Professional Documents

Culture Documents

Appendix-1-Updated (06032023) Opt TBSL Purlins

Appendix-1-Updated (06032023) Opt TBSL Purlins

Uploaded by

Rajendra PawarCopyright:

Available Formats

You might also like

- Parts Catalogue: 4TNV98T-GGEDocument35 pagesParts Catalogue: 4TNV98T-GGEVitorMello83% (6)

- Steel BOQ Square Warehouse Cover Shed 16-7-18Document23 pagesSteel BOQ Square Warehouse Cover Shed 16-7-18lucio444No ratings yet

- BoqDocument8 pagesBoqFoisul Alam100% (1)

- Final BOQ and Annexure - Fire Fighting - 00Document7 pagesFinal BOQ and Annexure - Fire Fighting - 00Anonymous x7ue2F4iNo ratings yet

- 20-123 Stainless Steel and Metal Works BOQDocument4 pages20-123 Stainless Steel and Metal Works BOQsobhiNo ratings yet

- Book 2Document80 pagesBook 2Pratik GuptaNo ratings yet

- Revised BOH R1Document10 pagesRevised BOH R1Avijit BhattacharjeeNo ratings yet

- Sr. No Description Unit Quantity Rate Amount Remarks Item Wise Cost For Pre-Fabricated Steel Structure Building at KarakDocument2 pagesSr. No Description Unit Quantity Rate Amount Remarks Item Wise Cost For Pre-Fabricated Steel Structure Building at Karakrefinedconstruction510No ratings yet

- Al Ain Distribution Company (Aadc) : JM 0209 SubstationDocument2 pagesAl Ain Distribution Company (Aadc) : JM 0209 SubstationRyo DavisNo ratings yet

- Tender Enquiry No. Bhe/Fp/Cvl/025 Section-IV Bill of QuantitiesDocument2 pagesTender Enquiry No. Bhe/Fp/Cvl/025 Section-IV Bill of QuantitiesSantanu ShresthaNo ratings yet

- Pisolkar - Estimate.Document10 pagesPisolkar - Estimate.Ankit Ratnakar GaidhaniNo ratings yet

- BOQ and Rate For Boundary WallDocument2 pagesBOQ and Rate For Boundary Wallsandesh negiNo ratings yet

- Boq - Pani BhabanDocument116 pagesBoq - Pani Bhabanapi-26147616No ratings yet

- Al Ain Distribution Company (Aadc) : JM 0223 SubstationDocument2 pagesAl Ain Distribution Company (Aadc) : JM 0223 SubstationRyo DavisNo ratings yet

- Shyadpur 1Document4 pagesShyadpur 1Riddhiman BhowmikNo ratings yet

- Boq Bah KarakDocument18 pagesBoq Bah KarakAbubakar NazirNo ratings yet

- Brick SolingDocument13 pagesBrick SolingM ShahidNo ratings yet

- Exide New BoqDocument7 pagesExide New Boqkishor veheleNo ratings yet

- Protection CamberDocument5 pagesProtection CamberAshishKumarNo ratings yet

- B.ODocument4 pagesB.Oranajouu11397No ratings yet

- Jhabua-Sor 20200702 181504Document4 pagesJhabua-Sor 20200702 181504Suaib VCSNo ratings yet

- Fs-Nawanagar Ag - A (Basudeva Village) - A8-ErectionDocument1 pageFs-Nawanagar Ag - A (Basudeva Village) - A8-Erectionbapi2pradeepNo ratings yet

- Japhat Civil Work BoqDocument8 pagesJaphat Civil Work BoqsatyaprakashNo ratings yet

- 5.5 Bill of Quantities For Different Unit of Rural Buildings With General Civil & Structural WorkDocument5 pages5.5 Bill of Quantities For Different Unit of Rural Buildings With General Civil & Structural WorkNIBEDITA DEYNo ratings yet

- BOQDocument25 pagesBOQBILAL HAJINo ratings yet

- ExcelSheetForCalculationPurposeOnly To MR Subburaman 29 04 23Document4 pagesExcelSheetForCalculationPurposeOnly To MR Subburaman 29 04 23slipformNo ratings yet

- Khaadi Fabric Store at - Boq (r2) - Id Works - 24-12-2018Document48 pagesKhaadi Fabric Store at - Boq (r2) - Id Works - 24-12-2018Kashan ShoukatNo ratings yet

- Shyadpur 2Document80 pagesShyadpur 2Riddhiman BhowmikNo ratings yet

- 0503223-01-CIV-BOQ-1021-AB (Laundry Shed BOQ Comparision)Document6 pages0503223-01-CIV-BOQ-1021-AB (Laundry Shed BOQ Comparision)CCCCCCC100% (1)

- Hazira-Sor 20200702 181418Document11 pagesHazira-Sor 20200702 181418Suaib VCSNo ratings yet

- Bruhat Bangalore Mahanagara Palike: SL No Name of WorkDocument6 pagesBruhat Bangalore Mahanagara Palike: SL No Name of WorkMangesh ChaudhariNo ratings yet

- Copy of MSIL DEVIATIONA(1)Document3 pagesCopy of MSIL DEVIATIONA(1)Mujahid choudharyNo ratings yet

- Final BUA BOQ Tender - OB Plot and Podium - 03.09.21Document11 pagesFinal BUA BOQ Tender - OB Plot and Podium - 03.09.21Jaysukh N SapraNo ratings yet

- 5th R.A. Stanford Una - 25.04.2018Document202 pages5th R.A. Stanford Una - 25.04.2018Gaurav SharmaNo ratings yet

- BOQ - Gurgaon - 25.06.23Document3 pagesBOQ - Gurgaon - 25.06.23Anurag ZullurwarNo ratings yet

- SORPT18 - PIPING BOQ - Copy 13Document1 pageSORPT18 - PIPING BOQ - Copy 13atulNo ratings yet

- Boq-Morth KanpurDocument2 pagesBoq-Morth KanpurDescon Infrastructures Pvt. Ltd.No ratings yet

- Traffic Sign Item PDFDocument3 pagesTraffic Sign Item PDFGourav ChavhanNo ratings yet

- Bill of Quantity: Baner Lifespaces LLPDocument7 pagesBill of Quantity: Baner Lifespaces LLPSales AlufacadesNo ratings yet

- Percentage Boq: Validate Print HelpDocument18 pagesPercentage Boq: Validate Print HelpASRAR AHMED KHANNo ratings yet

- Asgn 2Document6 pagesAsgn 2Siti HajarNo ratings yet

- Bsateen Palm View Quotation Updated by AlnafelDocument9 pagesBsateen Palm View Quotation Updated by Alnafelmarwan ashrafNo ratings yet

- BOQ - Periscope HouseDocument7 pagesBOQ - Periscope Housepaiya92No ratings yet

- BIDDOCUMENTDocument7 pagesBIDDOCUMENTJRB BelgaumNo ratings yet

- Structure & Piping OfferDocument2 pagesStructure & Piping OfferMukesh BerwaNo ratings yet

- UTC-Z3-Phase 01 - B02 (Block 5&6) - IFC Rev00Document131 pagesUTC-Z3-Phase 01 - B02 (Block 5&6) - IFC Rev00Mahmoud HamdyNo ratings yet

- 300nb Fire Water Line - BEEL - 071953Document2 pages300nb Fire Water Line - BEEL - 071953irshadiiitNo ratings yet

- DAB Modified FinalDocument74 pagesDAB Modified FinalFreedom Love Nabal100% (1)

- Surat DC Budget - Cold Room 250 SQ FT V01Document22 pagesSurat DC Budget - Cold Room 250 SQ FT V01Chaitanya IdateNo ratings yet

- Bills of Quantities SL - No Description Unit Qty Rate (RS.) Amount (RS.) KG Rate KG AmountDocument2 pagesBills of Quantities SL - No Description Unit Qty Rate (RS.) Amount (RS.) KG Rate KG AmountsmithNo ratings yet

- Vulcan Industrial Engineering Co. Pvt. LTDDocument3 pagesVulcan Industrial Engineering Co. Pvt. LTDk koradiaNo ratings yet

- SORPT18 - PIPING BOQ - Copy 29Document1 pageSORPT18 - PIPING BOQ - Copy 29atulNo ratings yet

- DEXCOM 3 - BoQ Metal Works (CER1-2, 3&CUB)Document41 pagesDEXCOM 3 - BoQ Metal Works (CER1-2, 3&CUB)MEAGAN CHNGNo ratings yet

- Estimate Jackpot CasinoDocument5 pagesEstimate Jackpot CasinoGsUpretiNo ratings yet

- CA No. GE (I) (CG) /KOCHI/ OF 2022-2023 Schedule 'A' Ser Page No.21Document8 pagesCA No. GE (I) (CG) /KOCHI/ OF 2022-2023 Schedule 'A' Ser Page No.21sajanjoseNo ratings yet

- UR To Bailey Bridge 1.25 Lakhs 10.5.11Document13 pagesUR To Bailey Bridge 1.25 Lakhs 10.5.11Kiran AEE BvrmNo ratings yet

- 23S3 Ot D 220 Me SP 0570 00Document7 pages23S3 Ot D 220 Me SP 0570 00Mohammad ghanaatpisheNo ratings yet

- BBS FormateDocument1 pageBBS FormateahamedthousifNo ratings yet

- Toyota Gujrat Motors Civil Works BoqDocument3 pagesToyota Gujrat Motors Civil Works BoqJahanzeb KhanNo ratings yet

- User Guide: Masonry Anchors For Tie-Down of Bottom Plates To SlabsDocument2 pagesUser Guide: Masonry Anchors For Tie-Down of Bottom Plates To SlabsPeter SemianiwNo ratings yet

- Bolts in ChinaDocument7 pagesBolts in ChinaJeff GajeNo ratings yet

- Ultimaker 2 Assembly Manual V1.1Document69 pagesUltimaker 2 Assembly Manual V1.1petrkalousNo ratings yet

- DigitalNimbusLabsInvader G17 Build ManualDocument35 pagesDigitalNimbusLabsInvader G17 Build Manualhans landaNo ratings yet

- Endopore Insert eDocument20 pagesEndopore Insert eMery MerryNo ratings yet

- W01 358 6900 Firestone Double Convoluted Air SpringDocument29 pagesW01 358 6900 Firestone Double Convoluted Air SpringMROstop.comNo ratings yet

- MAK205 Chapter4 PDFDocument20 pagesMAK205 Chapter4 PDFYunaChan100% (1)

- 09c01 Fuel Injection Pump (Rotor)Document6 pages09c01 Fuel Injection Pump (Rotor)hbpate3No ratings yet

- Australian Handyman 2013 10Document148 pagesAustralian Handyman 2013 10Marius Bălan100% (4)

- Technical Note - Anode Sled Bolt Design CheckDocument4 pagesTechnical Note - Anode Sled Bolt Design Checkejim2No ratings yet

- Parts Catalog: High-Level Orderpicker Lift TruckDocument268 pagesParts Catalog: High-Level Orderpicker Lift TruckCoque de LunaNo ratings yet

- Flanges SAE para Solda SN532-1Document5 pagesFlanges SAE para Solda SN532-1willianNo ratings yet

- Tenere700 Parts-ListDocument69 pagesTenere700 Parts-ListstephpovoNo ratings yet

- Module 6 B2Document10 pagesModule 6 B2morteeza1986No ratings yet

- TRD Supercharger InstallationDocument42 pagesTRD Supercharger InstallationErnesto Lopez100% (2)

- Ukuran Baut Dan Nut Pada FlangeDocument8 pagesUkuran Baut Dan Nut Pada FlangeaswarNo ratings yet

- Vessel Foundation Design PhilosophyDocument5 pagesVessel Foundation Design PhilosophyarnoldistunoNo ratings yet

- Sika AnchorFix 3+ - PDSDocument4 pagesSika AnchorFix 3+ - PDSAnonymous jbvNLNANLINo ratings yet

- Magnetic Liquid Level Indicators: Gauges Switches TransmittersDocument20 pagesMagnetic Liquid Level Indicators: Gauges Switches TransmittersElinton De Jesus SarmientoNo ratings yet

- ICC-ES Evaluation Report ESR-4266Document16 pagesICC-ES Evaluation Report ESR-4266yoshdog@gmail.comNo ratings yet

- 2016 Machine Shop Manual PDFDocument95 pages2016 Machine Shop Manual PDFShravan Shetty100% (1)

- Walworth PressureSealDocument20 pagesWalworth PressureSealtxlucky80No ratings yet

- Control 3.0 Troubleshooting GuideDocument20 pagesControl 3.0 Troubleshooting GuideyankeestylzeNo ratings yet

- Scubapro MK16 Repair GuideDocument11 pagesScubapro MK16 Repair GuideGuillermoNo ratings yet

- Brochure DineDocument114 pagesBrochure DineAlmacen DMTNo ratings yet

- Pdfsor 18177 20190226 160351Document50 pagesPdfsor 18177 20190226 160351bilalNo ratings yet

- Nut and BoltsDocument10 pagesNut and BoltsSam33% (3)

- Standard Tightening Torque: Service InformationDocument3 pagesStandard Tightening Torque: Service InformationJokoNo ratings yet

- Ilg DDocument4 pagesIlg DArmin HekićNo ratings yet

Appendix-1-Updated (06032023) Opt TBSL Purlins

Appendix-1-Updated (06032023) Opt TBSL Purlins

Uploaded by

Rajendra PawarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix-1-Updated (06032023) Opt TBSL Purlins

Appendix-1-Updated (06032023) Opt TBSL Purlins

Uploaded by

Rajendra PawarCopyright:

Available Formats

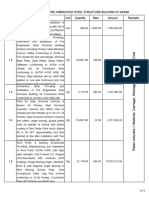

BOQ - STRUCTURAL STEEL WORKS - NMIAL - PIER & FLB

QUANTITY

Sl. No. Description of Work Unit RATE AMOUNT

PIER FLB TOTAL

Structural Steel Works

Open Web Sections - Grade E 350 - Br

Supplying and fabricating by welding, erecting, hoisting, fixing in position structural steel sections (conforming to IS 808/ IS12778:2004/BS 4-1:2005) using fusion welding quality steel of

Grade and sub-quality as described below conforming to IS 2062:2011 including site and shop fastening of members, bolting, welding (machining of members wherever necessary) at all

heights above ground level and in basement. The process shall also include but not limiting to straightening, cutting, bending to shape, edge preparation for welding, creating holes for

1

bolting, aligning and levelling in all respects for final installation. Rate shall include cost of material, bolts, nuts, washers, clamps, welding electrodes, connections, shims, packing pieces,

jigs,sag rods,temporary steel for fabrication and non-shrink grout as required complete in all respects required for the work. (machining of members where ever necessary) at all heights

above ground level including copper slag/grit blasted surface to SA2.5 Standards including all material and labour complete in all respects.

Rate including preparation of engineering & fabrication shop drawing for Employer / Client approval.

Measurement shall be done as per the Mode of Measurement Appendix-2A Document.

a Rolled Sections MT 423 151 574 1,16,000 6,65,84,000

b Fabricated Sections with plates MT 171 83 254 1,16,000 2,94,64,000

Hollow sections - Grade E350 Br

Supplying and fabricating by welding, erecting, hoisting and fixing in position structural steel work made up of single section or compounded from other structural steel sections like MS

angles, plates, tees, flats, channels, I sections,Tubular and RHS sections using steel of Grade E350 (Fe 490) conforming to IS:2062-2006 including site and shop fastening of

members,bolting,cutting to required size, straightening, bending if required, edge preparation, cleaning, preheating, bolting/welding of joints, (including sealing the joints of box sections with

2

continuous welding), providing and fixing end caps, finishing edges by grinding, fixing in line and level with temporary staging & bracing and removal of the same after erection, grouting with

MT 599 316 915 1,16,000 10,61,40,000

ordinary grout or premix free flow non shrink grout as specified, welding (machining of members where ever necessary) at all heights above ground level including copper slag/grit blasted

surface to SA2.5 Standards followed including all material and labour complete in all respects.

Rate including preparation of engineering & fabrication shop drawing for Employer / Client approval.

Measurement shall be done as per the Mode of Measurement Appendix-2A Document.

Cold Form Sections

Coldform Purlin 'Z' Sections- (250mm High & 2.4mm Thick) - Yst 350

3

Supplying, fabricating, erecting and fixing in position of steel structures at all elevations using light weight cold form sections of minimum tensile strength as mentioned below conforming to

MT 401 34 435 1,17,000 5,08,95,000

IS:1079,IS:811,IS:801, and glavanised with 275 GSM coating (minimum), with necessary punch holes for fixing, sag rods etc and all material and accessories like studs,gussets,screws, etc

and all material and labour complete. Minimum tensile strength of 350 N/mm2

4 Corrosion Protection coatings

Painting - Anticorrosive Paint System (120 Microns)

Supplying & Applying anti corrosive paint system with

a Primer - Epoxy based zinc rich / zinc inorganic type 50 micron

Finish paint - Polyurethane top coat of 70 microns (each coat 35 microns DFT) Sqm 27,657 6,747 34,404 350.00 1,20,41,400

of approved Make, quality and colour as per drawings & specifications.

List of Makes : Berger paints, Asian, Jotun & Akzonobel or Approved equivalent

Painting - Anticorrosive Paint System - AESS (Architecturally Exposed Structural Steel) (275 Microns)

Supplying & Applying anti corrosive paint system with Primer: Zinc rich epoxy 75 microns MINIMUM dry film thickness

b Barrier: Epoxy Micaceous Iron Oxide (MIO) 125 microns MINIMUM dry film thickness

Finish: Polyurethane (75 microns minimum DFT) Sqm - 1,428 1,428 710.00 10,13,880

of approved Make, quality and colour as per drawings & specifications.

List of Makes : Berger paints, Asian, Jotun & Akzonobel or Approved equivalent

6 TOTAL 26,61,38,280

7 TRANSPORTATION & UNLOADING Included

8 TOTAL LANDING COST - SUPPLY, FABRICATION, PAINTING & INSTALLATION 26,61,38,280

Note: GST - Extra as applicable

The Below Scope is considered

1 East Pier & West Pier

2 All FLB Structures

3 All FLB Staircases (with Paint Finish only- No Galvanization considered)

4 Secondary Steel sections for False Ceiling

5 Secondary Steel sections for Gutters & Skylights

6 COLD FORM PURLINS PRICE IS BASED ON TATA BLUESCOPE BASE PRICE OF RS. 90000/- LANDED AT SITE (GST EXTRA)

# Sensitivity: LNT Construction Internal Use

You might also like

- Parts Catalogue: 4TNV98T-GGEDocument35 pagesParts Catalogue: 4TNV98T-GGEVitorMello83% (6)

- Steel BOQ Square Warehouse Cover Shed 16-7-18Document23 pagesSteel BOQ Square Warehouse Cover Shed 16-7-18lucio444No ratings yet

- BoqDocument8 pagesBoqFoisul Alam100% (1)

- Final BOQ and Annexure - Fire Fighting - 00Document7 pagesFinal BOQ and Annexure - Fire Fighting - 00Anonymous x7ue2F4iNo ratings yet

- 20-123 Stainless Steel and Metal Works BOQDocument4 pages20-123 Stainless Steel and Metal Works BOQsobhiNo ratings yet

- Book 2Document80 pagesBook 2Pratik GuptaNo ratings yet

- Revised BOH R1Document10 pagesRevised BOH R1Avijit BhattacharjeeNo ratings yet

- Sr. No Description Unit Quantity Rate Amount Remarks Item Wise Cost For Pre-Fabricated Steel Structure Building at KarakDocument2 pagesSr. No Description Unit Quantity Rate Amount Remarks Item Wise Cost For Pre-Fabricated Steel Structure Building at Karakrefinedconstruction510No ratings yet

- Al Ain Distribution Company (Aadc) : JM 0209 SubstationDocument2 pagesAl Ain Distribution Company (Aadc) : JM 0209 SubstationRyo DavisNo ratings yet

- Tender Enquiry No. Bhe/Fp/Cvl/025 Section-IV Bill of QuantitiesDocument2 pagesTender Enquiry No. Bhe/Fp/Cvl/025 Section-IV Bill of QuantitiesSantanu ShresthaNo ratings yet

- Pisolkar - Estimate.Document10 pagesPisolkar - Estimate.Ankit Ratnakar GaidhaniNo ratings yet

- BOQ and Rate For Boundary WallDocument2 pagesBOQ and Rate For Boundary Wallsandesh negiNo ratings yet

- Boq - Pani BhabanDocument116 pagesBoq - Pani Bhabanapi-26147616No ratings yet

- Al Ain Distribution Company (Aadc) : JM 0223 SubstationDocument2 pagesAl Ain Distribution Company (Aadc) : JM 0223 SubstationRyo DavisNo ratings yet

- Shyadpur 1Document4 pagesShyadpur 1Riddhiman BhowmikNo ratings yet

- Boq Bah KarakDocument18 pagesBoq Bah KarakAbubakar NazirNo ratings yet

- Brick SolingDocument13 pagesBrick SolingM ShahidNo ratings yet

- Exide New BoqDocument7 pagesExide New Boqkishor veheleNo ratings yet

- Protection CamberDocument5 pagesProtection CamberAshishKumarNo ratings yet

- B.ODocument4 pagesB.Oranajouu11397No ratings yet

- Jhabua-Sor 20200702 181504Document4 pagesJhabua-Sor 20200702 181504Suaib VCSNo ratings yet

- Fs-Nawanagar Ag - A (Basudeva Village) - A8-ErectionDocument1 pageFs-Nawanagar Ag - A (Basudeva Village) - A8-Erectionbapi2pradeepNo ratings yet

- Japhat Civil Work BoqDocument8 pagesJaphat Civil Work BoqsatyaprakashNo ratings yet

- 5.5 Bill of Quantities For Different Unit of Rural Buildings With General Civil & Structural WorkDocument5 pages5.5 Bill of Quantities For Different Unit of Rural Buildings With General Civil & Structural WorkNIBEDITA DEYNo ratings yet

- BOQDocument25 pagesBOQBILAL HAJINo ratings yet

- ExcelSheetForCalculationPurposeOnly To MR Subburaman 29 04 23Document4 pagesExcelSheetForCalculationPurposeOnly To MR Subburaman 29 04 23slipformNo ratings yet

- Khaadi Fabric Store at - Boq (r2) - Id Works - 24-12-2018Document48 pagesKhaadi Fabric Store at - Boq (r2) - Id Works - 24-12-2018Kashan ShoukatNo ratings yet

- Shyadpur 2Document80 pagesShyadpur 2Riddhiman BhowmikNo ratings yet

- 0503223-01-CIV-BOQ-1021-AB (Laundry Shed BOQ Comparision)Document6 pages0503223-01-CIV-BOQ-1021-AB (Laundry Shed BOQ Comparision)CCCCCCC100% (1)

- Hazira-Sor 20200702 181418Document11 pagesHazira-Sor 20200702 181418Suaib VCSNo ratings yet

- Bruhat Bangalore Mahanagara Palike: SL No Name of WorkDocument6 pagesBruhat Bangalore Mahanagara Palike: SL No Name of WorkMangesh ChaudhariNo ratings yet

- Copy of MSIL DEVIATIONA(1)Document3 pagesCopy of MSIL DEVIATIONA(1)Mujahid choudharyNo ratings yet

- Final BUA BOQ Tender - OB Plot and Podium - 03.09.21Document11 pagesFinal BUA BOQ Tender - OB Plot and Podium - 03.09.21Jaysukh N SapraNo ratings yet

- 5th R.A. Stanford Una - 25.04.2018Document202 pages5th R.A. Stanford Una - 25.04.2018Gaurav SharmaNo ratings yet

- BOQ - Gurgaon - 25.06.23Document3 pagesBOQ - Gurgaon - 25.06.23Anurag ZullurwarNo ratings yet

- SORPT18 - PIPING BOQ - Copy 13Document1 pageSORPT18 - PIPING BOQ - Copy 13atulNo ratings yet

- Boq-Morth KanpurDocument2 pagesBoq-Morth KanpurDescon Infrastructures Pvt. Ltd.No ratings yet

- Traffic Sign Item PDFDocument3 pagesTraffic Sign Item PDFGourav ChavhanNo ratings yet

- Bill of Quantity: Baner Lifespaces LLPDocument7 pagesBill of Quantity: Baner Lifespaces LLPSales AlufacadesNo ratings yet

- Percentage Boq: Validate Print HelpDocument18 pagesPercentage Boq: Validate Print HelpASRAR AHMED KHANNo ratings yet

- Asgn 2Document6 pagesAsgn 2Siti HajarNo ratings yet

- Bsateen Palm View Quotation Updated by AlnafelDocument9 pagesBsateen Palm View Quotation Updated by Alnafelmarwan ashrafNo ratings yet

- BOQ - Periscope HouseDocument7 pagesBOQ - Periscope Housepaiya92No ratings yet

- BIDDOCUMENTDocument7 pagesBIDDOCUMENTJRB BelgaumNo ratings yet

- Structure & Piping OfferDocument2 pagesStructure & Piping OfferMukesh BerwaNo ratings yet

- UTC-Z3-Phase 01 - B02 (Block 5&6) - IFC Rev00Document131 pagesUTC-Z3-Phase 01 - B02 (Block 5&6) - IFC Rev00Mahmoud HamdyNo ratings yet

- 300nb Fire Water Line - BEEL - 071953Document2 pages300nb Fire Water Line - BEEL - 071953irshadiiitNo ratings yet

- DAB Modified FinalDocument74 pagesDAB Modified FinalFreedom Love Nabal100% (1)

- Surat DC Budget - Cold Room 250 SQ FT V01Document22 pagesSurat DC Budget - Cold Room 250 SQ FT V01Chaitanya IdateNo ratings yet

- Bills of Quantities SL - No Description Unit Qty Rate (RS.) Amount (RS.) KG Rate KG AmountDocument2 pagesBills of Quantities SL - No Description Unit Qty Rate (RS.) Amount (RS.) KG Rate KG AmountsmithNo ratings yet

- Vulcan Industrial Engineering Co. Pvt. LTDDocument3 pagesVulcan Industrial Engineering Co. Pvt. LTDk koradiaNo ratings yet

- SORPT18 - PIPING BOQ - Copy 29Document1 pageSORPT18 - PIPING BOQ - Copy 29atulNo ratings yet

- DEXCOM 3 - BoQ Metal Works (CER1-2, 3&CUB)Document41 pagesDEXCOM 3 - BoQ Metal Works (CER1-2, 3&CUB)MEAGAN CHNGNo ratings yet

- Estimate Jackpot CasinoDocument5 pagesEstimate Jackpot CasinoGsUpretiNo ratings yet

- CA No. GE (I) (CG) /KOCHI/ OF 2022-2023 Schedule 'A' Ser Page No.21Document8 pagesCA No. GE (I) (CG) /KOCHI/ OF 2022-2023 Schedule 'A' Ser Page No.21sajanjoseNo ratings yet

- UR To Bailey Bridge 1.25 Lakhs 10.5.11Document13 pagesUR To Bailey Bridge 1.25 Lakhs 10.5.11Kiran AEE BvrmNo ratings yet

- 23S3 Ot D 220 Me SP 0570 00Document7 pages23S3 Ot D 220 Me SP 0570 00Mohammad ghanaatpisheNo ratings yet

- BBS FormateDocument1 pageBBS FormateahamedthousifNo ratings yet

- Toyota Gujrat Motors Civil Works BoqDocument3 pagesToyota Gujrat Motors Civil Works BoqJahanzeb KhanNo ratings yet

- User Guide: Masonry Anchors For Tie-Down of Bottom Plates To SlabsDocument2 pagesUser Guide: Masonry Anchors For Tie-Down of Bottom Plates To SlabsPeter SemianiwNo ratings yet

- Bolts in ChinaDocument7 pagesBolts in ChinaJeff GajeNo ratings yet

- Ultimaker 2 Assembly Manual V1.1Document69 pagesUltimaker 2 Assembly Manual V1.1petrkalousNo ratings yet

- DigitalNimbusLabsInvader G17 Build ManualDocument35 pagesDigitalNimbusLabsInvader G17 Build Manualhans landaNo ratings yet

- Endopore Insert eDocument20 pagesEndopore Insert eMery MerryNo ratings yet

- W01 358 6900 Firestone Double Convoluted Air SpringDocument29 pagesW01 358 6900 Firestone Double Convoluted Air SpringMROstop.comNo ratings yet

- MAK205 Chapter4 PDFDocument20 pagesMAK205 Chapter4 PDFYunaChan100% (1)

- 09c01 Fuel Injection Pump (Rotor)Document6 pages09c01 Fuel Injection Pump (Rotor)hbpate3No ratings yet

- Australian Handyman 2013 10Document148 pagesAustralian Handyman 2013 10Marius Bălan100% (4)

- Technical Note - Anode Sled Bolt Design CheckDocument4 pagesTechnical Note - Anode Sled Bolt Design Checkejim2No ratings yet

- Parts Catalog: High-Level Orderpicker Lift TruckDocument268 pagesParts Catalog: High-Level Orderpicker Lift TruckCoque de LunaNo ratings yet

- Flanges SAE para Solda SN532-1Document5 pagesFlanges SAE para Solda SN532-1willianNo ratings yet

- Tenere700 Parts-ListDocument69 pagesTenere700 Parts-ListstephpovoNo ratings yet

- Module 6 B2Document10 pagesModule 6 B2morteeza1986No ratings yet

- TRD Supercharger InstallationDocument42 pagesTRD Supercharger InstallationErnesto Lopez100% (2)

- Ukuran Baut Dan Nut Pada FlangeDocument8 pagesUkuran Baut Dan Nut Pada FlangeaswarNo ratings yet

- Vessel Foundation Design PhilosophyDocument5 pagesVessel Foundation Design PhilosophyarnoldistunoNo ratings yet

- Sika AnchorFix 3+ - PDSDocument4 pagesSika AnchorFix 3+ - PDSAnonymous jbvNLNANLINo ratings yet

- Magnetic Liquid Level Indicators: Gauges Switches TransmittersDocument20 pagesMagnetic Liquid Level Indicators: Gauges Switches TransmittersElinton De Jesus SarmientoNo ratings yet

- ICC-ES Evaluation Report ESR-4266Document16 pagesICC-ES Evaluation Report ESR-4266yoshdog@gmail.comNo ratings yet

- 2016 Machine Shop Manual PDFDocument95 pages2016 Machine Shop Manual PDFShravan Shetty100% (1)

- Walworth PressureSealDocument20 pagesWalworth PressureSealtxlucky80No ratings yet

- Control 3.0 Troubleshooting GuideDocument20 pagesControl 3.0 Troubleshooting GuideyankeestylzeNo ratings yet

- Scubapro MK16 Repair GuideDocument11 pagesScubapro MK16 Repair GuideGuillermoNo ratings yet

- Brochure DineDocument114 pagesBrochure DineAlmacen DMTNo ratings yet

- Pdfsor 18177 20190226 160351Document50 pagesPdfsor 18177 20190226 160351bilalNo ratings yet

- Nut and BoltsDocument10 pagesNut and BoltsSam33% (3)

- Standard Tightening Torque: Service InformationDocument3 pagesStandard Tightening Torque: Service InformationJokoNo ratings yet

- Ilg DDocument4 pagesIlg DArmin HekićNo ratings yet