Professional Documents

Culture Documents

FMEA Dilemma and Countermeasures

FMEA Dilemma and Countermeasures

Uploaded by

Tahan SibueaCopyright:

Available Formats

You might also like

- FMEA 5th TablesDocument41 pagesFMEA 5th TablesR.BALASUBRAMANI100% (4)

- Marriage - FMEADocument1 pageMarriage - FMEAHariramNo ratings yet

- International Electrotechnical Commission: (Iecq HSPM)Document16 pagesInternational Electrotechnical Commission: (Iecq HSPM)biomech99100% (1)

- Process Hazard Analysis: (Failure Mode Effect Analysis)Document41 pagesProcess Hazard Analysis: (Failure Mode Effect Analysis)Nate JamesNo ratings yet

- IE Feasibility Study FormatDocument5 pagesIE Feasibility Study FormatiecscstNo ratings yet

- Chapter 15 - Lean Operations and JITDocument6 pagesChapter 15 - Lean Operations and JITmoza_musliuNo ratings yet

- LVHMDocument44 pagesLVHMNguyen Tuan VinhNo ratings yet

- QSG Quality Support Group Angelo Scangas Laura Halleck AIAG VDA FMEA IEEEDocument35 pagesQSG Quality Support Group Angelo Scangas Laura Halleck AIAG VDA FMEA IEEEEvandro MinatoNo ratings yet

- Design Failure Mode and Effect Analysis - Case StuDocument13 pagesDesign Failure Mode and Effect Analysis - Case Stusanjay chamoliNo ratings yet

- Peration Anagement: Concept of Quality Juran's PrincipleDocument24 pagesPeration Anagement: Concept of Quality Juran's PrincipleAyushi BisenNo ratings yet

- Seminar On Statistical Process Control On Cylinder LinersDocument56 pagesSeminar On Statistical Process Control On Cylinder LinersSatadru BeraNo ratings yet

- Product Characteristics ClassificationDocument9 pagesProduct Characteristics Classification80ALLA86iNo ratings yet

- IATF Rules 5th Edition - FAQs 1 3 - 23jan2017 - FINAL PDFDocument6 pagesIATF Rules 5th Edition - FAQs 1 3 - 23jan2017 - FINAL PDFsathyabalaramanNo ratings yet

- Repeatability and Reproducibility StudyDocument4 pagesRepeatability and Reproducibility Studysivaseeni100% (1)

- FMEA PG Seminar For WebsiteDocument21 pagesFMEA PG Seminar For WebsiteMuhd HazwanNo ratings yet

- Legal Concerns in Drafting A Policy For Reporting FraudDocument6 pagesLegal Concerns in Drafting A Policy For Reporting FraudFrancisco BraganzaNo ratings yet

- SGS CBE ISO 45001 Brochure A4 en InteractiveDocument7 pagesSGS CBE ISO 45001 Brochure A4 en InteractiveTatiana RiloNo ratings yet

- Aiag Fmea TrainingDocument10 pagesAiag Fmea TrainingJohn OoNo ratings yet

- Effects of Radiation On PlantsDocument35 pagesEffects of Radiation On PlantsOkaroFrankNo ratings yet

- Trailer IATF DocumentsDocument77 pagesTrailer IATF DocumentsSridharan VenkatNo ratings yet

- Xfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following FormsDocument6 pagesXfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following FormsRoland JoldisNo ratings yet

- Fundamentals of FMEA PDFDocument35 pagesFundamentals of FMEA PDFPriatna suheriNo ratings yet

- Fmea Alignment Aiag and VdaDocument14 pagesFmea Alignment Aiag and Vdahaitem100% (1)

- 19R-18-ME-137-Project Risk ManagementDocument15 pages19R-18-ME-137-Project Risk Managementkamran bhatNo ratings yet

- Communication On Progress (Cop) : The Ten Principles of The United Nations Global CompactDocument46 pagesCommunication On Progress (Cop) : The Ten Principles of The United Nations Global CompactVikrant KambleNo ratings yet

- MSA (Measurement System Analys)Document19 pagesMSA (Measurement System Analys)Dazslam New VersionNo ratings yet

- Boleh Merevisi Kriteria Severity, Kecuali 9 Dan 10Document3 pagesBoleh Merevisi Kriteria Severity, Kecuali 9 Dan 10Reza WijayaNo ratings yet

- Intelligent Use of FMEA Presented By: Quality Associates InternationalDocument66 pagesIntelligent Use of FMEA Presented By: Quality Associates Internationalpradeep100% (1)

- GAMP5Document56 pagesGAMP5mkm969100% (1)

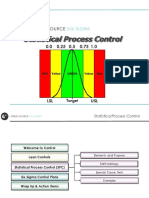

- SPC Training Material - 18!04!2018Document34 pagesSPC Training Material - 18!04!2018Rajesh KumarNo ratings yet

- The 5-Whys' Method: Example 1Document3 pagesThe 5-Whys' Method: Example 1initiative1972No ratings yet

- Lean Six Sigma ToolkitDocument63 pagesLean Six Sigma ToolkitLOLIMNo ratings yet

- SWOT Analysis and Project Selection MatrixDocument2 pagesSWOT Analysis and Project Selection MatrixSudhagarNo ratings yet

- G3 1 Index and ChecklistDocument123 pagesG3 1 Index and ChecklistWendy Al SyabanaNo ratings yet

- Case Study On FMEA Problem SolvingDocument6 pagesCase Study On FMEA Problem Solvingmg2001No ratings yet

- Warm-Up - Day 2: Place Self Others Team Purpose AgendaDocument85 pagesWarm-Up - Day 2: Place Self Others Team Purpose AgendaSanjeev SharmaNo ratings yet

- Welcome - Day 1 2012: Failure Mode and Effects AnalysisDocument63 pagesWelcome - Day 1 2012: Failure Mode and Effects AnalysisKaya Eralp AsanNo ratings yet

- QA-REC-122 Attiribute MSADocument4 pagesQA-REC-122 Attiribute MSAsunita choudharyNo ratings yet

- FINAL CB Training Package - Single MFG Site With Extended Site - 16feb2016-1Document58 pagesFINAL CB Training Package - Single MFG Site With Extended Site - 16feb2016-1Mauro PlatiniNo ratings yet

- Chiro - Requirements - Traceability - Matrix ExerciseDocument11 pagesChiro - Requirements - Traceability - Matrix ExerciseAkash AgarwalNo ratings yet

- The Case Against The AIAG-VDA DFMEADocument22 pagesThe Case Against The AIAG-VDA DFMEA57641No ratings yet

- 8D Problem AnalysisDocument99 pages8D Problem AnalysisLorena Martinez LaraNo ratings yet

- 15 Mistake ProofingDocument4 pages15 Mistake ProofingSteven Bonacorsi100% (2)

- Sec 04 IATF 16949 RequirementsDocument21 pagesSec 04 IATF 16949 RequirementsIsmehen TrabelsiNo ratings yet

- Internal Qms Audit Summary: Major/Minor/OIDocument33 pagesInternal Qms Audit Summary: Major/Minor/OIMEHAKNo ratings yet

- MRM Full ReportDocument47 pagesMRM Full Reportkoza12345678No ratings yet

- Updates Dec09 AIAG FMEA-Ranking-TablesDocument3 pagesUpdates Dec09 AIAG FMEA-Ranking-TablesSuresh Velu100% (1)

- Safety Dependabilty Durability Requirements EPS BL 3 0Document49 pagesSafety Dependabilty Durability Requirements EPS BL 3 0monutilisation0No ratings yet

- Processaudit VDA 6.3 - RecentDocument32 pagesProcessaudit VDA 6.3 - RecentAnkurNo ratings yet

- AQE (FMEA) Selling DocumentDocument17 pagesAQE (FMEA) Selling DocumentArshad AnsariNo ratings yet

- 2.1 EMS LA Delegate Manual - Clause 9-10Document14 pages2.1 EMS LA Delegate Manual - Clause 9-10Ali AlamranNo ratings yet

- PAPP Checklists and Forms PDFDocument4 pagesPAPP Checklists and Forms PDFsathyabalaramanNo ratings yet

- PCP & FmeaDocument4 pagesPCP & FmeaDaniela AscolaniNo ratings yet

- Moudling Operation GSIC Process: MouldingDocument13 pagesMoudling Operation GSIC Process: MouldingBalakumaran MurugesanNo ratings yet

- Case Study ShavingDocument5 pagesCase Study ShavingtitinNo ratings yet

- Mandatory Documents For IatfDocument6 pagesMandatory Documents For Iatfdhir.ankurNo ratings yet

- Checksheet Error ProofingDocument4 pagesChecksheet Error ProofingEzhilarasan DhoniNo ratings yet

- Formel Q-Capability Version 6.0 Supplier Training - Product AuditDocument11 pagesFormel Q-Capability Version 6.0 Supplier Training - Product AuditVijay LadNo ratings yet

- Agile Essentials You Always Wanted To Know: Self Learning ManagementFrom EverandAgile Essentials You Always Wanted To Know: Self Learning ManagementNo ratings yet

- 1.0 Dfmea PDFDocument127 pages1.0 Dfmea PDFDilip KulkarniNo ratings yet

- FINC304 Managerial Economics: Session 7: Organisation of The FirmDocument13 pagesFINC304 Managerial Economics: Session 7: Organisation of The FirmJephthah BansahNo ratings yet

- MIS Assignment: Systems Approach and CyberneticsDocument6 pagesMIS Assignment: Systems Approach and CyberneticsmrityunjayNo ratings yet

- 6002 - Group 3 - Urban Wind Group PresentationDocument15 pages6002 - Group 3 - Urban Wind Group Presentationsinichi33No ratings yet

- Thematic Analysis On The Teachers Dialogic Scaffolding Practices and Students Expression of Argumentation Agency PDFDocument287 pagesThematic Analysis On The Teachers Dialogic Scaffolding Practices and Students Expression of Argumentation Agency PDFTahan SibueaNo ratings yet

- Statistical Process Control PDFDocument66 pagesStatistical Process Control PDFTahan SibueaNo ratings yet

- Who - Sample Size DeterminationDocument57 pagesWho - Sample Size DeterminationTahan SibueaNo ratings yet

- 10 Tips For Highly Successful Quality LeadersDocument7 pages10 Tips For Highly Successful Quality LeadersTahan SibueaNo ratings yet

- 2014 Annual QM Management ReportDocument107 pages2014 Annual QM Management ReportTahan SibueaNo ratings yet

- 8 Wastes Check SheetDocument3 pages8 Wastes Check SheetTahan SibueaNo ratings yet

- Facility Validation - Theory, Practice, and Tools (PDFDrive)Document142 pagesFacility Validation - Theory, Practice, and Tools (PDFDrive)Tahan Sibuea100% (1)

- 7 Steps To Be IMPACTFUL As A Quality ManagerDocument7 pages7 Steps To Be IMPACTFUL As A Quality ManagerTahan SibueaNo ratings yet

- 3 Pillars of Effective Supplier Management: Ed PotoczakDocument7 pages3 Pillars of Effective Supplier Management: Ed PotoczakTahan SibueaNo ratings yet

- Process Capability - A Managers Tool For 6 Sigma Quality AdvantageDocument9 pagesProcess Capability - A Managers Tool For 6 Sigma Quality AdvantageTahan SibueaNo ratings yet

- GWP Verification White Paper - Safety FactorDocument2 pagesGWP Verification White Paper - Safety FactorTahan SibueaNo ratings yet

- MAXIMIZER™ Quick Change Squeegee, Black 2018801Document2 pagesMAXIMIZER™ Quick Change Squeegee, Black 2018801Tahan SibueaNo ratings yet

- GWP Verification White Paper - Performance VerificationDocument2 pagesGWP Verification White Paper - Performance VerificationTahan SibueaNo ratings yet

- 5 Techniques For Pressure Gauge Adjustment and Repair - Calibration AwarenessDocument9 pages5 Techniques For Pressure Gauge Adjustment and Repair - Calibration AwarenessTahan SibueaNo ratings yet

- Learner-Verification Essentials of European Medical Device Regulation (EU MDR) - 2017 - 745Document1 pageLearner-Verification Essentials of European Medical Device Regulation (EU MDR) - 2017 - 745Tahan SibueaNo ratings yet

- 27 GPS-VToolbox 131-139Document10 pages27 GPS-VToolbox 131-139Tahan SibueaNo ratings yet

- Learner Verification 9001 - 2015 Quality Management System (QMS)Document1 pageLearner Verification 9001 - 2015 Quality Management System (QMS)Tahan SibueaNo ratings yet

- Process Validation - DR Asmaa El-Kersh, M.SCDocument44 pagesProcess Validation - DR Asmaa El-Kersh, M.SCTahan SibueaNo ratings yet

- Learner-Verification Diploma in ISO Standards - Integrated Management System (IMS)Document2 pagesLearner-Verification Diploma in ISO Standards - Integrated Management System (IMS)Tahan SibueaNo ratings yet

- Quality Gurus / TQM Philosophers: Chapter 2Document22 pagesQuality Gurus / TQM Philosophers: Chapter 2Abhinav AnandNo ratings yet

- Mbaln 670 T02 PDFDocument13 pagesMbaln 670 T02 PDFKate0% (1)

- Ans OpDocument4 pagesAns OpShivansh SaxenaNo ratings yet

- Operation Management ToyotaDocument16 pagesOperation Management Toyotahusain albaqali100% (1)

- Cellular Manufacturing: and Plant LayoutDocument76 pagesCellular Manufacturing: and Plant Layoutdevmecz2696No ratings yet

- Volvo Internship ReportDocument38 pagesVolvo Internship ReportNachiketh SNo ratings yet

- Introduction & FundamentalsDocument157 pagesIntroduction & FundamentalsrhvenkatNo ratings yet

- AS 9100 Quality Systems Manual Template (Sample)Document9 pagesAS 9100 Quality Systems Manual Template (Sample)Centauri Business Group Inc.100% (1)

- The Illustrated Lean Agile and World Class Manufacturing Cookbook 2008 08 20Document107 pagesThe Illustrated Lean Agile and World Class Manufacturing Cookbook 2008 08 20Francois de Villiers100% (46)

- Production and Operation ManagementDocument21 pagesProduction and Operation ManagementRabbiya GhulamNo ratings yet

- Project On Inventory Management SystemDocument83 pagesProject On Inventory Management SystemPRATIK CHOPDENo ratings yet

- ExtruderDocument12 pagesExtruderDwiky ErlanggaNo ratings yet

- Machine Design I Ch1Document21 pagesMachine Design I Ch1Nichupan PratheepratNo ratings yet

- Quality ManagementDocument36 pagesQuality ManagementGIRITHARANNo ratings yet

- The Evolution of ERPDocument8 pagesThe Evolution of ERPapi-385457980% (5)

- Curriculum Vitae: Maruthupandian.P Maruthu - Sri@yahoo - Co.inDocument5 pagesCurriculum Vitae: Maruthupandian.P Maruthu - Sri@yahoo - Co.inPraveen KumarNo ratings yet

- Complete EDM Handbook - 10 PDFDocument0 pagesComplete EDM Handbook - 10 PDFds_srinivasNo ratings yet

- Prevent and Eliminate MUDADocument17 pagesPrevent and Eliminate MUDAGeleta BikilaNo ratings yet

- DispensingDocument17 pagesDispensingbharat_somalNo ratings yet

- ISO 22000 - Control of Documents and RecordsDocument29 pagesISO 22000 - Control of Documents and RecordsChinnu Trinadh100% (1)

- Project Report - Garment - SCMDocument10 pagesProject Report - Garment - SCMRajeev SinghNo ratings yet

- Pierre Guerin Process Vessels PDFDocument24 pagesPierre Guerin Process Vessels PDFIvan HrenNo ratings yet

- Chapter Two Theory of Production 2.1. The Production FunctionDocument24 pagesChapter Two Theory of Production 2.1. The Production Functionabadi gebruNo ratings yet

- Global Food Packaging Market 2013-2023Document19 pagesGlobal Food Packaging Market 2013-2023VisiongainGlobalNo ratings yet

- Unit-3-Productivity Problem PDFDocument9 pagesUnit-3-Productivity Problem PDFShakil KhanNo ratings yet

- Absorption CostingDocument17 pagesAbsorption Costingmahbuba19rahmanNo ratings yet

- Curriculum VitaeDocument5 pagesCurriculum VitaeReno AdiputraNo ratings yet

FMEA Dilemma and Countermeasures

FMEA Dilemma and Countermeasures

Uploaded by

Tahan SibueaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FMEA Dilemma and Countermeasures

FMEA Dilemma and Countermeasures

Uploaded by

Tahan SibueaCopyright:

Available Formats

FMEA Dilemma and

Countermeasures

Gary Jing, PhD

ASQ World Conference – Session W06 – May 2, 2018

Learning Objectives

• This session is intended for experienced

people to discuss / exchange how to better

handle the FMEA activities to get the best

out of it, by addressing challenges and

difficulties.

– Interactions are encouraged & appreciated

• It’s not intended to teach basics to

beginners who have no experience.

5/2/18 2018 WCQI W06 FMEA Gary Jing 2

Agenda

• Speaker’s Connection to the Topic

• The Challenges and Dilemma

• Which Parts being Difficult

• Tips to Deal With the Dilemma

• Integration with Related Activities

• An Unique Practice

• Takeaways

• Appendix - More Discussions on Confusing Points

5/2/18 2018 WCQI W06 FMEA Gary Jing 3

Gary Jing’s Background

Ø ASQ Fellow, MBA, PhD in IE, CQM / CQE

Ø Founding MBB @ Seagate TCO (1998 - 2005)

Ø Sr. Mgr., Global LS / Founding MBB @ Entegris (2005 - 2009)

Ø Global LSS Leader / MBB @ TE – ADC (2009 - 2015)

Ø CI Director / MBB @ CommScope (2015 - Present)

Ø US Delegation to ISO TC176 for ISO 9000 Revision

Ø Editorial Review Board of Six Sigma Forum Magazine

Ø IQPC/PEX LSS Award Judge Panel

Ø Development of ASQ BB Certification Program (participant)

Ø Delphi panel expert for SME/AME/Shingo Lean Certification Program

Ø Isixsigma DFSS Award (2011), Finalist of IQPC MBB of The Year (2008)

Ø Two patents in disc drive modeling from his Sigma work

Ø Series publications on Lean Sigma

Ø More details on http://www.linkedin.com/in/ggaryjing.

5/2/18 2018 WCQI W06 FMEA Gary Jing 4

Foreword

• FMEA concept and practice can be applied

to almost anything.

• Most common ones are on design and

production (process), which splits into:

– Pre (production) release – easier to change

design.

– Post release – harder to change design.

– Practice will be different b/w the 2 stages.

– This session focuses on the Pre.

5/2/18 2018 WCQI W06 FMEA Gary Jing 5

Foreword

• The mechanism of FMEA is quite

straightforward, yet to do it well isn’t easy.

So, what are the challenges?

Gary Jing, FMEA Dilemma, Six Sigma Forum Magazine, May, 2014

5/2/18 2018 WCQI W06 FMEA Gary Jing 6

What are the Biggest Challenges?

Scenario 1: Cowboy under OSHA

5/2/18 2018 WCQI W06 FMEA Gary Jing 7

Example: Functions Identified for a Marker Cap

20 “functions” identified.

- Too much for FMEA.

- Focus on NUD (new, unique,

difficult) ones instead.

5/2/18 2018 WCQI W06 FMEA Gary Jing 8

A Fundamental Limitation of FMEA & RCA

The cost aspect needed for business decision

is usually not considered in FMEA (or RCA).

Inc

Impact / Return / Reward

Hi

re

as

ing

De

Med

sir

ab

ilit

y

Low

Low Med Hi

Difficulty / Effort / Cost

5/2/18 2018 WCQI W06 FMEA Gary Jing 9

What are the Biggest Challenges?

Scenario 2: Everything is fine.

5/2/18 2018 WCQI W06 FMEA Gary Jing 10

So, What are the Biggest Challenges

in doing FMEA?

Effectiveness & Efficiency

• The quality of FMEA is hard to evaluate.

• No guaranty (or magic wand)

• With huge investment and no guaranty on results,

people have the tendency to cut corner.

5/2/18 2018 WCQI W06 FMEA Gary Jing 11

Typical Ways to Boost FMEA Quality

• Experience - Ultimate pursuit

• Formality (& structure) - Less effective

• Right Focus - More effective

• Quantity - Trade efficiency

Will be elaborated in the remaining sections.

5/2/18 2018 WCQI W06 FMEA Gary Jing 12

Different Industries have Different Expectations on

FMEA.

• More serious and formal in highly regulated

industries

– Medical Device, Aerospace, Automotive, etc.

– Can be used as legal documents.

• Less formal in Telecom

– Ad hoc in many cases.

• Less formal in Six Sigma activities

– May be customized or use less formal form, e.g.

Potential Problem Analysis (PPA).

5/2/18 2018 WCQI W06 FMEA Gary Jing 13

Agenda

• Speaker’s Connection to the Topic

• The Challenges and Dilemma

• Which Parts being Difficult

• Tips to Deal With the Dilemma

• Integration with Related Activities

• An Unique Practice

• Takeaways

• Appendix - More Discussions on Confusing Points

5/2/18 2018 WCQI W06 FMEA Gary Jing 14

Which Parts of FMEA are Difficult?

• Types of Failure Mode (FM)

• Types of Control

– Prevention or Detection?

• Is it a Cause or Effect?

– Cause – effect shifting

• Is it a process issue or design issue?

– Some FMs may belong to both

– Many process issues can be addressed by design

• Interaction between (sub-)structures (IBS)

– IBS induced issues are hard to capture

5/2/18 2018 WCQI W06 FMEA Gary Jing 15

Which Parts of FMEA are Difficult?

• Types of Failure Mode (FM)

– Failing to meet the specification

• Complete failure

• Too little (partial, uneven or not complete)

• Too much (over)

• Intermittent

• Failure over time

– Incorrect or inappropriate requirements

• Wrong, missing, hidden, unstated, assumed)

– Unintended use, application, or environment

– Does harm to others

5/2/18 2018 WCQI W06 FMEA Gary Jing 16

Which Parts of FMEA are Difficult?

• Is it a Cause or Effect?

– Chain of Causation

– Cause–effect shifting

Is Electrical Fault a

Cause, FM or Effect?

- It depends, on what

level you are looking at:

- At car level, it’s a

cause;

- At sub-assembly level

is a FM;

- At component level,

it’s an effect.

5/2/18 2018 WCQI W06 FMEA Gary Jing 17

Which Parts of FMEA are Difficult?

• Types of Control

– Prevention or Detection?

– One of most confusing items, hard to do it right.

– Prevention: Focus on preventing failure to occur,

affect Occurrence (O).

– Detection: Focus on preventing effect to occur,

affect Detection (D).

– Different sets for design and process, no overlap.

5/2/18 2018 WCQI W06 FMEA Gary Jing 18

Prevention vs. Detection Controls

DFMEA PFMEA

• Prevention Controls typically occur prior to • Prevention Controls occur

finalizing the design and reduce the risk of prior to manufacturing the

failures during Product Validation Testing product

- Engineering analysis and evaluation: Anti- - Equipment setup

overstress feature requirements

- Tolerance Stack-Up or Statistical Analysis, - Poka-yoke

- Finite Element Analysis • Detection Controls occur

• Detection Controls detect the failure mode, after manufacturing the

typically during Product Validation testing, product but prior to

prior to releasing design for customer orders shipping product to

- Examples include Reliability testing and

customers

Performance testing conducted as part of - Product testing

product validation testing

- Inspection

5/2/18 2018 WCQI W06 FMEA Gary Jing 19

Agenda

• Speaker’s Connection to the Topic

• The Challenges and Dilemma

• Which Parts being Difficult

• Tips to Deal With the Dilemma

• Integration with Related Activities

• An Unique Practice

• Takeaways

• Appendix - More Discussions on Confusing Points

5/2/18 2018 WCQI W06 FMEA Gary Jing 20

Poll

Are all of the FMEA columns equally important?

Options: Yes / No

Which ones are most important?

Options:

• RPN

• Detection

• Function

• Failure mode

• Action

• Others

5/2/18 2018 WCQI W06 FMEA Gary Jing 21

Tips on FMEA Efficiency & Effectiveness

Are all of the FMEA columns equally important?

Which ones are most important?

1. The most important column in FMEA is

potential failure mode (concerns)

– To identify potential failures as thoroughly &

completely as possible.

2. The 2nd most important is the

countermeasures (actions) identified

– To keep risk of FMs at acceptable level.

– Be conscious on cost.

5/2/18 2018 WCQI W06 FMEA Gary Jing 22

Tips on FMEA Efficiency & Effectiveness

3. The 3rd is the risk priority number (RPN)

– To assess the risk, establish priorities and guide

responses.

– Always highly subjective due to lack of data.

– Frequently mistaken as most important in FMEA.

– AIAG is moving away from using it.

4. Everything else is in supporting functions

– To help make better informed decisions in the

process.

5/2/18 2018 WCQI W06 FMEA Gary Jing 23

Redirect Team’s Brain Power to Boost FMEA

Efficiency & Effectiveness

Focusing team resource on NUD and the

top 2 most important columns can boost

efficiency & effectiveness of FMEA.

• The top 2 most important columns (failure

mode & countermeasures) can benefit from

team the most.

• An experienced lead person or a small

subset group can handle the rest well.

5/2/18 2018 WCQI W06 FMEA Gary Jing 24

Redirect Team’s Brain Power to Boost FMEA

Efficiency & Effectiveness

• We can let the whole group focus on

brainstorming for the top 2, and let an

experienced lead person take care of the

rest along with a small sub team.

• Focusing on NUD (new, unique, difficult),

easing on ECO (easy, common, old) items,

can gain efficiency.

5/2/18 2018 WCQI W06 FMEA Gary Jing 25

Agenda

• Speaker’s Connection to the Topic

• The Challenges and Dilemma

• Which Parts being Difficult

• Tips to Deal With the Dilemma

• Integration with Related Activities

• An Unique Practice

• Takeaways

• Appendix - More Discussions on Confusing Points

5/2/18 2018 WCQI W06 FMEA Gary Jing 26

Integration with Related Activities

• How is FMEA activity connected with

others that have similar intent? e.g.

– Six Sigma

– Product Development Process (PDP)

– Dynamic Control Plan (DCP)

• It’ll be much more effective & efficient if

systematically integrate FMEA with

activities with similar intent.

5/2/18 2018 WCQI W06 FMEA Gary Jing 27

Integration with Related Activities

• Six Sigma connection

– Lean Design for Six Sigma (LDFSS), e.g.

– VOC / requirement management, e.g.

• Failing to meet requirements is a/the primary

mode of failure.

• How to make sure you identified hidden /

latent / implied requirements?

à LDFSS VOC section.

5/2/18 2018 WCQI W06 FMEA Gary Jing 28

How is FMEA Integrated with Relevant Activities

- Product Development Stage AIAG is moving

V

V

to this direction

in joint effort

V

V S

S

S

W V

S S

Process/Product

S

V

S

V

V V V

V V V

Failure Modes and Effects Analysis

V V V

W V V

V

S V

W S S V

(FMEA)

W S

V V W V S V V

with VDA.

HOWs: Measurable Technical Requirements Customer

Assessment

Image Quality General Features Ease of Use Similar to 35

Customer Importance

Konica

Q

Viewfinding indicator graphics

Our Camera Co.

X

Fuji

Y

Store Brands

High appearance rating

A

Impact force resistance

OTU Camera Example

Flash re-charge time

Carrying mechanism

Maximize part re-use

External dimensions

min. of 27 pictures

Surface roughness

Snap load resistance

Process or

Viewfinder Area

Body contouring

Camera weight

Winding force

Color Saturation

Flash power

Prepared by:

Label clarity

Flash force

Snap force

35 mm film

Product Name:

Low Grain

Contrast

Density

UMC

0 1 2 3 4 5

Direction of Improvement K K K J K I K I K K J K K K K K I K K J K K K I

16.0

Responsible: FMEA Date (Orig) ______________ (Rev) _____________

Clear Pictures

Good Image Quality

F F F F F F A QX

Y

V

Low Graininess 11.0 F F A Q XY

V

W

Pictures can't be

5.0 F F F H F H A QXY

"washed out"

S Can't mis-fire when I

S S put it away in my 4.0 F H H F A QXY

V S pocket or purse

W V

Unique Features

S Has to be durable if

S 12.0

WHATs for One-Time-Use Camera (VOC Input Data)

I drop it F H H G A YX Q

V

W

V S

Low purchase price 15.0 F F H H G F H Q XY A

Process S O D R

W

V

V

V

W S

S

Must fit in my shirt

pocket

2.0 F G F H G G A X Q Y Step/Part E C E P

Want to take

6.0

V

V

V

W

W

W

pictures in any light

Has to be really

14.0

F G G H A XQ Y

Number Potential Failure Mode Potential Failure Effects V Potential Causes C Current Controls T N

easy to use H F F F F H F F F F H H G AQXY

Spin Draw Fiber Breakouts Undersized package, High SD Dirty Spinneret Visual Detection of Wraps and

V

W V Easy to wind 1.0 F F G G A YX

Q

V

Easy to use

S

2 8 broken Filaments 9 144

Large view finder

W S

W

W

W

V that helps me get

pictures centered

10.0 G F G F H F AX Y Q Process panel-hours lost

S W

easily

Has to be light &

13.0 H G F H F F F F A X YQ

Filament motion Visual Sight-glass

easy to carry

Regular 35 mm Camera performance

Prefer 35 mm format 8.0 H H H H F F Q

A

Y

X

W S V Has to be close to

9.0

5 2 8 80

W my 35mm in picture

quality

F F F F F F A XY

Q

Has to take a 3.0

minimum of 27

I don't want it to

7.0

H H F A Y

X

Q

Polymer defects Fuzzball Light

8 2 9 144

look cheap G H G H F F F F F G F F A X QY

How Much

Organizational Difficulty

Q Konica 5

0

Assessment

Fuji

Y 4

Technical

Store Brands

A 3

Our Camera Co.

X

2

0

78.

27.

29

29

29

36

16

34

14

24

28

17

14

13

19

14

37

19

29

22

19

22

57

33

Weighted Importance

Relative Importance

VOC / Concept DFMEA

Requirements Generation

Prototype Design for “X”

Functional Architectural Schematic

Ream of

Paper

Load / Store

Paper

Pick Paper

Increment and

Hold Paper

Deliver and

Store Paper

(The important functions and flows)

Delivered

Print

Design Review

Jetted

Ink Display

Process Status

Input Data Status Indication

Data

Ink Level Display Ink

Indication Level

Process/Product

Failure Modes and Effects Analysis

Material flow

Jet Ink (FMEA)

Power flow

Ink Store Ink

Signal flow

Process or

Vapors Prepared by:

Product Name:

Supply Responsible: FMEA Date (Orig) ______________ (Rev) _____________

110/220V AC

Power

Capture Hot Process

Remove Heat Filter Flow S O D R

Vapor Gases Step/Part

Heat E C E P

Number Potential Failure Mode Potential Failure Effects V Potential Causes C Current Controls T N

From Dave Cutherall, Design Edge,

Kristin Wood, Univ. of Texas, Spin Draw Fiber Breakouts Undersized package, High SD Dirty Spinneret Visual Detection of Wraps and

Kevin Otto, PDSS Consulting Process panel-hours lost 2 8 broken Filaments 9 144

Process Map

Cool air Filament motion Visual Sight-glass

5 2 8 80

Functional Analysis

Polymer defects Fuzzball Light

8 2 9 144

/ NUD-New, Pugh Analysis PFMEA

Unique, Difficult

5/2/18 2018 WCQI W06 FMEA Gary Jing 29

How is PFMEA Integrated with Relevant Activities

- Post Production Release

5/2/18 2018 WCQI W06 FMEA Gary Jing 30

Agenda

• Speaker’s Connection to the Topic

• The Challenges and Dilemma

• Which Parts being Difficult

• Tips to Deal With the Dilemma

• Integration with Related Activities

• An Unique Practice

• Takeaways

• Appendix - More Discussions on Confusing Points

5/2/18 2018 WCQI W06 FMEA Gary Jing 31

3-Day DFMA / FMEA Joint Event

- An Unique Practice

• Addresses a host of manufacturing related

concerns together, including: Many of them

have similar

– Design review intent in different

– Design for “X” angles, to identify

and eliminate

– Modularity / part reuse problems in the

– Lean manufacturing & assembly future, thus it’s

better to join

– Field installation & maintenance force.

– FMEA (Design, Process, Application)

• Typically done right after the 1st major

prototype acquired.

5/2/18 2018 WCQI W06 FMEA Gary Jing 32

Activities & Schedule of Joint Event

Pre Day 1 Day 1 Day 2 Day 2 Day 3 Day 3 Post

Event Morning Afternoon Morning Afternoon Morning Afternoon Event

Stage 0 Lead

Prep & optionally

pre-draft

Kick-off QFD &

FMEA

Stage 1 VOC

Review updates,

Teardown

Current prototype,

Design touch & feel.

Stage 2 Whole team Breakout to

Brainstorm / brainstorm, document

prioritize concerns on

Document concerns, FMEA,

Concerns quickly

assess risk.

Stage 3 Multiple Breakout to Breakout to

Generate rounds of Consolidate further

ideations on ideas & review develop

Better top concerns counter ideas

Solution measures

Stage 4 Breakout to Finalize

Finalizing review QFD improve

ments &

FMEA

5/2/18 2018 WCQI W06 FMEA Gary Jing 33

Take-aways

• What are the constant struggles with FMEA?

– Efficiency and effectiveness.

• The most important columns in FMEA are?

– Failure Mode & Countermeasures (Actions).

• Everything else is in?

– Secondary supporting role, to help making better

informed decisions.

• Focusing the group resource on the?

– Most important items can significantly improve the

efficiency and effectiveness of FMEA.

Questions?

Gary Jing - http://www.linkedin.com/in/ggaryjing

Appendix

More Discussions on Confusing Points

More Discussions on Confusing Points

• What’s the primary intent / ultimate goal of

FMEA?

– To prevent future problems.

• Choices of actions should build around this goal.

– Not for investigation / problem solving.

• FMEA format isn’t suited to show complicated

cause-effect relationships.

– Additional or variation on goals are possible.

5/2/18 2018 WCQI W06 FMEA Gary Jing 37

More Discussions on Confusing Points

• What’s in the Scope

– ASQ critical assumption for PFMEA

• All components coming into the process step are

defect-free. – Defective part out of scope.

– My view

• Anything that may jeopardize your goal is in

scope, incl. defective incoming material.

• Failures & solutions not limited to current design.

– May lead to new design, components or process.

• If FMEA doesn’t lead to design change during

development stage, it’s not as effective as it can.

5/2/18 2018 WCQI W06 FMEA Gary Jing 38

More Discussions on Confusing Points

• Expectation / “standard” on outputs

– There is no perfect FMEA or outputs for any

subjective analyses

– Different people doing the same subjective

analysis will get different results

• Which is ok à Delphi Theory – Things will

converge through iterations.

àUse your judgment to decide the best practice

for you.

5/2/18 2018 WCQI W06 FMEA Gary Jing 39

More Discussions on Confusing Points

• Could same FM have multiple effects with

different Severity (S), O and/or D?

– Possible to any of them.

• A FM may have multiple causes and/or effects.

• A cause or effect may associate to multiple FMs.

– To simplify the analysis, a popular practice is to

focus on the most server effect per FM.

• There is a chance to miss an effect with lower

severity yet higher RPN.

• That’s a risk to take to trade for efficiency.

5/2/18 2018 WCQI W06 FMEA Gary Jing 40

More Discussions on Confusing Points

• Can recommended actions lower Severity?

– A frequently debated item.

– Two schools of thought w/ opposite views.

– Ultimately what’s affected is Criticality = SxO.

– More common to keep S unchanged, only

change O, to keep things simple and avoid

confusing debate.

5/2/18 2018 WCQI W06 FMEA Gary Jing 41

More Discussions on Confusing Points

• What training style / format is more effective

– Standalone training w/ hypothetical example /

exercise (e.g. ASQ)?

– Learn through doing real projects?

• FMEA is evolving

– AIAG joining VDA* is proposing dramatic changes

• Emphasize structural analysis (similar to LDFSS)

• Eliminate RPN

– Industries will follow suit in the near future.

* VDA - German Association of the Automotive Industry

5/2/18 2018 WCQI W06 FMEA Gary Jing 42

AIAG/VDA to Emphasize Structural Analysis

AIAG moving toward VDA practice.

5/2/18 2018 WCQI W06 FMEA Gary Jing 43

AIAG/VDA to Replace RPN by Action Priority (AP)

Using more sophisticated Guidance Table to guide AP,

replacing single threshold for RPN.

5/2/18 2018 WCQI W06 FMEA Gary Jing 44

You might also like

- FMEA 5th TablesDocument41 pagesFMEA 5th TablesR.BALASUBRAMANI100% (4)

- Marriage - FMEADocument1 pageMarriage - FMEAHariramNo ratings yet

- International Electrotechnical Commission: (Iecq HSPM)Document16 pagesInternational Electrotechnical Commission: (Iecq HSPM)biomech99100% (1)

- Process Hazard Analysis: (Failure Mode Effect Analysis)Document41 pagesProcess Hazard Analysis: (Failure Mode Effect Analysis)Nate JamesNo ratings yet

- IE Feasibility Study FormatDocument5 pagesIE Feasibility Study FormatiecscstNo ratings yet

- Chapter 15 - Lean Operations and JITDocument6 pagesChapter 15 - Lean Operations and JITmoza_musliuNo ratings yet

- LVHMDocument44 pagesLVHMNguyen Tuan VinhNo ratings yet

- QSG Quality Support Group Angelo Scangas Laura Halleck AIAG VDA FMEA IEEEDocument35 pagesQSG Quality Support Group Angelo Scangas Laura Halleck AIAG VDA FMEA IEEEEvandro MinatoNo ratings yet

- Design Failure Mode and Effect Analysis - Case StuDocument13 pagesDesign Failure Mode and Effect Analysis - Case Stusanjay chamoliNo ratings yet

- Peration Anagement: Concept of Quality Juran's PrincipleDocument24 pagesPeration Anagement: Concept of Quality Juran's PrincipleAyushi BisenNo ratings yet

- Seminar On Statistical Process Control On Cylinder LinersDocument56 pagesSeminar On Statistical Process Control On Cylinder LinersSatadru BeraNo ratings yet

- Product Characteristics ClassificationDocument9 pagesProduct Characteristics Classification80ALLA86iNo ratings yet

- IATF Rules 5th Edition - FAQs 1 3 - 23jan2017 - FINAL PDFDocument6 pagesIATF Rules 5th Edition - FAQs 1 3 - 23jan2017 - FINAL PDFsathyabalaramanNo ratings yet

- Repeatability and Reproducibility StudyDocument4 pagesRepeatability and Reproducibility Studysivaseeni100% (1)

- FMEA PG Seminar For WebsiteDocument21 pagesFMEA PG Seminar For WebsiteMuhd HazwanNo ratings yet

- Legal Concerns in Drafting A Policy For Reporting FraudDocument6 pagesLegal Concerns in Drafting A Policy For Reporting FraudFrancisco BraganzaNo ratings yet

- SGS CBE ISO 45001 Brochure A4 en InteractiveDocument7 pagesSGS CBE ISO 45001 Brochure A4 en InteractiveTatiana RiloNo ratings yet

- Aiag Fmea TrainingDocument10 pagesAiag Fmea TrainingJohn OoNo ratings yet

- Effects of Radiation On PlantsDocument35 pagesEffects of Radiation On PlantsOkaroFrankNo ratings yet

- Trailer IATF DocumentsDocument77 pagesTrailer IATF DocumentsSridharan VenkatNo ratings yet

- Xfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following FormsDocument6 pagesXfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following FormsRoland JoldisNo ratings yet

- Fundamentals of FMEA PDFDocument35 pagesFundamentals of FMEA PDFPriatna suheriNo ratings yet

- Fmea Alignment Aiag and VdaDocument14 pagesFmea Alignment Aiag and Vdahaitem100% (1)

- 19R-18-ME-137-Project Risk ManagementDocument15 pages19R-18-ME-137-Project Risk Managementkamran bhatNo ratings yet

- Communication On Progress (Cop) : The Ten Principles of The United Nations Global CompactDocument46 pagesCommunication On Progress (Cop) : The Ten Principles of The United Nations Global CompactVikrant KambleNo ratings yet

- MSA (Measurement System Analys)Document19 pagesMSA (Measurement System Analys)Dazslam New VersionNo ratings yet

- Boleh Merevisi Kriteria Severity, Kecuali 9 Dan 10Document3 pagesBoleh Merevisi Kriteria Severity, Kecuali 9 Dan 10Reza WijayaNo ratings yet

- Intelligent Use of FMEA Presented By: Quality Associates InternationalDocument66 pagesIntelligent Use of FMEA Presented By: Quality Associates Internationalpradeep100% (1)

- GAMP5Document56 pagesGAMP5mkm969100% (1)

- SPC Training Material - 18!04!2018Document34 pagesSPC Training Material - 18!04!2018Rajesh KumarNo ratings yet

- The 5-Whys' Method: Example 1Document3 pagesThe 5-Whys' Method: Example 1initiative1972No ratings yet

- Lean Six Sigma ToolkitDocument63 pagesLean Six Sigma ToolkitLOLIMNo ratings yet

- SWOT Analysis and Project Selection MatrixDocument2 pagesSWOT Analysis and Project Selection MatrixSudhagarNo ratings yet

- G3 1 Index and ChecklistDocument123 pagesG3 1 Index and ChecklistWendy Al SyabanaNo ratings yet

- Case Study On FMEA Problem SolvingDocument6 pagesCase Study On FMEA Problem Solvingmg2001No ratings yet

- Warm-Up - Day 2: Place Self Others Team Purpose AgendaDocument85 pagesWarm-Up - Day 2: Place Self Others Team Purpose AgendaSanjeev SharmaNo ratings yet

- Welcome - Day 1 2012: Failure Mode and Effects AnalysisDocument63 pagesWelcome - Day 1 2012: Failure Mode and Effects AnalysisKaya Eralp AsanNo ratings yet

- QA-REC-122 Attiribute MSADocument4 pagesQA-REC-122 Attiribute MSAsunita choudharyNo ratings yet

- FINAL CB Training Package - Single MFG Site With Extended Site - 16feb2016-1Document58 pagesFINAL CB Training Package - Single MFG Site With Extended Site - 16feb2016-1Mauro PlatiniNo ratings yet

- Chiro - Requirements - Traceability - Matrix ExerciseDocument11 pagesChiro - Requirements - Traceability - Matrix ExerciseAkash AgarwalNo ratings yet

- The Case Against The AIAG-VDA DFMEADocument22 pagesThe Case Against The AIAG-VDA DFMEA57641No ratings yet

- 8D Problem AnalysisDocument99 pages8D Problem AnalysisLorena Martinez LaraNo ratings yet

- 15 Mistake ProofingDocument4 pages15 Mistake ProofingSteven Bonacorsi100% (2)

- Sec 04 IATF 16949 RequirementsDocument21 pagesSec 04 IATF 16949 RequirementsIsmehen TrabelsiNo ratings yet

- Internal Qms Audit Summary: Major/Minor/OIDocument33 pagesInternal Qms Audit Summary: Major/Minor/OIMEHAKNo ratings yet

- MRM Full ReportDocument47 pagesMRM Full Reportkoza12345678No ratings yet

- Updates Dec09 AIAG FMEA-Ranking-TablesDocument3 pagesUpdates Dec09 AIAG FMEA-Ranking-TablesSuresh Velu100% (1)

- Safety Dependabilty Durability Requirements EPS BL 3 0Document49 pagesSafety Dependabilty Durability Requirements EPS BL 3 0monutilisation0No ratings yet

- Processaudit VDA 6.3 - RecentDocument32 pagesProcessaudit VDA 6.3 - RecentAnkurNo ratings yet

- AQE (FMEA) Selling DocumentDocument17 pagesAQE (FMEA) Selling DocumentArshad AnsariNo ratings yet

- 2.1 EMS LA Delegate Manual - Clause 9-10Document14 pages2.1 EMS LA Delegate Manual - Clause 9-10Ali AlamranNo ratings yet

- PAPP Checklists and Forms PDFDocument4 pagesPAPP Checklists and Forms PDFsathyabalaramanNo ratings yet

- PCP & FmeaDocument4 pagesPCP & FmeaDaniela AscolaniNo ratings yet

- Moudling Operation GSIC Process: MouldingDocument13 pagesMoudling Operation GSIC Process: MouldingBalakumaran MurugesanNo ratings yet

- Case Study ShavingDocument5 pagesCase Study ShavingtitinNo ratings yet

- Mandatory Documents For IatfDocument6 pagesMandatory Documents For Iatfdhir.ankurNo ratings yet

- Checksheet Error ProofingDocument4 pagesChecksheet Error ProofingEzhilarasan DhoniNo ratings yet

- Formel Q-Capability Version 6.0 Supplier Training - Product AuditDocument11 pagesFormel Q-Capability Version 6.0 Supplier Training - Product AuditVijay LadNo ratings yet

- Agile Essentials You Always Wanted To Know: Self Learning ManagementFrom EverandAgile Essentials You Always Wanted To Know: Self Learning ManagementNo ratings yet

- 1.0 Dfmea PDFDocument127 pages1.0 Dfmea PDFDilip KulkarniNo ratings yet

- FINC304 Managerial Economics: Session 7: Organisation of The FirmDocument13 pagesFINC304 Managerial Economics: Session 7: Organisation of The FirmJephthah BansahNo ratings yet

- MIS Assignment: Systems Approach and CyberneticsDocument6 pagesMIS Assignment: Systems Approach and CyberneticsmrityunjayNo ratings yet

- 6002 - Group 3 - Urban Wind Group PresentationDocument15 pages6002 - Group 3 - Urban Wind Group Presentationsinichi33No ratings yet

- Thematic Analysis On The Teachers Dialogic Scaffolding Practices and Students Expression of Argumentation Agency PDFDocument287 pagesThematic Analysis On The Teachers Dialogic Scaffolding Practices and Students Expression of Argumentation Agency PDFTahan SibueaNo ratings yet

- Statistical Process Control PDFDocument66 pagesStatistical Process Control PDFTahan SibueaNo ratings yet

- Who - Sample Size DeterminationDocument57 pagesWho - Sample Size DeterminationTahan SibueaNo ratings yet

- 10 Tips For Highly Successful Quality LeadersDocument7 pages10 Tips For Highly Successful Quality LeadersTahan SibueaNo ratings yet

- 2014 Annual QM Management ReportDocument107 pages2014 Annual QM Management ReportTahan SibueaNo ratings yet

- 8 Wastes Check SheetDocument3 pages8 Wastes Check SheetTahan SibueaNo ratings yet

- Facility Validation - Theory, Practice, and Tools (PDFDrive)Document142 pagesFacility Validation - Theory, Practice, and Tools (PDFDrive)Tahan Sibuea100% (1)

- 7 Steps To Be IMPACTFUL As A Quality ManagerDocument7 pages7 Steps To Be IMPACTFUL As A Quality ManagerTahan SibueaNo ratings yet

- 3 Pillars of Effective Supplier Management: Ed PotoczakDocument7 pages3 Pillars of Effective Supplier Management: Ed PotoczakTahan SibueaNo ratings yet

- Process Capability - A Managers Tool For 6 Sigma Quality AdvantageDocument9 pagesProcess Capability - A Managers Tool For 6 Sigma Quality AdvantageTahan SibueaNo ratings yet

- GWP Verification White Paper - Safety FactorDocument2 pagesGWP Verification White Paper - Safety FactorTahan SibueaNo ratings yet

- MAXIMIZER™ Quick Change Squeegee, Black 2018801Document2 pagesMAXIMIZER™ Quick Change Squeegee, Black 2018801Tahan SibueaNo ratings yet

- GWP Verification White Paper - Performance VerificationDocument2 pagesGWP Verification White Paper - Performance VerificationTahan SibueaNo ratings yet

- 5 Techniques For Pressure Gauge Adjustment and Repair - Calibration AwarenessDocument9 pages5 Techniques For Pressure Gauge Adjustment and Repair - Calibration AwarenessTahan SibueaNo ratings yet

- Learner-Verification Essentials of European Medical Device Regulation (EU MDR) - 2017 - 745Document1 pageLearner-Verification Essentials of European Medical Device Regulation (EU MDR) - 2017 - 745Tahan SibueaNo ratings yet

- 27 GPS-VToolbox 131-139Document10 pages27 GPS-VToolbox 131-139Tahan SibueaNo ratings yet

- Learner Verification 9001 - 2015 Quality Management System (QMS)Document1 pageLearner Verification 9001 - 2015 Quality Management System (QMS)Tahan SibueaNo ratings yet

- Process Validation - DR Asmaa El-Kersh, M.SCDocument44 pagesProcess Validation - DR Asmaa El-Kersh, M.SCTahan SibueaNo ratings yet

- Learner-Verification Diploma in ISO Standards - Integrated Management System (IMS)Document2 pagesLearner-Verification Diploma in ISO Standards - Integrated Management System (IMS)Tahan SibueaNo ratings yet

- Quality Gurus / TQM Philosophers: Chapter 2Document22 pagesQuality Gurus / TQM Philosophers: Chapter 2Abhinav AnandNo ratings yet

- Mbaln 670 T02 PDFDocument13 pagesMbaln 670 T02 PDFKate0% (1)

- Ans OpDocument4 pagesAns OpShivansh SaxenaNo ratings yet

- Operation Management ToyotaDocument16 pagesOperation Management Toyotahusain albaqali100% (1)

- Cellular Manufacturing: and Plant LayoutDocument76 pagesCellular Manufacturing: and Plant Layoutdevmecz2696No ratings yet

- Volvo Internship ReportDocument38 pagesVolvo Internship ReportNachiketh SNo ratings yet

- Introduction & FundamentalsDocument157 pagesIntroduction & FundamentalsrhvenkatNo ratings yet

- AS 9100 Quality Systems Manual Template (Sample)Document9 pagesAS 9100 Quality Systems Manual Template (Sample)Centauri Business Group Inc.100% (1)

- The Illustrated Lean Agile and World Class Manufacturing Cookbook 2008 08 20Document107 pagesThe Illustrated Lean Agile and World Class Manufacturing Cookbook 2008 08 20Francois de Villiers100% (46)

- Production and Operation ManagementDocument21 pagesProduction and Operation ManagementRabbiya GhulamNo ratings yet

- Project On Inventory Management SystemDocument83 pagesProject On Inventory Management SystemPRATIK CHOPDENo ratings yet

- ExtruderDocument12 pagesExtruderDwiky ErlanggaNo ratings yet

- Machine Design I Ch1Document21 pagesMachine Design I Ch1Nichupan PratheepratNo ratings yet

- Quality ManagementDocument36 pagesQuality ManagementGIRITHARANNo ratings yet

- The Evolution of ERPDocument8 pagesThe Evolution of ERPapi-385457980% (5)

- Curriculum Vitae: Maruthupandian.P Maruthu - Sri@yahoo - Co.inDocument5 pagesCurriculum Vitae: Maruthupandian.P Maruthu - Sri@yahoo - Co.inPraveen KumarNo ratings yet

- Complete EDM Handbook - 10 PDFDocument0 pagesComplete EDM Handbook - 10 PDFds_srinivasNo ratings yet

- Prevent and Eliminate MUDADocument17 pagesPrevent and Eliminate MUDAGeleta BikilaNo ratings yet

- DispensingDocument17 pagesDispensingbharat_somalNo ratings yet

- ISO 22000 - Control of Documents and RecordsDocument29 pagesISO 22000 - Control of Documents and RecordsChinnu Trinadh100% (1)

- Project Report - Garment - SCMDocument10 pagesProject Report - Garment - SCMRajeev SinghNo ratings yet

- Pierre Guerin Process Vessels PDFDocument24 pagesPierre Guerin Process Vessels PDFIvan HrenNo ratings yet

- Chapter Two Theory of Production 2.1. The Production FunctionDocument24 pagesChapter Two Theory of Production 2.1. The Production Functionabadi gebruNo ratings yet

- Global Food Packaging Market 2013-2023Document19 pagesGlobal Food Packaging Market 2013-2023VisiongainGlobalNo ratings yet

- Unit-3-Productivity Problem PDFDocument9 pagesUnit-3-Productivity Problem PDFShakil KhanNo ratings yet

- Absorption CostingDocument17 pagesAbsorption Costingmahbuba19rahmanNo ratings yet

- Curriculum VitaeDocument5 pagesCurriculum VitaeReno AdiputraNo ratings yet