Professional Documents

Culture Documents

Module 5

Module 5

Uploaded by

Sahih AqeedahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Module 5

Module 5

Uploaded by

Sahih AqeedahCopyright:

Available Formats

PDHonline Course M110 (4 PDH)

Introduction to Fire Protection Systems

Instructor: Lawrence J. Marchetti, P.E.

2020

PDH Online | PDH Center

5272 Meadow Estates Drive

Fairfax, VA 22030-6658

Phone: 703-988-0088

www.PDHonline.com

An Approved Continuing Education Provider

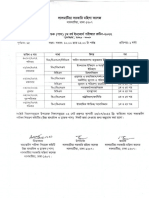

MODULE - 5

FIRE DETECTORS

This module will introduce the student to the following:

• Fire Signatures

• Various types of Smoke Detectors and theory of operation.

• Various types of heat detectors and theory of operation.

• Various types of flame sensing detectors and theory of operation.

Following successful completion of this module, the student should be

able to:

• Discuss various types of fire signatures produced.

• List types of smoke detectors and types of fires they are applied.

• List operational differences between smoke detector types.

• List types of heat detectors and types of fires they are applied.

• List types of flame sensing detectors and types of fires they are

applied.

• List various NFPA codes that apply to fire detection devices.

FIRE SIGNATURES

From the moment a fire begins, a number of changes occur in the

surrounding environment. These changes from the ambient conditions are

termed “fire signatures” and manifest themselves in the forms of smoke,

heat, light, and gas. Appropriate detection devices are selected to respond to

one or more of these fire signatures.

SMOKE PROPERTIES

Smoke involves the thermal release of large quantities of solid and liquid

particles into the surrounding atmosphere. The size of these particles can

range from 5x10 4 to 10 µm (micrometers). These particles that are

MODULE 5- FIRE DETECTION DEVICES 1

suspended in the air are termed aerosols. The aerosol particles that are

produced in a fire are classified into two types of fire signatures according to

their light scattering properties. Namely, invisible and visible fire signatures.

Generally, flaming fires burn hotter and result in more complete combustion,

and produce smaller aerosol (smoke) particles (approximately 0.3 µm or

less). These smoke particles are classified as invisible due to the inability to

scatter light.

Generally, ionization detectors are most effective with invisible smoke

particles.

Smoldering fires and fires that produce low temperature combustion

products produce larger aerosol (smoke) particles (larger than 0.3µm). These

particles scatter (reflect) light efficiently and are classified as visible

particles. Generally, photoelectric detectors are most effective with visible

smoke particles, and are applied where smoldering fires are anticipated.

SMOKE DETECTORS

Smoke detectors are identified according to their operating principles,

namely ionization and photoelectric type smoke detectors.

Ionization Type Detectors:

Ionization detectors operate by using a small amount of radioactive

material (Americium 241) to ionize (electrically charge) the air within a

sensing chamber in the detector. The ionization of the air permits the air

to conduct electricity between two electrodes within the chamber. As

smoke enters the chamber, the smoke particles become ionized and

reduce the conductivity of the air between the electrodes. This reduction

in conductivity between the electrodes is sensed and will cause the

detector to respond. Generally, these detectors are the lowest cost, and

respond to smaller smoke particles (the result of high-energy fires).

These detectors also have the greatest false alarm rate of smoke detectors

from cooking and other non-fire sources.

MODULE 5- FIRE DETECTION DEVICES 2

Photoelectric Type Detectors:

Photoelectric detectors operate on one of three different principles:

1. Light obscuration principle

2. Light scattering principle

3. Cloud Chamber principle

Light obscuration principle photoelectric detectors operate by projecting a

light beam onto a photosensitive device. As smoke particles enter the

chamber between the light source and the photosensitive device, the light

intensity diminishes and initiates an alarm at a predetermined level. Most

light obscuration detectors are the beam type and are used for smoke

detection of large open areas.

Light scattering principle photoelectric detectors operate with a light source

and a photosensitive device. However, unlike the light obscuration detector,

the photosensitive device is not in the light beam path. As smoke particles

enter the sensing chamber, light is reflected (scattered) from the smoke

particles onto the photosensitive device causing the detector to respond.

Cloud chamber principle detectors operate by drawing an air sample from

the protected area into a high humidity chamber within the detector. After

the air sample has been raised to the high humidity, the pressure is slightly

lowered. If smoke particles are in the chamber, a cloud will form. The

density of this cloud is measured with a photoelectric device. When the

“cloud” reaches a predetermined density, the detector will respond with an

alarm. Cloud chamber detectors are normally used where early detection is

required such as in computer rooms.

HEAT DETECTORS

Thermal detection systems are designed to operate from the thermal

output of a fire. The heat generated is dissipated throughout the area by

laminar and turbulent convective heat flows created by heated gases.

Turbulent flow is induced and regulated by the fire plume thermal

column effect of heated air and gases above the fire surface. The fire

MODULE 5- FIRE DETECTION DEVICES 3

plume characteristics and the ceiling jet flow of convective heated gases

are determined by the heat release rate of the diffusion flame combustion

and ceiling height. (NFPA 72 should be consulted with regard to thermal

detector spacing for varying ceiling heights). Additionally, variables

such as proximity to walls, room configuration, and ceiling obstruction

can affect the transport of convective heat flow necessary for thermal

detector operation.

A heat detector’s sensitivity to a given fire situation depends on the gas

temperature which is related to the ceiling height, the radial position of

the detector, and the fire’s heat release rate.

Heat detectors are identified according to their operating principles, and

are classified into the following types :

1. Fixed Temperature Detectors

2. Rate-of-Rise Detectors

3. Rate compensated Detectors

FIXED TEMPERATURE HEAT DETECTORS

Fixed temperature heat detectors are the simplest type of heat detector and

are designed to alarm when the sensing element reaches a predetermined

temperature. (Actually, a sprinkler head operates upon this same principle.)

Generally, the surrounding air temperature must be considerably higher than

the heat detector rating in order to raise the heat detector element to the

operating temperature. This condition is known as thermal lag. Generally,

fixed temperature heat detectors are constructed with fusible element type,

continuous line type and bimetal type.

The fusible element type operates similar to a sprinkler head where a

eutectic metal melts at a predetermined temperature releasing a spring under

tension and initiates an alarm signal. This type of detector is a spot type

detector.

The continuous line type heat detector generally consists of parallel wires

separated by a heat resistive insulation. When the insulation melts away at a

predetermined temperature (from a fire), the wires come into contact and an

MODULE 5- FIRE DETECTION DEVICES 4

alarm is initiated. These detectors are often used as fire detection devices

within tunnels, cable trays, etc.

The bimetal type of heat detectors relies on two joined metals with different

coefficients of expansion. As the metals expand (at different rates) when

heated, the bimetal will deflect toward the metal with the lower coefficient

of expansion. This deflection is normally designed to close a contact and

initiate an alarm.

RATE-OF RISE HEAT DETECTORS

Rate-of-rise heat detectors are designed to function when the rate of ambient

temperature increase exceeds a predetermined value, usually 12°F - 15°F per

minute. These detectors are designed to accommodate normal changes in the

ambient air temperature, which are anticipated under normal (non-fire)

conditions.

One type of rate-of-rise detector employs pneumatic tubing filled with air

with a relief vent. When the air is heated (within the normal conditions), the

air will expand with the excess volume exhausted through the vent port

before the pressure can build. Air expanding at a rate that exceeds the relief

capacity of the vent, will build pressure and initiate an alarm. These types of

detectors are available as spot and line types.

RATE COMPENSATED DETECTORS

Rate compensated heat detectors are designed to initiate an alarm when the

temperature of the surrounding air reaches a predetermined level, regardless

of the rate of temperature rise.

The detector is essentially constructed with temperature sensitive contacts

within a stainless steel shell. The coefficient of expansion of the shell is

different than the internal contacts. This rapid increase in air temperature

will cause the shell to expand before the internal contacts, producing a signal

(similar to a rate-of-rise detector). In the case of a slow heat release rate

from a fire, the unit (shell and internal contacts) heats up more evenly and

produces a signal at the predetermined temperature rating of the detector

(similar to a fixed temperature heat detector).

MODULE 5- FIRE DETECTION DEVICES 5

These detectors are designed to eliminate the thermal lag associated with a

fixed temperature detector as well as the problem of false alarms and the risk

of missing slow heat release combustion that are inherent with rate-of-rise

detectors.

OPTICAL FLAME DETECTORS

Optical flame detectors are the fastest responding type of detector since

these detectors rely on the visible and invisible radiation given off from

a heat source (and travels at the speed of light), and are usually applied

in high hazard areas such as fuel loading platforms, industrial process

areas, hyperbaric chambers, vaults, high ceilings, and atmospheres in

which explosions or very rapid fires can occur. Flame detectors are

designed to respond to radiant energy both visible and invisible to the

human eye. Essentially, flame detectors must be located to “see” the fire

so avoidance of obstructions is critical. (One exception to this is the IR

detector which can respond to reflected levels of optical radiation. For

instance, a fire out of the view of the detector can reflect optical

radiation off a wall which can be detected by the IR detector.) Basically,

there are three general types of optical flame detectors:

1. Infrared type flame detectors

2. Ultraviolet type flame detectors

3. Combination IR/UV type flame detectors

INFRARED (IR) TYPE FLAME DETECTORS

Infrared type flame detectors are normally used to protect large open areas

where an immediate, flame-producing fire is expected such as in the

protection of flammable liquid hazard. IR detectors are constructed

essentially of a lens and filter system that screens out unwanted wavelengths

and focuses the incoming energy on a photovoltaic or other type cell that is

sensitive to infrared energy. These types of detectors often also measure the

infrared radiation emitted from a flame (spiking at the 4.3 micron peak

radiation wavelength due to the presence of concentrated carbon dioxide

within the flame) and characteristic flame flicker associated with the flaming

mode of a fire that is in the 5 –30 Hz frequency range. Infrared detectors can

be subject to interference and false alarms from solar radiation if not

properly applied. One method employed is to use multiple IR detectors to

MODULE 5- FIRE DETECTION DEVICES 6

measure the amount of radiation in two or more wavelength bands to

discriminate between a flame and other IR sources.

ULTRAVIOLET (UV) TYPE FLAME DETECTORS

Ultraviolet type flame detectors are designed to respond to optical radiation

in the ultraviolet wavelengths (wavelengths below 4,000 Angstrom∗, usually

in the 2800 – 3000 Angstrom range) primarily emitted by higher intensity

flames. One drawback is that solar radiation can extend to as low 2900

Angstrom, while the detector must be able to respond to fire induced optical

radiation below 2900 Angstrom. Most detectors manufactured are effective

in discriminating between solar and fire induced radiation. These detectors

are normally applied where the detector can be located reasonably close to

the expected ignition source and the background can be protected from other

sources of ultraviolet radiation. One notable application for UV detectors is

for use in explosion suppression systems. UV flame detectors are essentially

solid state devices employing silicon carbide, aluminum nitride, or gas filled

tubes that measure the flame component wavelength range between 0.17 –

0.30 microns∗∗ which are insensitive to both sunlight and artificial light.

∗ 1 Angstrom = 1 / 10,000,000,000 meter

∗∗ 1 micron = 1/1,000,000 meter

Combination (UV/IR) type flame detectors are flame detectors using both

of the flame-sensing principles described above for greater discrimination

between fire and non-fire radiation sources.

MODULE 5- FIRE DETECTION DEVICES 7

You might also like

- Introduction To ANSI A137.2Document3 pagesIntroduction To ANSI A137.2Anonymous G6ceYCzwtNo ratings yet

- Literature Review Assingment 5Document5 pagesLiterature Review Assingment 5Nurul Syakinah50% (2)

- Presentation 1Document7 pagesPresentation 1Tushar SharmaNo ratings yet

- Overview of Fire/Smoke/Flame/Heat/G As DetectorsDocument5 pagesOverview of Fire/Smoke/Flame/Heat/G As DetectorsInter TungNo ratings yet

- Assignment 2Document28 pagesAssignment 2vpsrt12No ratings yet

- Fire SystemDocument28 pagesFire Systemvpsrt12No ratings yet

- Formatted Smoke DetectorsDocument48 pagesFormatted Smoke DetectorsSwathi MudumbaiNo ratings yet

- L5 - Fire Protection System - Automatic Fire Detection Alarm SystemDocument50 pagesL5 - Fire Protection System - Automatic Fire Detection Alarm SystempaulNo ratings yet

- Topic IV Fire and Gas SystemDocument13 pagesTopic IV Fire and Gas SystemJulius ChavezNo ratings yet

- 1 Fire DetectorsDocument5 pages1 Fire DetectorsUseless MeNo ratings yet

- Learning Module Me Elective 3 (ME 428)Document59 pagesLearning Module Me Elective 3 (ME 428)John Paul ParoNo ratings yet

- Definition of Heat DetectorDocument5 pagesDefinition of Heat Detectormuhammad zulfikriNo ratings yet

- Flame Detector MCLDocument22 pagesFlame Detector MCLraymond espeNo ratings yet

- Open Fire DetectionDocument8 pagesOpen Fire Detectionsjain_818574No ratings yet

- FIRRRRRREDocument14 pagesFIRRRRRRENerina ChanNo ratings yet

- Fire Detection and Alarm: System Basics Engineering DesignDocument115 pagesFire Detection and Alarm: System Basics Engineering DesignRomany ShafikNo ratings yet

- Radiation Pyrometre NaveenaDocument27 pagesRadiation Pyrometre NaveenaRahul RaaghavNo ratings yet

- Report WSDDocument34 pagesReport WSDDhanyata nirmalkumarNo ratings yet

- Fire Detection and Alarm System BasicsDocument115 pagesFire Detection and Alarm System Basicsscribd8421100% (8)

- Lecture 7 Fire Detection and Alarm Systems DegreeDocument9 pagesLecture 7 Fire Detection and Alarm Systems DegreenjuraimelvinNo ratings yet

- 3.1 Fire DetectorsDocument23 pages3.1 Fire DetectorsBHUVANESH MNo ratings yet

- Fire Detection and Alarm System BasicsDocument115 pagesFire Detection and Alarm System BasicsSutikno BlankNo ratings yet

- Fire Detection and Alarm System BasicsDocument115 pagesFire Detection and Alarm System BasicsAfzal KhanNo ratings yet

- Fire Alarm SystemDocument5 pagesFire Alarm SystemGDELA CRUZ, PRINCEZKHA ANN D.No ratings yet

- Fire Detection Alarm SystemDocument52 pagesFire Detection Alarm SystemCatherine Joyce SungaNo ratings yet

- Fire Detection and Alarm SystemDocument76 pagesFire Detection and Alarm SystemShambhu Saran Singh100% (4)

- Fire and Gas Detection PhilosophyDocument22 pagesFire and Gas Detection PhilosophyRam Kumar PandiNo ratings yet

- Fire Detection and Alarm System BasicsDocument115 pagesFire Detection and Alarm System BasicsPushpa Mohan AJ100% (1)

- Fire DetectorsDocument2 pagesFire DetectorsArvindNo ratings yet

- Fire, Flame & Smoke Detectors: Presented by Akaash Sahoo Roll No-210114001 M.Tech in Process Control & InstrumentationDocument21 pagesFire, Flame & Smoke Detectors: Presented by Akaash Sahoo Roll No-210114001 M.Tech in Process Control & InstrumentationRakesh NeheteNo ratings yet

- Fire Safety & Fire FightingDocument9 pagesFire Safety & Fire FightingShubhaang GoelaNo ratings yet

- Types of Fire DetectorsDocument5 pagesTypes of Fire DetectorsShivkumarNo ratings yet

- Se 1504 Planning and Design of Fire Protection Systems Module-IDocument32 pagesSe 1504 Planning and Design of Fire Protection Systems Module-IGaurav KumarNo ratings yet

- Fire Detection and Alarm PanelDocument18 pagesFire Detection and Alarm PanelShariq KhanNo ratings yet

- Fire DetectorDocument22 pagesFire DetectorSumit Pannu100% (1)

- Experiment: - 6: Theory:-Fire Detector and Alarm SystemDocument7 pagesExperiment: - 6: Theory:-Fire Detector and Alarm SystemAbhay tiwariNo ratings yet

- Fire Detection and Alarm SystemDocument39 pagesFire Detection and Alarm Systemfaridmd84No ratings yet

- Fire Alarm SystemDocument41 pagesFire Alarm SystemShailendra SinghNo ratings yet

- Fire Detection and Alarm SystemsDocument15 pagesFire Detection and Alarm SystemsAzmi Suhardi0% (1)

- Fire Detection and Fire Fighting Systems Chapter 1 Detection SystemDocument4 pagesFire Detection and Fire Fighting Systems Chapter 1 Detection SystemVasimNo ratings yet

- Fire Detection and Alarm SystemsDocument3 pagesFire Detection and Alarm SystemsJoan Bunao SeraficaNo ratings yet

- Guidelines: Top Five Things To Know About Heat DetectorsDocument1 pageGuidelines: Top Five Things To Know About Heat DetectorsramkrishnaNo ratings yet

- Fire DetectionDocument81 pagesFire DetectionKah HomNo ratings yet

- Eim 11Document32 pagesEim 11Franklin BallonNo ratings yet

- Pyro MeterDocument6 pagesPyro MeterGhulam MurtazaNo ratings yet

- Fire Alarm SystemDocument27 pagesFire Alarm SystemMohammed EmamNo ratings yet

- Introduction To Thermal TestingDocument14 pagesIntroduction To Thermal TestingSantos Junnior Hipolito SandovalNo ratings yet

- Radiation Pyrometer M & I PDFDocument9 pagesRadiation Pyrometer M & I PDFs.sainishok krishnaNo ratings yet

- 4 Ifipp PSSMDocument57 pages4 Ifipp PSSMOne JackNo ratings yet

- Smoke Gas Flame Detectors - Principle of OperationDocument3 pagesSmoke Gas Flame Detectors - Principle of Operationshivam trivediNo ratings yet

- Unit 4 HEAT DETECTORS - Fire Safety and Protection SystemsDocument9 pagesUnit 4 HEAT DETECTORS - Fire Safety and Protection SystemsDeepak RajNo ratings yet

- Fire Detection and Alarm SystemDocument41 pagesFire Detection and Alarm SystemMohamad Arif Ali100% (1)

- Fire AlarmDocument2 pagesFire AlarmJohn Lester M. Dela CruzNo ratings yet

- Fire SystemDocument133 pagesFire SystemGenetBezuNo ratings yet

- Pyrometer For Temperature Measurement in FurnacesDocument17 pagesPyrometer For Temperature Measurement in FurnacesMuhammad FahadNo ratings yet

- BasitDocument13 pagesBasitTalha ranaNo ratings yet

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Thermal Conductivity Measurements in Atomically Thin Materials and DevicesFrom EverandThermal Conductivity Measurements in Atomically Thin Materials and DevicesNo ratings yet

- Shining a Light on Cool Standards: Infrared Spectroscopy Theory Explored.From EverandShining a Light on Cool Standards: Infrared Spectroscopy Theory Explored.No ratings yet

- NoticeFile 14262Document1 pageNoticeFile 14262Sahih AqeedahNo ratings yet

- Tbhowaabvpp PDFDocument1 pageTbhowaabvpp PDFSahih AqeedahNo ratings yet

- BSB App Sheet PDFDocument1 pageBSB App Sheet PDFSahih AqeedahNo ratings yet

- hpOBN8EbR3mVP4IOQBQF9g EPD-AbbreviationDocument3 pageshpOBN8EbR3mVP4IOQBQF9g EPD-AbbreviationSahih AqeedahNo ratings yet

- Safe Footing ReportDocument154 pagesSafe Footing ReportLenielle AmatosaNo ratings yet

- IKO - Needle Roller Bearing Series - CAT5502CDocument292 pagesIKO - Needle Roller Bearing Series - CAT5502CValtier JOanNo ratings yet

- Transition Temperatures and EnthalpiesDocument7 pagesTransition Temperatures and EnthalpiesIrfan AliNo ratings yet

- JW Chapter5solutionsDocument25 pagesJW Chapter5solutionsUp ToyouNo ratings yet

- Submit The Motion Module Reading Notes AssognmentDocument8 pagesSubmit The Motion Module Reading Notes AssognmentTaha AfzalNo ratings yet

- Phys 203 CH 4 Lecture 1 PDFDocument17 pagesPhys 203 CH 4 Lecture 1 PDFRahmatSiregarNo ratings yet

- ASTM D 698 (LImeLight)Document3 pagesASTM D 698 (LImeLight)JQNo ratings yet

- Advanced Theories For Deformation, Damage and Failure in MaterialsDocument10 pagesAdvanced Theories For Deformation, Damage and Failure in MaterialsKholid BuiNo ratings yet

- Scie 4Document7 pagesScie 4Jam LumasacNo ratings yet

- Psa Co-Po Mapping SheetDocument2 pagesPsa Co-Po Mapping SheetDrMohammad Rafee ShaikNo ratings yet

- Kinetic Molecular Theory of GasesDocument4 pagesKinetic Molecular Theory of GasesSHRAVYA K REDDYNo ratings yet

- DeltaE Survey 2Document29 pagesDeltaE Survey 2sshiyunchanNo ratings yet

- Gear CalculationsDocument14 pagesGear CalculationsBabette FreyNo ratings yet

- MathptDocument10 pagesMathptAilyn Grace SullanoNo ratings yet

- Fluid Flow Postlab ReportDocument14 pagesFluid Flow Postlab Reportgracebrewster123No ratings yet

- The Anatomy of The Airfoil: General Aviation Aircraft Design Ó 2014 Elsevier Inc. All Rights ReservedDocument63 pagesThe Anatomy of The Airfoil: General Aviation Aircraft Design Ó 2014 Elsevier Inc. All Rights ReservedmiguelNo ratings yet

- Analysis of The Fin Performance of Offset Strip Fins Used in Plate-Fin Heat ExchangersDocument9 pagesAnalysis of The Fin Performance of Offset Strip Fins Used in Plate-Fin Heat Exchangersloose manusyaNo ratings yet

- Patterns and Numbers in Nature and The WorldDocument8 pagesPatterns and Numbers in Nature and The Worldayn pizzaNo ratings yet

- Indian Standard I: Covered Electrodes For Manual Metal Arc Welding of Carbon and Carbon Manganese Steel - SpecificationDocument30 pagesIndian Standard I: Covered Electrodes For Manual Metal Arc Welding of Carbon and Carbon Manganese Steel - SpecificationchepurthiNo ratings yet

- NUET 2022 Mathematics Specimen PaperDocument26 pagesNUET 2022 Mathematics Specimen Papernyry2005100% (1)

- Pawar Public School, Bhandup Class Subject Exam Marks Date Duration No. of Printed Pages X Physics Prelim 2 40 01.02.2022 1 Hours 5Document4 pagesPawar Public School, Bhandup Class Subject Exam Marks Date Duration No. of Printed Pages X Physics Prelim 2 40 01.02.2022 1 Hours 5kim loveNo ratings yet

- Heat Load CapacityDocument23 pagesHeat Load CapacityIsrael MuhiNo ratings yet

- MIT18 440S11 Lecture27Document18 pagesMIT18 440S11 Lecture27Jaco GreeffNo ratings yet

- Gr11 Mathematics Study GuideDocument222 pagesGr11 Mathematics Study GuideTOP10 HolUpNo ratings yet

- XRD - Amit ChawlaDocument19 pagesXRD - Amit ChawlaAshutosh BhardwajNo ratings yet

- Messko Product Catalogue Transformer SolutionsDocument28 pagesMessko Product Catalogue Transformer SolutionsVahidNo ratings yet

- 6ths Key Answers California 1Document37 pages6ths Key Answers California 1CanioNo ratings yet

- Experimental Monitoring of The Humber Bridge UsingDocument7 pagesExperimental Monitoring of The Humber Bridge Using정주호No ratings yet

- Berry (2001) Why Are Special Functions SpecialDocument3 pagesBerry (2001) Why Are Special Functions SpecialDany RubioNo ratings yet