Professional Documents

Culture Documents

Vanitha Eqp List

Vanitha Eqp List

Uploaded by

Vanitha ECopyright:

Available Formats

You might also like

- Piovan WTC Thw9Document48 pagesPiovan WTC Thw9T desNo ratings yet

- FE Civil Practice ExamDocument56 pagesFE Civil Practice ExamMonica Vega100% (3)

- Tata Consulting Engineers Limited: Compressor House Wind Loading Wind Loading at ColumnsDocument12 pagesTata Consulting Engineers Limited: Compressor House Wind Loading Wind Loading at ColumnsVed Vrat AryaNo ratings yet

- Pamphlet 001 Chlorine BasicsDocument61 pagesPamphlet 001 Chlorine Basicsthorem100% (1)

- 150 MW Reheat LP-A1Document4 pages150 MW Reheat LP-A1DeepikaNo ratings yet

- Iwp Hydrotesting Checklist: Appendix - 14Document4 pagesIwp Hydrotesting Checklist: Appendix - 14Soumitra GuptaNo ratings yet

- VRF LC Fixed KuwaitDocument12 pagesVRF LC Fixed KuwaitKamlesh LodhaNo ratings yet

- Zau 74 102017 CS 8180 00034 PDFDocument200 pagesZau 74 102017 CS 8180 00034 PDFvasudhaNo ratings yet

- Operating & Design Compress Air SystemDocument8 pagesOperating & Design Compress Air SystemFiauni VoNo ratings yet

- .Rotlr - : 36 TCCLLDocument36 pages.Rotlr - : 36 TCCLLVu duy HoangNo ratings yet

- Saka Indonesia Pangkah Limited Contract No. 4600012838: Piping Test Package W3-0103-01 Production HeaderDocument19 pagesSaka Indonesia Pangkah Limited Contract No. 4600012838: Piping Test Package W3-0103-01 Production HeaderriandiNo ratings yet

- 10 IN 00 IWD 009 - Rev.1 - 180611Document867 pages10 IN 00 IWD 009 - Rev.1 - 180611irfanNo ratings yet

- 002244spc 02 Issue 02 WC 45 High Temp Cascade 60hzDocument20 pages002244spc 02 Issue 02 WC 45 High Temp Cascade 60hzOlhaNo ratings yet

- BLA-G-TS-00-101: Surface Preparation, Palntinc and Galvanizing Specification Rev. A eDocument3 pagesBLA-G-TS-00-101: Surface Preparation, Palntinc and Galvanizing Specification Rev. A eAhmad Iksan KurniantoNo ratings yet

- Design CalculationDocument1 pageDesign Calculationapi-3728508No ratings yet

- 8103 M-42 6u2816013 Plate Type CoolersDocument60 pages8103 M-42 6u2816013 Plate Type CoolersABDULLAHNo ratings yet

- Technical Datasheet For Instrument Air DryersDocument5 pagesTechnical Datasheet For Instrument Air DryersVăn HùngNo ratings yet

- Olukunle Afeni - Datasheet Pneumatic ConveyingDocument2 pagesOlukunle Afeni - Datasheet Pneumatic ConveyingBolakale UthmanNo ratings yet

- Measurement of Payment (Electrical Work)Document14 pagesMeasurement of Payment (Electrical Work)Steven JosephNo ratings yet

- API 650 Storage Tank HRD - SubDocument7 pagesAPI 650 Storage Tank HRD - SubBimal DeyNo ratings yet

- IC#9 HBL Inspection Waiver ProfomaDocument2 pagesIC#9 HBL Inspection Waiver ProfomaAashish MoyalNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Link ClickDocument3 pagesLink ClickAhmad KamilNo ratings yet

- Datasheet For Flow ComputerDocument2 pagesDatasheet For Flow ComputerAngela BarberNo ratings yet

- HLC - TLC - FO - 08 - G07-APPENDIX D - Pergola Calculation - Rev - BDocument23 pagesHLC - TLC - FO - 08 - G07-APPENDIX D - Pergola Calculation - Rev - BPhú NguyễnNo ratings yet

- Nozzle CFDDocument41 pagesNozzle CFDYusuf RampNo ratings yet

- Project: Final Project Doc. No.: 01 - 42 15 002 - PD Rev. No.: Parameter Design Konstrukksi Rampdoor Roro Barge Kapasitas 80 TONDocument6 pagesProject: Final Project Doc. No.: 01 - 42 15 002 - PD Rev. No.: Parameter Design Konstrukksi Rampdoor Roro Barge Kapasitas 80 TONBagusPrambudiNo ratings yet

- TT Datasheet (QGX-24-09-IN-DS-NA-133 - 00)Document11 pagesTT Datasheet (QGX-24-09-IN-DS-NA-133 - 00)Ayberk AslanNo ratings yet

- 3 - APA1 - Appendix D Flow Diagrams Heat and Material Balances and Plot PlanDocument43 pages3 - APA1 - Appendix D Flow Diagrams Heat and Material Balances and Plot PlanNiell Anakeen dela CruzNo ratings yet

- Equipment Displacement Calculation Sheet: Input DataDocument3 pagesEquipment Displacement Calculation Sheet: Input DataHarish HarishNo ratings yet

- ARUV578BTE5Document2 pagesARUV578BTE5jaimegutierrezlinganNo ratings yet

- Field Inspection Report - Intermediate and Finish Painting Inspection Record For PipingDocument2 pagesField Inspection Report - Intermediate and Finish Painting Inspection Record For PipingraghbirNo ratings yet

- Daily Progress Report: Project: Ostt-Ssjetty Submarine Pipeline, Location:Ss Jetty, Salpg, Durga Beach, VisakhapatnamDocument1 pageDaily Progress Report: Project: Ostt-Ssjetty Submarine Pipeline, Location:Ss Jetty, Salpg, Durga Beach, VisakhapatnamNaseer PullatNo ratings yet

- QN DeNOx Technical Proposal State IIDocument672 pagesQN DeNOx Technical Proposal State IIMạnh CườngNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Eyewash & Safety ShowerDocument5 pagesEyewash & Safety Showershiekh faizNo ratings yet

- 001.17056.000028-AK008-01 1st Stage PreheaterDocument5 pages001.17056.000028-AK008-01 1st Stage PreheaterQuy RomNo ratings yet

- Es 22 002406 Ing Aci CH 001 00Document16 pagesEs 22 002406 Ing Aci CH 001 00Eduardo Serrano AtiroNo ratings yet

- B-57.481 - B - Plumbing Design CalculationDocument14 pagesB-57.481 - B - Plumbing Design CalculationChimex KenNo ratings yet

- MWM J - (Ii) 0003Document90 pagesMWM J - (Ii) 0003Taufik 'opics' AkbarNo ratings yet

- 001.17056.000028-AK007-01 Cartridge FilterDocument5 pages001.17056.000028-AK007-01 Cartridge FilterQuy RomNo ratings yet

- Ejemplo de Calculo Recipiente A PresionDocument50 pagesEjemplo de Calculo Recipiente A PresionSicea IngenieriaNo ratings yet

- Heavy And/Or Bulky Cargo Sketch: Khyco PT 000 PP PRC 0001 02Document1 pageHeavy And/Or Bulky Cargo Sketch: Khyco PT 000 PP PRC 0001 02Mohammad SadatNo ratings yet

- CC ITP Sample PDFDocument4 pagesCC ITP Sample PDFMRezaNo ratings yet

- Dimension Inspection Report: Pt. Indra KaryaDocument1 pageDimension Inspection Report: Pt. Indra KaryaMahfudRido'iRonggomaniaNo ratings yet

- 09C00040-C-3840-5-HD-102 09C00040-C-3840-5-HD-102: Hoja de Datos de Bombas C-3820-PP-1804/1805 Mecánica Rev. 0Document4 pages09C00040-C-3840-5-HD-102 09C00040-C-3840-5-HD-102: Hoja de Datos de Bombas C-3820-PP-1804/1805 Mecánica Rev. 0jose.carrillo1582No ratings yet

- Slb-Mer 03gdp-Hes-Ivr-001Document3 pagesSlb-Mer 03gdp-Hes-Ivr-001Iin Kumala sariNo ratings yet

- TM0248-2 - Loop Diagram - R2Document42 pagesTM0248-2 - Loop Diagram - R2NOEMINo ratings yet

- Quality Assurance Plan: Manufacturer'S Name & AddressDocument1 pageQuality Assurance Plan: Manufacturer'S Name & AddressEWTRNo ratings yet

- Quality Assurance Plan: Manufacturer'S Name & AddressDocument2 pagesQuality Assurance Plan: Manufacturer'S Name & AddressEWTRNo ratings yet

- Mom - PumpDocument53 pagesMom - PumphadiNo ratings yet

- IMS-QC-FM-078 PunchlistDocument3 pagesIMS-QC-FM-078 PunchlistJonas DordziNo ratings yet

- 1045-BB1-ME-CAL-001 - A ScopeDocument187 pages1045-BB1-ME-CAL-001 - A ScopeAlfredo Bautista HernándezNo ratings yet

- Structure Steel Design Calculation (Closed Drain Pump)Document359 pagesStructure Steel Design Calculation (Closed Drain Pump)vamcodong100% (1)

- 220 V2a MHCB 00029Document93 pages220 V2a MHCB 00029faradioNo ratings yet

- BC Booster Irrigation Sump Transfer Pump Head CalculationDocument11 pagesBC Booster Irrigation Sump Transfer Pump Head CalculationPrabaKaranNo ratings yet

- Zapata BurdnyDocument1 pageZapata BurdnyjoseNo ratings yet

- RFI - 1 ConcretingDocument8 pagesRFI - 1 Concretingnevinpaul1234No ratings yet

- Compressor Welding Procedure (1-25)Document25 pagesCompressor Welding Procedure (1-25)mohammed talha khanNo ratings yet

- Hydro TestingDocument26 pagesHydro TestingMahaveer SinghNo ratings yet

- Calculation Cover SheetDocument6 pagesCalculation Cover SheetAnonymous a4Jwz14WNo ratings yet

- A6cv-Pddm-T-13786 (Programa Conservación Auditiva y Ergonomia-K137)Document1 pageA6cv-Pddm-T-13786 (Programa Conservación Auditiva y Ergonomia-K137)Carlos AvilaNo ratings yet

- Calculus Based Physics 2 All in Source PDFDocument62 pagesCalculus Based Physics 2 All in Source PDFNicoco LocoNo ratings yet

- Tutorial Eleven Reaction: 4 Edition, Jan. 2018Document10 pagesTutorial Eleven Reaction: 4 Edition, Jan. 2018komodiemoNo ratings yet

- Project Bank - 2nd Semester 2021-22Document34 pagesProject Bank - 2nd Semester 2021-22VEDANT singhNo ratings yet

- Hardware Design and Implementation of An Electromagnetic Levitation System in An Additive Manufacturing EnvironmentDocument121 pagesHardware Design and Implementation of An Electromagnetic Levitation System in An Additive Manufacturing EnvironmentFeyza KaragözNo ratings yet

- Silt Density Index - SDI Membrane Fouling ControlDocument5 pagesSilt Density Index - SDI Membrane Fouling ControlSergioNo ratings yet

- 80375-01 r0 Technical Data Sheet, AT-250Document1 page80375-01 r0 Technical Data Sheet, AT-250pablolz712No ratings yet

- 3 Novec™ 1230 Fire Protection Fluid Data SheetDocument4 pages3 Novec™ 1230 Fire Protection Fluid Data SheetL ONo ratings yet

- The Unusual Behavior of A Milos Bentonite in Cement SuspensionsDocument7 pagesThe Unusual Behavior of A Milos Bentonite in Cement SuspensionsIbrahim SouleimanNo ratings yet

- XII 22 Phy CH 15Document60 pagesXII 22 Phy CH 15joelNo ratings yet

- Haloalkanes and Haloarenes QDocument35 pagesHaloalkanes and Haloarenes QAbhinav BishtNo ratings yet

- Endogenic Processes Plutonism and VolcanismDocument21 pagesEndogenic Processes Plutonism and VolcanismBen Josiah BayotNo ratings yet

- Question 1 of 6: For 25 PointsDocument10 pagesQuestion 1 of 6: For 25 PointsAnhNo ratings yet

- G9 - Q4 Long Test - 2022 2023Document5 pagesG9 - Q4 Long Test - 2022 2023Jarnel CabalsaNo ratings yet

- Quinones-Vii': UK 8 Nom&r W77: Accepted For PmbkatioDocument3 pagesQuinones-Vii': UK 8 Nom&r W77: Accepted For PmbkatioprashantNo ratings yet

- JJ Mec - Mep UpdateDocument83 pagesJJ Mec - Mep UpdatesalesNo ratings yet

- Polarization Independent, Tunable Waveguide Bragg Gratings in Lithium Niobate by Femtosecond Laser MicromachiningDocument2 pagesPolarization Independent, Tunable Waveguide Bragg Gratings in Lithium Niobate by Femtosecond Laser MicromachiningjohnNo ratings yet

- Reportsheet#4 Calorimetry Chem1103lDocument6 pagesReportsheet#4 Calorimetry Chem1103lMarielleCaindecNo ratings yet

- Chapter 18 FiltrationDocument18 pagesChapter 18 FiltrationGMDGMD11No ratings yet

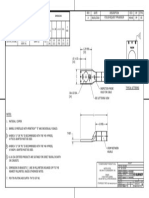

- Ground Floor Plan: Existing Fcu-01 1-SCD 600X600 MM, NECK 150X150 MM 30 L/S Per EachDocument1 pageGround Floor Plan: Existing Fcu-01 1-SCD 600X600 MM, NECK 150X150 MM 30 L/S Per Eachmhmedgomaa74No ratings yet

- Questions 11-20Document3 pagesQuestions 11-20Samuel Francisco SinagaNo ratings yet

- Aeroshell Fluid 71Document2 pagesAeroshell Fluid 71mertaktayNo ratings yet

- Arun Sir Project PPT NewDocument29 pagesArun Sir Project PPT NewsumeetNo ratings yet

- Conductivity,: Ionic Mobilities, Transport NumberDocument11 pagesConductivity,: Ionic Mobilities, Transport NumberHARTK 70No ratings yet

- Natural ResourcesDocument24 pagesNatural ResourcesJane Marry IgnacioNo ratings yet

- Chemistry 445 Lecture 18 MO Theory and D-D SpectraDocument22 pagesChemistry 445 Lecture 18 MO Theory and D-D SpectraAbhinav JainNo ratings yet

- Department of Mechanical Engineering: Lesson PlanDocument5 pagesDepartment of Mechanical Engineering: Lesson PlansivashanmugamNo ratings yet

- Lecture5 - Chemical Oxygen Demand PDFDocument40 pagesLecture5 - Chemical Oxygen Demand PDFgagileNo ratings yet

Vanitha Eqp List

Vanitha Eqp List

Uploaded by

Vanitha EOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vanitha Eqp List

Vanitha Eqp List

Uploaded by

Vanitha ECopyright:

Available Formats

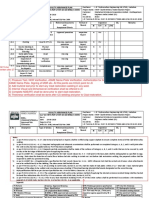

Equipment List

Glycol cooling phase out

Project No. : HV15364

Client Ref. No. : -

Client : Kemira polymers manufacturing B.V

Location : Rotterdam-The Netherlands

PROJECT NOTES: PROJECT HOLDS: 03

1) A) 02

2) B) 01

3) C) 00 6-Feb-23 First Issue ST PR JDB Kemira

4) D) Rev. Date Description Prepared by Checked by Approved by Client Appr.

5) E) Project Title Glycol cooling phase out Project Number

VICOMA Equipment List Cover [Sheet 1 of 4]

6) F) Plant / Unit C.S.P/110 HV15364

7) G) Client Kemira polymers manufacturing B.V Client Project Number

8) H) Location Rotterdam-The Netherlands -

Document No. HV15364-L-Pxxx

Rev 00

Document Type Equipment List

VICOMA Equipment List Cover [Sheet 2 of 4]

Document Type Equipment List Revision : 00 Info (column no.): 46) A = ATEX directive, DS = PGS 29 (Dangerous substance), H = Environmental Notes: Abbreviatons:

Project Title : Glycol cooling phase outPrepared by : V = ST

Vertical, H = Horizontal,

3) C = Centrifugal, PD = Positive displacement Act (Wet Milieubeheer), P = Pressure Equipment Directive 2014-68-EU 1) 6) N/A Not Applicable

Project No. : HV15364 Checked by : PR A = Axial, S = Screw, T = Turbine, F = Fan, P = Plate, S&T = Shell & tube M = Machinery Directive, E = EMC, S = Steamact (Stoomwet vòòr 29 mei 2004) 2) 7) TBD To Be Determined

Client Ref. No. : - Approved by : JDB BU = Bucket, B = Bag, C = Cartridge 3) 8) VTA/VTC Vendor To Advise/To Complete

Document No. : HV15364-L-Pxxx V =10)

Vapour, G = Gas, L = Liquid, S = Solid 4) 9) KVI Keuring Voor Ingebruikname (NL)

15) & 21) FV = Full Vacuüm 5) 10) SEP Sound Engineering Practice

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

Physical Properties Primary Side Secundary Side Design Materials of construction PED

Vaporpressure at Design

Applicable Directives

Pressure Power

Temperature Max

Temperature Max

Dimensions:

Temperature Min

Temperature Min

Mark / Type of

Registration No.

Weight (empty)

Equipment No. Description Type Manufacturer Model No. Design Code P&ID No. Lxdiam. Surface area Notes

KVI Applicable

Specification internals

Pressure Max

Pressure Max

Pressure Min

PED Remarks

Pressure Min

Temperature

Temperature

Temperature

LxBxH

Fluid Group

Fluid

Mol weight

Operating

Operating

Operating

Operating

Insulation

Diff. head

Category

Internals

Viscosity

Estimate

Pressure

Pressure

Capacity

Selected

Revision

Housing

Module

Volume

Density

Design

Design

Design

Design

Design

Design

Design

Design

Outlet

Install

Phase

Phase

Table

Shell

Inlet

kg/m³ cP g/mol barg barg barg °C °C °C barg barg barg °C °C °C bara m³ m³/h m barg barg kW kW mm, m² mm kg Y/N

STEAM/CHILLED 2.78 / 0.01 / 18.0 NA /

Heat exchanger Plate CTA VTA NA PED 2-FS-5803-E WATER

G/L

946 0.27

4.3 CTA CTA 154 CTA CTA 4.5 CTA CTA 102 CTA CTA

< 1.5 bara

VTA TBD NA NA NA TBD VTA VTA VTA Plate VTA VTA VTA VTA TBD TBD TBD TBD TBD TBD TBD 00

2-101-325

2-101-324 Pump Centrifugal 2-FS-5803-E CHILLED WATER L 00

00

00

PE-EL-002-Rev:29-9-2020 - Print date: 03/08/2023 10:07:46 VICOMA Equipment List [Sheet 3 of 4]

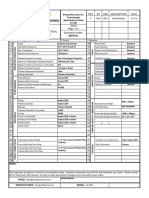

Document Type Equipment List Revision : 00 Info (column no.): 46) A = ATEX directive, DS = PGS 29 (Dangerous substance), H = Environmental Notes: Abbreviatons:

Project Title : Glycol cooling phase outPrepared by : V = ST

Vertical, H = Horizontal,

3) C = Centrifugal, PD = Positive displacement Act (Wet Milieubeheer), P = Pressure Equipment Directive 2014-68-EU 1) 6) N/A Not Applicable

Project No. : HV15364 Checked by : PR A = Axial, S = Screw, T = Turbine, F = Fan, P = Plate, S&T = Shell & tube M = Machinery Directive, E = EMC, S = Steamact (Stoomwet vòòr 29 mei 2004) 2) 7) TBD To Be Determined

Client Ref. No. : - Approved by : JDB BU = Bucket, B = Bag, C = Cartridge 3) 8) VTA/VTC Vendor To Advise/To Complete

Document No. : HV15364-L-Pxxx V =10)

Vapour, G = Gas, L = Liquid, S = Solid 4) 9) KVI Keuring Voor Ingebruikname (NL)

15) & 21) FV = Full Vacuüm 5) 10) SEP Sound Engineering Practice

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

Physical Properties Primary Side Secundary Side Design Materials of construction PED

Vaporpressure at Design

Applicable Directives

Pressure Power

Temperature Max

Temperature Max

Dimensions:

Temperature Min

Temperature Min

Mark / Type of

Registration No.

Weight (empty)

Equipment No. Description Type Manufacturer Model No. Design Code P&ID No. Lxdiam. Surface area Notes

KVI Applicable

Specification internals

Pressure Max

Pressure Max

Pressure Min

PED Remarks

Pressure Min

Temperature

Temperature

Temperature

LxBxH

Fluid Group

Fluid

Mol weight

Operating

Operating

Operating

Operating

Insulation

Diff. head

Category

Internals

Viscosity

Estimate

Pressure

Pressure

Capacity

Selected

Revision

Housing

Module

Volume

Density

Design

Design

Design

Design

Design

Design

Design

Design

Outlet

Install

Phase

Phase

Table

Shell

Inlet

kg/m³ cP g/mol barg barg barg °C °C °C barg barg barg °C °C °C bara m³ m³/h m barg barg kW kW mm, m² mm kg Y/N

PE-EL-002-Rev:29-9-2020 - Print date: 03/08/2023 10:07:46 VICOMA Equipment List [Sheet 4 of 4]

You might also like

- Piovan WTC Thw9Document48 pagesPiovan WTC Thw9T desNo ratings yet

- FE Civil Practice ExamDocument56 pagesFE Civil Practice ExamMonica Vega100% (3)

- Tata Consulting Engineers Limited: Compressor House Wind Loading Wind Loading at ColumnsDocument12 pagesTata Consulting Engineers Limited: Compressor House Wind Loading Wind Loading at ColumnsVed Vrat AryaNo ratings yet

- Pamphlet 001 Chlorine BasicsDocument61 pagesPamphlet 001 Chlorine Basicsthorem100% (1)

- 150 MW Reheat LP-A1Document4 pages150 MW Reheat LP-A1DeepikaNo ratings yet

- Iwp Hydrotesting Checklist: Appendix - 14Document4 pagesIwp Hydrotesting Checklist: Appendix - 14Soumitra GuptaNo ratings yet

- VRF LC Fixed KuwaitDocument12 pagesVRF LC Fixed KuwaitKamlesh LodhaNo ratings yet

- Zau 74 102017 CS 8180 00034 PDFDocument200 pagesZau 74 102017 CS 8180 00034 PDFvasudhaNo ratings yet

- Operating & Design Compress Air SystemDocument8 pagesOperating & Design Compress Air SystemFiauni VoNo ratings yet

- .Rotlr - : 36 TCCLLDocument36 pages.Rotlr - : 36 TCCLLVu duy HoangNo ratings yet

- Saka Indonesia Pangkah Limited Contract No. 4600012838: Piping Test Package W3-0103-01 Production HeaderDocument19 pagesSaka Indonesia Pangkah Limited Contract No. 4600012838: Piping Test Package W3-0103-01 Production HeaderriandiNo ratings yet

- 10 IN 00 IWD 009 - Rev.1 - 180611Document867 pages10 IN 00 IWD 009 - Rev.1 - 180611irfanNo ratings yet

- 002244spc 02 Issue 02 WC 45 High Temp Cascade 60hzDocument20 pages002244spc 02 Issue 02 WC 45 High Temp Cascade 60hzOlhaNo ratings yet

- BLA-G-TS-00-101: Surface Preparation, Palntinc and Galvanizing Specification Rev. A eDocument3 pagesBLA-G-TS-00-101: Surface Preparation, Palntinc and Galvanizing Specification Rev. A eAhmad Iksan KurniantoNo ratings yet

- Design CalculationDocument1 pageDesign Calculationapi-3728508No ratings yet

- 8103 M-42 6u2816013 Plate Type CoolersDocument60 pages8103 M-42 6u2816013 Plate Type CoolersABDULLAHNo ratings yet

- Technical Datasheet For Instrument Air DryersDocument5 pagesTechnical Datasheet For Instrument Air DryersVăn HùngNo ratings yet

- Olukunle Afeni - Datasheet Pneumatic ConveyingDocument2 pagesOlukunle Afeni - Datasheet Pneumatic ConveyingBolakale UthmanNo ratings yet

- Measurement of Payment (Electrical Work)Document14 pagesMeasurement of Payment (Electrical Work)Steven JosephNo ratings yet

- API 650 Storage Tank HRD - SubDocument7 pagesAPI 650 Storage Tank HRD - SubBimal DeyNo ratings yet

- IC#9 HBL Inspection Waiver ProfomaDocument2 pagesIC#9 HBL Inspection Waiver ProfomaAashish MoyalNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Link ClickDocument3 pagesLink ClickAhmad KamilNo ratings yet

- Datasheet For Flow ComputerDocument2 pagesDatasheet For Flow ComputerAngela BarberNo ratings yet

- HLC - TLC - FO - 08 - G07-APPENDIX D - Pergola Calculation - Rev - BDocument23 pagesHLC - TLC - FO - 08 - G07-APPENDIX D - Pergola Calculation - Rev - BPhú NguyễnNo ratings yet

- Nozzle CFDDocument41 pagesNozzle CFDYusuf RampNo ratings yet

- Project: Final Project Doc. No.: 01 - 42 15 002 - PD Rev. No.: Parameter Design Konstrukksi Rampdoor Roro Barge Kapasitas 80 TONDocument6 pagesProject: Final Project Doc. No.: 01 - 42 15 002 - PD Rev. No.: Parameter Design Konstrukksi Rampdoor Roro Barge Kapasitas 80 TONBagusPrambudiNo ratings yet

- TT Datasheet (QGX-24-09-IN-DS-NA-133 - 00)Document11 pagesTT Datasheet (QGX-24-09-IN-DS-NA-133 - 00)Ayberk AslanNo ratings yet

- 3 - APA1 - Appendix D Flow Diagrams Heat and Material Balances and Plot PlanDocument43 pages3 - APA1 - Appendix D Flow Diagrams Heat and Material Balances and Plot PlanNiell Anakeen dela CruzNo ratings yet

- Equipment Displacement Calculation Sheet: Input DataDocument3 pagesEquipment Displacement Calculation Sheet: Input DataHarish HarishNo ratings yet

- ARUV578BTE5Document2 pagesARUV578BTE5jaimegutierrezlinganNo ratings yet

- Field Inspection Report - Intermediate and Finish Painting Inspection Record For PipingDocument2 pagesField Inspection Report - Intermediate and Finish Painting Inspection Record For PipingraghbirNo ratings yet

- Daily Progress Report: Project: Ostt-Ssjetty Submarine Pipeline, Location:Ss Jetty, Salpg, Durga Beach, VisakhapatnamDocument1 pageDaily Progress Report: Project: Ostt-Ssjetty Submarine Pipeline, Location:Ss Jetty, Salpg, Durga Beach, VisakhapatnamNaseer PullatNo ratings yet

- QN DeNOx Technical Proposal State IIDocument672 pagesQN DeNOx Technical Proposal State IIMạnh CườngNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Eyewash & Safety ShowerDocument5 pagesEyewash & Safety Showershiekh faizNo ratings yet

- 001.17056.000028-AK008-01 1st Stage PreheaterDocument5 pages001.17056.000028-AK008-01 1st Stage PreheaterQuy RomNo ratings yet

- Es 22 002406 Ing Aci CH 001 00Document16 pagesEs 22 002406 Ing Aci CH 001 00Eduardo Serrano AtiroNo ratings yet

- B-57.481 - B - Plumbing Design CalculationDocument14 pagesB-57.481 - B - Plumbing Design CalculationChimex KenNo ratings yet

- MWM J - (Ii) 0003Document90 pagesMWM J - (Ii) 0003Taufik 'opics' AkbarNo ratings yet

- 001.17056.000028-AK007-01 Cartridge FilterDocument5 pages001.17056.000028-AK007-01 Cartridge FilterQuy RomNo ratings yet

- Ejemplo de Calculo Recipiente A PresionDocument50 pagesEjemplo de Calculo Recipiente A PresionSicea IngenieriaNo ratings yet

- Heavy And/Or Bulky Cargo Sketch: Khyco PT 000 PP PRC 0001 02Document1 pageHeavy And/Or Bulky Cargo Sketch: Khyco PT 000 PP PRC 0001 02Mohammad SadatNo ratings yet

- CC ITP Sample PDFDocument4 pagesCC ITP Sample PDFMRezaNo ratings yet

- Dimension Inspection Report: Pt. Indra KaryaDocument1 pageDimension Inspection Report: Pt. Indra KaryaMahfudRido'iRonggomaniaNo ratings yet

- 09C00040-C-3840-5-HD-102 09C00040-C-3840-5-HD-102: Hoja de Datos de Bombas C-3820-PP-1804/1805 Mecánica Rev. 0Document4 pages09C00040-C-3840-5-HD-102 09C00040-C-3840-5-HD-102: Hoja de Datos de Bombas C-3820-PP-1804/1805 Mecánica Rev. 0jose.carrillo1582No ratings yet

- Slb-Mer 03gdp-Hes-Ivr-001Document3 pagesSlb-Mer 03gdp-Hes-Ivr-001Iin Kumala sariNo ratings yet

- TM0248-2 - Loop Diagram - R2Document42 pagesTM0248-2 - Loop Diagram - R2NOEMINo ratings yet

- Quality Assurance Plan: Manufacturer'S Name & AddressDocument1 pageQuality Assurance Plan: Manufacturer'S Name & AddressEWTRNo ratings yet

- Quality Assurance Plan: Manufacturer'S Name & AddressDocument2 pagesQuality Assurance Plan: Manufacturer'S Name & AddressEWTRNo ratings yet

- Mom - PumpDocument53 pagesMom - PumphadiNo ratings yet

- IMS-QC-FM-078 PunchlistDocument3 pagesIMS-QC-FM-078 PunchlistJonas DordziNo ratings yet

- 1045-BB1-ME-CAL-001 - A ScopeDocument187 pages1045-BB1-ME-CAL-001 - A ScopeAlfredo Bautista HernándezNo ratings yet

- Structure Steel Design Calculation (Closed Drain Pump)Document359 pagesStructure Steel Design Calculation (Closed Drain Pump)vamcodong100% (1)

- 220 V2a MHCB 00029Document93 pages220 V2a MHCB 00029faradioNo ratings yet

- BC Booster Irrigation Sump Transfer Pump Head CalculationDocument11 pagesBC Booster Irrigation Sump Transfer Pump Head CalculationPrabaKaranNo ratings yet

- Zapata BurdnyDocument1 pageZapata BurdnyjoseNo ratings yet

- RFI - 1 ConcretingDocument8 pagesRFI - 1 Concretingnevinpaul1234No ratings yet

- Compressor Welding Procedure (1-25)Document25 pagesCompressor Welding Procedure (1-25)mohammed talha khanNo ratings yet

- Hydro TestingDocument26 pagesHydro TestingMahaveer SinghNo ratings yet

- Calculation Cover SheetDocument6 pagesCalculation Cover SheetAnonymous a4Jwz14WNo ratings yet

- A6cv-Pddm-T-13786 (Programa Conservación Auditiva y Ergonomia-K137)Document1 pageA6cv-Pddm-T-13786 (Programa Conservación Auditiva y Ergonomia-K137)Carlos AvilaNo ratings yet

- Calculus Based Physics 2 All in Source PDFDocument62 pagesCalculus Based Physics 2 All in Source PDFNicoco LocoNo ratings yet

- Tutorial Eleven Reaction: 4 Edition, Jan. 2018Document10 pagesTutorial Eleven Reaction: 4 Edition, Jan. 2018komodiemoNo ratings yet

- Project Bank - 2nd Semester 2021-22Document34 pagesProject Bank - 2nd Semester 2021-22VEDANT singhNo ratings yet

- Hardware Design and Implementation of An Electromagnetic Levitation System in An Additive Manufacturing EnvironmentDocument121 pagesHardware Design and Implementation of An Electromagnetic Levitation System in An Additive Manufacturing EnvironmentFeyza KaragözNo ratings yet

- Silt Density Index - SDI Membrane Fouling ControlDocument5 pagesSilt Density Index - SDI Membrane Fouling ControlSergioNo ratings yet

- 80375-01 r0 Technical Data Sheet, AT-250Document1 page80375-01 r0 Technical Data Sheet, AT-250pablolz712No ratings yet

- 3 Novec™ 1230 Fire Protection Fluid Data SheetDocument4 pages3 Novec™ 1230 Fire Protection Fluid Data SheetL ONo ratings yet

- The Unusual Behavior of A Milos Bentonite in Cement SuspensionsDocument7 pagesThe Unusual Behavior of A Milos Bentonite in Cement SuspensionsIbrahim SouleimanNo ratings yet

- XII 22 Phy CH 15Document60 pagesXII 22 Phy CH 15joelNo ratings yet

- Haloalkanes and Haloarenes QDocument35 pagesHaloalkanes and Haloarenes QAbhinav BishtNo ratings yet

- Endogenic Processes Plutonism and VolcanismDocument21 pagesEndogenic Processes Plutonism and VolcanismBen Josiah BayotNo ratings yet

- Question 1 of 6: For 25 PointsDocument10 pagesQuestion 1 of 6: For 25 PointsAnhNo ratings yet

- G9 - Q4 Long Test - 2022 2023Document5 pagesG9 - Q4 Long Test - 2022 2023Jarnel CabalsaNo ratings yet

- Quinones-Vii': UK 8 Nom&r W77: Accepted For PmbkatioDocument3 pagesQuinones-Vii': UK 8 Nom&r W77: Accepted For PmbkatioprashantNo ratings yet

- JJ Mec - Mep UpdateDocument83 pagesJJ Mec - Mep UpdatesalesNo ratings yet

- Polarization Independent, Tunable Waveguide Bragg Gratings in Lithium Niobate by Femtosecond Laser MicromachiningDocument2 pagesPolarization Independent, Tunable Waveguide Bragg Gratings in Lithium Niobate by Femtosecond Laser MicromachiningjohnNo ratings yet

- Reportsheet#4 Calorimetry Chem1103lDocument6 pagesReportsheet#4 Calorimetry Chem1103lMarielleCaindecNo ratings yet

- Chapter 18 FiltrationDocument18 pagesChapter 18 FiltrationGMDGMD11No ratings yet

- Ground Floor Plan: Existing Fcu-01 1-SCD 600X600 MM, NECK 150X150 MM 30 L/S Per EachDocument1 pageGround Floor Plan: Existing Fcu-01 1-SCD 600X600 MM, NECK 150X150 MM 30 L/S Per Eachmhmedgomaa74No ratings yet

- Questions 11-20Document3 pagesQuestions 11-20Samuel Francisco SinagaNo ratings yet

- Aeroshell Fluid 71Document2 pagesAeroshell Fluid 71mertaktayNo ratings yet

- Arun Sir Project PPT NewDocument29 pagesArun Sir Project PPT NewsumeetNo ratings yet

- Conductivity,: Ionic Mobilities, Transport NumberDocument11 pagesConductivity,: Ionic Mobilities, Transport NumberHARTK 70No ratings yet

- Natural ResourcesDocument24 pagesNatural ResourcesJane Marry IgnacioNo ratings yet

- Chemistry 445 Lecture 18 MO Theory and D-D SpectraDocument22 pagesChemistry 445 Lecture 18 MO Theory and D-D SpectraAbhinav JainNo ratings yet

- Department of Mechanical Engineering: Lesson PlanDocument5 pagesDepartment of Mechanical Engineering: Lesson PlansivashanmugamNo ratings yet

- Lecture5 - Chemical Oxygen Demand PDFDocument40 pagesLecture5 - Chemical Oxygen Demand PDFgagileNo ratings yet