Professional Documents

Culture Documents

Polyethylene Insulation

Polyethylene Insulation

Uploaded by

JeghiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polyethylene Insulation

Polyethylene Insulation

Uploaded by

JeghiCopyright:

Available Formats

Document No.

JKR 20500-0087-20

Edition 2020

SPECIFICATIONS FOR AIR COOLED Document Section 3.2

CHILLER SYSTEM Revision No. 00

Revision Date -

Page 58 of 113

External Insulation Material

Selection of insulation shall be as per Schedule of Design Requirements.

i) External Insulation of Ducts (Fiberglass)

All air conditioning supply and return air ductwork shall generally be insulated

externally with fiberglass of not less than 25 mm thick and having a thermal

conductivity of not more than 0.0332 W/m²K. The density of the fiberglass

insulation shall not be less than 32 kg/m3.

All ductwork in the ceiling space immediately below the roof and in the vertical duct

shaft shall be insulated externally with 50 mm thick fiberglass insulation, with the

thermal conductivity of not more than 0.0332 W/m²K and density not less than 32

kg/m3.

All ductworks within the plant room and conditioned air ducts exposed to weather

shall be insulated externally with 50 mm thick fiberglass insulation with metal

cladding finished.

All fiberglass insulation shall be adhered to the duct surface using a manufacturer

approved fire resistant adhesive. The adhesive shall be of good quality molten

bitumen and applied uniformly throughout the surface of the duct to have a good

bonding between the insulation and sheet metal duct.

All external fiberglass used in insulation for the supply and return air ducts shall be

wrapped up with a vapour barrier foil. The vapour barrier foil shall be reinforced,

double sided aluminium foil and fire resistant.

The vapour barrier foil shall have 75 mm minimum overlap at all joints, and adhered

with an approved fire resistant adhesive to ensure an effective vapour seal. All

joints for the foil shall be sealed with an approved 75 mm wide, pressure sensitive

vapour impervious tape.

Flexible connections on ductwork shall also be insulated with 50mm thick fiberglass

polyethylene mats and finished with vapor proof canvas cloth sewn on.

ii) External Insulation of Ducts (Polyethylene Foam Sheet)

All air-conditioning supply and return air ducts shall generally be insulated

externally with polyethylene (PE) foam of not less than 12.0 mm thick and having

a thermal conductivity of not more than 0.036 W/mK. The PE foam material shall

be chemically or physically cross linked closed-cell type with a foam density of not

less than 25 kg/m3 and faced on one side with appropriate thickness factory applied

reinforced aluminium foil.

The PE foam shall be fire-retardant and Class O in compliance with BS 476 Part 6

EN1366 and 7 and approved by Jabatan Bomba dan Penyelamat Malaysia.

All ductwork in the ceiling space immediately below the roof or in any vertical shaft

Section 3.2 Air Cooled Chiller System © Copyright CKM2020

Document No. JKR 20500-0087-20

Edition 2020

SPECIFICATIONS FOR AIR COOLED Document Section 3.2

CHILLER SYSTEM Revision No. 00

Revision Date -

Page 59 of 113

shall be insulated externally with PE foam of not less than 20.0 mm thick and

having a thermal conductivity of not more than 0.036 W/mK. The PE foam material

shall be chemically or physically cross linked closed-cell type with a foam density

of not less than 25 kg/m3 and faced on one side with appropriate thickness factory

applied reinforced aluminium foil.

All ductworks within the plant room and conditioned air ducts exposed to weather

shall be insulated with 20 mm thick PE foam reinforced with metal cladding

finished.

All ductworks for serving 24 hours shall be insulated externally with PE foam of not

less than 20.0 mm thick and having a thermal conductivity of not more than 0.036

W/mK. The PE foam material shall be chemically or physically cross linked closed-

cell type with a foam density of not less than 25 kg/m3 and faced on one side with

appropriate thickness factory applied reinforced aluminium foil.

The complete surface of duct and insulation material shall be coated with

manufacturer approved adhesive before pressing together. Insulation shall be

carried out at all flexible connections and points subject to condensation. The end

of joints in the insulation shall be coated with adhesive and cemented together to

ensure continuity of the insulation.

iii) External Insulation of Ducts (Closed Cell Nitrile Rubber Insulation)

All air conditioning supply and return air ductwork shall be externally insulated with

not less than 10 mm thick closed cell nitrile rubber. The closed cell nitrile rubber

insulation shall have density of not less than 55 kg/m 3 and thermal conductivity not

more than of 0.036 W/mK.

The closed cell nitrile rubber insulation shall be fire-retardant and Class O in

compliance with BS 476 Part 6 and 7 and approved by Jabatan Bomba dan

Penyelamat Malaysia.

All ductwork in the ceiling space immediately below the roof or in any vertical shaft

shall have not less than 13 mm thick closed cell nitrile rubber, having density of not

less than 55 kg/m3 and thermal conductivity of not more than 0.036 W/mK.

All ductworks within the plant room and conditioned air ducts exposed to weather

shall be insulated with 13 mm closed cell nitrile rubber reinforced with metal

cladding finished.

The water vapour diffusion resistance factor, µ for the closed cell nitrile rubber

insulation shall not be less than 7,000 in accordance with EN 12086.

The complete surface of duct and insulation material shall be coated with

manufacturer approved adhesive before pressing together. Insulation shall be

carried out at all flexible connections and points subject to condensation. The end

of joints in the insulation shall be coated with adhesive and cemented together to

ensure continuity of the insulation.

Section 3.2 Air Cooled Chiller System © Copyright CKM2020

You might also like

- MS 1196-2020Document6 pagesMS 1196-2020LAVOSNo ratings yet

- 291 - 9902 - 301 - Pemasangan Elektrik Untuk Pembinaan Ibu Pejabat Polis Kontinjen Pulau Pinang - Tender DrawingDocument238 pages291 - 9902 - 301 - Pemasangan Elektrik Untuk Pembinaan Ibu Pejabat Polis Kontinjen Pulau Pinang - Tender DrawingIzzuddin MustapaNo ratings yet

- Concrete Mechanics and Design - Solution ManualDocument277 pagesConcrete Mechanics and Design - Solution Manualramya_an241167% (3)

- 0983-03 Method Statement For Installation & Testing of Fire Fighting PipesDocument4 pages0983-03 Method Statement For Installation & Testing of Fire Fighting Pipeshasan_67648961650% (2)

- BS5422 InsulationDocument82 pagesBS5422 InsulationStefan CampeanNo ratings yet

- Schedule of Unit Rates: Piping InstallationDocument6 pagesSchedule of Unit Rates: Piping InstallationJeghiNo ratings yet

- 02 BQ - TENTERA - FP SiapDocument13 pages02 BQ - TENTERA - FP SiapJeghiNo ratings yet

- Pu-Dhda33-4 Rev1Document3 pagesPu-Dhda33-4 Rev1Deepak DeepuNo ratings yet

- Yetta Company ProfileDocument6 pagesYetta Company ProfileAfizi GhazaliNo ratings yet

- Air TestDocument13 pagesAir TestNur Fatin AzarinaNo ratings yet

- Revised BQ - Monsoon Drain - From Amer Assoicates 27june11Document5 pagesRevised BQ - Monsoon Drain - From Amer Assoicates 27june11Nurhayati Muhamad NorNo ratings yet

- Design of Floor JoistDocument5 pagesDesign of Floor JoistXDXDXDNo ratings yet

- Hdpe TNB Cable Solid Wall Red Pipe Page 24Document1 pageHdpe TNB Cable Solid Wall Red Pipe Page 24delvin26No ratings yet

- MK Four 1 Pair 0 63mm Telephone CableDocument2 pagesMK Four 1 Pair 0 63mm Telephone CableDEEP FREEZE SOLUTION100% (1)

- 1. 2017-12-06-长大BR02-CIDB certDocument2 pages1. 2017-12-06-长大BR02-CIDB certWong See PohNo ratings yet

- Greencon Catalogue 2018 PDFDocument16 pagesGreencon Catalogue 2018 PDFAfizshueNo ratings yet

- jpjk7 1 2016 Borang Permohonan Salinan Gantian Sijil Pemilikan Kenderaan LKM Lesen Perdagangan Kenderaan MotorDocument3 pagesjpjk7 1 2016 Borang Permohonan Salinan Gantian Sijil Pemilikan Kenderaan LKM Lesen Perdagangan Kenderaan MotorAida Citra NusantaraNo ratings yet

- Reinforcement CouplersDocument24 pagesReinforcement Couplersvishalgore100% (1)

- Pentens - Green Carpark SystemDocument20 pagesPentens - Green Carpark SystemJun QuanNo ratings yet

- SRS 12kV Switchgear (Ver 1.01)Document12 pagesSRS 12kV Switchgear (Ver 1.01)Hafiyana HFyyaNo ratings yet

- DOSH Machinery Inspection FlowchartDocument1 pageDOSH Machinery Inspection FlowchartXionNo ratings yet

- PDS - Sika MonoTop-412 MYDocument4 pagesPDS - Sika MonoTop-412 MYNorlizawati YusofNo ratings yet

- SAGA Catalogue MegapowerDocument16 pagesSAGA Catalogue Megapowerarchery100% (2)

- Downloaditem File 000915 PDFDocument39 pagesDownloaditem File 000915 PDFsulphurdioxide0% (1)

- HIT-RE - 500 - V3 in Natural Stone - Testing Data - MOIN 2017Document5 pagesHIT-RE - 500 - V3 in Natural Stone - Testing Data - MOIN 2017titir bagchiNo ratings yet

- As NZS 1462.4-2002 Methods of Test For Plastics Pipes and Fittings Method of Determining Reversion of UPVC PiDocument2 pagesAs NZS 1462.4-2002 Methods of Test For Plastics Pipes and Fittings Method of Determining Reversion of UPVC PiSAI Global - APACNo ratings yet

- Dayang Topaz SpecDocument2 pagesDayang Topaz Specben_aizziNo ratings yet

- Section 14 Part 5 Roofing Tiles and ShinglesDocument4 pagesSection 14 Part 5 Roofing Tiles and ShinglesRotsapNayrbNo ratings yet

- Acmv - Symbols & Legend: For TenderDocument1 pageAcmv - Symbols & Legend: For TenderVan DiepNo ratings yet

- 002 Admin Form (Replacement Leave)Document4 pages002 Admin Form (Replacement Leave)Ahmad Syauqi Abd RazakNo ratings yet

- The Proposal 3Document36 pagesThe Proposal 3hadiNo ratings yet

- Iwwtp-Ifc-Pi-P-007-R1 (PFD)Document1 pageIwwtp-Ifc-Pi-P-007-R1 (PFD)maizanazaNo ratings yet

- The Chemistry of Polyethylene Insulation PDFDocument11 pagesThe Chemistry of Polyethylene Insulation PDFluna bfqNo ratings yet

- AMSGB Power Transformer Brochure (Final 27.05.2010)Document4 pagesAMSGB Power Transformer Brochure (Final 27.05.2010)winston11No ratings yet

- MK Conduit & Mini Egatube Conduit TechnicalDocument11 pagesMK Conduit & Mini Egatube Conduit TechnicalIwan PrasetyoNo ratings yet

- Project1-Version1 FinalDocument3 pagesProject1-Version1 FinalFauzan nur SyahalamNo ratings yet

- BS 7671 TemplateDocument1 pageBS 7671 TemplateKarim AmerNo ratings yet

- Interspec: Technical SpecificationDocument12 pagesInterspec: Technical Specificationopmn-mNo ratings yet

- BQ - KK3 Karak Bentong 1st Quote PDFDocument6 pagesBQ - KK3 Karak Bentong 1st Quote PDFAbu Harith HanzalahNo ratings yet

- Schedule of Technical DataDocument12 pagesSchedule of Technical DataMuhammad Firdaus ZarmaniNo ratings yet

- Specification For Polyaluminium Chloride - Lpac - Used in Potable Water Supply PDFDocument6 pagesSpecification For Polyaluminium Chloride - Lpac - Used in Potable Water Supply PDFMOHD JIDINo ratings yet

- Raytech Retail Price ListDocument1 pageRaytech Retail Price ListAndy AG100% (1)

- PDS Sika AnchorFix SDocument6 pagesPDS Sika AnchorFix SdostjanNo ratings yet

- BFC 3042 Chapter 4bDocument10 pagesBFC 3042 Chapter 4bInahMisumiNo ratings yet

- JKR Standard Specification 2014Document1 pageJKR Standard Specification 2014Mohd Izzuddin ZainiNo ratings yet

- Decklite Access SolutionsDocument22 pagesDecklite Access Solutionshash117No ratings yet

- LS02Document33 pagesLS02nazmiNo ratings yet

- Rumah - Banglo Mesra Rakyat 1 TingkatDocument1 pageRumah - Banglo Mesra Rakyat 1 TingkatmaizansofiaNo ratings yet

- Boat Rules, 1953Document7 pagesBoat Rules, 1953mfuzee_jlsNo ratings yet

- Work Method StatementDocument9 pagesWork Method StatementdjvhNo ratings yet

- Landscape Quotation 22 09 2022Document2 pagesLandscape Quotation 22 09 2022Tanya MistyNo ratings yet

- TNB BGDocument3 pagesTNB BGAZAN WTA50% (2)

- Acson Anti Corrosion Treatment CatalogueDocument2 pagesAcson Anti Corrosion Treatment CatalogueAli AimranNo ratings yet

- 6 - Final Rectification Report PDFDocument11 pages6 - Final Rectification Report PDFLeo CalejaNo ratings yet

- SikaTop-Seal 107 PDFDocument4 pagesSikaTop-Seal 107 PDFSed BeelzeNo ratings yet

- 2.6 Lampu KecemasanDocument1 page2.6 Lampu Kecemasanenergy empireNo ratings yet

- MSDS HB Hydrosafe 101Document8 pagesMSDS HB Hydrosafe 101Hazrin HasanNo ratings yet

- Storage of Liquid Fuel Rev 0Document8 pagesStorage of Liquid Fuel Rev 0Sipang JalaiNo ratings yet

- Red Oxide Primer QD JotunDocument4 pagesRed Oxide Primer QD JotunDebNo ratings yet

- As 2353-1999 Pedestrian Push-Button AssembliesDocument7 pagesAs 2353-1999 Pedestrian Push-Button AssembliesSAI Global - APACNo ratings yet

- Concealed Ducted Split Units R22 24-60 MBH 50HzDocument20 pagesConcealed Ducted Split Units R22 24-60 MBH 50HzMeshal Al-mutairi100% (2)

- Method Statement: Underfloor Trunking, Conduit and Junction BoxesDocument2 pagesMethod Statement: Underfloor Trunking, Conduit and Junction Boxesfatinjamal22100% (1)

- SECTION 15081: Duct Insulation 15081Document5 pagesSECTION 15081: Duct Insulation 15081fatREVITNo ratings yet

- Specification of Pipe InsulationDocument6 pagesSpecification of Pipe InsulationNoldz SantosNo ratings yet

- SECTION 15082 Equipment Insulation Part 1 - General 1.1 GeneralDocument5 pagesSECTION 15082 Equipment Insulation Part 1 - General 1.1 GeneralfatREVITNo ratings yet

- Pittsburgh Corning Foamglass Cold Process Piping Installation GuidelineDocument7 pagesPittsburgh Corning Foamglass Cold Process Piping Installation Guidelinenaseema1No ratings yet

- Product Documentation CamFFU Compact SolutionDocument1 pageProduct Documentation CamFFU Compact SolutionJeghiNo ratings yet

- 05 - CoolingLoad Estimator - Imtiaz - Admin - GRD - BLK PengetuaDocument2 pages05 - CoolingLoad Estimator - Imtiaz - Admin - GRD - BLK PengetuaJeghiNo ratings yet

- Design Brief Aircond PHQ For GBIDocument2 pagesDesign Brief Aircond PHQ For GBIJeghiNo ratings yet

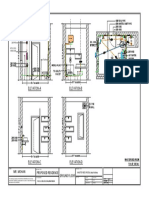

- Detail Pipe JointDocument1 pageDetail Pipe JointJeghiNo ratings yet

- 03 - CoolingLoad Estimator - Imtiaz - Admin - GRD - BLK KesihatanDocument2 pages03 - CoolingLoad Estimator - Imtiaz - Admin - GRD - BLK KesihatanJeghiNo ratings yet

- Ei Mech Proton City 2B #2 - 18.1.2023Document1 pageEi Mech Proton City 2B #2 - 18.1.2023JeghiNo ratings yet

- PTS As Per ContractDocument2 pagesPTS As Per ContractJeghiNo ratings yet

- Wcpu Table Flow Rate 1Document2 pagesWcpu Table Flow Rate 1JeghiNo ratings yet

- Workshop ER Compliance - Mech ServicesDocument5 pagesWorkshop ER Compliance - Mech ServicesJeghiNo ratings yet

- MBRP Pa 18.1.2023Document1 pageMBRP Pa 18.1.2023JeghiNo ratings yet

- QS ER Comparison - 2022.01.10Document7 pagesQS ER Comparison - 2022.01.10JeghiNo ratings yet

- Dehumidifier Equipment ScheduleDocument1 pageDehumidifier Equipment ScheduleJeghiNo ratings yet

- Katalog-Ceiling Conceal Inverter R32-1Document1 pageKatalog-Ceiling Conceal Inverter R32-1JeghiNo ratings yet

- SPAN-HB (30june2023)Document2 pagesSPAN-HB (30june2023)JeghiNo ratings yet

- BMS Rev.1 - Reengineering - 13.12.2018Document2 pagesBMS Rev.1 - Reengineering - 13.12.2018JeghiNo ratings yet

- HMI Minutes - by Hadzlina 20220929 - CHF 20220930Document1 pageHMI Minutes - by Hadzlina 20220929 - CHF 20220930JeghiNo ratings yet

- Jpbasic-Pt: Auto Pressure UnitsDocument1 pageJpbasic-Pt: Auto Pressure UnitsJeghiNo ratings yet

- List of Mech DWG PHQ - 19.2.2019Document3 pagesList of Mech DWG PHQ - 19.2.2019JeghiNo ratings yet

- List of Mech Equipment PHQ - 11.11.2021Document1 pageList of Mech Equipment PHQ - 11.11.2021JeghiNo ratings yet

- Tank Calculation LatestDocument2 pagesTank Calculation LatestJeghiNo ratings yet

- The Following Is A Summary of Our Tender Sum:-: Perunding AzfarDocument4 pagesThe Following Is A Summary of Our Tender Sum:-: Perunding AzfarJeghiNo ratings yet

- 04 - Wet Chemical SystemDocument1 page04 - Wet Chemical SystemJeghiNo ratings yet

- Pusat Darah Wilayah Utara, Sungai Petani, Kedah (Reka & Bina)Document3 pagesPusat Darah Wilayah Utara, Sungai Petani, Kedah (Reka & Bina)JeghiNo ratings yet

- Air System Sizing Summary For AHU-01Document29 pagesAir System Sizing Summary For AHU-01JeghiNo ratings yet

- Efficient Solutions For Important Environments: Multi-DENCODocument12 pagesEfficient Solutions For Important Environments: Multi-DENCOJeghiNo ratings yet

- 02 - Heat Load DataDocument29 pages02 - Heat Load DataJeghiNo ratings yet

- 05 BQ - TENTERA - KE SiapDocument5 pages05 BQ - TENTERA - KE SiapJeghiNo ratings yet

- 05 BQ - TENTERA - POL SiapDocument4 pages05 BQ - TENTERA - POL SiapJeghiNo ratings yet

- Astm A480-A480m-05Document24 pagesAstm A480-A480m-05NadhiraNo ratings yet

- Plumbing Layout Master BedroomDocument1 pagePlumbing Layout Master BedroomRuman SiddiquiNo ratings yet

- Haura Risyad MandiriDocument10 pagesHaura Risyad MandiriWarsono LukitoNo ratings yet

- Vinay Pavankumar .K 1 Year PG Student Dept of Prosthodontics Aecs Maaruti Dental CollegeDocument85 pagesVinay Pavankumar .K 1 Year PG Student Dept of Prosthodontics Aecs Maaruti Dental Collegedrvivek reddyNo ratings yet

- Built Up Rate ReinforcementDocument25 pagesBuilt Up Rate Reinforcementsyazwan_badboyzNo ratings yet

- Cosmothene g812 LdpeDocument1 pageCosmothene g812 LdpedanuNo ratings yet

- Submerged Arc Welding Consumables For Mild Steel and 490N/mm Class High Tensile Strength SteelDocument17 pagesSubmerged Arc Welding Consumables For Mild Steel and 490N/mm Class High Tensile Strength SteelManish MNo ratings yet

- Bolting Unit: Docmine Drill Steel Sup - 200X200 Plates 8999361000-001 Boltec SDocument10 pagesBolting Unit: Docmine Drill Steel Sup - 200X200 Plates 8999361000-001 Boltec Scristian nahuelcuraNo ratings yet

- Effective Layouts - Superior Radiant ProductsDocument6 pagesEffective Layouts - Superior Radiant ProductsAllan GomezNo ratings yet

- Gaurav Jhalani SeminarDocument47 pagesGaurav Jhalani SeminarrezarazaqaNo ratings yet

- E2Four Probe Exp For StudentDocument28 pagesE2Four Probe Exp For Studentkaushik prajapatiNo ratings yet

- Mechanical Engineering Important MCQ PDF-Fluid MechanicsDocument9 pagesMechanical Engineering Important MCQ PDF-Fluid Mechanicskibrom atsbhaNo ratings yet

- S&T Roofing Solutions Product Guide Mar2018-DP1 0Document12 pagesS&T Roofing Solutions Product Guide Mar2018-DP1 0sattar12345No ratings yet

- How Brass Is MadeDocument7 pagesHow Brass Is MadeHokuto No KenNo ratings yet

- DCR Ratio Method For Progressive Failure of A StructureDocument9 pagesDCR Ratio Method For Progressive Failure of A StructureOnee Yetoo AseemeNo ratings yet

- Fabrication Steps MOS Process Flow Semiconductor Manufacturing TechnologyDocument41 pagesFabrication Steps MOS Process Flow Semiconductor Manufacturing TechnologyAhmed Fouad MusaNo ratings yet

- Reliance Engineering Associates (P) Limited Welding Procedure SpecificationDocument1 pageReliance Engineering Associates (P) Limited Welding Procedure SpecificationdeepakNo ratings yet

- Tutorial Week 3c - MECH3361 Workbench GuideDocument2 pagesTutorial Week 3c - MECH3361 Workbench GuideashokkumarNo ratings yet

- BS En.1996.1.1.2005Document125 pagesBS En.1996.1.1.2005Habib Ur Rahman100% (1)

- BOQ Arsitek PIMDocument65 pagesBOQ Arsitek PIMahmadfananiNo ratings yet

- C713-Operator Manual English PDFDocument58 pagesC713-Operator Manual English PDFJosh YounisNo ratings yet

- 318 14 SeminarDocument65 pages318 14 Seminarmahantesh_82No ratings yet

- Soal Ulangan Tengah Semester Paket BDocument4 pagesSoal Ulangan Tengah Semester Paket BDiyardita DipaNo ratings yet

- Clima Diagrama 118630Document47 pagesClima Diagrama 118630Enrique RamirezNo ratings yet

- Is-456 With Aci 318 & BS 8110Document28 pagesIs-456 With Aci 318 & BS 8110SacademicusNo ratings yet

- VRV III-Q (Cooling Only)Document6 pagesVRV III-Q (Cooling Only)cyclon2010No ratings yet