Professional Documents

Culture Documents

Biodegradable Bandage 1 2

Biodegradable Bandage 1 2

Uploaded by

api-527875218Copyright:

Available Formats

You might also like

- Amazing Chewy Bagels From Scratch - Recipe - ChefSteps PDFDocument3 pagesAmazing Chewy Bagels From Scratch - Recipe - ChefSteps PDFVicente Ferraro50% (2)

- Experiment 8: Fixed and Fluidized BedDocument6 pagesExperiment 8: Fixed and Fluidized BedTuğbaNo ratings yet

- Mushroom Grow Guide 8.21.links Yah50nDocument1 pageMushroom Grow Guide 8.21.links Yah50nIvan BaigorriaNo ratings yet

- Stress - The Different Kinds of StressDocument4 pagesStress - The Different Kinds of StressbogdanNo ratings yet

- Msma PDFDocument100 pagesMsma PDFMimi Aireen Harmira HassimNo ratings yet

- Mushroom Grow Guide 9.21.linksDocument1 pageMushroom Grow Guide 9.21.linksThomas MartiNo ratings yet

- Gold Example Project 3Document7 pagesGold Example Project 3Bushra AmirNo ratings yet

- Mushroom Grow Guide 2.22.linksDocument1 pageMushroom Grow Guide 2.22.linksSabrina ShorttNo ratings yet

- U6 LvlTestDocument1 pageU6 LvlTestwanNo ratings yet

- GOOSE GRASS Eulisine Indica 1Document10 pagesGOOSE GRASS Eulisine Indica 1Eyamichaela FloresNo ratings yet

- Puta Tapos Na TalagaDocument7 pagesPuta Tapos Na TalagaCharise Mansilla LapastoraNo ratings yet

- Gold Example Project 3Document7 pagesGold Example Project 3sameehmuhammed30No ratings yet

- Bioplastic: Year 2Document19 pagesBioplastic: Year 2SHAL NeyNo ratings yet

- Recommending Suitable Substrate/s For Cultivation: ExcerptDocument1 pageRecommending Suitable Substrate/s For Cultivation: ExcerptBimal K. Chetri100% (1)

- Worm Composting Bin: Agriculture and Natural ResourcesDocument4 pagesWorm Composting Bin: Agriculture and Natural ResourcesGreater Charlotte Harbor Sierra ClubNo ratings yet

- 2020 NCW Activity Making Glue at HomeDocument2 pages2020 NCW Activity Making Glue at Homealiumpar123No ratings yet

- Agar Plate Children'S: Activity PackDocument7 pagesAgar Plate Children'S: Activity PackNatalija Atanasova-PancevskaNo ratings yet

- Starch BasedDocument6 pagesStarch BasedBongzkie Irudistan AmanteNo ratings yet

- Growing Microgreens Cheat Sheets: Soil Only & Must Pre-Soak SeedsDocument2 pagesGrowing Microgreens Cheat Sheets: Soil Only & Must Pre-Soak SeedsM Mohsin ChowdhuryNo ratings yet

- SF Powerpoint AkishorDocument1 pageSF Powerpoint Akishorapi-527956594No ratings yet

- NhungPham ReportDocument16 pagesNhungPham ReportphamNo ratings yet

- PROJECT TATVA FinalDocument19 pagesPROJECT TATVA FinalMuskan MukhiNo ratings yet

- NationalScienceDay Long PDFDocument7 pagesNationalScienceDay Long PDFPpa Gpat AmitNo ratings yet

- Types and Uses/benefits of Concoctions 1. Imo: Indigenous Micro Organisms (IMO1 - 2)Document10 pagesTypes and Uses/benefits of Concoctions 1. Imo: Indigenous Micro Organisms (IMO1 - 2)Jean SuarezNo ratings yet

- Preparation and Evaluation of Paracetamol Tablets With DifferentDocument1 pagePreparation and Evaluation of Paracetamol Tablets With Differentsakshichede8No ratings yet

- 2021 Canning 101Document5 pages2021 Canning 101Alan Winston SedzeNo ratings yet

- Edible CutleryDocument5 pagesEdible CutleryAman Sadhra100% (1)

- Indigenous Micro Organisms (IMO1 - 2) : How To Make The ConcoctionDocument1 pageIndigenous Micro Organisms (IMO1 - 2) : How To Make The ConcoctionMarycon NacitoNo ratings yet

- Science and Technology Education Report-WPS OfficeDocument21 pagesScience and Technology Education Report-WPS OfficeJay Jasper GoNo ratings yet

- DegradablevsbiodegradableDocument13 pagesDegradablevsbiodegradablesourajitchakraborty9No ratings yet

- Survival PDFDocument10 pagesSurvival PDFyyssbxcnNo ratings yet

- Handcrafted Sugar Flowers: Step-by-Step InstructionsDocument2 pagesHandcrafted Sugar Flowers: Step-by-Step InstructionssimonaNo ratings yet

- Troubleshooting Your Compost Pile: Symptom Possible Causes PrescriptionDocument2 pagesTroubleshooting Your Compost Pile: Symptom Possible Causes PrescriptionOmar RodriguezNo ratings yet

- CAULIFLOWERDocument15 pagesCAULIFLOWERYira Dessiré SalinasNo ratings yet

- Sci Fair 1Document7 pagesSci Fair 1api-420631518No ratings yet

- Biogas BookDocument16 pagesBiogas BookIne RiswantiNo ratings yet

- Equipment/Material: Bag TechniqueDocument4 pagesEquipment/Material: Bag TechniqueKrisyll Meah Torred RamalNo ratings yet

- AS-and-A-level-Biology-B-Core-Practical-14-Starch-Agar-Assay - (Student,-Teacher,-Technician-Worksheets)Document8 pagesAS-and-A-level-Biology-B-Core-Practical-14-Starch-Agar-Assay - (Student,-Teacher,-Technician-Worksheets)amnasadathNo ratings yet

- Chapter 3 Group 5Document13 pagesChapter 3 Group 5A - CAYAGA, Kirby, C 12 - HermonNo ratings yet

- 9.2 Teks Prosedur Resep Makananminuman Dan Manual - KK DTDocument6 pages9.2 Teks Prosedur Resep Makananminuman Dan Manual - KK DTjulio krisnaNo ratings yet

- IAS Biology TRP1 CP9 Stu ModDocument4 pagesIAS Biology TRP1 CP9 Stu ModAyesha GulzarNo ratings yet

- Science Fair Trifold 2021 - Hackworth EllaryDocument1 pageScience Fair Trifold 2021 - Hackworth Ellaryapi-484215877No ratings yet

- BioplasticDocument17 pagesBioplasticМишээл ЯдамсүрэнNo ratings yet

- Bio - Plastic ReportDocument2 pagesBio - Plastic ReportSophia SpiliopulosNo ratings yet

- CapstoneDocument11 pagesCapstoneChristian PaulNo ratings yet

- LifeBrL3 05 01 01Document1 pageLifeBrL3 05 01 01Marcos Morales AlburquerqueNo ratings yet

- Chapter 5 TestDocument3 pagesChapter 5 Testkatherine Vanessa Cruz NarvaezNo ratings yet

- Lesson Presentation Separating MixturesDocument24 pagesLesson Presentation Separating MixturesRania HazemNo ratings yet

- Research and Discussion (G12-Nipa Palm Fronds Used As An Alternative Paper Making Source)Document6 pagesResearch and Discussion (G12-Nipa Palm Fronds Used As An Alternative Paper Making Source)wheeyycoldandhot55No ratings yet

- Biology Depth StudyDocument4 pagesBiology Depth StudyCharlotte JaisonNo ratings yet

- 2022 Science Fair Trifold d1 Print - TTDocument1 page2022 Science Fair Trifold d1 Print - TTapi-564040637No ratings yet

- 2021 SFDocument1 page2021 SFapi-527956594No ratings yet

- Degradation of Paper Waste by Eisenia FoetidaDocument24 pagesDegradation of Paper Waste by Eisenia FoetidaAravind vishnu Saravanan GNo ratings yet

- Powders and GranulesDocument4 pagesPowders and GranulesKRISTINE ANN OLILANGNo ratings yet

- Office of The Laboratory Schools-Senior High School: University of Northern PhilippinesDocument3 pagesOffice of The Laboratory Schools-Senior High School: University of Northern PhilippinesMa. Rochelle CabralesNo ratings yet

- Alat - Alat Yang Digunakan Dilaboratorium Farmasi Fungsi: Distillation FlaskDocument11 pagesAlat - Alat Yang Digunakan Dilaboratorium Farmasi Fungsi: Distillation FlaskRazita Zahra utamiNo ratings yet

- WWW Wikihow Com Make Rat Poison - Text Mix 20together 20flour 2C 20baking 20soda Mixture 20and 20stir 20it 20togetherDocument15 pagesWWW Wikihow Com Make Rat Poison - Text Mix 20together 20flour 2C 20baking 20soda Mixture 20and 20stir 20it 20togetherbotogiti1No ratings yet

- Recycling: We Can RecycleDocument2 pagesRecycling: We Can RecycleJuan HerreraNo ratings yet

- Recipe CardDocument4 pagesRecipe Cardapi-582453684No ratings yet

- Food Waste BiomassDocument5 pagesFood Waste Biomassyuhan decanoNo ratings yet

- The Neoble JournalDocument4 pagesThe Neoble JournalmuhammaddzakyalmairzaidanNo ratings yet

- How To Make Your Own Dressings and Bandages BurDocument3 pagesHow To Make Your Own Dressings and Bandages BurKOSTASPDFNo ratings yet

- Harrison Stem Student Volunteer TimeDocument1 pageHarrison Stem Student Volunteer Timeapi-527875218No ratings yet

- Emergency Department PresentationDocument15 pagesEmergency Department Presentationapi-527875218No ratings yet

- Steminar GT Biomedical Engineeringrsch - Sophie Marin 1Document2 pagesSteminar GT Biomedical Engineeringrsch - Sophie Marin 1api-527875218No ratings yet

- Resume Sophie 2Document3 pagesResume Sophie 2api-527875218No ratings yet

- Concussion PBL Student Documents Repaired 1 1Document11 pagesConcussion PBL Student Documents Repaired 1 1api-527875218No ratings yet

- Scanned Documents 3Document1 pageScanned Documents 3api-527875218No ratings yet

- Lactase LabDocument9 pagesLactase Labapi-527875218No ratings yet

- Powerpoint For Science ExperimentDocument1 pagePowerpoint For Science Experimentapi-527875218No ratings yet

- Harrison Stem Student Volunteer LimeDocument1 pageHarrison Stem Student Volunteer Limeapi-527875218No ratings yet

- Scanned Documents 1Document1 pageScanned Documents 1api-527875218No ratings yet

- Scanned Documents 2Document1 pageScanned Documents 2api-527875218No ratings yet

- Medicine ProjectDocument24 pagesMedicine Projectapi-527875218No ratings yet

- Squirrel Island Project 1Document11 pagesSquirrel Island Project 1api-527875218No ratings yet

- Budgeting Project 4Document7 pagesBudgeting Project 4api-527875218No ratings yet

- Rationale 2Document4 pagesRationale 2api-527875218No ratings yet

- BS 03900 0 2010Document26 pagesBS 03900 0 2010selvaNo ratings yet

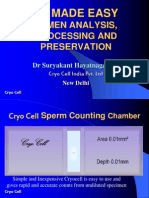

- Iui Made Easy: Semen Analysis, Processing and PreservationDocument97 pagesIui Made Easy: Semen Analysis, Processing and PreservationSuryakant HayatnagarkarNo ratings yet

- CPX, CPXR, CPXN, CPXP PDFDocument44 pagesCPX, CPXR, CPXN, CPXP PDFAhunahonNo ratings yet

- FINAL Ulster Combined Report From STONE 12-15Document104 pagesFINAL Ulster Combined Report From STONE 12-15Watershed PostNo ratings yet

- 6 Biomechanical Basis of Extraction Space Closure - Pocket DentistryDocument5 pages6 Biomechanical Basis of Extraction Space Closure - Pocket DentistryParameswaran ManiNo ratings yet

- Hotpoint Washing Machine Wmf740Document16 pagesHotpoint Washing Machine Wmf740furheavensakeNo ratings yet

- 5 MuscleDocument3 pages5 MuscleNicolePorsueloNo ratings yet

- 3b Domestic Water Meter Installation in Meter Room GuidelinesDocument10 pages3b Domestic Water Meter Installation in Meter Room GuidelinesVinish HARIDAS NAIRNo ratings yet

- Pdf&rendition 1Document61 pagesPdf&rendition 1Dulce DeNo ratings yet

- 1st Year Chemistry Sc1 ChemistryDocument896 pages1st Year Chemistry Sc1 Chemistrybiranchi satapathyNo ratings yet

- Product Range: Trelleborg Se Aling SolutionsDocument39 pagesProduct Range: Trelleborg Se Aling SolutionssandeepNo ratings yet

- 8.16 References PDFDocument1 page8.16 References PDFnickNo ratings yet

- Light and ShadowDocument5 pagesLight and ShadowLisa Lipsett50% (2)

- Edux110 SimDocument307 pagesEdux110 SimElijahNo ratings yet

- Unit-Iv Nanomaterials and Nanotechnology: Part-ADocument4 pagesUnit-Iv Nanomaterials and Nanotechnology: Part-AKrishna ThiruvengadamNo ratings yet

- PT EnglishDocument6 pagesPT EnglishGener Taña AntonioNo ratings yet

- Linear AlgebraDocument395 pagesLinear AlgebraRehan Javed100% (2)

- Dit 24Document1 pageDit 24Abvolt IndiaNo ratings yet

- The Ultimate Guide To Arduino LibraryDocument76 pagesThe Ultimate Guide To Arduino LibraryNguyễn Hòa75% (4)

- Chapter No.1 Meat CookeryDocument15 pagesChapter No.1 Meat CookeryKrishna Chaudhary0% (1)

- Zeiss Erosion ModuleDocument13 pagesZeiss Erosion ModulepakhiddeyasNo ratings yet

- Guidelines To An Informal LetterDocument3 pagesGuidelines To An Informal LetterNik Syahina0% (1)

- ColaTeric BE 16Document2 pagesColaTeric BE 16mndmattNo ratings yet

- Piping Info - Pipe Support Design GuidelinesDocument4 pagesPiping Info - Pipe Support Design GuidelinesSUSHANTBIJAM100% (1)

- Brenes 2006Document6 pagesBrenes 2006Alfonso CáceresNo ratings yet

- Bio 2022 PreparationDocument21 pagesBio 2022 PreparationAGENT SAYONNo ratings yet

- Verb Patterns: Verb + Infinitive or Verb + - Ing?: Verbs Followed by A To-InfinitiveDocument5 pagesVerb Patterns: Verb + Infinitive or Verb + - Ing?: Verbs Followed by A To-InfinitiveTeodora PluskoskaNo ratings yet

Biodegradable Bandage 1 2

Biodegradable Bandage 1 2

Uploaded by

api-527875218Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Biodegradable Bandage 1 2

Biodegradable Bandage 1 2

Uploaded by

api-527875218Copyright:

Available Formats

Biodegradable Bandage

Sophie Marin

BACKGROUND

MATERIALS AND METHODS RESULTS

Bandages are used to stop bleeding and infection when a minor

lesion occurs. Typically, bandages and plastics are made from a The original recipe used to make the biodegradable bandages created

Materials:

substance called petroleum which is neither a renewable resource nor

• Corn starch • Small pot chalky bandages which crumbled when touched. After this was realized a new

biodegradable. Many bandages end up in landfills or littered on the • Agar powder • Wooden spoon recipe needed to be made: more water and less agar powder. The new bandage

ground. Bandages are usually accessible in pharmacies or grocery • Water • 24 Lumbricus terrestris (earth worms) recipe worked well to make bandages which held together and had a gelatinous

stores, but these stores are not always located in rural environments. • White distilled vinegar • 6 pots texture. Since glycerin is a lipid, which allows plastic to be more pliable, it was

If stores with bandages are not nearby, then other materials may be • Honey • Potting soil best to only change that aspect of the recipe. The spring scale worked

• Glycerin • 20 N spring scale competently to measure the force each bandage could handle. Three bandages

used to cover the wounds. One outcome of not having access to

• Thermometer • Parchment paper were made with each recipe and then the spring scale’s hook was poked trough

bandages is the use of other materials that may have collected the center to measure the maximum force. The first of the 6g glycerin bandages

infectious pathogens. Without access to bandages, the chance of a could handle 5N before it completely tore. The second and third bandages could

wound getting infected increases which becomes more serious than a Method(s) handle 3.5N and 4N. The three other bandages made from 12g of glycerin could

minor cut. If the bandage problem was solved with an inexpensive 1. Measure 4 grams of corn starch, 26 mL of water, 4 mL of vinegar, 2 g of aloe, 4 g of honey, 2 g of agar and 6 g of handle 2N, 1.5N, and 2.5N. The bandages made from 6g of glycerin could

bio-degradable, then more areas will have access to bandages glycerin into a bowl. withstand more force and from observations they had a dry texture, while the

decreasing the need for medical treatment for infections. The 2. Put a pot on the stove and turn the stove onto medium heat. add the ingredients just measured into the pot and stir. other bandages were more glutinous. This result was because glycerin is the

plasticizer in the recipe that allows the mixture to absorb more water.

inexpensive bandages will not litter the environment and if enough 3. Stir the ingredients until they are dissolved.

The most notable parts of the 7-day period of the 6g glycerin bandages

are made they can be distributed to rural homes. Since, the total cost 4. Allow the mixture to cool down until it is room temperature. Test it with a thermometer to check the temperature of

was the development of a mold growth on one of the pieces. The bandages did

of ingredients is low more bandages can be made and distributed in the mixture. partially decompose with the help of the Lumbricus terrestris. The 12g glycerin

addition to other resources, such as food. 5. Pour mixture onto parchment paper; evenly pour the mixture. bandages seemed to relatively decompose as well. This information was just

Biodegradable plastic or bioplastics are usually able to 6. Cut the bandage to be 5 cm by 5 cm to make each bandage the same size for testing. (Another bandage with the based on observations because the bandages could have shrunk in size because of

decompose after a period of time. Bioplastics are polymers made up same ingredient measurements may need to be made). the drying process or the temperature of the room they were located in. Based on

of monomers, that are linked together to form a chain. Usually, this information it is best to say both bandage recipes decreased in size after

7. 6 bandages will be made. The bandages will need to dry for at least two days.

bioplastics are synthesized within microbes or polymerized from being in soil with Lumbricus terrestris for 7 days. The 12g glycerin bandages may

8. Put one bandage into a small pot of one cup of soil with 4 Lumbricus terrestris. Record info about how the bandage

have been decomposed at a higher rate because the extra glycerin could be more

lactic acid. The lactic acid comes from plant-derived sugars and biodegrades over a 7-day period. The two other bandages will be put in separate pots of soil. appealing to the microorganisms. Overall, it is still difficult to tell which bandage

starches. The chemical links between the monomers can be broken by

9. The other three bandages will be tested for strength. Test the other bandage’s strength by stretching it until it tears recipe decomposed more or at a higher rate.

living organisms and water allowing them fully decomposability.

and measure the force applied when it was ripped. This shows the highest force that can be exerted onto the

Polylactic acid or PLA which is polymerized from lactic acid and is an

bandage. Use a spring scale with the max measurement being 20 N.

example of a type of bioplastic. (Fridovich-Keil, 2020).

7. Make another recipe with 4 grams of corn starch, 26 mL of water, 4 mL of vinegar, 2 g of aloe, 4 g of honey, 2 g of

EXPIREMENTAL DESIGN

CONCLUSIONS

agar and 12 g of glycerin. A total of 6 bandages will be made. Repeat steps 2-9 with this different recipe.

Hypothesis: If more glycerin is added to the basic plastic recipe, then the plastic 8. Three bandages are tested for strength and the others tested for ability to biodegrade.

will be softer allowing it to stretch and be easier to biodegrade. 9. The bandages are tested for strength with the use of a spring scale. This tool’s hook is poked trough the center of a The hypothesis made was incorrect since the bandages made with 12

Independent Variable: The amount of glycerin doubled from 6 grams to 12 bandage and the bandage is stretched until the hook completely goes through the bandage. grams of glycerin could withstand less force than the other bandages. The

grams. 10. The force in Newtons is recorded. texture was more gelatinous and softer, but these properties did not make the

Dependent Variable: Compare the recipe with a normal amount of glycerin and bandage stronger. The 12g bandage would cling better to the skin because it

11.The other three bandages are tested for the ability to biodegrade with the use of Lumbricus terrestris.

the other recipe with a doubled amount. The strength of either bandage will be absorbed more water molecules creating a stickier bandage. If the agar powder

measured and the ability to biodegrade is observed. was excluded, it may make a stronger bandage. This could occur because

Controls: The corn starch, agar powder, aloe, vinegar, water, and honey keep the

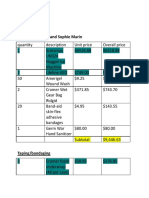

Image 1: Figure 1: typically agar powder or glycerin is used in bioplastics instead of both

same measurements for either recipe, so only the glycerin’s affect is observed. ingredients. The reason agar powder was chosen to be used in addition to

Objective: Create a biodegradable bandage with 6g of glycerin, then double the glycerin was to give the bandage the gelatinous texture to easily shape around

glycerin. Figure out the change in force and biodegradability between the recipes. the skin. This texture occurred as expected and was more prevalent in the

bandages made with the 12g of glycerin. In the future, another aspect of the

Figure 2:

bandage should be changed to see the ingredient’s affect on the results of each

test. This experimentation was more to test the differences in bandages made

with different amounts of glycerin. It is interesting to see the difference doubling

an ingredient amount could make to a recipe that is identical.

REFERENCES

Encyclopædia Britannica. (n.d.). Bioplastic. Britannica School. Retrieved December

1, 2022, from https://school-eb-

All six bandages in soil with Lumbricus terrestris com.us1.proxy.openathens.net/levels/high/article/bioplastic/471398

Maximum force for each trial with the use of a Fridovich-Keil, 2020

20N spring scale. Green is the maximum forces All images and chars produced by Sophie Marin

Biodegradability of both bandages made from 6g glycerin

of three different 6g glycerin bandages. The

and 12g glycerin. Different bandages than bandages

used with spring scale. blue is the 12g glycerin bandages.

You might also like

- Amazing Chewy Bagels From Scratch - Recipe - ChefSteps PDFDocument3 pagesAmazing Chewy Bagels From Scratch - Recipe - ChefSteps PDFVicente Ferraro50% (2)

- Experiment 8: Fixed and Fluidized BedDocument6 pagesExperiment 8: Fixed and Fluidized BedTuğbaNo ratings yet

- Mushroom Grow Guide 8.21.links Yah50nDocument1 pageMushroom Grow Guide 8.21.links Yah50nIvan BaigorriaNo ratings yet

- Stress - The Different Kinds of StressDocument4 pagesStress - The Different Kinds of StressbogdanNo ratings yet

- Msma PDFDocument100 pagesMsma PDFMimi Aireen Harmira HassimNo ratings yet

- Mushroom Grow Guide 9.21.linksDocument1 pageMushroom Grow Guide 9.21.linksThomas MartiNo ratings yet

- Gold Example Project 3Document7 pagesGold Example Project 3Bushra AmirNo ratings yet

- Mushroom Grow Guide 2.22.linksDocument1 pageMushroom Grow Guide 2.22.linksSabrina ShorttNo ratings yet

- U6 LvlTestDocument1 pageU6 LvlTestwanNo ratings yet

- GOOSE GRASS Eulisine Indica 1Document10 pagesGOOSE GRASS Eulisine Indica 1Eyamichaela FloresNo ratings yet

- Puta Tapos Na TalagaDocument7 pagesPuta Tapos Na TalagaCharise Mansilla LapastoraNo ratings yet

- Gold Example Project 3Document7 pagesGold Example Project 3sameehmuhammed30No ratings yet

- Bioplastic: Year 2Document19 pagesBioplastic: Year 2SHAL NeyNo ratings yet

- Recommending Suitable Substrate/s For Cultivation: ExcerptDocument1 pageRecommending Suitable Substrate/s For Cultivation: ExcerptBimal K. Chetri100% (1)

- Worm Composting Bin: Agriculture and Natural ResourcesDocument4 pagesWorm Composting Bin: Agriculture and Natural ResourcesGreater Charlotte Harbor Sierra ClubNo ratings yet

- 2020 NCW Activity Making Glue at HomeDocument2 pages2020 NCW Activity Making Glue at Homealiumpar123No ratings yet

- Agar Plate Children'S: Activity PackDocument7 pagesAgar Plate Children'S: Activity PackNatalija Atanasova-PancevskaNo ratings yet

- Starch BasedDocument6 pagesStarch BasedBongzkie Irudistan AmanteNo ratings yet

- Growing Microgreens Cheat Sheets: Soil Only & Must Pre-Soak SeedsDocument2 pagesGrowing Microgreens Cheat Sheets: Soil Only & Must Pre-Soak SeedsM Mohsin ChowdhuryNo ratings yet

- SF Powerpoint AkishorDocument1 pageSF Powerpoint Akishorapi-527956594No ratings yet

- NhungPham ReportDocument16 pagesNhungPham ReportphamNo ratings yet

- PROJECT TATVA FinalDocument19 pagesPROJECT TATVA FinalMuskan MukhiNo ratings yet

- NationalScienceDay Long PDFDocument7 pagesNationalScienceDay Long PDFPpa Gpat AmitNo ratings yet

- Types and Uses/benefits of Concoctions 1. Imo: Indigenous Micro Organisms (IMO1 - 2)Document10 pagesTypes and Uses/benefits of Concoctions 1. Imo: Indigenous Micro Organisms (IMO1 - 2)Jean SuarezNo ratings yet

- Preparation and Evaluation of Paracetamol Tablets With DifferentDocument1 pagePreparation and Evaluation of Paracetamol Tablets With Differentsakshichede8No ratings yet

- 2021 Canning 101Document5 pages2021 Canning 101Alan Winston SedzeNo ratings yet

- Edible CutleryDocument5 pagesEdible CutleryAman Sadhra100% (1)

- Indigenous Micro Organisms (IMO1 - 2) : How To Make The ConcoctionDocument1 pageIndigenous Micro Organisms (IMO1 - 2) : How To Make The ConcoctionMarycon NacitoNo ratings yet

- Science and Technology Education Report-WPS OfficeDocument21 pagesScience and Technology Education Report-WPS OfficeJay Jasper GoNo ratings yet

- DegradablevsbiodegradableDocument13 pagesDegradablevsbiodegradablesourajitchakraborty9No ratings yet

- Survival PDFDocument10 pagesSurvival PDFyyssbxcnNo ratings yet

- Handcrafted Sugar Flowers: Step-by-Step InstructionsDocument2 pagesHandcrafted Sugar Flowers: Step-by-Step InstructionssimonaNo ratings yet

- Troubleshooting Your Compost Pile: Symptom Possible Causes PrescriptionDocument2 pagesTroubleshooting Your Compost Pile: Symptom Possible Causes PrescriptionOmar RodriguezNo ratings yet

- CAULIFLOWERDocument15 pagesCAULIFLOWERYira Dessiré SalinasNo ratings yet

- Sci Fair 1Document7 pagesSci Fair 1api-420631518No ratings yet

- Biogas BookDocument16 pagesBiogas BookIne RiswantiNo ratings yet

- Equipment/Material: Bag TechniqueDocument4 pagesEquipment/Material: Bag TechniqueKrisyll Meah Torred RamalNo ratings yet

- AS-and-A-level-Biology-B-Core-Practical-14-Starch-Agar-Assay - (Student,-Teacher,-Technician-Worksheets)Document8 pagesAS-and-A-level-Biology-B-Core-Practical-14-Starch-Agar-Assay - (Student,-Teacher,-Technician-Worksheets)amnasadathNo ratings yet

- Chapter 3 Group 5Document13 pagesChapter 3 Group 5A - CAYAGA, Kirby, C 12 - HermonNo ratings yet

- 9.2 Teks Prosedur Resep Makananminuman Dan Manual - KK DTDocument6 pages9.2 Teks Prosedur Resep Makananminuman Dan Manual - KK DTjulio krisnaNo ratings yet

- IAS Biology TRP1 CP9 Stu ModDocument4 pagesIAS Biology TRP1 CP9 Stu ModAyesha GulzarNo ratings yet

- Science Fair Trifold 2021 - Hackworth EllaryDocument1 pageScience Fair Trifold 2021 - Hackworth Ellaryapi-484215877No ratings yet

- BioplasticDocument17 pagesBioplasticМишээл ЯдамсүрэнNo ratings yet

- Bio - Plastic ReportDocument2 pagesBio - Plastic ReportSophia SpiliopulosNo ratings yet

- CapstoneDocument11 pagesCapstoneChristian PaulNo ratings yet

- LifeBrL3 05 01 01Document1 pageLifeBrL3 05 01 01Marcos Morales AlburquerqueNo ratings yet

- Chapter 5 TestDocument3 pagesChapter 5 Testkatherine Vanessa Cruz NarvaezNo ratings yet

- Lesson Presentation Separating MixturesDocument24 pagesLesson Presentation Separating MixturesRania HazemNo ratings yet

- Research and Discussion (G12-Nipa Palm Fronds Used As An Alternative Paper Making Source)Document6 pagesResearch and Discussion (G12-Nipa Palm Fronds Used As An Alternative Paper Making Source)wheeyycoldandhot55No ratings yet

- Biology Depth StudyDocument4 pagesBiology Depth StudyCharlotte JaisonNo ratings yet

- 2022 Science Fair Trifold d1 Print - TTDocument1 page2022 Science Fair Trifold d1 Print - TTapi-564040637No ratings yet

- 2021 SFDocument1 page2021 SFapi-527956594No ratings yet

- Degradation of Paper Waste by Eisenia FoetidaDocument24 pagesDegradation of Paper Waste by Eisenia FoetidaAravind vishnu Saravanan GNo ratings yet

- Powders and GranulesDocument4 pagesPowders and GranulesKRISTINE ANN OLILANGNo ratings yet

- Office of The Laboratory Schools-Senior High School: University of Northern PhilippinesDocument3 pagesOffice of The Laboratory Schools-Senior High School: University of Northern PhilippinesMa. Rochelle CabralesNo ratings yet

- Alat - Alat Yang Digunakan Dilaboratorium Farmasi Fungsi: Distillation FlaskDocument11 pagesAlat - Alat Yang Digunakan Dilaboratorium Farmasi Fungsi: Distillation FlaskRazita Zahra utamiNo ratings yet

- WWW Wikihow Com Make Rat Poison - Text Mix 20together 20flour 2C 20baking 20soda Mixture 20and 20stir 20it 20togetherDocument15 pagesWWW Wikihow Com Make Rat Poison - Text Mix 20together 20flour 2C 20baking 20soda Mixture 20and 20stir 20it 20togetherbotogiti1No ratings yet

- Recycling: We Can RecycleDocument2 pagesRecycling: We Can RecycleJuan HerreraNo ratings yet

- Recipe CardDocument4 pagesRecipe Cardapi-582453684No ratings yet

- Food Waste BiomassDocument5 pagesFood Waste Biomassyuhan decanoNo ratings yet

- The Neoble JournalDocument4 pagesThe Neoble JournalmuhammaddzakyalmairzaidanNo ratings yet

- How To Make Your Own Dressings and Bandages BurDocument3 pagesHow To Make Your Own Dressings and Bandages BurKOSTASPDFNo ratings yet

- Harrison Stem Student Volunteer TimeDocument1 pageHarrison Stem Student Volunteer Timeapi-527875218No ratings yet

- Emergency Department PresentationDocument15 pagesEmergency Department Presentationapi-527875218No ratings yet

- Steminar GT Biomedical Engineeringrsch - Sophie Marin 1Document2 pagesSteminar GT Biomedical Engineeringrsch - Sophie Marin 1api-527875218No ratings yet

- Resume Sophie 2Document3 pagesResume Sophie 2api-527875218No ratings yet

- Concussion PBL Student Documents Repaired 1 1Document11 pagesConcussion PBL Student Documents Repaired 1 1api-527875218No ratings yet

- Scanned Documents 3Document1 pageScanned Documents 3api-527875218No ratings yet

- Lactase LabDocument9 pagesLactase Labapi-527875218No ratings yet

- Powerpoint For Science ExperimentDocument1 pagePowerpoint For Science Experimentapi-527875218No ratings yet

- Harrison Stem Student Volunteer LimeDocument1 pageHarrison Stem Student Volunteer Limeapi-527875218No ratings yet

- Scanned Documents 1Document1 pageScanned Documents 1api-527875218No ratings yet

- Scanned Documents 2Document1 pageScanned Documents 2api-527875218No ratings yet

- Medicine ProjectDocument24 pagesMedicine Projectapi-527875218No ratings yet

- Squirrel Island Project 1Document11 pagesSquirrel Island Project 1api-527875218No ratings yet

- Budgeting Project 4Document7 pagesBudgeting Project 4api-527875218No ratings yet

- Rationale 2Document4 pagesRationale 2api-527875218No ratings yet

- BS 03900 0 2010Document26 pagesBS 03900 0 2010selvaNo ratings yet

- Iui Made Easy: Semen Analysis, Processing and PreservationDocument97 pagesIui Made Easy: Semen Analysis, Processing and PreservationSuryakant HayatnagarkarNo ratings yet

- CPX, CPXR, CPXN, CPXP PDFDocument44 pagesCPX, CPXR, CPXN, CPXP PDFAhunahonNo ratings yet

- FINAL Ulster Combined Report From STONE 12-15Document104 pagesFINAL Ulster Combined Report From STONE 12-15Watershed PostNo ratings yet

- 6 Biomechanical Basis of Extraction Space Closure - Pocket DentistryDocument5 pages6 Biomechanical Basis of Extraction Space Closure - Pocket DentistryParameswaran ManiNo ratings yet

- Hotpoint Washing Machine Wmf740Document16 pagesHotpoint Washing Machine Wmf740furheavensakeNo ratings yet

- 5 MuscleDocument3 pages5 MuscleNicolePorsueloNo ratings yet

- 3b Domestic Water Meter Installation in Meter Room GuidelinesDocument10 pages3b Domestic Water Meter Installation in Meter Room GuidelinesVinish HARIDAS NAIRNo ratings yet

- Pdf&rendition 1Document61 pagesPdf&rendition 1Dulce DeNo ratings yet

- 1st Year Chemistry Sc1 ChemistryDocument896 pages1st Year Chemistry Sc1 Chemistrybiranchi satapathyNo ratings yet

- Product Range: Trelleborg Se Aling SolutionsDocument39 pagesProduct Range: Trelleborg Se Aling SolutionssandeepNo ratings yet

- 8.16 References PDFDocument1 page8.16 References PDFnickNo ratings yet

- Light and ShadowDocument5 pagesLight and ShadowLisa Lipsett50% (2)

- Edux110 SimDocument307 pagesEdux110 SimElijahNo ratings yet

- Unit-Iv Nanomaterials and Nanotechnology: Part-ADocument4 pagesUnit-Iv Nanomaterials and Nanotechnology: Part-AKrishna ThiruvengadamNo ratings yet

- PT EnglishDocument6 pagesPT EnglishGener Taña AntonioNo ratings yet

- Linear AlgebraDocument395 pagesLinear AlgebraRehan Javed100% (2)

- Dit 24Document1 pageDit 24Abvolt IndiaNo ratings yet

- The Ultimate Guide To Arduino LibraryDocument76 pagesThe Ultimate Guide To Arduino LibraryNguyễn Hòa75% (4)

- Chapter No.1 Meat CookeryDocument15 pagesChapter No.1 Meat CookeryKrishna Chaudhary0% (1)

- Zeiss Erosion ModuleDocument13 pagesZeiss Erosion ModulepakhiddeyasNo ratings yet

- Guidelines To An Informal LetterDocument3 pagesGuidelines To An Informal LetterNik Syahina0% (1)

- ColaTeric BE 16Document2 pagesColaTeric BE 16mndmattNo ratings yet

- Piping Info - Pipe Support Design GuidelinesDocument4 pagesPiping Info - Pipe Support Design GuidelinesSUSHANTBIJAM100% (1)

- Brenes 2006Document6 pagesBrenes 2006Alfonso CáceresNo ratings yet

- Bio 2022 PreparationDocument21 pagesBio 2022 PreparationAGENT SAYONNo ratings yet

- Verb Patterns: Verb + Infinitive or Verb + - Ing?: Verbs Followed by A To-InfinitiveDocument5 pagesVerb Patterns: Verb + Infinitive or Verb + - Ing?: Verbs Followed by A To-InfinitiveTeodora PluskoskaNo ratings yet