Professional Documents

Culture Documents

4

4

Uploaded by

Gino0 ratings0% found this document useful (0 votes)

11 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

11 views3 pages4

4

Uploaded by

GinoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 3

Cutmpipe

RS OTeM et sre ma eer

Application

Spiral welded pipes are using most industrial and residental water

pipeline systems. Such as;

Oil, Natural Gas, Water lines,

+ Flammable & nonflammable liquid conveyance and distribution

pipelines

+* Steel structures for construction

= Presured Air Lines.

+ Liquid Hydrocarbon lines

+ Rafineries

‘High Temperature water

+ Energy Santrals and othe energy projects ete.

Product Range:

Outside Diameter...

Wall Thickness.

Unit Length..

- 148" / 219 mm - 3750 mm

: 4mm-25,4mm

:8m to 38m most common 18,5m

Material Grade :

APISLPSL 1. GrA, Gr B, X 42, X 46, X52, X 56, X 60, X 65, X 70

API5L PSL 2 Gr B, X42 , X46 , X52 , X56 , X60, X65 , X70, X80

ASTMASS.

ASTM A252.

TS EN 10217-1(EN 10217-1)

EN 10224....

EN 10219- 1/2.

GPA, GrB

GRADE1, GRADE2, GRADES

P.195 TR1, P 235 TR1, P 265 TR1, P 195 TR2, P 235 TR2, P 265 TR2

L235, L 275, L 360

$235, S 275, S 355

Production Standarts :

TS EN 10217-1(EN 10217-1).....: P'195 TR1, P. 235 TR1, P. 265 TR1, P. 195 TR2, P 235 TR2, P 265 TR2

EN 10224 L235, L275, | 360

1$03183:2015.2. : L245NB, | 290NB, L 360NB

GOST 20295, K34,K38,K42,K50,K52, and KS5,

Surface Preparation. +1 ISO 8501 - 1, ISO 8502 - 3, ISO 8503 - 1

Coating Standards :

Polyethylene AWWA C 215, DIN 30670, NFA 49710, TS EN 10288, UNI 9099

Polypropylene DIN 30678, NFA 49711

Solvent Free Epoxy: AWWA C 210, EN 10289, NFA 49709

Fusion-bonded Epoxy : AWWA C 213

Bitumen DIN 30673, BS 534

cca Cie errr)

Pan Ua CTE re LEE}

Cutmpipe

piral Welded Pipes

Lining Standards :

Epoxy: AWWA C 210, EN 10289, NFA 49709

Cement mortar = AWWA C 205, DIN 2614, TS 8590, EN 10298,

+ Oil, Natural Gas, Water lines.

+ Flammable & nonflammable liquid conveyance and distribution

pipelines

+ Steel structures for construction

+ Presured Air Lines

+ Liquid Hydrocarbon lines

+ Rafineries

+ High Temperature water

+ Energy Santrals and othe energy projects etc.

Pipe End :

‘= Welded Joint End

aya baa / wold Join.

+ Spigot and Socket Joint End

pil 4

rr ayrak bans

‘ples and socket ent

Tests

Non Destuctive Tests :

‘= AUT Coil Lamination with 100% Coverage

‘+ AUT Online Weld Inspection

+ First Visual Inspection Manual

+ Ultrasonic Inspection

+ Hydrotest

‘+ AUT Online Weld HAZ and Pipe End Lamination Inspection

+ Digital X Ray Weld Inspection

+ Pipe End Magnetic Examination

‘+ Magnetic Particle Inspection Final Visual and Dimensional Inspection

cca Pron

Cie errr)

Ce Ue Oe aCe RSAC

GE AEE ee LEE}

Cutmpipe

piral Welded Pipes

Destructive Tests:

+ Tensile Test Bending Test

* Charpy V Notch Impact Test

+ Hardness Test

* Macro and Micro Metallographic Examination

+ DWTT - Drop Weight Tear Test

* Chemical Analysis Crack Tip Opening Displacement (CTOD) Test

Test Certificates

+10 9712

+180 11484

+ MTC according to EN10204/3.1.

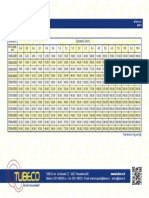

Sizes:

eo =

a oo

aaa asa ae ae ae

a

ee] 3] ||} fe es] 3] Sle fe |e e/a) =|elelela|ele/ajelelaie leis ie) |s

5] |} |=] fs] ||| |p lll lb |

cca Pron Cie errr)

Cen Ue em One aCe IRCCS DEEL See LEE}

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PB PCDocument2 pagesPB PCGinoNo ratings yet

- LamiereInox 160513Document1 pageLamiereInox 160513GinoNo ratings yet

- 3 9Document13 pages3 9GinoNo ratings yet

- 49228-L6 - Tabelle LastreDocument8 pages49228-L6 - Tabelle LastreGinoNo ratings yet

- Rivestimento in Polietilene Applicato Per EstrusioneDocument1 pageRivestimento in Polietilene Applicato Per EstrusioneGinoNo ratings yet