty thermostat probe. With COF=0 compressor tbA Buzzer and alarm relay silencing: by pushing one of the keypad buttons.

Warning: disconnect all electrical connections before any kind of 4.6 TO START A MANUAL DEFROST is always active. n= Only the Buzzer is silenced;

maintenance. Switch ON and OFF the cold room light. y= Buzzer and relay are silenced.

Fit the probe where it is not accessible by the End User. The instrument must DISPLAY nPS Pressure switch number: (0 15) Number of activation of the pressure

1. Push the DEF key for more than 2 seconds and a manual

not be opened. CF Temperature measurement unit: °C = Celsius; °F = Fahrenheit . When the switch, during the “did” interval, before signalling the alarm event (I2F= PAL).

By holding it pressed for 3s Energy Saving function is started or defrost will start.

In case of failure or faulty operation send the instrument back to the distributor measurement unit is changed the SET point and the values of the regulation

stopped. PROBE INPUTS

or to “Dixell S.r.l.” (see address) with a detailed description of the fault. parameters have to be modified

Consider the maximum current which can be applied to each relay (see 4.7 TO ENTER IN PARAMETERS LIST “PR1” Ot Thermostat probe calibration: (-12.012.0°C/ -2121°F) allows to adjust

rES Resolution (for °C): (in = 1°C; de = 0,1°C) allows decimal point display. possible offset of the thermostat probe.

Technical Data). Present in T820 Keyboard ( for connection to XW270K). To enter the parameter list “Pr1” (user accessible parameters) operate as follows:

Switch ON and OFF the auxiliary output. de = 0,1°C OE Evaporator probe calibration: (-12.012.0°C/ -2121°F) allows to adjust

Ensure that the wires for probes, loads and the power supply are separated in = 1 °C

and far enough from each other, without crossing or intertwining. possible offsets of the evaporator probe.

1. Enter the Programming mode by pressing the Set Red Remote display : select which probe is displayed by the remote display

Present in T821 Keyboard ( for connection to XW271K). O3 Auxiliary probe calibration: (-12.012.0°C/ -2121°F) allows to adjust

In case of applications in industrial environments, the use of mains filters (our and DOWN key for few seconds ( and (T820 or T821)

Switch ON and OFF the anti-condensing heater output. possible offsets of the evaporator probe.

mod. FT1) in parallel with inductive loads could be useful. P1 = Thermostat probe

start blinking). P2P Evaporator probe presence:

P2 = Evaporator probe n= not present: the defrost stops only by time; y= present: the defrost stops

2. GENERAL DESCRIPTION Switch ON and OFF the instrument.

2. The instrument will show the first parameter P3 = auxiliary probe by temperature and time.

Models XW270K and XW271K are microprocessor based controllers suitable for present in “Pr1” 1r2 = difference between P1 and P2 (P1-P2) P3P Auxiliary probe presence: n= not present; y= present.

applications on medium or low temperature refrigerating units. They must be KEY COMBINATIONS HES Temperature increase during the Energy Saving cycle : (-30,0°C

connected by means of a two-wire cable ( 1mm) at a distance of up to 30 meters DEFROST 30,0°C / -22÷86°F) sets the increasing value of the set point during the

to the keyboards T820 or T821. They are provided with six relay outputs to control 4.8 TO ENTER IN PARAMETERS LIST “PR2”

tdF Defrost type: Energy Saving cycle.

compressor, defrost - which can be either electrical or hot gas - the evaporator

fans, the lights, the alarm and an auxiliary output. In XW271L the auxiliary output is + To lock and unlock the keyboard. To access parameters in “Pr2”:

1. Enter the “Pr1” level.

rE = electrical heater (Compressor OFF)

rT = thermostat defrost. During the defrost time “MdF”, the heater switches

DIGITAL INPUTS

configured as anti-condensing heater. 2. Select “Pr2” parameter and press the “SET” key. On and OFF depending on the evaporator temperature and “dtE” value. odc Compressor and fan status when open door:

They are also provided with three NTC probe inputs, one for temperature control,

one to control the defrost end temperature of the evaporator and the third, optional, + To enter the programming mode. 3. The “PAS” flashing message is displayed, shortly followed by “0 - -” with a

flashing zero.

in = hot gas (Compressor and defrost relays ON)

EdF Defrost mode:

no = normal;

Fan = Fan OFF;

for the display. There are two digital inputs (free contact) for the door switch and 4. Use o or n to input the security code in the flashing digit; confirm the in = interval mode. The defrost starts when the time “Idf” is expired. CPr = Compressor OFF;

configurable by parameter.

The standard TTL output allows the user to connect, by means of a TTL/RS485 + To exit the programming mode.

5.

figure by pressing “SET”. The security code is “321“.

If the security code is correct the access to “Pr2” is enabled by pressing “SET”

Sd = Smartfrost mode. The time IdF (interval between defrosts) is increased

only when the compressor is running (even non consecutively) and only if the

F_C = Compressor and fan OFF.

I1P Door switch input polarity:

external module, a ModBUS-RTU compatible monitoring system and to programme on the last digit. evaporator temperature is less than the value in "SdF” (set point for CL : the digital input is activated by closing the contact;

the parameter list with the “Hot Key”. An optional output for RS485 direct is SMARTFROST). OP : the digital input is activated by opening the contact.

available. 4.1 USE OF LEDS Another possibility is the following: after switching ON the instrument the user can SdF Set point for SMARTFROST: (-3030 °C/ -2286 °F) evaporator I2P Configurable digital input polarity:

push Set and DOWN keys within 30 seconds. temperature which allows the IdF counting (interval between defrosts) in CL : the digital input is activated by closing the contact;

3. CONTROLLING LOADS Each LED function is described in the following table. OP : the digital input is activated by opening the contact

SMARTFROST mode.

LED MODE Function NOTE: each parameter in “Pr2” can be removed or put into “Pr1” (user level) by dtE Defrost termination temperature: (-50,0÷110,0°C; -58÷230°F) (Enabled I2F Digital input operating mode: configure the digital input function:

3.1 THE COMPRESSOR ON The compressor is running pressing “SET” + o. When a parameter is present in “Pr1” LED is on. only when the evaporator probe is present) sets the temperature measured by EAL = generic alarm;

the evaporator probe which causes the end of defrost. bAL = serious alarm mode;

The regulation is performed according to the temperature measured by the PAL = Pressure switch;

FLASHING - Programming Phase (flashing with LED ) 4.9 HOW TO CHANGE THE PARAMETER VALUE IdF Interval between defrosts: (1÷120h) Determines the time interval between

thermostat probe with a positive differential from the set point: if the temperature dFr = Start defrost;

increases and reaches set point plus differential the compressor is started and then - Anti-short cycle delay enabled 1. Enter the Programming mode. the beginning of two defrost cycles.

MdF (Maximum) duration of defrost: (0÷255 min) When P2P = n, no evaporator AUS = Relay AUX actuation;

turned off when the temperature reaches the set point value again. ON The fan is running 2. Select the required parameter with o or n. Es = Energy Saving;

In case of fault in the thermostat probe the start and stop of the compressor are probe, it sets the defrost duration, when P2P = y, defrost end based on

3. Press the “SET” key to display its value ( and LED starts blinking). temperature, it sets the maximum length for defrost. onF = remote On/OFF.

timed through parameters “COn” and “COF”. FLASHING

Programming Phase (flashing with LED ) 4. Use o or n to change its value. dFd Display during defrost: did Time interval/delay for digital input alarm:(0255 min.) Time interval to

ON The defrost is enabled 5. Press “SET” to store the new value and move to the following parameter. rt = real temperature; calculate the number of the pressure switch activation when I2F=PAL. If

3.2 FAST FREEZING I2F=EAL or bAL (external alarms), “did” parameter defines the time delay

To exit: Press SET + UP or wait 15s without pressing a key. it = temperature reading at the defrost start;

When defrost is not in progress, it can be activated the keypad by holding the o FLASHING Drip time in progress NOTE: the new programming is stored even when the procedure is exited by Set = set point; between the detection and the successive signalling of the alarm.

key pressed for about 3 seconds. The compressor operates in continuous mode for waiting the time-out. dEF = “dEF” label; SAA Set Point for anti-condensing heater: (-50,0÷110,0°C; -58÷230°F) defines

ON The Fast Freezing cycle is enabled the room temperature setpoint to switch on the anti-condensing heater.

the time set through the “CCt” parameter. The cycle can be terminated before the dEG = “dEG” label;

end of the set time using the same activation key, o for about 3 seconds. ON - ALARM signal 4.10 HOW TO LOCK THE KEYBOARD dAd Defrost display time out: (0255 min) Sets the maximum time between the

- In “Pr2” indicates that the parameter is also end of defrost and the restarting of the real room temperature display. OTHER

1. Keep the o and n keys pressed together for more than 3 s

Fdt Drain down time: (0÷60 min.) time interval between reaching defrost

3.3 DEFROST present in “Pr1” the o andn keys. Adr RS485 serial address (1÷247): Identifies the instrument address when

Three defrost modes are available through the “tdF” parameter: defrost with ON (Present only in T821 keyboard) termination temperature and the restoring of the control’s normal operation. connected to a ModBUS compatible monitoring system.

The Anti-condensing heater relay (Aux) is ON.

2. The “POF” message will be displayed and the keyboard is This time allows the evaporator to eliminate water drops that might have Rel Release software: (read only) Software version of the microprocessor.

electrical heater, hot gas or thermostatic defrost. The defrost interval is control by locked. At this point it is only possible the viewing of the set

means of parameter “EdF”: (EdF=in) the defrost is made every “IdF” time, (EdF=Sd) formed due to defrost. Ptb Parameter table: (read only) it shows the original code of the Dixell

point or the MAX o Min temperature stored and to switch ON dPO First defrost after start-up: parameter map.

the interval “IdF” is calculate through Smart Defrost algorithm (only when the Function of the LEDs placed on the left top side of buttons: and OFF the light, the auxiliary output and the instrument.

compressor is ON and the evaporator temperature is bigger than “SdF” parameter). y = Immediately; Prd Probes display: (read only) display the temperature values of the evaporator

At the end of defrost the drip time is controlled through the “Fdt” parameter. n = after the IdF time probe Pb2 and the auxiliary probe Pb3.

BUTTON MODE FUNCTION TO UNLOCK THE KEYBOARD dAF Defrost delay after fast freezing: (0min÷23h 50min) after a Fast Freezing Pr2 Access to the protected parameter list (read only).

SET FLASHING The Set point is displayed and it can be cycle, the first defrost will be delayed for this time.

3.4 CONTROL OF EVAPORATOR FANS modified Keep the o andn keys pressed together for more than 3s. 6. DIGITAL INPUTS

The fan control mode is selected by means of the “FnC” parameter: DEFROST ON The Manual Defrost is activated

FANS The Wing series can support up to 2 free contact digital inputs. One is always

ENERGY SAVING ON The Energy Saving is enabled

C-n = running with the compressor, OFF during the defrost; LIGHT ON The Light is ON FnC Fan operating mode: configured as door switch, the second is programmable in seven different

4.11 ON/OFF FUNCTION

C-y = running with the compressor, ON during the defrost; C-n = running with the compressor, OFF during the defrost; configurations by the “I2F” parameter.

AUX ON The Auxiliary output is ON (T820) By pushing the ON/OFF key, the instrument shows “OFF” for 5 sec.

O-n = continuous mode, OFF during the defrost; C-y = running with the compressor, ON during the defrost;

HEATER ON The Anti-condensing heater is ON (T821) and the ON/OFF LED is switched ON. O-n = continuous mode, OFF during the defrost; 6.1 DOOR SWITCH INPUT

O-y = continuous mode, ON during the defrost;

ON/OFF ON The instrument is OFF During the OFF status, all the relays are switched OFF and the O-y = continuous mode, ON during the defrost; It signals the door status and the corresponding relay output status through the

regulations are stopped; if a monitoring system is connected, it does Fnd Fan delay after defrost: (0÷255 min) The time interval between the defrost

An additional parameter “FSt” provides the setting of temperature, detected by the “odc” parameter:

not record the instrument data and alarms. end and evaporator fans start.

evaporator probe, above which the fans are always OFF. This can be used to make no = normal (any change);

N.B. During the OFF status the Light and AUX buttons are FSt Fan stop temperature: (-50÷110°C; -58÷230°F) setting of temperature,

sure circulation of air only if his temperature is lower than set in “FSt”. Fan = Fan OFF;

active. detected by evaporator probe, above which the fan is always OFF. CPr = Compressor OFF;

F_C = Compressor and fan OFF.

1592009530 XW271K GB r.1.0 06.08.2015 XW270K - XW271K 1/2

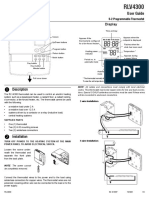

Since the door is opened, after the delay time set through parameter “dOA”, the 7.3 MOUNTING WITH KEYBOARD COVER OPENING UPWARD To reset the “EE” alarm and restart the normal functioning press any key, the “rSt” Label Name Range Default Level

alarm output is enabled and the display shows the message “dA”. The alarm stops message is displayed for about 3s. ALARMS rE

as soon as the external digital input is disabled again. During this time and then for ALC Temperature alarms rE÷Ab 10/20 Pr2 Pr2

the delay “dot” after closing the door, the high and low temperature alarms are 11.1 SILENCING BUZZER / ALARM RELAY OUTPUT configuration

disabled. If “tbA = y”, once the alarm signal is detected the buzzer and the relay are is ALU MAXIMUM temperature -50,0÷110°C 10/20 Pr1 Pr1

silenced by pressing any key. alarm -58÷230°F

6.2 CONFIGURABLE INPUT - GENERIC ALARM (EAL) 1 If “tbA = n”, only the buzzer is silenced while the alarm relay is on until the alarm ALL minimum temperature -50,0÷110°C 2/4 Pr1 Pr1

As soon as the digital input is activated the unit will wait for “did” time delay before 3

2 condition recovers. alarm -58÷230°F

signalling the “EAL” alarm message. The outputs status don’t change. The alarm 1

Buzzer is mounted in the T820 and T821 keyboards and it is an option. AFH Temperature alarm and 0,1÷25,5 °C 15

stops just after the digital input is de-activated. fan differential 1÷45°F

11.2 “EE” ALARM ALd Temperature alarm 0÷255 min. 1,3 Pr2 Pr2

6.3 CONFIGURABLE INPUT - SERIOUS ALARM MODE (BAL) 2

The Dixell instruments are provided with an internal check for the data integrity. delay

When the digital input is activated, the unit will wait for “did” delay before signalling 3 Alarm “EE” flashes when a failure in the memory data occurs. In such cases the dAO Delay of temperature 0 ÷ 23h 50 min. 30 Pr2 Pr2

the “BAL” alarm message. The relay outputs are switched OFF. The alarm will stop 2 CLICK! alarm output is enabled. alarm at start up

as soon as the digital input is de-activated. 1

EdA Alarm delay at the end 0÷255 min. 15 Pr2 Pr2

11.3 ALARM RECOVERY of defrost

6.4 CONFIGURABLE INPUT - PRESSURE SWITCH (PAL) Probe alarms : “P1” (probe1 faulty), “P2” and “P3”; they automatically stop 10s after dot Delay of temperature 0÷255 min. 15 Pr2 Pr2

If during the interval time set by “did” parameter, the pressure switch has reached the probe restarts normal operation. Check connections before replacing the probe. alarm after closing the

the number of activation of the “nPS” parameter, the “PAL” pressure alarm 8. ELECTRICAL CONNECTIONS Temperature alarms “HA” and “LA” automatically stop as soon as the thermostat door

message will be displayed. The compressor and the regulation are stopped. When XW270K and XW271K are provided with screw terminal block to connect cables temperature returns to normal values or when the defrost starts. dOA Open door alarm delay 0÷255 min. y Pr2 Pr2

the digital input is ON the compressor is always OFF. with a cross section up to 2,5 mm2 for the RS485(optional) and the keyboard. Door switch alarm “dA” stop as soon as the door is closed. tBA Alarm relay silencing y÷n 0 Pr2 Pr2

Connecting other inputs, power supply and relays, XW270K and XW271K are External alarms “EAL”, “BAL” stop as soon as the external digital input is disabled

nPS Pressure switch 0÷15 Pr2 Pr2

6.5 CONFIGURABLE INPUT - START DEFROST (DFR) provided with Faston connection (6,3mm). Heat-resistant cables have to be used. “PAL” alarm is recovered by switching OFF the instrument.

activation number

It executes a defrost if there are the right conditions. After the defrost is finished, the Before connecting cables make sure the power supply complies with the ANALOGUE INPUTS 0

normal regulation will restart only if the digital input is disabled otherwise the instrument’s requirements. Separate the probe cables from the power supply 12. TECHNICAL DATA Connector Description Connector Description Ot Thermostat probe -12,0÷12,0°C 0 Pr1 Pr1

instrument will wait until the “Mdf” safety time is expired. cables, from the outputs and the power connections. Do not exceed the maximum T820 and T821 keyboards calibration -21÷21°F

number number

current allowed on each relay, in case of heavier loads use a suitable external relay. Housing: self extinguishing ABS.

HOT KEY Hot key for programming 11 - 12 Alarm relay OE Evaporator probe -12,0÷12,0°C 0 Pr2 Pr2

6.6 CONFIGURABLE INPUT - RELAY AUX ACTUATION (AUS) N.B. Maximum current allowed for all the loads is 20A. Case: facia 38x185 mm; depth 23mm

calibration -21÷21°F

This function allows to turn ON and OFF the auxiliary relay by using the digital input Mounting : RS485 RS485 direct output 13 - 14 Compressor relay

panel mounting in a 150x31 mm panel cut-out with two screws. 3 x 2mm. O3 Auxiliary probe -12,0÷12,0°C y Pr2 Pr2

as external switch. 8.1 PROBE CONNECTIONS

(Optional) calibration -21÷21°F

The probes shall be mounted with the bulb upwards to prevent damages due to Distance between the holes 165mm

Protection: IP20. KEY (+) + :connection for keyboard 15 Phase P2P Evaporator probe n÷y n Pr2 Pr2

6.7 CONFIGURABLE INPUT - ENERGY SAVING (ES) casual liquid infiltration. It is recommended to place the thermostat probe away from presence

air streams to correctly measure the average room temperature. Place the defrost Frontal protection: IP65 with frontal gasket mod RG-L. (optional) KEY (-) - : connection for keyboard 16 Neutral

The Energy Saving function allows to change the set point value as the result of the P3P Auxiliary probe n÷y 0 Pr2 Pr2

termination probe among the evaporator fins in the coldest place, where most ice is Connections: Screw terminal block 2,5 mm2 heat-resistant wiring and 6,3mm

SET+ HES (parameter) sum. This function is enabled until the digital input is 1–2 Display probe 17 - 18 Light relay presence

formed, far from heaters or from the warmest place during defrost, to prevent Power supply: from XW270K or XW271K power module

activated. HES Temperature increase -30÷30°C Pr2 Pr2

premature defrost termination. Display: 3 digits, red LED, 14,2 mm high. 3-4 Defrost probe 19 - 20 Defrost relay

Optional output: buzzer during the Energy -22÷86°F

6.8 CONFIGURABLE INPUT - REMOTE ON/OFF (ONF) 5-6 Room probe 21 - 22 Fan relay Saving cycle

This function allows to switch ON and OFF the instrument.

9. TTL/RS485 SERIAL LINE

Power modules XW270K and XW271K 7-8 Configurable digital input 18 -19 Auxiliary relay DIGITAL INPUTS Fan

The TTL connector allows, by means of the external module TTL/RS485 (XJ485), to Case: 9 - 10 Door switch Odc Open door control no, Fan, CPr, F_C CL Pr2 Pr2

6.9 DIGITAL INPUTS POLARITY connect the unit to a network line ModBUS-RTU compatible as the Dixell “OS”: open board 132x 94 mm; height: 40mm.

monitoring system XJ500 (Version 3.0). I1P Door switch polarity CL÷OP CL Pr2 Pr2

The digital inputs polarity depends on “I1P” and “I2P” parameters. “OA”: open board with aluminium protection 176x 123mm; height: 52mm. I2P Configurable digital CL÷OP EAL Pr2 Pr2

The same TTL connector is used to upload and download the parameter list of the “GS”: case 155x114; height 70mm. Self extinguishing ABS. IP55

CL : the digital input is activated by closing the contact. input polarity

OP : the digital input is activated by opening the contact

“HOT KEY“. The instruments can be ordered wit the serial output RS485(Optional). “PS”: case 147x110; height 47mm. Self extinguishing ABS. IP55. UL approved 14. DEFAULT SETTING VALUES

i2F Digital input EAL, bAL, PAL, 5 Pr2 Pr2

Connections: Screw terminal block 2,5 mm2 heat-resistant wiring and 6,3mm configuration dFr, AUS, ES, OnF

10. USE OF THE PROGRAMMING “HOT KEY “ Faston

7. INSTALLATION AND MOUNTING Label Name Range Default Level dId Digital input alarm delay 0÷255 min. -20.0/4 Pr2 Pr2

The Wing units can UPLOAD or DOWNLOAD the parameter list from its own E2 Power supply: 230Vac or. 110Vac 10%

T820 and T821 keyboards shall be mounted on vertical panel, in a 150x31 mm REGULATION °C/°F XW270K XW271K SAA Set point for anti- -50,0÷110°C --- Pr2

internal memory to the “Hot Key” and vice-versa. Power absorption: 10VA max.

hole, and fixed using two screws 3 x 2mm. To obtain an IP65 protection grade Set Set point LS÷US -5/23 Pr1 Pr1 condensing heater -58÷230°F

Inputs: 3 NTC probes

use the front panel rubber gasket (mod. RG-L). Power modules XW270K and 10.1 DOWNLOAD (FROM THE “HOT KEY” TO THE INSTRUMENT) Hy Differential 0,1÷25,5 °C 2/4 Pr1 Pr1 OTHER 1

Digital inputs: 2 free voltage

XW271K shall be mounted in a panel with two or more screws and they must be 1÷45°F Adr Serial address 0÷247 1.0 Pr1 Pr1

1. Turn OFF the instrument by means of the ON/OFF key, remove the TTL Relay outputs: Total current on loads MAX. 20A

connected to the keyboards by means of a two-wire cable ( 1mm). The compressor: relay SPST 20(8) A, 250Vac LS Minimum set point -50,0°C÷SET -30/-22 Pr2 Pr2 rEL Software release --- --- Pr2 Pr2

temperature range allowed for correct operation is 0 - 60 °C. Avoid places subject serial cable if present, insert the “Hot Key” and then turn the Wing ON.

light: relay SPST 16(3) A, 250Vac -58°F÷SET Ptb Map code --- --- Pr2 Pr2

to strong vibrations, corrosive gases, excessive dirt or humidity. The same 2. Automatically the parameter list of the “Hot Key” is downloaded into the

Wing memory, the “DoL” message is blinking. After 10 seconds the fans: relay SPST 8(3) A, 250Vac US Maximum set point SET ÷ 110°C 20/68 Pr2 Pr2 Prd Probes display Pb1÷Pb3 --- Pr2 Pr2

recommendations apply to probes. Let the air circulate by the cooling holes. defrost: relay SPST 8(3) A, 250Vac SET ÷ 230°F

instrument will restart working with the new parameters. Pr2 Access parameter list --- --- Pr2 Pr2

3. Turn OFF the instrument remove the “Hot Key”, plug in the TTL serial alarm: SPST relay 8(3) A, 250Vac OdS Outputs activation delay 0÷255 min. 1 Pr2 Pr2

7.1 T820 AND T821 CUT OUT cable, then turn it ON again. auxiliary (XW270K): SPST relay 16(3) A, 250Vac at start up

At the end of the data transfer phase the instrument displays the following heater (XW271K): SPST relay 16(3) A, 250Vac AC Anti-short cycle delay 0÷30 min. 1 Pr1 Pr1

Serial output : TTL standard. RS485 optional

+1

165 -1

messages: CCt Compressor ON time 0 ÷ 23h 50 min. 0 Pr2 Pr2

150

+0.5

-0 “end “ for right programming. Communication protocol: Modbus - RTU during fast freezing

The instrument starts regularly with the new programming. Data storing: on the non-volatile memory (EEPROM). COn Compressor ON time 0÷255 min. 15 Pr2 Pr2

“err” for failed programming. Kind of action: 1B. with faulty probe

+0.5

Pollution grade: normal

-0

In this case turn the unit off and then on if you want to restart the download COF Compressor OFF time 0÷255 min. 30 Pr2 Pr2

31

again or remove the “Hot key” to abort the operation. Software class: A. with faulty probe

Operating temperature: 0÷60 °C. DISPLAY

10.2 UPLOAD (FROM THE INSTRUMENT TO THE “HOT KEY”) Storage temperature: -25÷60 °C.

CF Temperature °C ÷ °F °C/°F Pr2 Pr2

Ø3 x2 Relative humidity: 2085% (no condensing)

1. Turn OFF the instrument by means of the ON/OFF key and remove the TTL measurement unit

Measuring and regulation range: NTC probe: -40÷110°C (-58÷230°F)

serial cable if present; then turn it ON again. rES Resolution in ÷ de de Pr1 Pr1

Resolution: 0,1 °C or 1°C or 1 °F (selectable).

2. When the Wing unit is ON, insert the “Hot key” and push o key; the (integer/decimal point)

7.2 MOUNTING WITH KEYBOARD COVER OPENING DOWNWARD Accuracy (ambient temp. 25°C): ±0,5 °C ±1 digit

"uPL" message appears. Lod Local display P1 ÷ 1r2 P1 Pr2 Pr2

3. Push “SET” key to start the UPLOAD; the “uPL” message is blinking. Red Remote display P1 ÷ 1r2 Pr2 Pr2

4. Turn OFF the instrument remove the “Hot Key”, plug in the TTL serial

13. CONNECTIONS

DEFROST rE

cable, then turn it ON again.

13.1 XW270K / XW271K tdF Defrost type rE, rT, in In Pr1 Pr1

At the end of the data transfer phase the instrument displays the following

2 CLICK! messages: EdF Defrost mode In, Sd 0 Pr2 Pr2

“end “ for right programming. SdF Set point for SMART -30 ÷ +30°C 8/46 Pr2 Pr2

“err” for failed programming. In this case push “SET” key if you want to DEFROST -22÷+86°F

restart the programming again or remove the not programmed “Hot key”. dtE Defrost termination -50,0÷110°C 6 Pr1 Pr1

1

temperature -58÷230°F

3

11. ALARM SIGNALS (1°Evaporator)

IdF Interval between defrost 1÷120h 30 Pr1 Pr1

Message Cause Outputs

cycles

1 “P1” Thermostat probe failure Alarm output ON; Compressor output

MdF (Maximum) length for 1° 0÷255 min. it Pr1 Pr1

2 according to parameters “COn” and “COF”

3 defrost

1

“P2” Evaporator probe failure Alarm output ON; Other outputs unchanged

dFd Displaying during rt, it, SEt, dEF, 30 Pr2 Pr2

“P3” Auxiliary probe failure Alarm output ON; Other outputs unchanged defrost dEG

“HA” Maximum temperature Alarm output ON; Other outputs unchanged dAd MAX display delay after 0÷255 min. 0 Pr2 Pr2

alarm defrost

“LA” Minimum temperature Alarm output ON; Other outputs unchanged Fdt Draining time 0÷60 min. n Pr2 Pr2

alarm

dPO First defrost after start n÷y 2 Pr2 Pr2

“EE” Data or memory failure Alarm output ON; Other outputs unchanged up

“dA” Door switch alarm Alarm output ON; Other outputs unchanged dAF Defrost delay after fast 0 ÷ 23h 50 min. Pr2 Pr2

“EAL” External alarm Alarm output ON; Other outputs unchanged freezing

“BAL” Serious external alarm Alarm output ON; Other outputs OFF FANS O-n

“PAL” Pressure switch alarm Alarm output ON; Other outputs OFF FnC Fans operating mode C-n, C-y, O-n, O-y 10 Pr2 Pr2

(*) In XW271L, AUX is an anticondensing heater

The alarm message is displayed until the alarm condition is recovery. Fnd Fans delay after defrost 0÷255 min. 2/35 Pr2 Pr2

All the alarm messages are showed alternating with the room temperature except FSt Fans stop temperature -50,0÷110°C Pr2 Pr2

for the “P1” which is flashing. -58÷230°F

1592009530 XW271K GB r.1.0 06.08.2015 XW270K - XW271K 2/2

You might also like

- St501-Ln1kv 04fs EnglishDocument12 pagesSt501-Ln1kv 04fs Englishsanthoshs241s0% (1)

- DCB31 Eng.Document15 pagesDCB31 Eng.Aimad ChamsaouiNo ratings yet

- AutoCAD VBA ProgrammingDocument59 pagesAutoCAD VBA ProgrammingZeljko Ristic100% (3)

- Live Code User GuideDocument625 pagesLive Code User GuideironickNo ratings yet

- Shield Traning ManualDocument50 pagesShield Traning ManualArith Krishnanandan88% (16)

- Controllers For Refrigerated Cabinets, Counters and Islands, With Energy-Saving Strategies and Compatible With The Evconnect AppDocument2 pagesControllers For Refrigerated Cabinets, Counters and Islands, With Energy-Saving Strategies and Compatible With The Evconnect AppMihai Lungu100% (1)

- Parameter List: To Unlock The KeyboardDocument2 pagesParameter List: To Unlock The KeyboardJennifer Eszter SárközyNo ratings yet

- HP11 Manual 4.0Document1 pageHP11 Manual 4.0Mauricio Plaza SalinasNo ratings yet

- At2-5 Instructions For Use: Range DescriptionDocument2 pagesAt2-5 Instructions For Use: Range DescriptionIulian DobrinNo ratings yet

- 53 Instruction ManualDocument2 pages53 Instruction ManualAlejandro Palomino AmaroNo ratings yet

- DeltaOhm 9785T Ve 9765T Online PHDocument4 pagesDeltaOhm 9785T Ve 9765T Online PHEnisNo ratings yet

- Auber Instruments SYL-1614 ManualDocument4 pagesAuber Instruments SYL-1614 ManualDNo ratings yet

- SD660 UserDocument10 pagesSD660 UserPhat Dat NguyenNo ratings yet

- XR10C - XR10D: Digital Controller With Cooling or Heating ActionDocument4 pagesXR10C - XR10D: Digital Controller With Cooling or Heating ActionJennifer Eszter SárközyNo ratings yet

- Operating Instructions SINGLE SBC - ControllerDocument12 pagesOperating Instructions SINGLE SBC - ControllerASCI MaintenanceNo ratings yet

- Procool Electronic Panel: Ako-17632, Ako-17633, Ako-17634, Ako-17635, Ako-17636, Ako-17637, Ako-17520, Ako-17521Document4 pagesProcool Electronic Panel: Ako-17632, Ako-17633, Ako-17634, Ako-17635, Ako-17636, Ako-17637, Ako-17520, Ako-17521Amic BanatNo ratings yet

- UsermanualREKA3 3Document8 pagesUsermanualREKA3 3David Lemos Sanchez100% (1)

- EWPX 190 (.E) 6.97 IngDocument4 pagesEWPX 190 (.E) 6.97 Ingroby72No ratings yet

- XW230K GB r1.0 04.08.2015Document2 pagesXW230K GB r1.0 04.08.2015Jennifer Eszter SárközyNo ratings yet

- Xwa11v v8 2 01-3110Document8 pagesXwa11v v8 2 01-3110lopez IvánNo ratings yet

- Operating Instructions: Scroll Through Parameters & Increases Parameter ValueDocument2 pagesOperating Instructions: Scroll Through Parameters & Increases Parameter ValuePradhish VNNo ratings yet

- Operating Instructions: SZ-7556-P-DDocument5 pagesOperating Instructions: SZ-7556-P-Djaganks100% (1)

- Ac1-5 Instruction For Use: PAR Range DescriptionDocument2 pagesAc1-5 Instruction For Use: PAR Range Descriptionnajdo1No ratings yet

- Digital Controler - Pizza de VerdadDocument5 pagesDigital Controler - Pizza de VerdadEdison EspinalNo ratings yet

- ST 710 KHJV 03Document13 pagesST 710 KHJV 03Saad rechamNo ratings yet

- Termostato Digital - SMP55Document88 pagesTermostato Digital - SMP55Julio Cesar T ProcopioNo ratings yet

- XR30C - XR30D: Digital Controller With Off Cycle DefrostDocument4 pagesXR30C - XR30D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNo ratings yet

- HP46 InstDocument2 pagesHP46 InstmahmudNo ratings yet

- Freezer&Fridge KeypadDocument21 pagesFreezer&Fridge Keypadjohnwayne314No ratings yet

- EN-ST129-JB1BV.10FP - DIN RailDocument11 pagesEN-ST129-JB1BV.10FP - DIN RailДмитий ЦымбалNo ratings yet

- Ac1-5 Instruction For Use: PAR Range DescriptionDocument2 pagesAc1-5 Instruction For Use: PAR Range Descriptionhisham falousNo ratings yet

- Ac1-5 Instruction For Use: PAR Range DescriptionDocument2 pagesAc1-5 Instruction For Use: PAR Range Descriptiondiab aliNo ratings yet

- AKO-14012 AKO-14023, AKO-14123,: 1411H210 Thermometers and Thermostats With 1 Probe and 1 Relay: AKO-140XX, AKO-141XXDocument2 pagesAKO-14012 AKO-14023, AKO-14123,: 1411H210 Thermometers and Thermostats With 1 Probe and 1 Relay: AKO-140XX, AKO-141XXmartinNo ratings yet

- CAUTION: Eye Damage May Result From Direct: Adjusting The Alarm Set Points) - Press and Hold ToDocument2 pagesCAUTION: Eye Damage May Result From Direct: Adjusting The Alarm Set Points) - Press and Hold ToSomkiat K. DonNo ratings yet

- Ir-Gun-S: Thermometer Operating InstructionsDocument2 pagesIr-Gun-S: Thermometer Operating InstructionsRamadhan FebriNo ratings yet

- Digital Relay E1200 PDFDocument5 pagesDigital Relay E1200 PDFMisdehRasmanNo ratings yet

- ST710-JB1BA.10: Wiring DiagramDocument11 pagesST710-JB1BA.10: Wiring DiagramAsd AsdNo ratings yet

- Nabertherm Controller R7Document3 pagesNabertherm Controller R7Diógenes Honorato PivaNo ratings yet

- 23.5 Eliwell Bedieing Ontdooithermostaat Id985-E-lx enDocument16 pages23.5 Eliwell Bedieing Ontdooithermostaat Id985-E-lx enjosepadilla1987No ratings yet

- Controller For DHW Heat Pump Heaters: EN EnglishDocument4 pagesController For DHW Heat Pump Heaters: EN EnglishToussaintNo ratings yet

- TR-42 TR-42: Orion ItaliaDocument4 pagesTR-42 TR-42: Orion ItaliaCAMILONo ratings yet

- Termostato UMA CasablancaDocument3 pagesTermostato UMA CasablancaCris YañezNo ratings yet

- SZ 7521Document3 pagesSZ 7521Praveen RajNo ratings yet

- Manual Display Bomba NM076BYDocument1 pageManual Display Bomba NM076BYzuriqueNo ratings yet

- XR30C - XR30D: Installing and Operating InstructionsDocument4 pagesXR30C - XR30D: Installing and Operating InstructionsJennifer Eszter SárközyNo ratings yet

- Im Ec 50154 20180813Document28 pagesIm Ec 50154 20180813Jeff BaumanNo ratings yet

- Thermostat InstructionsDocument8 pagesThermostat InstructionswdreilingNo ratings yet

- 9400 Thermostat Manual - 110-1039Document11 pages9400 Thermostat Manual - 110-1039andrewh3No ratings yet

- Keld KLT11Document1 pageKeld KLT11user userNo ratings yet

- HL2027 (Luna) Only Cooling User Manual (2017.2.16)Document2 pagesHL2027 (Luna) Only Cooling User Manual (2017.2.16)carmen hernandezNo ratings yet

- FTC100D Panel Interface AT052610Document8 pagesFTC100D Panel Interface AT052610Azahra Bintang DyahNo ratings yet

- EWPC 901/A: Temperature Controller With Alarm OutputDocument5 pagesEWPC 901/A: Temperature Controller With Alarm OutputOswaldo Rengifo MuozNo ratings yet

- Shenzhen Willhi Electronics Co., Ltd. Tel:0755 - 29539385 Fax:86-0755 - 2953 9395 Technical Support: Engineer TianDocument6 pagesShenzhen Willhi Electronics Co., Ltd. Tel:0755 - 29539385 Fax:86-0755 - 2953 9395 Technical Support: Engineer TianHoney GibraltarNo ratings yet

- Thermo-Hygrostat Controller: InstallationDocument2 pagesThermo-Hygrostat Controller: Installationeurotunnels100% (1)

- Eliwell EWPC905ManualDocument3 pagesEliwell EWPC905ManualvitapabloNo ratings yet

- EWPC 901/AR: Temperature Controller With Alarm OutputDocument3 pagesEWPC 901/AR: Temperature Controller With Alarm OutputOswaldo Rengifo MuozNo ratings yet

- Zanotti Parameter SP SplitaggregatDocument17 pagesZanotti Parameter SP SplitaggregatSinan BulutNo ratings yet

- Thermostat Honeywell RLV3100Document4 pagesThermostat Honeywell RLV3100LSNo ratings yet

- Temperature Controller, Ad2-5Document2 pagesTemperature Controller, Ad2-5bartosz15023No ratings yet

- Flag Alarm Relay: Description For D.C. or A.C. Supply Operating On "Pick-Up" or "Reset"Document2 pagesFlag Alarm Relay: Description For D.C. or A.C. Supply Operating On "Pick-Up" or "Reset"hendranafiat.aisNo ratings yet

- TACm Instruction Obs Ver 560Document4 pagesTACm Instruction Obs Ver 560Aidan PitsisNo ratings yet

- XT110C - XT111C - XT110D - XT111D: Single Stage Digital Controller With Multi Probe InputDocument4 pagesXT110C - XT111C - XT110D - XT111D: Single Stage Digital Controller With Multi Probe InputJennifer Eszter SárközyNo ratings yet

- Esquema Frigorifico Multi FujitsuDocument1 pageEsquema Frigorifico Multi Fujitsufilipko123No ratings yet

- Ev Aoyg14kbta2 MLDocument6 pagesEv Aoyg14kbta2 MLfilipko123No ratings yet

- Herald Spitfire VitesseDocument417 pagesHerald Spitfire Vitessefilipko123100% (1)

- Carpigiani MINIWIP:GDocument7 pagesCarpigiani MINIWIP:Gfilipko123100% (1)

- Release Notes Csi Bridge 2017 V 1900Document9 pagesRelease Notes Csi Bridge 2017 V 1900Ihab El AghouryNo ratings yet

- 3BSE020926-510 en S800 I O Fieldbus Communication Interface For PROFIBUS DP DPV1Document130 pages3BSE020926-510 en S800 I O Fieldbus Communication Interface For PROFIBUS DP DPV1Format_CNo ratings yet

- 09 SlideDocument54 pages09 SlideMem MemNo ratings yet

- Tutorial ModefrontierDocument8 pagesTutorial ModefrontierOsmar Francisco Reis SilvaNo ratings yet

- XDXL Instruction ManualDocument381 pagesXDXL Instruction ManualeversonsolomaoNo ratings yet

- Digital Input 6ES7521 1BH00 0AB0Document64 pagesDigital Input 6ES7521 1BH00 0AB0najiruddinshaikNo ratings yet

- C++ Programming: From Problem Analysis To Program Design, Fourth Edition (Chapter 3: Input/Output)Document26 pagesC++ Programming: From Problem Analysis To Program Design, Fourth Edition (Chapter 3: Input/Output)Jaid HedrianaNo ratings yet

- 3-Migrating and DataLoading Into ADBDocument9 pages3-Migrating and DataLoading Into ADBAndersonLondoñoNo ratings yet

- Eps 2 PGFDocument6 pagesEps 2 PGFziddasyNo ratings yet

- Semester 1 FinalDocument29 pagesSemester 1 FinalBudi NugrohoNo ratings yet

- Polygon PyDocument18 pagesPolygon Pyheriegeo99No ratings yet

- 3BSE042835R5001 CIO LibObjDesignDocument90 pages3BSE042835R5001 CIO LibObjDesignCristi CrseNo ratings yet

- Standard BASIC LanguageDocument140 pagesStandard BASIC LanguageedhanaaNo ratings yet

- Fx-82sx 220plus Etc enDocument2 pagesFx-82sx 220plus Etc enMegan Graciela IceMintzNo ratings yet

- Unit V Files, Modules, Packages File and Its Operation: Format (I.e .0's and 1's)Document16 pagesUnit V Files, Modules, Packages File and Its Operation: Format (I.e .0's and 1's)nancypeterNo ratings yet

- Simulation Optimization Research On Logistics Distribution Center Picking OperationDocument5 pagesSimulation Optimization Research On Logistics Distribution Center Picking OperationMiguel PeñaNo ratings yet

- IBM Content Manager OnDemand and FileNet-4Document88 pagesIBM Content Manager OnDemand and FileNet-4David ResendizNo ratings yet

- The Evolution of LispDocument109 pagesThe Evolution of LispJeff Pratt100% (2)

- UntitledDocument76 pagesUntitledPankaj MaryeNo ratings yet

- IT104 Discrete StructuresDocument31 pagesIT104 Discrete StructuresAina Maree Eusebio SiasonNo ratings yet

- 2009 06Document350 pages2009 06Venkateswara RaoNo ratings yet

- C++ Function (With Examples)Document13 pagesC++ Function (With Examples)DegageNo ratings yet

- Core Java Question Bank (Set-1)Document22 pagesCore Java Question Bank (Set-1)Amitav BiswasNo ratings yet

- How To Create An Exit ProgramDocument7 pagesHow To Create An Exit Programrachmat99No ratings yet

- Documentation QDDDocument14 pagesDocumentation QDDcistron77No ratings yet

- Lopez 2019 ADocument7 pagesLopez 2019 ARenev UP2B Jawa BaratNo ratings yet

- Math - The Commons Math User Guide - Numerical AnalysisDocument13 pagesMath - The Commons Math User Guide - Numerical AnalysisJean claude onanaNo ratings yet