Professional Documents

Culture Documents

OPS12 - Operational Report

OPS12 - Operational Report

Uploaded by

Emre AlgülOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OPS12 - Operational Report

OPS12 - Operational Report

Uploaded by

Emre AlgülCopyright:

Available Formats

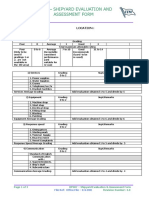

OPS12 – OPERATIONAL REPORT

Ship:

Managing Office:

Attending MSQ Supt:

DATE OF THIS VISIT PORT

FROM:

TO:

LAST FLEET SUPT VISIT

LAST MSQ SUPT VISIT

CREW DETAILS

OFFICERS (NATIONALITY)

NUMBER

CREW (NATIONALITY)

NUMBER

MASTER(TIME IN RANK) YEARS

MASTER(TIME IN COMPANY) YEARS

C/E (TIME IN RANK) YEARS

C/E (TIME IN COMPANY) YEARS

Page 1 of 5 OPS12 – Operational Report

File Ref: Office File – 1G Revision Number: 4.0

OPS12 – OPERATIONAL REPORT

Mark Condition Description Condition Maintenance Procedures

Explanation Condition

9 Excellent New or Fully Well maintained no To the highest standards.

reconditioned or repairs required no

Superior in all deficiencies noted.

respects Maintenance 100%

up-to-date, well

planned & executed

8 Very Good Superior most Well maintained no To a Superior standard

respects (unlikely to repairs required no

improve further) major deficiencies

noted

7 Good Well run, maintained Well maintained no To a good standard (Some

& presented. (Some repairs required no improvement possible)

improvement major deficiencies

possible) noted. No

significant

outstanding

maintenance

6 Fair Fairly good. Above Good maintenance Fairly good. Above and

and improving from ongoing, minor improving from basic

basic operational deficiencies only acceptable standard

condition which being

addressed

5 Satisfactory Basic sustainable Adequate Minimum required standard

operational condition maintenance,

number of minor

deficiencies only

which being

addressed

4 Serviceable Below or Maintenance Below or deteriorating from

deteriorating from ongoing but several what expected as basic

what expected as deficiencies which minimum standard

basic operational must receive more

condition attention than given

to date

3 Poor Requiring corrective Routine Well below required

measures starting maintenance standard

soonest insufficient for

correction and

additional measures

arranged

2 Very Poor Requiring significant Routine Significantly below standard

corrective measures maintenance

insufficient for

correction and

additional measures

required to be

arranged

1 Unsatisfactory Significant Urgent corrective Unacceptable standards

deficiencies measures required

to be arranged

0 Unexamined Unexamined Unexamined Unexamined

X Not Applicable Not Applicable Not Applicable Not Applicable

Page 2 of 5 OPS12 – Operational Report

File Ref: Office File – 1G Revision Number: 4.0

OPS12 – OPERATIONAL REPORT

Executive Summary

Agreed This

Standard Last Report Report Condition Explanation

Operational Condition

Rating

Safety Rating

Fabric Condition &

Maintenance Rating

Accommodation

Condition

Ship Average Overall

Rating

Brief synopsis of the visit including but not limited to the following:

1) Operations in progress at the time of boarding

2) Reason for boarding

3) Comment on any third party inspection

4) Any immediate concerns that would need urgent attention both by vessel of the office

Operational Condition

Administration

Sight all trading certificates

Review of alcohol sales and onboard testing records

Review of environmental logs such as Oil Record Book, Garbage Record Book, Ballast Water Records

Crew

Brief report on crew management on board including but not limited to:

1) Nationalities on board and communication issues if any

2) Any crew complaints

3) Relief arrangements and subsequent familiarisation

4) Comment on performance issues

5) Crew awareness on VMS, ISPS

6) Crew appearance and general disposition

7) Work & Rest records onboard.

8) Familiarisation records

9) Comment on validity of seafarers certification including medical certification

10) Maintenance of onboard medical records.

Cargo Operation

Brief report of cargo operation(s) carried out at the time of the visit. Check cargo plans for

adherence VMS procedures and also with various seasonal levels, loadline zones, etc.

Please include your comments of the Cargo and ballast system.

Navigation Procedures

Navigation Audit to be carried out using NAV 26 template along with additional questions as

appropriate to the visit. It is preferable to complete the audit during a “sailing visit” in order to

properly assess the effectiveness of the Bridge Team.

Page 3 of 5 OPS12 – Operational Report

File Ref: Office File – 1G Revision Number: 4.0

OPS12 – OPERATIONAL REPORT

Fabric Condition & Maintenance

Fabric

Brief report on cosmetic condition of vessel including but not limited to:

1) General appearance of the vessel

2) Loadline defects if any

3) Any immediate cosmetic improvement required

Deck and Mooring Equipment

Brief report on:-

Condition of deck machinery such as davits, cranes and associated wires.

Condition of mooring equipment including ropes, wires, mooring tails, shackles, bitts and stoppers.

Condition of anchoring equipment

Housekeeping within forward store rooms and machinery spaces.

Engine Room and Steering Gear

Brief report on housekeeping and any equipment found inoperative at time of visit.

Brief report on tests carried out including:-

1) Witness a test of the emergency fire pump, and emergency D/Alt (both methods of

starting)

2) Sight the deck fire main under full pressure from the engine room fire pump.

3) Witness a test of the steering gear from the steering gear compartment.

4) Witness a test of the O.W.S. and sight the full length of the pipe run from the separator to

the overboard valve.

Safety

Brief report on:-

1) Fire / Boat Drill carried out during visit. Witness lifeboat drill and observe both boats lowered

to embarkation deck unless vessel is alongside in which case off side boat only. Particular note

is to be taken of; condition of davits and winch foundation, operation of limit switches,

operation of brake and condition of falls and hooks.

2) LSA and FFA items – condition sighted and corresponding SSTRB and PMS Records

3) Risk Assessment Database

4) Isolation Control – Lock Out – Tag Out implementation

5) Permits to Work

6) Accident, Incident and Near Miss follow-up onboard.

7) Safety Meetings – Outstandings

Accommodation

Brief report on:-

Page 4 of 5 OPS12 – Operational Report

File Ref: Office File – 1G Revision Number: 4.0

OPS12 – OPERATIONAL REPORT

1) Condition of officer & crew cabins, alleyways, smoke rooms, recreation facilities, hospital,

laundries, ventilation, lightening, and other ambient factors such as excessive noise and vibration.

2) Review of Ship Sanitation Control Manual including inspection records of galley & pantries,

fridge rooms, and equipment.

3) Review of the Master’s Weekly Inspection reports.

Internal VMS, ISPS and EMS audit Summary

Refer to audit report paperwork

Deficiencies Noted & Follow-Up Items

List the deficiencies noted in the attached “Defect Report Template” format.

Findings from previous inspections to be updated in Shipsure Inspection Manager.

Photographs

Please include only pertinent photographs.

Page 5 of 5 OPS12 – Operational Report

File Ref: Office File – 1G Revision Number: 4.0

You might also like

- Darbour Group Hospitals Case Study and Action PlanDocument18 pagesDarbour Group Hospitals Case Study and Action PlanBisho AtefNo ratings yet

- OPS 07 - Shipyard Evaluation and Assessment FormDocument3 pagesOPS 07 - Shipyard Evaluation and Assessment FormEmre AlgülNo ratings yet

- 2004-2015 Toyota Hilux Fuse Box Diagram Fuse DiagramDocument12 pages2004-2015 Toyota Hilux Fuse Box Diagram Fuse DiagramJunior Salazar100% (2)

- Jisu Hozen PillarDocument98 pagesJisu Hozen PillarAndrei MarinNo ratings yet

- KaizenDocument32 pagesKaizenAmit KumarNo ratings yet

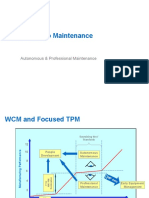

- Yamashina WCM Introduzione PPT Compatibility Mode RepairedDocument85 pagesYamashina WCM Introduzione PPT Compatibility Mode RepairededuardolucosNo ratings yet

- Yamashina WCM Introduzione - PPT (Compatibility Mode) (Repaired)Document85 pagesYamashina WCM Introduzione - PPT (Compatibility Mode) (Repaired)Ahmed Redwan100% (1)

- Jetream 32 07Document2 pagesJetream 32 07Eric ShahNo ratings yet

- Camión AspiradorDocument2 pagesCamión AspiradormasterlennonNo ratings yet

- Kertas 2ujian 1 English Paper 2 Form 4Document20 pagesKertas 2ujian 1 English Paper 2 Form 4Honey AzmiNo ratings yet

- Grab Assignment Semester 6Document12 pagesGrab Assignment Semester 6Lia Fotocopy50% (2)

- 04 Preventive MaintenanceDocument7 pages04 Preventive Maintenanceosama303No ratings yet

- Cooperharper FullDocument1 pageCooperharper FullaugustuswgNo ratings yet

- Company Profile AWI - C (2) - 240115 - 102436Document27 pagesCompany Profile AWI - C (2) - 240115 - 102436joshtsandriNo ratings yet

- Downcycling Vendor Inspection Sheet: Factory: Factory Team: Vendor Name Vendor AuditeeDocument14 pagesDowncycling Vendor Inspection Sheet: Factory: Factory Team: Vendor Name Vendor AuditeeFanuel KurniaNo ratings yet

- Assess Performance Failure Modes PDFDocument41 pagesAssess Performance Failure Modes PDFayaz hasan100% (1)

- TPM Overview: Manufacturing & Administrative ExcellenceDocument16 pagesTPM Overview: Manufacturing & Administrative Excellencestefmont2004No ratings yet

- INTRO To MaintenanceDocument76 pagesINTRO To MaintenancehwhhadiNo ratings yet

- Low and Medium Voltage Motor Repair Shop Selection GuidelineDocument10 pagesLow and Medium Voltage Motor Repair Shop Selection GuidelineGunadevan ChandrasekaranNo ratings yet

- Rank Description of Condition Very Good ConditionDocument3 pagesRank Description of Condition Very Good ConditionMichael MatshonaNo ratings yet

- INTRO To MaintenanceDocument76 pagesINTRO To MaintenancehwhhadiNo ratings yet

- Autonomous Maintenence Step1 - 3Document33 pagesAutonomous Maintenence Step1 - 3Sydney DodooNo ratings yet

- Autonomous Maintenance Step 1 To Step 3Document14 pagesAutonomous Maintenance Step 1 To Step 3R.BALASUBRAMANINo ratings yet

- KK Pillar PDFDocument91 pagesKK Pillar PDFdiwesh26decNo ratings yet

- Autonomous Operator Training Step 0 PDFDocument17 pagesAutonomous Operator Training Step 0 PDFjesusmemNo ratings yet

- 04 Auto MaintenanceDocument486 pages04 Auto Maintenanceanderson pariz100% (1)

- All+Rating+Guidelines ManufacturingDocument4 pagesAll+Rating+Guidelines ManufacturingSegu PratheekNo ratings yet

- Flood Damage Inspection Method For Public Buildings in MalaysiaDocument6 pagesFlood Damage Inspection Method For Public Buildings in MalaysiaTiwi PratiwiNo ratings yet

- unit 3 sbm process , principle of strategyDocument6 pagesunit 3 sbm process , principle of strategydpandya2209No ratings yet

- Engr. Mariam Altaf Tarar: Module LeaderDocument28 pagesEngr. Mariam Altaf Tarar: Module LeaderUsman AyyubNo ratings yet

- PSCP FormsDocument4 pagesPSCP FormsGhia PornillosNo ratings yet

- Change Management Process TrainingDocument37 pagesChange Management Process TrainingFlavio ManriqueNo ratings yet

- Process Safety AwarenessDocument19 pagesProcess Safety AwarenessiekazalyNo ratings yet

- Pfmea: Why Use It? How To Do It?Document7 pagesPfmea: Why Use It? How To Do It?imNo ratings yet

- 06.QC.T - 7 Steps of Quality MaintenanceDocument17 pages06.QC.T - 7 Steps of Quality MaintenancevictorNo ratings yet

- Pra-Workshop WPC & Serp GMDocument7 pagesPra-Workshop WPC & Serp GMErwin RaitzNo ratings yet

- Planned Maintenance Manual Step 1Document21 pagesPlanned Maintenance Manual Step 1AtulPalNo ratings yet

- Audit Program - Inventory Management - RRRDocument9 pagesAudit Program - Inventory Management - RRRashishhpandey99No ratings yet

- Specimen Internal Audit Report: Appendix 15Document5 pagesSpecimen Internal Audit Report: Appendix 15Selva Bavani SelwaduraiNo ratings yet

- Total Quality Management (Without Solution)Document30 pagesTotal Quality Management (Without Solution)anushaomar8No ratings yet

- Jishu HozenDocument85 pagesJishu HozenRakesh TigadiNo ratings yet

- Prioritizing Maintenance Works PDFDocument30 pagesPrioritizing Maintenance Works PDFMohammad Abubakar Siddiq100% (1)

- WLFO Risk Registry (CIP)Document33 pagesWLFO Risk Registry (CIP)tintin_costaNo ratings yet

- Section 3Document64 pagesSection 3Ahmed FaragNo ratings yet

- 8 Process Safety Awareness PresentationDocument27 pages8 Process Safety Awareness PresentationVincent Magtibay67% (3)

- Asset Performance MetricsDocument10 pagesAsset Performance MetricsRogelio SotoNo ratings yet

- Ntegrated Ean Igma: Maintenance ConceptsDocument26 pagesNtegrated Ean Igma: Maintenance Conceptsjeanfelipesantos100% (1)

- Maintenance Theory PDFDocument181 pagesMaintenance Theory PDFkaca82100% (2)

- Self Assessment Basic Care ChecklistDocument8 pagesSelf Assessment Basic Care ChecklistAbdul AwanNo ratings yet

- ISO27001 Gap AnalysisDocument7 pagesISO27001 Gap Analysissu yuNo ratings yet

- Autonomous Maintenance Step 1 7Document18 pagesAutonomous Maintenance Step 1 7Dũng Tây NinhNo ratings yet

- Internal Qms Audit Summary: Major/Minor/OIDocument33 pagesInternal Qms Audit Summary: Major/Minor/OIMEHAKNo ratings yet

- Adidas - Quality Concept Best PracticeDocument24 pagesAdidas - Quality Concept Best Practicemgttrainee16No ratings yet

- The Reservation Nightmare Case AnalysisDocument3 pagesThe Reservation Nightmare Case Analysis22100185No ratings yet

- Internal Audit Report: Overall Rating and Summary of FindingsDocument4 pagesInternal Audit Report: Overall Rating and Summary of FindingsMohamed SayedNo ratings yet

- NSF PB-Case Study-KPIs From A Site Quality HeadDocument2 pagesNSF PB-Case Study-KPIs From A Site Quality Headisrael afolayan mayomiNo ratings yet

- SAMI Triangle & MatrixDocument2 pagesSAMI Triangle & MatrixJosé RodríguezNo ratings yet

- Increase Availability, Reduce Maintenance Cost: Based On Failure Analysis Must Answer 7 Basic QuestionsDocument13 pagesIncrease Availability, Reduce Maintenance Cost: Based On Failure Analysis Must Answer 7 Basic QuestionsAlfian KamilNo ratings yet

- BACKFIT RCM Tri-Fold - MSCDocument2 pagesBACKFIT RCM Tri-Fold - MSCAmar Saadi100% (1)

- Q1 Nature of Operations Carried Out: Response ResponseDocument7 pagesQ1 Nature of Operations Carried Out: Response ResponseCA Sathya KumarNo ratings yet

- Strategic Control CH IXDocument51 pagesStrategic Control CH IXsujata dawadiNo ratings yet

- Autonomos Maintenance IIDocument15 pagesAutonomos Maintenance IIAditya KurniawanNo ratings yet

- FR-QM-MRM - Management Review Minutes - v0.0Document6 pagesFR-QM-MRM - Management Review Minutes - v0.0arabella.banawisNo ratings yet

- Supplier Improvement ChecksheetDocument8 pagesSupplier Improvement Checksheetkiran vkNo ratings yet

- Corporate Management, Governance, and Ethics Best PracticesFrom EverandCorporate Management, Governance, and Ethics Best PracticesNo ratings yet

- Cutting Edge Maintenance Management Strategies: Sequel to World Class Maintenance Management, The 12 Disciplines: 1, #4From EverandCutting Edge Maintenance Management Strategies: Sequel to World Class Maintenance Management, The 12 Disciplines: 1, #4No ratings yet

- OPS 09 - Technical Division ReportingDocument1 pageOPS 09 - Technical Division ReportingEmre AlgülNo ratings yet

- OPS 13 Vessel Defect Report-Action ListDocument1 pageOPS 13 Vessel Defect Report-Action ListEmre AlgülNo ratings yet

- OPS 06 - Quarterly ReportDocument1 pageOPS 06 - Quarterly ReportEmre AlgülNo ratings yet

- OPS 03 - Vessel Inspection ReportDocument1 pageOPS 03 - Vessel Inspection ReportEmre AlgülNo ratings yet

- OPS 5 Invitation To TenderDocument4 pagesOPS 5 Invitation To TenderEmre AlgülNo ratings yet

- OPS 02 - Pre-Visit Checklist For SuperintendentsDocument6 pagesOPS 02 - Pre-Visit Checklist For SuperintendentsEmre AlgülNo ratings yet

- OPS 08 - Purifier Data Log SheetDocument1 pageOPS 08 - Purifier Data Log SheetEmre AlgülNo ratings yet

- OPS 01 - Fleet Superintendent's Onboard Meeting ChecklistDocument3 pagesOPS 01 - Fleet Superintendent's Onboard Meeting ChecklistEmre AlgülNo ratings yet

- ICL CIRMAR 002 Guideline For Condition Surveys and Pre Purchase InspectionsDocument7 pagesICL CIRMAR 002 Guideline For Condition Surveys and Pre Purchase InspectionsEmre AlgülNo ratings yet

- Principles of Ship HandlingDocument10 pagesPrinciples of Ship HandlingGlen MacNo ratings yet

- BD16-82 Dec2000Document4 pagesBD16-82 Dec2000Doug WeirNo ratings yet

- Digital Can OBD2 Diagnostic Tool 3100 ManualDocument64 pagesDigital Can OBD2 Diagnostic Tool 3100 ManualdesertfiremanNo ratings yet

- Application For Irrevocable Documentary Credit (DC) : DD M M Y Y Y YDocument3 pagesApplication For Irrevocable Documentary Credit (DC) : DD M M Y Y Y YHelge SandoyNo ratings yet

- Auto - Question Bank PDFDocument4 pagesAuto - Question Bank PDFcharulapNo ratings yet

- Tender Notice: Invitation For Prequalification (IFP)Document5 pagesTender Notice: Invitation For Prequalification (IFP)Megha choukseyNo ratings yet

- Construction Stage Analysis of Segmental Cantilever BridgeDocument10 pagesConstruction Stage Analysis of Segmental Cantilever BridgeIAEME PublicationNo ratings yet

- Bike Share ProposalDocument31 pagesBike Share ProposalChristina WilkinsonNo ratings yet

- CB 8051 4wg Icb BrochureDocument8 pagesCB 8051 4wg Icb BrochureDeca2509No ratings yet

- 20180130120606HI SK200 SK210LC-10 Tier 4 Final BrochureDocument20 pages20180130120606HI SK200 SK210LC-10 Tier 4 Final BrochureAkhmad SebehNo ratings yet

- Outdoor LightingDocument72 pagesOutdoor LightingGoran GudeljNo ratings yet

- Certifying Statement Application Results and Certificates Form 7Document4 pagesCertifying Statement Application Results and Certificates Form 7Haider QureshiNo ratings yet

- Analysis of Flexible Pavements Using IIT Pave: Harish G RDocument4 pagesAnalysis of Flexible Pavements Using IIT Pave: Harish G RAyush KumarNo ratings yet

- Kenaikan Harga Federal Parts Per 01 Maret 2018Document14 pagesKenaikan Harga Federal Parts Per 01 Maret 2018Alexander LautanNo ratings yet

- Contributory Factorsof Traffic Accidentsin Lahore UsingDocument12 pagesContributory Factorsof Traffic Accidentsin Lahore UsingRiffat BokhariNo ratings yet

- Pavement Design: Repor Ters: Kent Justin Ocenar Jeneva Francisco EZA Estoperez Jean Nikka Simon Harold HiquianaDocument13 pagesPavement Design: Repor Ters: Kent Justin Ocenar Jeneva Francisco EZA Estoperez Jean Nikka Simon Harold HiquianaKent OcenarNo ratings yet

- Research Topics: Prepared By: Delima Jennielou G. Melgar Donna C. Sigue Cherry Ann C. Bsce 4-ADocument7 pagesResearch Topics: Prepared By: Delima Jennielou G. Melgar Donna C. Sigue Cherry Ann C. Bsce 4-ADonna Cece MelgarNo ratings yet

- We Are Not Afraid To DieDocument15 pagesWe Are Not Afraid To Dieabi shin100% (1)

- Wabco™ - C - and D-Version HABS Replacement PCDocument8 pagesWabco™ - C - and D-Version HABS Replacement PCHILLNo ratings yet

- Soal SoalReadingSectionDocument35 pagesSoal SoalReadingSectionMHSUANo ratings yet

- Model APS 750: Installation ManualDocument66 pagesModel APS 750: Installation ManualMario LugoNo ratings yet

- Criminal Jurisdiction For Ship Collision and MarinDocument9 pagesCriminal Jurisdiction For Ship Collision and MarinRavindra RathoreNo ratings yet

- pc-9 SB 53-015Document18 pagespc-9 SB 53-015Muralidharan ShanmugamNo ratings yet

- Glossary of TermsDocument5 pagesGlossary of Termsoctavio hernandezNo ratings yet

- Pilot Guide 1.6.1Document16 pagesPilot Guide 1.6.1danang sentosaNo ratings yet