Professional Documents

Culture Documents

NSK Self

NSK Self

Uploaded by

Chandru VelCopyright:

Available Formats

You might also like

- 21 Spherical Plain BearingDocument26 pages21 Spherical Plain Bearingjitendrapanda336No ratings yet

- Self-Aligning Ball BearingsDocument7 pagesSelf-Aligning Ball BearingsVarsha SinghNo ratings yet

- Spherical Roller Bearings Exq Series NachiDocument8 pagesSpherical Roller Bearings Exq Series Nachijuan gordonNo ratings yet

- Bearing Tables Thrust Cylindrical Roller BearingsDocument14 pagesBearing Tables Thrust Cylindrical Roller BearingsNemanja DavidovicNo ratings yet

- THK Spherical Rod EndsDocument80 pagesTHK Spherical Rod EndsСергій СушкоNo ratings yet

- CAM & Follower FinalDocument14 pagesCAM & Follower FinalRohit NewarNo ratings yet

- Single-Row and Matched Angular Contact Ball BearingsDocument15 pagesSingle-Row and Matched Angular Contact Ball BearingsThái Mai ĐìnhNo ratings yet

- Cat173ex - RHR SRBsDocument5 pagesCat173ex - RHR SRBsTiago AnaniasNo ratings yet

- FAG Rolling Bearings Current InsulatedDocument6 pagesFAG Rolling Bearings Current InsulatedMekanisasi SubangNo ratings yet

- Catalogue of Spherical Roller and Special BearingsDocument67 pagesCatalogue of Spherical Roller and Special BearingsVolodymyrNo ratings yet

- Steel Connections: ResultsDocument6 pagesSteel Connections: ResultsJay SalasNo ratings yet

- Caged, With Inner Ring, No End Washers, Sealed, Yoke-Type (Na22 Series)Document1 pageCaged, With Inner Ring, No End Washers, Sealed, Yoke-Type (Na22 Series)Anonymous yQ7SQrNo ratings yet

- ISB Supporti Autoallineanti Self Aligning Bearing Units 01.09.19 - 5Document1 pageISB Supporti Autoallineanti Self Aligning Bearing Units 01.09.19 - 5Antonio FacipieriNo ratings yet

- Thrust Ball BearingsDocument9 pagesThrust Ball BearingsHydro PartsNo ratings yet

- It Should Be Less Than R /3 or 10mDocument5 pagesIt Should Be Less Than R /3 or 10mMawan BentzNo ratings yet

- Hyundai Steel Products GuideDocument40 pagesHyundai Steel Products GuidecarloNo ratings yet

- Ch14 BearingsDocument76 pagesCh14 Bearingsabdallah ghannamNo ratings yet

- Valores de Correcion Del Factor de Velocidad de Las Grasas LubricantesDocument8 pagesValores de Correcion Del Factor de Velocidad de Las Grasas LubricantesLeonardo CardosoNo ratings yet

- Rod End: A Product DescriptionsDocument18 pagesRod End: A Product DescriptionsNopNo ratings yet

- NIKO Track Roller Bearing CatalogueDocument29 pagesNIKO Track Roller Bearing CataloguezhiqianxuNo ratings yet

- ZKL Brno Katalog 2007 enDocument74 pagesZKL Brno Katalog 2007 enPhanHathamNo ratings yet

- Final Exam AppendixDocument2 pagesFinal Exam AppendixGeorge AbdallahNo ratings yet

- Spur Gear CalculationsDocument7 pagesSpur Gear Calculationsaniket patilNo ratings yet

- Timken Part Number H242649 - H242610CD, Tapered Roller Bearings - TDO (Tapered Double Outer) ImperialDocument5 pagesTimken Part Number H242649 - H242610CD, Tapered Roller Bearings - TDO (Tapered Double Outer) ImperialHector DuarteNo ratings yet

- E1224Document3 pagesE1224Alejandro Garcia FloresNo ratings yet

- NSK FreeDocument3 pagesNSK FreeSachin NambiarNo ratings yet

- Plastic Section Moduli For I.S. Rolled Steel Beam Sections Zpy About Y-Y AxisDocument8 pagesPlastic Section Moduli For I.S. Rolled Steel Beam Sections Zpy About Y-Y AxisIJRASETPublicationsNo ratings yet

- SHAFT GoodSod Deriv07Document10 pagesSHAFT GoodSod Deriv07Theodoros AtheridisNo ratings yet

- Introduction To Antifriction BearingsDocument39 pagesIntroduction To Antifriction BearingsTalha AhmadNo ratings yet

- Parker Piston Seal StaticDocument5 pagesParker Piston Seal Statictarno12No ratings yet

- CEA FINAL-converted Word FileDocument5 pagesCEA FINAL-converted Word FilePol OlmedillaNo ratings yet

- Bearing Shaft Fits and Tolerances 1Document9 pagesBearing Shaft Fits and Tolerances 1Arun KumarNo ratings yet

- Bearing FitsDocument9 pagesBearing Fitsm2110No ratings yet

- SHAFT-GoodSod Deriv07Document11 pagesSHAFT-GoodSod Deriv07Raj Bahadur YadavNo ratings yet

- High-Performance External Gear Pump Azpb: FeaturesDocument4 pagesHigh-Performance External Gear Pump Azpb: FeaturesMichail ArmitageNo ratings yet

- Bearing Basics PDFDocument112 pagesBearing Basics PDFSPELECTRICAL NINLNo ratings yet

- Ball Thrust Bearings - American Roller BearingDocument3 pagesBall Thrust Bearings - American Roller BearingAyushKumarJaiswalNo ratings yet

- Bearing FitsDocument7 pagesBearing FitsBurak KoyuncuogluNo ratings yet

- Bridge Engineering Handbook Ch13Document25 pagesBridge Engineering Handbook Ch13Vladimir VozianNo ratings yet

- (Static) : Radial Outer SealingDocument2 pages(Static) : Radial Outer SealingVratislav Němec ml.No ratings yet

- Gearing AgmaDocument17 pagesGearing AgmaDomingos AzevedoNo ratings yet

- EX0604Document4 pagesEX0604igualdi53No ratings yet

- Single Acting, Spring Return, With Wiper Max. Operating Pressure 500 BarDocument1 pageSingle Acting, Spring Return, With Wiper Max. Operating Pressure 500 BarmirzetNo ratings yet

- Linear GuideDocument1,539 pagesLinear Guidered_shobo_85No ratings yet

- Laterally LoadDocument92 pagesLaterally LoadMadhusudan MadhuNo ratings yet

- Restriction Orifice T95500enDocument2 pagesRestriction Orifice T95500enCarlos SopasNo ratings yet

- Babbitt (Metal) : Babbitt, Also Called Babbitt Metal or Bearing Metal, Is Any of SeveralDocument6 pagesBabbitt (Metal) : Babbitt, Also Called Babbitt Metal or Bearing Metal, Is Any of SeveralCarlos BustamanteNo ratings yet

- SKF NameDocument26 pagesSKF NameIslam Fawzy100% (1)

- LAGOS DORMITORY-BeamDesignDocument147 pagesLAGOS DORMITORY-BeamDesignadetokunbo fapuroNo ratings yet

- L357049NW L357010CD TaperedRollerBearings TDO (TaperedDoubleOuter) ImperialDocument5 pagesL357049NW L357010CD TaperedRollerBearings TDO (TaperedDoubleOuter) ImperialMohamed AliNo ratings yet

- SpringsDocument31 pagesSpringsyoussef.mahmoud031No ratings yet

- RTJ PDFDocument5 pagesRTJ PDFEmiliano ZappaterraNo ratings yet

- H006 011Document7 pagesH006 011Guilherme FleschNo ratings yet

- Timken Ball Bearing Catalog 10734Document126 pagesTimken Ball Bearing Catalog 10734NeoNo ratings yet

- Struc DGN U DrainDocument131 pagesStruc DGN U Drainsudhirkumarsharma1966No ratings yet

- Wind CoefficientDocument2 pagesWind Coefficientvisva scgNo ratings yet

- 33-Synchronous Generators Part2 PDFDocument4 pages33-Synchronous Generators Part2 PDFpurseyNo ratings yet

- Design of BearingsDocument46 pagesDesign of BearingsSatyaprakash Dinesh Vispute100% (1)

- (Static) : Radial Outer SealingDocument2 pages(Static) : Radial Outer SealingAntonio Carlos Gaspar JuniorNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- File 5e87d775f21ecDocument6 pagesFile 5e87d775f21ecChandru VelNo ratings yet

- US4458549Document8 pagesUS4458549Chandru VelNo ratings yet

- 0817 TTDocument1 page0817 TTChandru VelNo ratings yet

- Research On Automatic Programming Methods of CNC Machining Parameters of GearDocument3 pagesResearch On Automatic Programming Methods of CNC Machining Parameters of GearChandru VelNo ratings yet

- Jäœehl Ä C G Â K W G ®KHD¡ FHF Èäbl : Ä F LZ UójDocument1 pageJäœehl Ä C G Â K W G ®KHD¡ FHF Èäbl : Ä F LZ UójChandru VelNo ratings yet

- Software For Calculation of Involute Splines According To ISO 4156 and ANSI B92.2MDocument2 pagesSoftware For Calculation of Involute Splines According To ISO 4156 and ANSI B92.2MChandru VelNo ratings yet

- Theoretical Calculation and Simulation Analysis of No-Load Torque of Main ReducerDocument7 pagesTheoretical Calculation and Simulation Analysis of No-Load Torque of Main ReducerChandru VelNo ratings yet

- Guide For Safety and Comfort of Operator of Agricultural Tractors and Power TillersDocument14 pagesGuide For Safety and Comfort of Operator of Agricultural Tractors and Power TillersChandru VelNo ratings yet

- Transaction Status: Transaction ID: Transaction Date Time: Transaction Reference No.: Consumer No: Transaction Amount: Payment ModeDocument1 pageTransaction Status: Transaction ID: Transaction Date Time: Transaction Reference No.: Consumer No: Transaction Amount: Payment ModeChandru VelNo ratings yet

- HTD Shcs 12.9 T TorqueDocument1 pageHTD Shcs 12.9 T TorqueChandru Vel100% (1)

- Module 3Document51 pagesModule 3Chandru VelNo ratings yet

- GT 1190Document52 pagesGT 1190Chandru VelNo ratings yet

- Botany J-Adhikary Enzymology 1Document17 pagesBotany J-Adhikary Enzymology 1Bhagirath GogikarNo ratings yet

- 05 Graphical Analysis of MotionDocument31 pages05 Graphical Analysis of MotionAnish Anshuman ChoudhuryNo ratings yet

- Sound in Architecture PDFDocument5 pagesSound in Architecture PDFDiana DidiNo ratings yet

- Partial Pressure DeterminationDocument5 pagesPartial Pressure Determinationanon_378146815No ratings yet

- Diffraction ExperimentsDocument5 pagesDiffraction ExperimentsArooj Mukarram100% (2)

- WIZ SeriesDocument4 pagesWIZ SeriesJon HamonNo ratings yet

- Basalt Rock Rebar 01 - Materials - Rebar: Why Not Use Regular Steel Rebar?Document7 pagesBasalt Rock Rebar 01 - Materials - Rebar: Why Not Use Regular Steel Rebar?Sahil GandhiNo ratings yet

- M 11 L 29Document18 pagesM 11 L 29Mandar NadgaundiNo ratings yet

- Vacuum PhysicsDocument24 pagesVacuum PhysicsThomas BranleyNo ratings yet

- 7a TacheometryDocument19 pages7a Tacheometrysyarifah_arinaNo ratings yet

- Chemsheets As 1005 Ionisation EnergiesDocument2 pagesChemsheets As 1005 Ionisation Energiesangel ranaNo ratings yet

- PHYS1314 Spring 2015 Solution of Homework 2Document5 pagesPHYS1314 Spring 2015 Solution of Homework 2AuHoPangNo ratings yet

- Irc Gov in SP 100 2014 PDFDocument100 pagesIrc Gov in SP 100 2014 PDFGaneshkumar PandiyanNo ratings yet

- PE-209 Lecture-01Document34 pagesPE-209 Lecture-01Adeem AbbasNo ratings yet

- Beam-Column Precast Joint - Breccolotti Et Al - 2016Document16 pagesBeam-Column Precast Joint - Breccolotti Et Al - 2016marcob74100% (2)

- Assoc. Prof. Dr. Emrah Özahi Group B - : Assitant(s) : Alperen TozluDocument45 pagesAssoc. Prof. Dr. Emrah Özahi Group B - : Assitant(s) : Alperen TozluBurak EzelNo ratings yet

- Avogadro's Number: ExampleDocument10 pagesAvogadro's Number: ExampleAnonymous FhH8sPrNo ratings yet

- Chemistry of Silicates and AluminosilicatesDocument12 pagesChemistry of Silicates and AluminosilicatesER NurNo ratings yet

- GX40 CR Ni Si 2512Document2 pagesGX40 CR Ni Si 2512Diego BoiagoNo ratings yet

- The Light Bulb: The Concept of LighteningDocument15 pagesThe Light Bulb: The Concept of LighteningOmar Reda Abdel Hakim El saaedNo ratings yet

- CETRA 2018 Rail Structure Interaction of Bridge Across Balram RiverDocument9 pagesCETRA 2018 Rail Structure Interaction of Bridge Across Balram RiverAnuj AsatiNo ratings yet

- ITs More Fun in The Philippines Vs Wow PhilippinesDocument22 pagesITs More Fun in The Philippines Vs Wow PhilippinesN JoNo ratings yet

- Balancing Redox Reactions - Half-Reaction Method NotesDocument2 pagesBalancing Redox Reactions - Half-Reaction Method NotesSana SyedNo ratings yet

- Examination 1 - Geotechnical Engineering 1Document3 pagesExamination 1 - Geotechnical Engineering 1jefreyNo ratings yet

- Tacómetro Óptico y Mecánico SKFDocument108 pagesTacómetro Óptico y Mecánico SKFValidaciones VicarNo ratings yet

- WIND Sensor TechnologyDocument2 pagesWIND Sensor TechnologyAlvaro EvaristoNo ratings yet

- 2017-LPA KarachiDocument7 pages2017-LPA KarachiHammad RazaNo ratings yet

- UFAD PresentationDocument42 pagesUFAD Presentationsenthilarasu5No ratings yet

- ZKL MRP Pricelist 2011Document55 pagesZKL MRP Pricelist 2011Mahesh Daxini Thakker100% (4)

- ME-503 (B) : Departmental Elective Dynamics of Machine: Department of Mechanical EngineeringDocument226 pagesME-503 (B) : Departmental Elective Dynamics of Machine: Department of Mechanical EngineeringAmit ChandsarkarNo ratings yet

NSK Self

NSK Self

Uploaded by

Chandru VelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NSK Self

NSK Self

Uploaded by

Chandru VelCopyright:

Available Formats

SELF-ALIGNING BALL BEARINGS

SELF-ALIGNING BALL BEARINGS Bore Diameter 5 – 110 mm ··············· B78

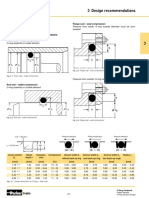

DESIGN, TYPES, AND FEATURES

The outer ring has a spherical raceway and its center of curvature

coincides with that of the bearing; therefore, the axis of the inner ring, balls

and cage can deflect to some extent around the bearing center. This type is

recommended when the alignment of the shaft and housing is difficult and

when the shaft may bend. Since the contact angle is small, the axial load

capacity is low.

Pressed steel cages are usually used.

PROTRUSION AMOUNT OF BALLS

Among self-aligning ball bearings, there are some in which the balls

protrude from the side face as shown below. This protrusion amount b1 is

listed in the following table.

Bearing No. b1 (mm)

b1

2222(K), 2316(K) 0.5

2319(K), 2320(K) 0.5

2321 , 2322(K)

1318(K) 1.5

1319(K) 2

1320(K), 1321 3

1322(K)

TOLERANCES AND RUNNING

ACCURACY ······························································· Table 8.2 (Pages A60 to A63)

RECOMMENDED FITS ·········································· Table 9.2 (Page A84)

Table 9.4 (Page A85)

INTERNAL CLEARANCE ······································· Table 9.12 (Page A90)

PERMISSIBLE MISALIGNMENT

The permissible misalignment of self-aligning ball bearings is

approximately 0.07 to 0.12 radian (4° to 7°) under normal loads. However,

depending on the surrounding structure, such an angle may not be possible.

Use care in the structural design.

B 76 B 77

B076-083E.indd 76-77 11/5/12 5:30:09 PM

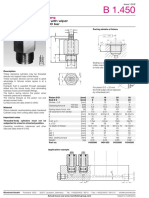

SELF-ALIGNING BALL BEARINGS

Bore Diameter 5 – 30 mm

B B

r r ra

r

ra

Dynamic Equivalent Load

jD jd jD P = X Fr +Y Fa

jd

jD a jda

Fa/ Fr≤e Fa/ Fr>e

X Y X Y

1 Y3 0.65 Y2

Static Equivalent Load

P0 =Fr +Y0 Fa

Cylindrical Bore Tapered Bore

The values of e, Y2 , Y3 , and Y0

are listed in the table below.

Boundary Dimensions Basic Load Ratings Limiting Speeds Bearing Numbers Abutment and Fillet Dimensions Constant Axial Load Factors Mass

(mm) (N) {kgf} (min –1) (mm) (kg)

d D B r Cr C 0r Cr C 0r Grease Oil Cylindrical Tapered da Da ra e Y2 Y3 Y0

min. Bore Bore(1) min. max. max. approx.

5 19 6 0.3 2 530 475 258 49 30 000 36 000 135 — 7 17 0.3 0.34 2.9 1.9 1.9 0.009

6 19 6 0.3 2 530 475 258 49 30 000 36 000 126 — 8 17 0.3 0.34 2.9 1.9 1.9 0.008

7 22 7 0.3 2 750 600 280 61 26 000 32 000 127 — 9 20 0.3 0.31 3.1 2.0 2.1 0.013

8 22 7 0.3 2 750 600 280 61 26 000 32 000 108 — 10 20 0.3 0.31 3.1 2.0 2.1 0.016

9 26 8 0.6 4 150 895 425 91 26 000 30 000 129 — 13 22 0.6 0.32 3.1 2.0 2.1 0.021

10 30 9 0.6 5 550 1 190 570 121 22 000 28 000 1200 — 14 26 0.6 0.32 3.1 2.0 2.1 0.033

30 14 0.6 7 450 1 590 760 162 24 000 28 000 2200 — 14 26 0.6 0.64 1.5 0.98 1.0 0.042

35 11 0.6 7 350 1 620 750 165 20 000 24 000 1300 — 14 31 0.6 0.35 2.8 1.8 1.9 0.057

35 17 0.6 9 200 2 010 935 205 18 000 22 000 2300 — 14 31 0.6 0.71 1.4 0.89 0.93 0.077

12 32 10 0.6 5 700 1 270 580 130 22 000 26 000 1201 — 16 28 0.6 0.36 2.7 1.8 1.8 0.039

32 14 0.6 7 750 1 730 790 177 22 000 26 000 2201 — 16 28 0.6 0.58 1.7 1.1 1.1 0.048

37 12 1 9 650 2 160 985 221 18 000 22 000 1301 — 17 32 1 0.33 2.9 1.9 2.0 0.066

37 17 1 12 100 2 730 1 240 278 17 000 22 000 2301 — 17 32 1 0.60 1.6 1.1 1.1 0.082

15 35 11 0.6 7 600 1 750 775 179 18 000 22 000 1202 — 19 31 0.6 0.32 3.1 2.0 2.1 0.051

35 14 0.6 7 800 1 850 795 188 18 000 22 000 2202 — 19 31 0.6 0.50 1.9 1.3 1.3 0.055

42 13 1 9 700 2 290 990 234 16 000 20 000 1302 — 20 37 1 0.33 2.9 1.9 2.0 0.093

42 17 1 12 300 2 910 1 250 296 14 000 18 000 2302 — 20 37 1 0.51 1.9 1.2 1.3 0.108

17 40 12 0.6 8 000 2 010 815 205 16 000 20 000 1203 — 21 36 0.6 0.31 3.1 2.0 2.1 0.072

40 16 0.6 9 950 2 420 1 010 247 16 000 20 000 2203 — 21 36 0.6 0.50 1.9 1.3 1.3 0.085

47 14 1 12 700 3 200 1 300 325 14 000 17 000 1303 — 22 42 1 0.32 3.1 2.0 2.1 0.13

47 19 1 14 700 3 550 1 500 365 13 000 16 000 2303 — 22 42 1 0.51 1.9 1.2 1.3 0.15

20 47 14 1 10 000 2 610 1 020 266 14 000 17 000 1204 1204 K 25 42 1 0.29 3.4 2.2 2.3 0.12

47 18 1 12 800 3 300 1 310 340 14 000 17 000 2204 2204 K 25 42 1 0.47 2.1 1.3 1.4 0.133

52 15 1.1 12 600 3 350 1 280 340 12 000 15 000 1304 1304 K 26.5 45.5 1 0.29 3.4 2.2 2.3 0.165

52 21 1.1 18 500 4 700 1 880 480 11 000 14 000 2304 2304 K 26.5 45.5 1 0.50 1.9 1.2 1.3 0.193

25 52 15 1 12 200 3 300 1 250 335 12 000 14 000 1205 1205 K 30 47 1 0.28 3.5 2.3 2.4 0.14

52 18 1 12 400 3 450 1 270 350 12 000 14 000 2205 2205 K 30 47 1 0.41 2.4 1.5 1.6 0.15

62 17 1.1 18 200 5 000 1 850 510 10 000 13 000 1305 1305 K 31.5 55.5 1 0.28 3.5 2.3 2.4 0.255

62 24 1.1 24 900 6 600 2 530 675 9 500 12 000 2305 2305 K 31.5 55.5 1 0.47 2.1 1.4 1.4 0.319

30 62 16 1 15 800 4 650 1 610 475 10 000 12 000 1206 1206 K 35 57 1 0.25 3.9 2.5 2.6 0.22

62 20 1 15 300 4 550 1 560 460 10 000 12 000 2206 2206 K 35 57 1 0.38 2.5 1.6 1.7 0.249

72 19 1.1 21 400 6 300 2 190 645 8 500 11 000 1306 1306 K 36.5 65.5 1 0.26 3.7 2.4 2.5 0.385

72 27 1.1 32 000 8 750 3 250 895 8 000 10 000 2306 2306 K 36.5 65.5 1 0.44 2.2 1.4 1.5 0.48

Note (1) The suffix K represents bearings with tapered bores (1 : 12)

Remarks For the dimensions related to adapters, refer to Page B358.

B 78 B 79

B076-083E.indd 78-79 11/5/12 5:30:09 PM

SELF-ALIGNING BALL BEARINGS

Bore Diameter 35 – 70 mm

B B

r r ra

r

ra

Dynamic Equivalent Load

jD jd jD P = X Fr +Y Fa

jd

jD a jda

Fa/ Fr≤e Fa/ Fr>e

X Y X Y

1 Y3 0.65 Y2

Static Equivalent Load

P0 =Fr +Y0 Fa

Cylindrical Bore Tapered Bore

The values of e, Y2 , Y3 , and Y0

are listed in the table below.

Boundary Dimensions Basic Load Ratings Limiting Speeds Bearing Numbers Abutment and Fillet Dimensions Constant Axial Load Factors Mass

(mm) (N) {kgf} (min –1) (mm) (kg)

d D B r Cr C 0r Cr C 0r Grease Oil Cylindrical Tapered da Da ra e Y2 Y3 Y0

min. Bore Bore(1) min. max. max. approx.

35 72 17 1.1 15 900 5 100 1 620 520 8 500 10 000 1207 1207 K 41.5 65.5 1 0.23 4.2 2.7 2.8 0.32

72 23 1.1 21 700 6 600 2 210 675 8 500 10 000 2207 2207 K 41.5 65.5 1 0.37 2.6 1.7 1.8 0.378

80 21 1.5 25 300 7 850 2 580 800 7 500 9 500 1307 1307 K 43 72 1.5 0.26 3.8 2.5 2.6 0.51

80 31 1.5 40 000 11 300 4 100 1 150 7 100 9 000 2307 2307 K 43 72 1.5 0.46 2.1 1.4 1.4 0.642

40 80 18 1.1 19 300 6 500 1 970 665 7 500 9 000 1208 1208 K 46.5 73.5 1 0.22 4.3 2.8 2.9 0.415

80 23 1.1 22 400 7 350 2 290 750 7 500 9 000 2208 2208 K 46.5 73.5 1 0.33 3.0 1.9 2.0 0.477

90 23 1.5 29 800 9 700 3 050 990 6 700 8 500 1308 1308 K 48 82 1.5 0.24 4.0 2.6 2.7 0.715

90 33 1.5 45 500 13 500 4 650 1 380 6 300 8 000 2308 2308 K 48 82 1.5 0.43 2.3 1.5 1.5 0.889

45 85 19 1.1 22 000 7 350 2 240 750 7 100 8 500 1209 1209 K 51.5 78.5 1 0.21 4.7 3.0 3.1 0.465

85 23 1.1 23 300 8 150 2 380 830 7 100 8 500 2209 2209 K 51.5 78.5 1 0.30 3.2 2.1 2.2 0.522

100 25 1.5 38 500 12 700 3 900 1 300 6 000 7 500 1309 1309 K 53 92 1.5 0.25 4.0 2.6 2.7 0.955

100 36 1.5 55 000 16 700 5 600 1 700 5 600 7 100 2309 2309 K 53 92 1.5 0.41 2.4 1.5 1.6 1.2

50 90 20 1.1 22 800 8 100 2 330 830 6 300 8 000 1210 1210 K 56.5 83.5 1 0.21 4.7 3.1 3.2 0.525

90 23 1.1 23 300 8 450 2 380 865 6 300 8 000 2210 2210 K 56.5 83.5 1 0.28 3.4 2.2 2.3 0.564

110 27 2 43 500 14 100 4 450 1 440 5 600 6 700 1310 1310 K 59 101 2 0.23 4.2 2.7 2.8 1.25

110 40 2 65 000 20 200 6 650 2 060 5 000 6 300 2310 2310 K 59 101 2 0.42 2.3 1.5 1.6 1.58

55 100 21 1.5 26 900 10 000 2 750 1 020 6 000 7 100 1211 1211 K 63 92 1.5 0.20 4.9 3.2 3.3 0.705

100 25 1.5 26 700 9 900 2 720 1 010 6 000 7 100 2211 2211 K 63 92 1.5 0.28 3.5 2.3 2.4 0.746

120 29 2 51 500 17 900 5 250 1 820 5 000 6 300 1311 1311 K 64 111 2 0.23 4.2 2.7 2.8 1.6

120 43 2 76 500 24 000 7 800 2 450 4 800 6 000 2311 2311 K 64 111 2 0.41 2.4 1.5 1.6 2.03

60 110 22 1.5 30 500 11 500 3 100 1 180 5 300 6 300 1212 1212 K 68 102 1.5 0.18 5.3 3.4 3.6 0.90

110 28 1.5 34 000 12 600 3 500 1 290 5 300 6 300 2212 2212 K 68 102 1.5 0.28 3.5 2.3 2.4 1.03

130 31 2.1 57 500 20 800 5 900 2 130 4 500 5 600 1312 1312 K 71 119 2 0.23 4.3 2.8 2.9 2.03

130 46 2.1 88 500 28 300 9 000 2 880 4 300 5 300 2312 2312 K 71 119 2 0.40 2.4 1.6 1.6 2.57

65 120 23 1.5 31 000 12 500 3 150 1 280 4 800 6 000 1213 1213 K 73 112 1.5 0.17 5.7 3.7 3.8 1.15

120 31 1.5 43 500 16 400 4 450 1 670 4 800 6 000 2213 2213 K 73 112 1.5 0.28 3.5 2.3 2.4 1.4

140 33 2.1 62 500 22 900 6 350 2 330 4 300 5 300 1313 1313 K 76 129 2 0.23 4.2 2.7 2.9 2.54

140 48 2.1 97 000 32 500 9 900 3 300 3 800 4 800 2313 2313 K 76 129 2 0.39 2.5 1.6 1.7 3.2

70 125 24 1.5 35 000 13 800 3 550 1 410 4 800 5 600 1214 — 78 117 1.5 0.18 5.3 3.4 3.6 1.3

125 31 1.5 44 000 17 100 4 500 1 740 4 500 5 600 2214 — 78 117 1.5 0.26 3.7 2.4 2.5 1.52

150 35 2.1 75 000 27 700 7 650 2 830 4 000 5 000 1314 — 81 139 2 0.22 4.4 2.8 3.0 3.19

150 51 2.1 111 000 37 500 11 300 3 850 3 600 4 500 2314 — 81 139 2 0.38 2.6 1.7 1.8 3.9

Note (1) The suffix K represents bearings with tapered bores (1 : 12)

Remarks For the dimensions related to adapters, refer to Page B358 and B359.

B 80 B 81

B076-083E.indd 80-81 11/5/12 5:30:10 PM

SELF-ALIGNING BALL BEARINGS

Bore Diameter 75 – 110 mm

B B

r r ra

r

ra

Dynamic Equivalent Load

jD jd jD P = X Fr +Y Fa

jd

jD a jda

Fa/ Fr≤e Fa/ Fr>e

X Y X Y

1 Y3 0.65 Y2

Static Equivalent Load

P0 =Fr +Y0 Fa

Cylindrical Bore Tapered Bore

The values of e, Y2 , Y3 , and Y0

are listed in the table below.

Boundary Dimensions Basic Load Ratings Limiting Speeds Bearing Numbers Abutment and Fillet Dimensions Constant Axial Load Factors Mass

(mm) (N) {kgf} (min –1) (mm) (kg)

d D B r Cr C 0r Cr C 0r Grease Oil Cylindrical Tapered da Da ra e Y2 Y3 Y0

min. Bore Bore(1) min. max. max. approx.

75 130 25 1.5 39 000 15 700 4 000 1 600 4 300 5 300 1215 1215 K 83 122 1.5 0.17 5.6 3.6 3.8 1.41

130 31 1.5 44 500 17 800 4 550 1 820 4 300 5 300 2215 2215 K 83 122 1.5 0.25 3.9 2.5 2.6 1.6

160 37 2.1 80 000 30 000 8 150 3 050 3 800 4 500 1315 1315 K 86 149 2 0.22 4.4 2.8 2.9 3.65

160 55 2.1 125 000 43 000 12 700 4 400 3 400 4 300 2315 2315 K 86 149 2 0.38 2.5 1.6 1.7 4.77

80 140 26 2 40 000 17 000 4 100 1 730 4 000 5 000 1216 1216 K 89 131 2 0.16 6.0 3.9 4.1 1.73

140 33 2 49 000 19 900 5 000 2 030 4 000 5 000 2216 2216 K 89 131 2 0.25 3.9 2.5 2.7 1.97

170 39 2.1 89 000 33 000 9 100 3 400 3 600 4 300 1316 1316 K 91 159 2 0.22 4.5 2.9 3.1 4.31

170 58 2.1 130 000 45 000 13 200 4 600 3 200 4 000 * 2316 * 2316 K 91 159 2 0.39 2.5 1.6 1.7 5.54

85 150 28 2 49 500 20 800 5 050 2 120 3 800 4 500 1217 1217 K 94 141 2 0.17 5.7 3.7 3.8 2.09

150 36 2 58 500 23 600 5 950 2 400 3 800 4 800 2217 2217 K 94 141 2 0.25 3.9 2.5 2.6 2.48

180 41 3 98 500 38 000 10 000 3 850 3 400 4 000 1317 1317 K 98 167 2.5 0.21 4.6 2.9 3.1 5.13

180 60 3 142 000 51 500 14 500 5 250 3 000 3 800 2317 2317 K 98 167 2.5 0.37 2.6 1.7 1.8 6.56

90 160 30 2 57 500 23 500 5 850 2 400 3 600 4 300 1218 1218 K 99 151 2 0.17 5.8 3.8 3.9 2.55

160 40 2 70 500 28 700 7 200 2 930 3 600 4 300 2218 2218 K 99 151 2 0.27 3.7 2.4 2.5 3.13

190 43 3 117 000 44 500 12 000 4 550 3 200 3 800 * 1318 * 1318 K 103 177 2.5 0.22 4.3 2.8 2.9 5.94

190 64 3 154 000 57 500 15 700 5 850 2 800 3 600 2318 2318 K 103 177 2.5 0.38 2.6 1.7 1.7 7.76

95 170 32 2.1 64 000 27 100 6 550 2 770 3 400 4 000 1219 1219 K 106 159 2 0.17 5.8 3.7 3.9 3.21

170 43 2.1 84 000 34 500 8 550 3 500 3 400 4 000 2219 2219 K 106 159 2 0.27 3.7 2.4 2.5 3.87

200 45 3 129 000 51 000 13 200 5 200 3 000 3 600 * 1319 * 1319 K 108 187 2.5 0.23 4.3 2.8 2.9 6.84

200 67 3 161 000 64 500 16 400 6 550 2 800 3 400 * 2319 * 2319 K 108 187 2.5 0.38 2.6 1.7 1.8 9.01

100 180 34 2.1 69 500 29 700 7 100 3 050 3 200 3 800 1220 1220 K 111 169 2 0.17 5.6 3.6 3.8 3.82

180 46 2.1 94 500 38 500 9 650 3 900 3 200 3 800 2220 2220 K 111 169 2 0.27 3.7 2.4 2.5 4.53

215 47 3 140 000 57 500 14 300 5 850 2 800 3 400 * 1320 * 1320 K 113 202 2.5 0.24 4.1 2.7 2.8 8.46

215 73 3 187 000 79 000 19 100 8 050 2 400 3 200 * 2320 * 2320 K 113 202 2.5 0.38 2.6 1.7 1.8 11.6

105 190 36 2.1 75 000 32 500 7 650 3 300 3 000 3 600 1221 — 116 179 2 0.18 5.5 3.6 3.7 4.52

190 50 2.1 109 000 45 000 11 100 4 550 3 000 3 600 2221 — 116 179 2 0.28 3.5 2.3 2.4 5.64

225 49 3 154 000 64 500 15 700 6 600 2 600 3 200 * 1321 — 118 212 2.5 0.23 4.2 2.7 2.9 10

225 77 3 200 000 87 000 20 400 8 850 2 400 3 000 * 2321 — 118 212 2.5 0.38 2.6 1.7 1.7 14.4

110 200 38 2.1 87 000 38 500 8 900 3 950 2 800 3 400 1222 1222 K 121 189 2 0.17 5.7 3.7 3.9 5.33

200 53 2.1 122 000 51 500 12 500 5 250 2 800 3 400 * 2222 * 2222 K 121 189 2 0.28 3.5 2.2 2.3 6.64

240 50 3 161 000 72 000 16 400 7 300 2 400 3 000 * 1322 * 1322 K 123 227 2.5 0.22 4.4 2.8 3.0 12

240 80 3 211 000 94 500 21 600 9 650 2 200 2 800 * 2322 * 2322 K 123 227 2.5 0.37 2.6 1.7 1.8 17.4

Notes (1) The suffix K represents bearings with tapered bores (1 : 12)

(*) The balls of the bearings marked * protrude slightly from the bearing face. The protrusion amounts are shown on

Page B77.

Remarks For the dimensions related to adapters, refer to Pages B360 and B361.

B 82 B 83

B076-083E.indd 82-83 11/5/12 5:30:11 PM

You might also like

- 21 Spherical Plain BearingDocument26 pages21 Spherical Plain Bearingjitendrapanda336No ratings yet

- Self-Aligning Ball BearingsDocument7 pagesSelf-Aligning Ball BearingsVarsha SinghNo ratings yet

- Spherical Roller Bearings Exq Series NachiDocument8 pagesSpherical Roller Bearings Exq Series Nachijuan gordonNo ratings yet

- Bearing Tables Thrust Cylindrical Roller BearingsDocument14 pagesBearing Tables Thrust Cylindrical Roller BearingsNemanja DavidovicNo ratings yet

- THK Spherical Rod EndsDocument80 pagesTHK Spherical Rod EndsСергій СушкоNo ratings yet

- CAM & Follower FinalDocument14 pagesCAM & Follower FinalRohit NewarNo ratings yet

- Single-Row and Matched Angular Contact Ball BearingsDocument15 pagesSingle-Row and Matched Angular Contact Ball BearingsThái Mai ĐìnhNo ratings yet

- Cat173ex - RHR SRBsDocument5 pagesCat173ex - RHR SRBsTiago AnaniasNo ratings yet

- FAG Rolling Bearings Current InsulatedDocument6 pagesFAG Rolling Bearings Current InsulatedMekanisasi SubangNo ratings yet

- Catalogue of Spherical Roller and Special BearingsDocument67 pagesCatalogue of Spherical Roller and Special BearingsVolodymyrNo ratings yet

- Steel Connections: ResultsDocument6 pagesSteel Connections: ResultsJay SalasNo ratings yet

- Caged, With Inner Ring, No End Washers, Sealed, Yoke-Type (Na22 Series)Document1 pageCaged, With Inner Ring, No End Washers, Sealed, Yoke-Type (Na22 Series)Anonymous yQ7SQrNo ratings yet

- ISB Supporti Autoallineanti Self Aligning Bearing Units 01.09.19 - 5Document1 pageISB Supporti Autoallineanti Self Aligning Bearing Units 01.09.19 - 5Antonio FacipieriNo ratings yet

- Thrust Ball BearingsDocument9 pagesThrust Ball BearingsHydro PartsNo ratings yet

- It Should Be Less Than R /3 or 10mDocument5 pagesIt Should Be Less Than R /3 or 10mMawan BentzNo ratings yet

- Hyundai Steel Products GuideDocument40 pagesHyundai Steel Products GuidecarloNo ratings yet

- Ch14 BearingsDocument76 pagesCh14 Bearingsabdallah ghannamNo ratings yet

- Valores de Correcion Del Factor de Velocidad de Las Grasas LubricantesDocument8 pagesValores de Correcion Del Factor de Velocidad de Las Grasas LubricantesLeonardo CardosoNo ratings yet

- Rod End: A Product DescriptionsDocument18 pagesRod End: A Product DescriptionsNopNo ratings yet

- NIKO Track Roller Bearing CatalogueDocument29 pagesNIKO Track Roller Bearing CataloguezhiqianxuNo ratings yet

- ZKL Brno Katalog 2007 enDocument74 pagesZKL Brno Katalog 2007 enPhanHathamNo ratings yet

- Final Exam AppendixDocument2 pagesFinal Exam AppendixGeorge AbdallahNo ratings yet

- Spur Gear CalculationsDocument7 pagesSpur Gear Calculationsaniket patilNo ratings yet

- Timken Part Number H242649 - H242610CD, Tapered Roller Bearings - TDO (Tapered Double Outer) ImperialDocument5 pagesTimken Part Number H242649 - H242610CD, Tapered Roller Bearings - TDO (Tapered Double Outer) ImperialHector DuarteNo ratings yet

- E1224Document3 pagesE1224Alejandro Garcia FloresNo ratings yet

- NSK FreeDocument3 pagesNSK FreeSachin NambiarNo ratings yet

- Plastic Section Moduli For I.S. Rolled Steel Beam Sections Zpy About Y-Y AxisDocument8 pagesPlastic Section Moduli For I.S. Rolled Steel Beam Sections Zpy About Y-Y AxisIJRASETPublicationsNo ratings yet

- SHAFT GoodSod Deriv07Document10 pagesSHAFT GoodSod Deriv07Theodoros AtheridisNo ratings yet

- Introduction To Antifriction BearingsDocument39 pagesIntroduction To Antifriction BearingsTalha AhmadNo ratings yet

- Parker Piston Seal StaticDocument5 pagesParker Piston Seal Statictarno12No ratings yet

- CEA FINAL-converted Word FileDocument5 pagesCEA FINAL-converted Word FilePol OlmedillaNo ratings yet

- Bearing Shaft Fits and Tolerances 1Document9 pagesBearing Shaft Fits and Tolerances 1Arun KumarNo ratings yet

- Bearing FitsDocument9 pagesBearing Fitsm2110No ratings yet

- SHAFT-GoodSod Deriv07Document11 pagesSHAFT-GoodSod Deriv07Raj Bahadur YadavNo ratings yet

- High-Performance External Gear Pump Azpb: FeaturesDocument4 pagesHigh-Performance External Gear Pump Azpb: FeaturesMichail ArmitageNo ratings yet

- Bearing Basics PDFDocument112 pagesBearing Basics PDFSPELECTRICAL NINLNo ratings yet

- Ball Thrust Bearings - American Roller BearingDocument3 pagesBall Thrust Bearings - American Roller BearingAyushKumarJaiswalNo ratings yet

- Bearing FitsDocument7 pagesBearing FitsBurak KoyuncuogluNo ratings yet

- Bridge Engineering Handbook Ch13Document25 pagesBridge Engineering Handbook Ch13Vladimir VozianNo ratings yet

- (Static) : Radial Outer SealingDocument2 pages(Static) : Radial Outer SealingVratislav Němec ml.No ratings yet

- Gearing AgmaDocument17 pagesGearing AgmaDomingos AzevedoNo ratings yet

- EX0604Document4 pagesEX0604igualdi53No ratings yet

- Single Acting, Spring Return, With Wiper Max. Operating Pressure 500 BarDocument1 pageSingle Acting, Spring Return, With Wiper Max. Operating Pressure 500 BarmirzetNo ratings yet

- Linear GuideDocument1,539 pagesLinear Guidered_shobo_85No ratings yet

- Laterally LoadDocument92 pagesLaterally LoadMadhusudan MadhuNo ratings yet

- Restriction Orifice T95500enDocument2 pagesRestriction Orifice T95500enCarlos SopasNo ratings yet

- Babbitt (Metal) : Babbitt, Also Called Babbitt Metal or Bearing Metal, Is Any of SeveralDocument6 pagesBabbitt (Metal) : Babbitt, Also Called Babbitt Metal or Bearing Metal, Is Any of SeveralCarlos BustamanteNo ratings yet

- SKF NameDocument26 pagesSKF NameIslam Fawzy100% (1)

- LAGOS DORMITORY-BeamDesignDocument147 pagesLAGOS DORMITORY-BeamDesignadetokunbo fapuroNo ratings yet

- L357049NW L357010CD TaperedRollerBearings TDO (TaperedDoubleOuter) ImperialDocument5 pagesL357049NW L357010CD TaperedRollerBearings TDO (TaperedDoubleOuter) ImperialMohamed AliNo ratings yet

- SpringsDocument31 pagesSpringsyoussef.mahmoud031No ratings yet

- RTJ PDFDocument5 pagesRTJ PDFEmiliano ZappaterraNo ratings yet

- H006 011Document7 pagesH006 011Guilherme FleschNo ratings yet

- Timken Ball Bearing Catalog 10734Document126 pagesTimken Ball Bearing Catalog 10734NeoNo ratings yet

- Struc DGN U DrainDocument131 pagesStruc DGN U Drainsudhirkumarsharma1966No ratings yet

- Wind CoefficientDocument2 pagesWind Coefficientvisva scgNo ratings yet

- 33-Synchronous Generators Part2 PDFDocument4 pages33-Synchronous Generators Part2 PDFpurseyNo ratings yet

- Design of BearingsDocument46 pagesDesign of BearingsSatyaprakash Dinesh Vispute100% (1)

- (Static) : Radial Outer SealingDocument2 pages(Static) : Radial Outer SealingAntonio Carlos Gaspar JuniorNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- File 5e87d775f21ecDocument6 pagesFile 5e87d775f21ecChandru VelNo ratings yet

- US4458549Document8 pagesUS4458549Chandru VelNo ratings yet

- 0817 TTDocument1 page0817 TTChandru VelNo ratings yet

- Research On Automatic Programming Methods of CNC Machining Parameters of GearDocument3 pagesResearch On Automatic Programming Methods of CNC Machining Parameters of GearChandru VelNo ratings yet

- Jäœehl Ä C G Â K W G ®KHD¡ FHF Èäbl : Ä F LZ UójDocument1 pageJäœehl Ä C G Â K W G ®KHD¡ FHF Èäbl : Ä F LZ UójChandru VelNo ratings yet

- Software For Calculation of Involute Splines According To ISO 4156 and ANSI B92.2MDocument2 pagesSoftware For Calculation of Involute Splines According To ISO 4156 and ANSI B92.2MChandru VelNo ratings yet

- Theoretical Calculation and Simulation Analysis of No-Load Torque of Main ReducerDocument7 pagesTheoretical Calculation and Simulation Analysis of No-Load Torque of Main ReducerChandru VelNo ratings yet

- Guide For Safety and Comfort of Operator of Agricultural Tractors and Power TillersDocument14 pagesGuide For Safety and Comfort of Operator of Agricultural Tractors and Power TillersChandru VelNo ratings yet

- Transaction Status: Transaction ID: Transaction Date Time: Transaction Reference No.: Consumer No: Transaction Amount: Payment ModeDocument1 pageTransaction Status: Transaction ID: Transaction Date Time: Transaction Reference No.: Consumer No: Transaction Amount: Payment ModeChandru VelNo ratings yet

- HTD Shcs 12.9 T TorqueDocument1 pageHTD Shcs 12.9 T TorqueChandru Vel100% (1)

- Module 3Document51 pagesModule 3Chandru VelNo ratings yet

- GT 1190Document52 pagesGT 1190Chandru VelNo ratings yet

- Botany J-Adhikary Enzymology 1Document17 pagesBotany J-Adhikary Enzymology 1Bhagirath GogikarNo ratings yet

- 05 Graphical Analysis of MotionDocument31 pages05 Graphical Analysis of MotionAnish Anshuman ChoudhuryNo ratings yet

- Sound in Architecture PDFDocument5 pagesSound in Architecture PDFDiana DidiNo ratings yet

- Partial Pressure DeterminationDocument5 pagesPartial Pressure Determinationanon_378146815No ratings yet

- Diffraction ExperimentsDocument5 pagesDiffraction ExperimentsArooj Mukarram100% (2)

- WIZ SeriesDocument4 pagesWIZ SeriesJon HamonNo ratings yet

- Basalt Rock Rebar 01 - Materials - Rebar: Why Not Use Regular Steel Rebar?Document7 pagesBasalt Rock Rebar 01 - Materials - Rebar: Why Not Use Regular Steel Rebar?Sahil GandhiNo ratings yet

- M 11 L 29Document18 pagesM 11 L 29Mandar NadgaundiNo ratings yet

- Vacuum PhysicsDocument24 pagesVacuum PhysicsThomas BranleyNo ratings yet

- 7a TacheometryDocument19 pages7a Tacheometrysyarifah_arinaNo ratings yet

- Chemsheets As 1005 Ionisation EnergiesDocument2 pagesChemsheets As 1005 Ionisation Energiesangel ranaNo ratings yet

- PHYS1314 Spring 2015 Solution of Homework 2Document5 pagesPHYS1314 Spring 2015 Solution of Homework 2AuHoPangNo ratings yet

- Irc Gov in SP 100 2014 PDFDocument100 pagesIrc Gov in SP 100 2014 PDFGaneshkumar PandiyanNo ratings yet

- PE-209 Lecture-01Document34 pagesPE-209 Lecture-01Adeem AbbasNo ratings yet

- Beam-Column Precast Joint - Breccolotti Et Al - 2016Document16 pagesBeam-Column Precast Joint - Breccolotti Et Al - 2016marcob74100% (2)

- Assoc. Prof. Dr. Emrah Özahi Group B - : Assitant(s) : Alperen TozluDocument45 pagesAssoc. Prof. Dr. Emrah Özahi Group B - : Assitant(s) : Alperen TozluBurak EzelNo ratings yet

- Avogadro's Number: ExampleDocument10 pagesAvogadro's Number: ExampleAnonymous FhH8sPrNo ratings yet

- Chemistry of Silicates and AluminosilicatesDocument12 pagesChemistry of Silicates and AluminosilicatesER NurNo ratings yet

- GX40 CR Ni Si 2512Document2 pagesGX40 CR Ni Si 2512Diego BoiagoNo ratings yet

- The Light Bulb: The Concept of LighteningDocument15 pagesThe Light Bulb: The Concept of LighteningOmar Reda Abdel Hakim El saaedNo ratings yet

- CETRA 2018 Rail Structure Interaction of Bridge Across Balram RiverDocument9 pagesCETRA 2018 Rail Structure Interaction of Bridge Across Balram RiverAnuj AsatiNo ratings yet

- ITs More Fun in The Philippines Vs Wow PhilippinesDocument22 pagesITs More Fun in The Philippines Vs Wow PhilippinesN JoNo ratings yet

- Balancing Redox Reactions - Half-Reaction Method NotesDocument2 pagesBalancing Redox Reactions - Half-Reaction Method NotesSana SyedNo ratings yet

- Examination 1 - Geotechnical Engineering 1Document3 pagesExamination 1 - Geotechnical Engineering 1jefreyNo ratings yet

- Tacómetro Óptico y Mecánico SKFDocument108 pagesTacómetro Óptico y Mecánico SKFValidaciones VicarNo ratings yet

- WIND Sensor TechnologyDocument2 pagesWIND Sensor TechnologyAlvaro EvaristoNo ratings yet

- 2017-LPA KarachiDocument7 pages2017-LPA KarachiHammad RazaNo ratings yet

- UFAD PresentationDocument42 pagesUFAD Presentationsenthilarasu5No ratings yet

- ZKL MRP Pricelist 2011Document55 pagesZKL MRP Pricelist 2011Mahesh Daxini Thakker100% (4)

- ME-503 (B) : Departmental Elective Dynamics of Machine: Department of Mechanical EngineeringDocument226 pagesME-503 (B) : Departmental Elective Dynamics of Machine: Department of Mechanical EngineeringAmit ChandsarkarNo ratings yet