Professional Documents

Culture Documents

Wps 7018 Smaw

Wps 7018 Smaw

Uploaded by

Erick VazquezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wps 7018 Smaw

Wps 7018 Smaw

Uploaded by

Erick VazquezCopyright:

Available Formats

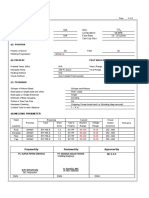

PREQUALIFIED WELDING PROCEDURE SPECIFICATION

WPS No.

Company Name: Date:

Authorized by: Signature:

WELDING PROCESS Shielded Metal Arc Welding (SMAW) TYPE Manual

JOINT DESIGN USED POSITION

Type Lap Joint (Fillet Weld) L-F12/L-F12a Position of Groove - Fillet 1F, 2F, 3F, 4F

Single Yes Double Yes Vertical Progression (Up/Down) Up for 3F

Backing (Yes/No) None

Backing Material None ELECTRICAL CHARACTERISTICS

Root Opening 0 Transfer Mode Varies

Groove Angle N/A (Short Circuit, Globular, Spray, Pulsed)

Backgouging (Yes/No) None Current DCEP (DC+)

BASE METALS

Material Spec Any Group I or II to any Group I or II TECHNIQUE

Type or Grade - Stringer or Weave Either (Stringer on all root passes)

Thickness Groove - Fillet 1/8 - Unl. Single or Multipass Both

Diameter (Pipe) N/A CTTWD N/A

Peening NONE

FILLER METALS Interpass Cleaning Wire Brush/Wire Wheel

AWS Specification A5.1 Remove all slag before next pass

AWS Classification E7018 H4R PREHEAT

Thickness of Thickest Part at Point of Preheat and Interpass

SHIELDING Welding Temperature

Gas N/A Composition N/A in mm

Flow Rate N/A Gas Cup Size N/A 1/8 to 3/4 3 to 20 32 0

Over 3/4 to 1-1/2 Over 20 to 38 150 65

POST WELD HEAT TREATMENT Over 1-1/2 to 2-1/2 Over 38 to 65 225 110

Temp. NONE Time N/A Over 2-1/2 Over 65 300 150

Note on Preheat and Interpass Temperature: When the base metal temperature is below 32

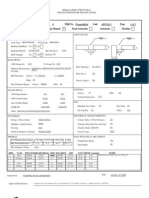

WELDING PROCEDURE JOINT DETAILS & TOLERANCES

Filler Metal Current Current Type Travel Speed

Position & Polarity

Class Diameter (Amps) (in/min)

All E7018 H4R 1/8 90 - 110 DC+ 3- 5

All E7018 H4R 1/8 110 - 125 DC+ 4- 8

All E7018 H4R 1/8 125 - 140 DC+ 6 - 10

F, H E7018 H4R 1/8 140 - 150 DC+ 8 - 12

NOTE: Verify that the above parameters are in line with the filler metal manufacturer's

recommendations and that travel speeds can produced welds that do not exceed the

limitations imposed by AWS D1.1 Table 5.1 - Prequalified WPS Requirements

Additional Requirements

Maximum Single Pass Fillet Size: 3/8" (F), 5/16" (H&OH), 1/2" (V)

Maximum Layer Width: Split layers when layer width is w > 5/8" (F,H,OH)

Split layers when layer width is w > 1" (V)

Minimum Fillet Weld Size: See Table 7.7 of AWS D1.1 (2020)

Perpendicularity of members shall be +/- 10

See clause 7.21.1 for additional fillet weld assembly requirements or exceptions

Minimum size fillet weld shall not be smaller than the size required to transmit the applied load nor that provided in the Table 7.7 AWS D1.1 (2020)

You might also like

- Energy Loss in Pipe and FittingsDocument10 pagesEnergy Loss in Pipe and FittingsMuhd Fadhil Nazer25% (4)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Smaw Fillet Aws d1.1Document1 pageSmaw Fillet Aws d1.1fallalovaldes100% (1)

- NAG 1/W5A580 Auto Transmission Diagnosis and RepairDocument42 pagesNAG 1/W5A580 Auto Transmission Diagnosis and RepairKamerom CunninghamNo ratings yet

- Alu WpsDocument4 pagesAlu WpsdselvakuuNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- WPS Format For AWS D1.1 - WPS - SAWDocument1 pageWPS Format For AWS D1.1 - WPS - SAWThe Welding Inspections CommunityNo ratings yet

- Welding Procedure Specification: Neo StructoDocument2 pagesWelding Procedure Specification: Neo Structohareesh13hNo ratings yet

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- Sa 516 WPQDocument1 pageSa 516 WPQElgen IgloriaNo ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- Procedure Qualification Record (PQR) : JointDocument2 pagesProcedure Qualification Record (PQR) : JointBalkishan DyavanapellyNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Visual Inspection Report - During WeldingDocument1 pageVisual Inspection Report - During WeldingsurwaneNo ratings yet

- WPS-PQR Pengelasan (AA)Document12 pagesWPS-PQR Pengelasan (AA)Abrianto AkuanNo ratings yet

- Welding Control Procedure (Project Standards and Specifications)Document4 pagesWelding Control Procedure (Project Standards and Specifications)Axtella Global for Information Technology CompanyqNo ratings yet

- Manual Structural WeldingDocument12 pagesManual Structural WeldingwalitedisonNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDocument1 pageWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- PQR Sample PrintoutDocument2 pagesPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Alignment Inspection Report For Erection of Structural Steel (Gallery & Trestle)Document1 pageAlignment Inspection Report For Erection of Structural Steel (Gallery & Trestle)sivaNo ratings yet

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- Welder Qualification Register 01Document3 pagesWelder Qualification Register 01Andrei UrsacheNo ratings yet

- API Welding ProcedureDocument2 pagesAPI Welding ProcedureSamarakoon BandaNo ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- WPS PQR WQT WPQDocument43 pagesWPS PQR WQT WPQAmmar Čabaravdić100% (1)

- WQT Aws D1.1Document1 pageWQT Aws D1.1Ali HammoudaNo ratings yet

- Welding Qualification As Per AWS D1.1Document19 pagesWelding Qualification As Per AWS D1.1Ouni AchrefNo ratings yet

- 385 2 Internal Gtaw+SmawDocument2 pages385 2 Internal Gtaw+Smawsubash1688No ratings yet

- 171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQDocument4 pages171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- ASME IX-Welder Performance Qualification (WPQ) : Welding and NDT Purposed FormatDocument1 pageASME IX-Welder Performance Qualification (WPQ) : Welding and NDT Purposed FormatArshadAliNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- Wps PQR Aws d11 FormDocument2 pagesWps PQR Aws d11 Formflakosisas100% (1)

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Prequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Document2 pagesPrequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Nuril VS theWorldNo ratings yet

- WPS 1aDocument2 pagesWPS 1aPrasenjit BhanjaNo ratings yet

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)ventas ventasNo ratings yet

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- Format WPQDocument2 pagesFormat WPQAkash Singh TomarNo ratings yet

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- Welding Procedure Specification (WPS) : Joint Design PositionDocument9 pagesWelding Procedure Specification (WPS) : Joint Design PositionpetermanroelibraryNo ratings yet

- Welding Procedure Specification: WPS For SS Material 304 (GTAW+SMAW)Document1 pageWelding Procedure Specification: WPS For SS Material 304 (GTAW+SMAW)Lipika GayenNo ratings yet

- AnilDocument7 pagesAnilanil kumarNo ratings yet

- Weld Repair Rate - MFJO542Document2 pagesWeld Repair Rate - MFJO542Salahuddin Farooqui100% (1)

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- WPS & Materials Applicable MatrixDocument5 pagesWPS & Materials Applicable Matrixundeath123100% (1)

- Welding Procedure Specification (WPS)Document3 pagesWelding Procedure Specification (WPS)Jignasa ShahNo ratings yet

- Prequalified Qualified by TestingDocument5 pagesPrequalified Qualified by Testingcarlosoliveros1967No ratings yet

- 07 SMAW 332 18 532 332 E7018 Prequalified WPSsDocument82 pages07 SMAW 332 18 532 332 E7018 Prequalified WPSsErick Vazquez100% (1)

- Quinco Steel Inc.: Welding Procedure Specification (WPS)Document1 pageQuinco Steel Inc.: Welding Procedure Specification (WPS)wmajordan13No ratings yet

- QC E7018 CJP B-L1a OverheadDocument1 pageQC E7018 CJP B-L1a Overheadwmajordan13No ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Welding Procedure Specifications (Wps - 6G) : 2mm (Max)Document2 pagesWelding Procedure Specifications (Wps - 6G) : 2mm (Max)Gbenga Mobolade100% (1)

- WPS-ASME SEC IX-for PSODocument3 pagesWPS-ASME SEC IX-for PSOSultan ZebNo ratings yet

- WPS Welding Performance SpecialistDocument2 pagesWPS Welding Performance SpecialistGobinath GovindarajNo ratings yet

- WPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless SteelDocument1 pageWPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless SteelAhmed Gomaa100% (1)

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- Oil Based Mud ThinnerDocument2 pagesOil Based Mud ThinnerjangriNo ratings yet

- Spirit RoverukkahDocument1 pageSpirit RoverukkahindythegeekNo ratings yet

- Technical Data Sheet: Product Name: Product Form: Chemical NameDocument3 pagesTechnical Data Sheet: Product Name: Product Form: Chemical Namesahajahan shaikhNo ratings yet

- The Heychris DramaDocument14 pagesThe Heychris DramaAnnNo ratings yet

- Navi Planner PDFDocument309 pagesNavi Planner PDFМилен Долапчиев100% (1)

- Case Study: Banana Plantation Impact On Economy of MindanaoDocument6 pagesCase Study: Banana Plantation Impact On Economy of Mindanaolyramae.dezaNo ratings yet

- C O / C - S,, Y V: /Itdversions/19.3.0.1/Itdstart - Aspx?Svc 3F50C3C0-1874-400E-Af3A-5036E 79Dec9FDocument201 pagesC O / C - S,, Y V: /Itdversions/19.3.0.1/Itdstart - Aspx?Svc 3F50C3C0-1874-400E-Af3A-5036E 79Dec9FharshiniNo ratings yet

- Activity 4Document4 pagesActivity 4Niche 005No ratings yet

- Non Spore Forming Gram Positive Rods: CorynebacteriumDocument6 pagesNon Spore Forming Gram Positive Rods: CorynebacteriumggzgzhhsNo ratings yet

- Medications AdministrationDocument9 pagesMedications AdministrationGeylla FaeldoniaNo ratings yet

- 2012 Article 61Document15 pages2012 Article 61Novita SariNo ratings yet

- Skate 3Document2 pagesSkate 3Muhammad FaridNo ratings yet

- Archaeology: Spatial Analysis in Archaeology. Ian Hodder and Clive OrtonDocument3 pagesArchaeology: Spatial Analysis in Archaeology. Ian Hodder and Clive OrtonjackNo ratings yet

- Lecture Notes For Week Ten Mechanics of Chain DrivesDocument11 pagesLecture Notes For Week Ten Mechanics of Chain DrivesJohn KimaniNo ratings yet

- Yogesh Aghav 2Document7 pagesYogesh Aghav 2pranjalbaruah8No ratings yet

- Adsorption Kinetic Models: Physical Meanings, Applications, and Solving MethodsDocument18 pagesAdsorption Kinetic Models: Physical Meanings, Applications, and Solving MethodsNórida Pájaro GómezNo ratings yet

- 09D9022054B1 PDFDocument25 pages09D9022054B1 PDFnolive28No ratings yet

- Creep Analysis of Plastically Deformed Shrink-Fitted Joints: Researcharticle-MechanicalengineeringDocument12 pagesCreep Analysis of Plastically Deformed Shrink-Fitted Joints: Researcharticle-MechanicalengineeringshyamNo ratings yet

- MJPRU Exam SchemeDocument9 pagesMJPRU Exam SchemePrabhat SharmaNo ratings yet

- ADMModule - S11 12PS-IIIa-2Document28 pagesADMModule - S11 12PS-IIIa-2Lebz Ricaram33% (3)

- Dendrocalamus Asper PDFDocument7 pagesDendrocalamus Asper PDFVictor Eduardo Barraza SalgueroNo ratings yet

- File Dryflex Cable Compounds Product GuideDocument15 pagesFile Dryflex Cable Compounds Product Guidetwo travellerNo ratings yet

- Presentation Urban DesignDocument17 pagesPresentation Urban DesignLGU GALIMUYODNo ratings yet

- Clarifying The Two TruthsDocument10 pagesClarifying The Two TruthsÁtilaNo ratings yet

- Kelas 7 SOAL ASESMEN AKHIR SEMESTER 1Document6 pagesKelas 7 SOAL ASESMEN AKHIR SEMESTER 1binta azkiyaNo ratings yet

- Primary HyperparathyroidismDocument5 pagesPrimary HyperparathyroidismAbdul QuyyumNo ratings yet

- Chapter 4.4 Pure SteamDocument45 pagesChapter 4.4 Pure SteamThefairman UnkownNo ratings yet

- 3 - Panel DataDocument35 pages3 - Panel DataDaniel PatraboyNo ratings yet