Professional Documents

Culture Documents

MF7203 Theory of Metal Forming

MF7203 Theory of Metal Forming

Uploaded by

KanagarajanCopyright:

Available Formats

You might also like

- Single Motor Double Door MechanismDocument34 pagesSingle Motor Double Door MechanismKanagarajan100% (1)

- Belt Press - Mass BalanceDocument6 pagesBelt Press - Mass BalanceAshuNo ratings yet

- Mechanical Behaviour and Testing of MaterialsDocument5 pagesMechanical Behaviour and Testing of MaterialsSachi DhanandamNo ratings yet

- Question Paper Code:: (10×2 20 Marks)Document3 pagesQuestion Paper Code:: (10×2 20 Marks)Viswanath ViswaNo ratings yet

- MT5330ENDQuiz2020 PDFDocument2 pagesMT5330ENDQuiz2020 PDFJhansi KokkiligaddaNo ratings yet

- Question Paper Code:: PART A - (10 X 2 20 Marks) 1. State Gibbs Phase RuleDocument2 pagesQuestion Paper Code:: PART A - (10 X 2 20 Marks) 1. State Gibbs Phase RuleKanagasabai SabaNo ratings yet

- Answer Any Three Questions, Each Carries 10 Marks.: Reg No.: - NameDocument2 pagesAnswer Any Three Questions, Each Carries 10 Marks.: Reg No.: - NameRajulapati Sunil KumarNo ratings yet

- MP IatDocument4 pagesMP Iatazhagan.mecNo ratings yet

- r05322003 Metal FormingDocument8 pagesr05322003 Metal FormingSRINIVASA RAO GANTANo ratings yet

- ACFrOgAKq0cnCrVNaUnOG8x3Rz37Dx4lL51ywVQOIZyXrllm3CuF0qwwhbyLysO-L44ha HoLGUr4oWpcYEqTTae0BIBP3ly9XSFm6nzLk5bADYZnSJ 0W7WrMH jxDn34l3g0LyJJpL6Yh6typlDocument2 pagesACFrOgAKq0cnCrVNaUnOG8x3Rz37Dx4lL51ywVQOIZyXrllm3CuF0qwwhbyLysO-L44ha HoLGUr4oWpcYEqTTae0BIBP3ly9XSFm6nzLk5bADYZnSJ 0W7WrMH jxDn34l3g0LyJJpL6Yh6typlShine KunnathNo ratings yet

- Ramaiah: Semester End Examinations - January 2020Document2 pagesRamaiah: Semester End Examinations - January 2020hari krishnaNo ratings yet

- E C1165 Pages 2: Answer Any Three Questions, Each Carries 10 MarksDocument2 pagesE C1165 Pages 2: Answer Any Three Questions, Each Carries 10 MarksShine KunnathNo ratings yet

- 2019 May ME210-H - Ktu QbankDocument2 pages2019 May ME210-H - Ktu QbankkannanNo ratings yet

- L-4/T - 2/MME Date: 16/0112016Document13 pagesL-4/T - 2/MME Date: 16/0112016Arif AmancioNo ratings yet

- Fifth Semester B.Tech Degree Regular and Supplementary Examination December 2020Document3 pagesFifth Semester B.Tech Degree Regular and Supplementary Examination December 2020Sreejith S NairNo ratings yet

- Au Qp-Adv in Casting and Welding-Dec2020Document3 pagesAu Qp-Adv in Casting and Welding-Dec2020Ohmsakthi vel RNo ratings yet

- VSA Group of Institutions,: Department of Mechanical EngineeringDocument1 pageVSA Group of Institutions,: Department of Mechanical EngineeringMohanraj SubramaniNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityD VNo ratings yet

- Question Paper Code:: Reg. No.Document2 pagesQuestion Paper Code:: Reg. No.kanishkrivith.sNo ratings yet

- rr322003 Foundry - WeldingDocument5 pagesrr322003 Foundry - WeldingSRINIVASA RAO GANTANo ratings yet

- Past Year Chap 3Document7 pagesPast Year Chap 3Aida Syauqina Ibrahim 7BNo ratings yet

- Question Paper Code:: (10×2 20 Marks)Document3 pagesQuestion Paper Code:: (10×2 20 Marks)P MithunNo ratings yet

- MP Previous Qp-Me3393Document21 pagesMP Previous Qp-Me3393azhagan.mecNo ratings yet

- Aircraft Materials and ProcessesDocument4 pagesAircraft Materials and ProcessesthandialNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.Priyadharshan RNo ratings yet

- EMM ME 2253 Nov2010 PDFDocument2 pagesEMM ME 2253 Nov2010 PDFRamancoronaNo ratings yet

- r05311802 Mechanical MetallurgyDocument8 pagesr05311802 Mechanical MetallurgySrinivasa Rao GNo ratings yet

- UntitledDocument2 pagesUntitledsegarvijay vijayNo ratings yet

- Materials ScienceDocument49 pagesMaterials ScienceAbhishek KaleNo ratings yet

- Model Question PaperDocument3 pagesModel Question PaperMohanraj KulandasamyNo ratings yet

- E305 Metallurgy and Material Science Set1 1Document2 pagesE305 Metallurgy and Material Science Set1 1NAGA16100% (1)

- K.S.Rangasamy College of Technology, Tiruchengode - 637 215: (Autonomous)Document4 pagesK.S.Rangasamy College of Technology, Tiruchengode - 637 215: (Autonomous)balakaleesNo ratings yet

- 9A14401 Production TechnologyDocument4 pages9A14401 Production TechnologysivabharathamurthyNo ratings yet

- EMM Model 1Document2 pagesEMM Model 1ChandrakanthPrinceNo ratings yet

- MII Manufacturing TechnologyDocument5 pagesMII Manufacturing TechnologyRameez FaroukNo ratings yet

- MT5330ENDQuiz2021 PDFDocument1 pageMT5330ENDQuiz2021 PDFJhansi KokkiligaddaNo ratings yet

- April 2012 Final Exam CCSM 101 V5Document4 pagesApril 2012 Final Exam CCSM 101 V5JCNo ratings yet

- Em MiDocument2 pagesEm MisathishskymechNo ratings yet

- M. Tech. Semester - IX: Highway Materials (IBMCETE 903)Document20 pagesM. Tech. Semester - IX: Highway Materials (IBMCETE 903)saurabh1116No ratings yet

- 100 Morks 1 Bonds. 2 Structure. 3 4 5 6 7 8 9 l0: Metallurgy MaterialDocument2 pages100 Morks 1 Bonds. 2 Structure. 3 4 5 6 7 8 9 l0: Metallurgy MaterialManeesh TNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityMaulik PatelNo ratings yet

- Manufacturing Technology Question Papers of JntuaDocument15 pagesManufacturing Technology Question Papers of JntuaHimadhar SaduNo ratings yet

- rr321803 Foundry TechnologyDocument6 pagesrr321803 Foundry TechnologySRINIVASA RAO GANTANo ratings yet

- Manufacturing Process 1 Question BankDocument6 pagesManufacturing Process 1 Question BankAshok PradhanNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHet ShahNo ratings yet

- Be Winter 2019Document1 pageBe Winter 2019chandsixNo ratings yet

- L-2ff-2/IPE Date: 01/0412019: Section - ADocument24 pagesL-2ff-2/IPE Date: 01/0412019: Section - Ajenalyncelzomedina19No ratings yet

- Question Papers - Heat TreatmentDocument9 pagesQuestion Papers - Heat TreatmentSrilakshmi Shunmugaraj100% (3)

- 2017 July ME210-C - Ktu QbankDocument2 pages2017 July ME210-C - Ktu QbankkannanNo ratings yet

- rr310301 Production TechnologyDocument6 pagesrr310301 Production TechnologySRINIVASA RAO GANTANo ratings yet

- Rr321803 Foundry TechnologyDocument5 pagesRr321803 Foundry TechnologySrinivasa Rao GNo ratings yet

- Manufacturing Process 1 Question BankDocument6 pagesManufacturing Process 1 Question BankAshok PradhanNo ratings yet

- Material Chemistry TutorialsDocument14 pagesMaterial Chemistry TutorialsBORUTO ANIMEZONENo ratings yet

- Me 8 Sem Advanced Manufacturing Techniques Winter 2018Document2 pagesMe 8 Sem Advanced Manufacturing Techniques Winter 2018AakashNo ratings yet

- 2k19 5th Sem Papers - Watermark-1Document15 pages2k19 5th Sem Papers - Watermark-1Vishal kumarNo ratings yet

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Sparks Academy Student - Test Series Result Tom 1Document14 pagesSparks Academy Student - Test Series Result Tom 1KanagarajanNo ratings yet

- PNEUMATIC METAL SHEET RevitDocument42 pagesPNEUMATIC METAL SHEET RevitKanagarajanNo ratings yet

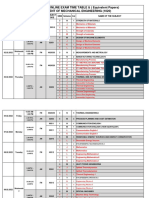

- Revised Time Table February 2022Document179 pagesRevised Time Table February 2022KanagarajanNo ratings yet

- Mech - Equivalent-Feb 2022Document4 pagesMech - Equivalent-Feb 2022KanagarajanNo ratings yet

- Sparks Academy Student - Test Series Result UcmpDocument14 pagesSparks Academy Student - Test Series Result UcmpKanagarajanNo ratings yet

- Sparks Academy Student - Test Series Result PPCDocument13 pagesSparks Academy Student - Test Series Result PPCKanagarajanNo ratings yet

- Diploma Board Examination - February 2022Document2 pagesDiploma Board Examination - February 2022KanagarajanNo ratings yet

- MechDocument4 pagesMechKanagarajanNo ratings yet

- Ge6261 Computer Aided Drafting and Modeling Lab (Civil)Document50 pagesGe6261 Computer Aided Drafting and Modeling Lab (Civil)KanagarajanNo ratings yet

- SynopsisDocument1 pageSynopsisKanagarajanNo ratings yet

- 1 s2.0 S1474667016354386 MainDocument6 pages1 s2.0 S1474667016354386 MainKanagarajanNo ratings yet

- MF84012012AM2019Document2 pagesMF84012012AM2019KanagarajanNo ratings yet

- Purchasing Policies and Procedures: October 2019Document57 pagesPurchasing Policies and Procedures: October 2019KanagarajanNo ratings yet

- IMECE2006-15221: Strain Measurement of Microsamples Using Laser InterferometryDocument5 pagesIMECE2006-15221: Strain Measurement of Microsamples Using Laser InterferometryKanagarajanNo ratings yet

- Material Data Sheet: Ductile Iron in DIN 1693Document4 pagesMaterial Data Sheet: Ductile Iron in DIN 1693Leandro de BittencourtNo ratings yet

- PDF What Is This Thing Called Knowledge Duncan Pritchard Ebook Full ChapterDocument53 pagesPDF What Is This Thing Called Knowledge Duncan Pritchard Ebook Full Chapterlaura.sullivan161100% (1)

- Honing Units: Available Stones From StockDocument83 pagesHoning Units: Available Stones From StockLucas Isaias da SilvaNo ratings yet

- Ripstar Primer v3Document1 pageRipstar Primer v3john paulNo ratings yet

- CBC - GmawDocument22 pagesCBC - GmawPrances PelobelloNo ratings yet

- JK Paper Limited HeheDocument34 pagesJK Paper Limited HehematushriNo ratings yet

- Sand CastingDocument2 pagesSand CastingAhmad NabilNo ratings yet

- New IS COA - FASTIDocument5 pagesNew IS COA - FASTIacctngjayNo ratings yet

- Casting 1Document32 pagesCasting 1Ahmed MahmoudNo ratings yet

- Engineering MaterialsDocument43 pagesEngineering MaterialsKristine SantosNo ratings yet

- International Standard: Castings - System of Dimensional Tolerances and Machining AllowancesDocument20 pagesInternational Standard: Castings - System of Dimensional Tolerances and Machining AllowancesDaniel VilchesNo ratings yet

- Foundry LabDocument4 pagesFoundry LabChidiebere JohnNo ratings yet

- English Language Teachers' Digital Literacy DevelopmentDocument54 pagesEnglish Language Teachers' Digital Literacy DevelopmentRestania d sansaNo ratings yet

- Chemical Composition. Recommended Heat Treating Practice Normalizing. AnnealingDocument4 pagesChemical Composition. Recommended Heat Treating Practice Normalizing. AnnealingGil CabreraNo ratings yet

- Inzenjerstvo PovrsinaDocument23 pagesInzenjerstvo PovrsinamasinacmasinacNo ratings yet

- Zinc-Coated Steel Doors and Frames: (Galvanized/Galvannealed)Document4 pagesZinc-Coated Steel Doors and Frames: (Galvanized/Galvannealed)abualamalNo ratings yet

- Assignment No 03 Electro Discharge Machining Wire Cut TypeDocument2 pagesAssignment No 03 Electro Discharge Machining Wire Cut TypeChirag BotkondleNo ratings yet

- JI S (Japanes E) Stand Ards For ST EE L Ma TE RI ALSDocument2 pagesJI S (Japanes E) Stand Ards For ST EE L Ma TE RI ALSDamar Wardhana100% (1)

- Egatra: Quality ControlDocument6 pagesEgatra: Quality ControlAndreas Schlager100% (3)

- Lec 01 - 1 Materials Processing TechnologyDocument12 pagesLec 01 - 1 Materials Processing Technologyamele25No ratings yet

- Catalogue 2018Document1 pageCatalogue 2018Hassan FawazNo ratings yet

- Recent Innovations in Paper Recycling Flotation)Document4 pagesRecent Innovations in Paper Recycling Flotation)kayee516No ratings yet

- 1020 Bright Carbon Steel Bar 2Document3 pages1020 Bright Carbon Steel Bar 2thyskieNo ratings yet

- Cal Guard Anti Spatter SprayDocument2 pagesCal Guard Anti Spatter SprayMarhadi AdiNo ratings yet

- Full Thickness Repair Welding Welding Procedure Specification (WPS) in Accordance With API 1104 21: 2016Document6 pagesFull Thickness Repair Welding Welding Procedure Specification (WPS) in Accordance With API 1104 21: 2016Juni KurniyantoNo ratings yet

- PART 161 Resistance and Mechanical JoiningDocument2 pagesPART 161 Resistance and Mechanical Joiningravindra_jivaniNo ratings yet

- 70.00.00 Standard Practices - RepairDocument8 pages70.00.00 Standard Practices - RepairTimoteo Molina RomeroNo ratings yet

- Dokumen - Tips - SSPC Pa 1 PDF Wordpresscom A SSPC Pa 1 PDF SSPC Pa 1 Shop Field and PDFDocument2 pagesDokumen - Tips - SSPC Pa 1 PDF Wordpresscom A SSPC Pa 1 PDF SSPC Pa 1 Shop Field and PDFAbhilashNo ratings yet

- Worldwide Fastener Standard: WX 100 Finish Specification 1. ScopeDocument19 pagesWorldwide Fastener Standard: WX 100 Finish Specification 1. ScopeCarmen HernandezNo ratings yet

MF7203 Theory of Metal Forming

MF7203 Theory of Metal Forming

Uploaded by

KanagarajanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MF7203 Theory of Metal Forming

MF7203 Theory of Metal Forming

Uploaded by

KanagarajanCopyright:

Available Formats

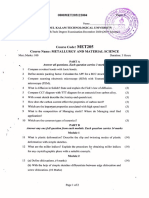

Reg.

No

Question Paper Code: 86779

M.E. DEGREE EXAMINATION MAY/JUNE 2016

First Semester

M.E Manufacturing Engineering

MF 7203 – THEORY OF METAL FORMING

( Regulations 2013)

Time: Three hours Maximum:100marks

Answer ALL questions.

Part A-(10x2=20marks)

1. What is meant by stress concentration.

2. What is meant by strain energy ?

3. What are the different types of friction ?

4. State coulomb’s law of friction and state its limitations.

5. What are the advantages and disadvantages of super plastic forming ?

6. Give any four examples for hydro forming components.

7. State the difference between convectional and high speed extrusion.

8. State the advantages and disadvantages of isothermal forming.

9. What is gliding velocity ?

10. Define formability.

PART – B (5 * 13 = 65 Marks )

11. (a) Explain Tresca and von-Mises criterion and compare the both with simple

sketches

OR

(b) Explain Mohr’’s circle representation of a state of stress in two and three

dimensional with simple sketches

12. (a) Determine the true strain rate in extruding a round billet of radius

function of distance from the entry of a conical die

OR

(b) Discuss in detail the design consideration in formimg process.

13. (a) (i) State the general characteristics of sheet metal forming processes. 8

(ii) State the difference between blanking and fine blanking. 5

OR

(b) (i) Explain explosive forming process with neat sketches. 8

(ii) State the advantages and limitations of super plastic forming 5

process.

14. (a) (i) Explain super plastic forming and state its advantages and 6.5

limitations.

(ii) Explain in detail powder rolling processes with neat sketches. 6.5

OR

(b) (i) Explain in detail high speed extrusion with sketches 6.5

(ii) Explain hot isostatic pressing with neat sketches. 6.5

15. (a) (i) Explain friction between metallic layers neat sketch. 6.5

(ii) Discuss about thin aluminium alloy cladding. 6.5

OR

(b) (i) Explain the process to evaluate formability of laminated sheet. 6.5

(ii) Explain triplex steel rolling process. 6.5

PART –C (1 *15= 15 Marks)

16. (a) Analyse thermo mechanical regimes of Ti and Al alloy during

deformation.

OR

(b) Explain how water hammer is formed with an example.

You might also like

- Single Motor Double Door MechanismDocument34 pagesSingle Motor Double Door MechanismKanagarajan100% (1)

- Belt Press - Mass BalanceDocument6 pagesBelt Press - Mass BalanceAshuNo ratings yet

- Mechanical Behaviour and Testing of MaterialsDocument5 pagesMechanical Behaviour and Testing of MaterialsSachi DhanandamNo ratings yet

- Question Paper Code:: (10×2 20 Marks)Document3 pagesQuestion Paper Code:: (10×2 20 Marks)Viswanath ViswaNo ratings yet

- MT5330ENDQuiz2020 PDFDocument2 pagesMT5330ENDQuiz2020 PDFJhansi KokkiligaddaNo ratings yet

- Question Paper Code:: PART A - (10 X 2 20 Marks) 1. State Gibbs Phase RuleDocument2 pagesQuestion Paper Code:: PART A - (10 X 2 20 Marks) 1. State Gibbs Phase RuleKanagasabai SabaNo ratings yet

- Answer Any Three Questions, Each Carries 10 Marks.: Reg No.: - NameDocument2 pagesAnswer Any Three Questions, Each Carries 10 Marks.: Reg No.: - NameRajulapati Sunil KumarNo ratings yet

- MP IatDocument4 pagesMP Iatazhagan.mecNo ratings yet

- r05322003 Metal FormingDocument8 pagesr05322003 Metal FormingSRINIVASA RAO GANTANo ratings yet

- ACFrOgAKq0cnCrVNaUnOG8x3Rz37Dx4lL51ywVQOIZyXrllm3CuF0qwwhbyLysO-L44ha HoLGUr4oWpcYEqTTae0BIBP3ly9XSFm6nzLk5bADYZnSJ 0W7WrMH jxDn34l3g0LyJJpL6Yh6typlDocument2 pagesACFrOgAKq0cnCrVNaUnOG8x3Rz37Dx4lL51ywVQOIZyXrllm3CuF0qwwhbyLysO-L44ha HoLGUr4oWpcYEqTTae0BIBP3ly9XSFm6nzLk5bADYZnSJ 0W7WrMH jxDn34l3g0LyJJpL6Yh6typlShine KunnathNo ratings yet

- Ramaiah: Semester End Examinations - January 2020Document2 pagesRamaiah: Semester End Examinations - January 2020hari krishnaNo ratings yet

- E C1165 Pages 2: Answer Any Three Questions, Each Carries 10 MarksDocument2 pagesE C1165 Pages 2: Answer Any Three Questions, Each Carries 10 MarksShine KunnathNo ratings yet

- 2019 May ME210-H - Ktu QbankDocument2 pages2019 May ME210-H - Ktu QbankkannanNo ratings yet

- L-4/T - 2/MME Date: 16/0112016Document13 pagesL-4/T - 2/MME Date: 16/0112016Arif AmancioNo ratings yet

- Fifth Semester B.Tech Degree Regular and Supplementary Examination December 2020Document3 pagesFifth Semester B.Tech Degree Regular and Supplementary Examination December 2020Sreejith S NairNo ratings yet

- Au Qp-Adv in Casting and Welding-Dec2020Document3 pagesAu Qp-Adv in Casting and Welding-Dec2020Ohmsakthi vel RNo ratings yet

- VSA Group of Institutions,: Department of Mechanical EngineeringDocument1 pageVSA Group of Institutions,: Department of Mechanical EngineeringMohanraj SubramaniNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityD VNo ratings yet

- Question Paper Code:: Reg. No.Document2 pagesQuestion Paper Code:: Reg. No.kanishkrivith.sNo ratings yet

- rr322003 Foundry - WeldingDocument5 pagesrr322003 Foundry - WeldingSRINIVASA RAO GANTANo ratings yet

- Past Year Chap 3Document7 pagesPast Year Chap 3Aida Syauqina Ibrahim 7BNo ratings yet

- Question Paper Code:: (10×2 20 Marks)Document3 pagesQuestion Paper Code:: (10×2 20 Marks)P MithunNo ratings yet

- MP Previous Qp-Me3393Document21 pagesMP Previous Qp-Me3393azhagan.mecNo ratings yet

- Aircraft Materials and ProcessesDocument4 pagesAircraft Materials and ProcessesthandialNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.Priyadharshan RNo ratings yet

- EMM ME 2253 Nov2010 PDFDocument2 pagesEMM ME 2253 Nov2010 PDFRamancoronaNo ratings yet

- r05311802 Mechanical MetallurgyDocument8 pagesr05311802 Mechanical MetallurgySrinivasa Rao GNo ratings yet

- UntitledDocument2 pagesUntitledsegarvijay vijayNo ratings yet

- Materials ScienceDocument49 pagesMaterials ScienceAbhishek KaleNo ratings yet

- Model Question PaperDocument3 pagesModel Question PaperMohanraj KulandasamyNo ratings yet

- E305 Metallurgy and Material Science Set1 1Document2 pagesE305 Metallurgy and Material Science Set1 1NAGA16100% (1)

- K.S.Rangasamy College of Technology, Tiruchengode - 637 215: (Autonomous)Document4 pagesK.S.Rangasamy College of Technology, Tiruchengode - 637 215: (Autonomous)balakaleesNo ratings yet

- 9A14401 Production TechnologyDocument4 pages9A14401 Production TechnologysivabharathamurthyNo ratings yet

- EMM Model 1Document2 pagesEMM Model 1ChandrakanthPrinceNo ratings yet

- MII Manufacturing TechnologyDocument5 pagesMII Manufacturing TechnologyRameez FaroukNo ratings yet

- MT5330ENDQuiz2021 PDFDocument1 pageMT5330ENDQuiz2021 PDFJhansi KokkiligaddaNo ratings yet

- April 2012 Final Exam CCSM 101 V5Document4 pagesApril 2012 Final Exam CCSM 101 V5JCNo ratings yet

- Em MiDocument2 pagesEm MisathishskymechNo ratings yet

- M. Tech. Semester - IX: Highway Materials (IBMCETE 903)Document20 pagesM. Tech. Semester - IX: Highway Materials (IBMCETE 903)saurabh1116No ratings yet

- 100 Morks 1 Bonds. 2 Structure. 3 4 5 6 7 8 9 l0: Metallurgy MaterialDocument2 pages100 Morks 1 Bonds. 2 Structure. 3 4 5 6 7 8 9 l0: Metallurgy MaterialManeesh TNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityMaulik PatelNo ratings yet

- Manufacturing Technology Question Papers of JntuaDocument15 pagesManufacturing Technology Question Papers of JntuaHimadhar SaduNo ratings yet

- rr321803 Foundry TechnologyDocument6 pagesrr321803 Foundry TechnologySRINIVASA RAO GANTANo ratings yet

- Manufacturing Process 1 Question BankDocument6 pagesManufacturing Process 1 Question BankAshok PradhanNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHet ShahNo ratings yet

- Be Winter 2019Document1 pageBe Winter 2019chandsixNo ratings yet

- L-2ff-2/IPE Date: 01/0412019: Section - ADocument24 pagesL-2ff-2/IPE Date: 01/0412019: Section - Ajenalyncelzomedina19No ratings yet

- Question Papers - Heat TreatmentDocument9 pagesQuestion Papers - Heat TreatmentSrilakshmi Shunmugaraj100% (3)

- 2017 July ME210-C - Ktu QbankDocument2 pages2017 July ME210-C - Ktu QbankkannanNo ratings yet

- rr310301 Production TechnologyDocument6 pagesrr310301 Production TechnologySRINIVASA RAO GANTANo ratings yet

- Rr321803 Foundry TechnologyDocument5 pagesRr321803 Foundry TechnologySrinivasa Rao GNo ratings yet

- Manufacturing Process 1 Question BankDocument6 pagesManufacturing Process 1 Question BankAshok PradhanNo ratings yet

- Material Chemistry TutorialsDocument14 pagesMaterial Chemistry TutorialsBORUTO ANIMEZONENo ratings yet

- Me 8 Sem Advanced Manufacturing Techniques Winter 2018Document2 pagesMe 8 Sem Advanced Manufacturing Techniques Winter 2018AakashNo ratings yet

- 2k19 5th Sem Papers - Watermark-1Document15 pages2k19 5th Sem Papers - Watermark-1Vishal kumarNo ratings yet

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Sparks Academy Student - Test Series Result Tom 1Document14 pagesSparks Academy Student - Test Series Result Tom 1KanagarajanNo ratings yet

- PNEUMATIC METAL SHEET RevitDocument42 pagesPNEUMATIC METAL SHEET RevitKanagarajanNo ratings yet

- Revised Time Table February 2022Document179 pagesRevised Time Table February 2022KanagarajanNo ratings yet

- Mech - Equivalent-Feb 2022Document4 pagesMech - Equivalent-Feb 2022KanagarajanNo ratings yet

- Sparks Academy Student - Test Series Result UcmpDocument14 pagesSparks Academy Student - Test Series Result UcmpKanagarajanNo ratings yet

- Sparks Academy Student - Test Series Result PPCDocument13 pagesSparks Academy Student - Test Series Result PPCKanagarajanNo ratings yet

- Diploma Board Examination - February 2022Document2 pagesDiploma Board Examination - February 2022KanagarajanNo ratings yet

- MechDocument4 pagesMechKanagarajanNo ratings yet

- Ge6261 Computer Aided Drafting and Modeling Lab (Civil)Document50 pagesGe6261 Computer Aided Drafting and Modeling Lab (Civil)KanagarajanNo ratings yet

- SynopsisDocument1 pageSynopsisKanagarajanNo ratings yet

- 1 s2.0 S1474667016354386 MainDocument6 pages1 s2.0 S1474667016354386 MainKanagarajanNo ratings yet

- MF84012012AM2019Document2 pagesMF84012012AM2019KanagarajanNo ratings yet

- Purchasing Policies and Procedures: October 2019Document57 pagesPurchasing Policies and Procedures: October 2019KanagarajanNo ratings yet

- IMECE2006-15221: Strain Measurement of Microsamples Using Laser InterferometryDocument5 pagesIMECE2006-15221: Strain Measurement of Microsamples Using Laser InterferometryKanagarajanNo ratings yet

- Material Data Sheet: Ductile Iron in DIN 1693Document4 pagesMaterial Data Sheet: Ductile Iron in DIN 1693Leandro de BittencourtNo ratings yet

- PDF What Is This Thing Called Knowledge Duncan Pritchard Ebook Full ChapterDocument53 pagesPDF What Is This Thing Called Knowledge Duncan Pritchard Ebook Full Chapterlaura.sullivan161100% (1)

- Honing Units: Available Stones From StockDocument83 pagesHoning Units: Available Stones From StockLucas Isaias da SilvaNo ratings yet

- Ripstar Primer v3Document1 pageRipstar Primer v3john paulNo ratings yet

- CBC - GmawDocument22 pagesCBC - GmawPrances PelobelloNo ratings yet

- JK Paper Limited HeheDocument34 pagesJK Paper Limited HehematushriNo ratings yet

- Sand CastingDocument2 pagesSand CastingAhmad NabilNo ratings yet

- New IS COA - FASTIDocument5 pagesNew IS COA - FASTIacctngjayNo ratings yet

- Casting 1Document32 pagesCasting 1Ahmed MahmoudNo ratings yet

- Engineering MaterialsDocument43 pagesEngineering MaterialsKristine SantosNo ratings yet

- International Standard: Castings - System of Dimensional Tolerances and Machining AllowancesDocument20 pagesInternational Standard: Castings - System of Dimensional Tolerances and Machining AllowancesDaniel VilchesNo ratings yet

- Foundry LabDocument4 pagesFoundry LabChidiebere JohnNo ratings yet

- English Language Teachers' Digital Literacy DevelopmentDocument54 pagesEnglish Language Teachers' Digital Literacy DevelopmentRestania d sansaNo ratings yet

- Chemical Composition. Recommended Heat Treating Practice Normalizing. AnnealingDocument4 pagesChemical Composition. Recommended Heat Treating Practice Normalizing. AnnealingGil CabreraNo ratings yet

- Inzenjerstvo PovrsinaDocument23 pagesInzenjerstvo PovrsinamasinacmasinacNo ratings yet

- Zinc-Coated Steel Doors and Frames: (Galvanized/Galvannealed)Document4 pagesZinc-Coated Steel Doors and Frames: (Galvanized/Galvannealed)abualamalNo ratings yet

- Assignment No 03 Electro Discharge Machining Wire Cut TypeDocument2 pagesAssignment No 03 Electro Discharge Machining Wire Cut TypeChirag BotkondleNo ratings yet

- JI S (Japanes E) Stand Ards For ST EE L Ma TE RI ALSDocument2 pagesJI S (Japanes E) Stand Ards For ST EE L Ma TE RI ALSDamar Wardhana100% (1)

- Egatra: Quality ControlDocument6 pagesEgatra: Quality ControlAndreas Schlager100% (3)

- Lec 01 - 1 Materials Processing TechnologyDocument12 pagesLec 01 - 1 Materials Processing Technologyamele25No ratings yet

- Catalogue 2018Document1 pageCatalogue 2018Hassan FawazNo ratings yet

- Recent Innovations in Paper Recycling Flotation)Document4 pagesRecent Innovations in Paper Recycling Flotation)kayee516No ratings yet

- 1020 Bright Carbon Steel Bar 2Document3 pages1020 Bright Carbon Steel Bar 2thyskieNo ratings yet

- Cal Guard Anti Spatter SprayDocument2 pagesCal Guard Anti Spatter SprayMarhadi AdiNo ratings yet

- Full Thickness Repair Welding Welding Procedure Specification (WPS) in Accordance With API 1104 21: 2016Document6 pagesFull Thickness Repair Welding Welding Procedure Specification (WPS) in Accordance With API 1104 21: 2016Juni KurniyantoNo ratings yet

- PART 161 Resistance and Mechanical JoiningDocument2 pagesPART 161 Resistance and Mechanical Joiningravindra_jivaniNo ratings yet

- 70.00.00 Standard Practices - RepairDocument8 pages70.00.00 Standard Practices - RepairTimoteo Molina RomeroNo ratings yet

- Dokumen - Tips - SSPC Pa 1 PDF Wordpresscom A SSPC Pa 1 PDF SSPC Pa 1 Shop Field and PDFDocument2 pagesDokumen - Tips - SSPC Pa 1 PDF Wordpresscom A SSPC Pa 1 PDF SSPC Pa 1 Shop Field and PDFAbhilashNo ratings yet

- Worldwide Fastener Standard: WX 100 Finish Specification 1. ScopeDocument19 pagesWorldwide Fastener Standard: WX 100 Finish Specification 1. ScopeCarmen HernandezNo ratings yet