Professional Documents

Culture Documents

CR..A Series

CR..A Series

Uploaded by

phamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CR..A Series

CR..A Series

Uploaded by

phamCopyright:

Available Formats

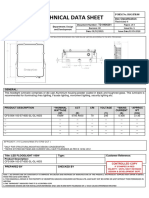

Data Sheet

Customer:

Product: Automotive Grade Chip Resistor – CR..A Series

Size: 0201/0402/0603/0805/1206/1210/2010/2512

Issued Date: 15-Jun-22

Edition: REV.B9

VIKING TECH CORPORATION VIKING TECH CORPORATION KAOHSIUNG BRANCH VIKING ELECTRONICS (WUXI) CO., LTD.

光頡科技股份有限公司 光頡科技股份有限公司高雄分公司 光頡電子(無錫)有限公司

No.70 Guangfu N. Rd., Hukou No.248-3, Sin-Sheng Rd., Cian-Jhen Dist., Kaohsiung, No.22 Xixia Road, Machinery & Industry Park,

Township, Hsinchu County 303, 806, Taiwan National Hi-Tech Industrial Development Zone

Taiwan of Wuxi, Wuxi, Jiangsu Province, China

Zip Code:214028

TEL:886-3-5972931 TEL:886-7-8217999 TEL:86-510-85203339

FAX:886-3-5972935•886-3-5973494 FAX:886-7-8228229 FAX:86-510-85203667•86-510-85203977

E-mail:sales@viking.com.tw E-mail:sales@viking.com.tw E-mail:china@viking.com.tw

Produced by Checked Approved by Prepared by Accepted by

(QC) (QC) (QC) (Sales) (Customer)

15-Jun-22 15-Jun-22 15-Jun-22

Alice Hsiao Susan Huang Susan Huang

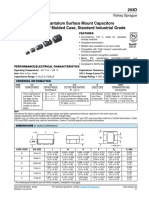

Automotive Grade Chip Resistor【CR..A Series】

Automotive Grade Chip Resistor-CR..A Series

■Scope

-This specification applies to all sizes of rectangular-type fixed

chip resistors with Ruthenium-base as material.

■Features

-AEC-Q200 Compliance

-Highly reliable multilayer electrode construction

-Special construction to prevent sulfuration in a

sulfur containing environment

-Compatible with all soldering process

-100% CCD inspection

■Construction ■Applications

-Automotive Industry

L

-Telecommunication Equipments

D1 -Radio and Tape Recorders, TV Tuners

-Digital Cameras, Watches, Pocket Calculators

W -Computers, Instruments

-Medical Equipment

T

D2

Alumina Substrate Edge Electrode Resistor Layer

Bottom Electrode Barrier Layer Primary Overcoat

Top Electrode External Electrode Secondary Overcoat

■Dimensions

Weight

Size L W T D1 D2

Type (g)

(Inch) (mm) (mm) (mm) (mm) (mm) (1000pcs)

CR-01 0201 0.60±0.03 0.30±0.03 0.23±0.03 0.15±0.05 0.15±0.05 0.150

CR-02 0402 1.00±0.05 0.50±0.05 0.35±0.05 0.20±0.10 0.20±0.10 0.620

CR-03 0603 1.60±0.10 0.80±0.10 0.45±0.10 0.30±0.20 0.30±0.20 2.042

CR-05 0805 2.00±0.10 1.25±0.10 0.50±0.10 0.35±0.20 0.40±0.20 4.368

CR-06 1206 3.10±0.10 1.55±0.10 0.55±0.10 0.50±0.25 0.50±0.20 8.947

CR-10 1210 3.10±0.10 2.60±0.15 0.55±0.10 0.50±0.25 0.50±0.20 15.959

CR-0A 2010 5.00±0.10 2.50±0.15 0.55±0.10 0.60±0.25 0.50±0.20 24.241

CR-12 2512 6.35±0.10 3.10±0.15 0.55±0.10 0.60±0.25 0.50±0.20 39.448

www.viking.com.tw For detail questions, contact:sales@viking.com.tw Edition: REV.B9

1 Revision: 15-Jun-2022

【CR..A Series】

Automotive Grade Chip Resistor

■Part Numbering

Part Number:CR-03FA7---10R

CR- 03 F A 7 - - - 1 0 R

Product Dimensions Resistance Function Packaging Resistance

Type Tolerance Code Code

CR- 01: 0201 D: ±0.5% A: Automotive Grade 4: 7” Reel 4Kpcs - - - 1R2: 1.2Ω

02: 0402 F: ±1% C: High Power & Automotive 6: 7” Reel 10Kpcs - - - 3K3: 3.3KΩ

03: 0603 J: ±5% Grade 7: 7” Reel 5Kpcs - - - 10K: 10KΩ

9: 10” Reel 8Kpcs - - 100K: 100KΩ

05: 0805

A: 10” Reel 10Kpcs “-“ to fill up 6 spaces

06: 1206

B: 10” Reel 20Kpcs

10: 1210

C: 13” Reel 40Kpcs

0A: 2010 D: 13” Reel 20Kpcs

12: 2512

■Recommend Land Pattern ■Derating Curve

100

90

C 80

70

Power ratio(%)

60

50

40

B A 30

20

10

A B C 0

Type -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160

(mm) (mm) (mm)

CR-01 0.30 0.25 0.30 Ambient Temperature(℃)

CR-02 0.50 0.45 0.60

CR-03 0.90 0.60 0.90

CR-05 1.20 0.70 1.30

CR-06 2.00 0.90 1.60

CR-10 2.00 0.90 2.80

CR-0A 3.80 0.90 2.80

CR-12 4.90 1.60 3.50

www.viking.com.tw For detail questions, contact:sales@viking.com.tw Edition: REV.B9

2 Revision: 15-Jun-2022

【CR..A Series】

Automotive Grade Chip Resistor

■Soldering Condition (Ref. IPC/JEDEC J-STD-020 & J-STD-002)

Reflow Profiles

Profile Feature Pb-Free Assembly

Preheat

Min. Temperature (Tsmin) 150 °C

Max Temperature (Tsmax) 200 °C

Preheating time (ts) from (Tsmin to Tsmax) 60-120 seconds

Ramp-up rate (TL to Tp) 3 °C/second max.

Liquidous temperature (TL) 217 °C

Time (tL) maintained above TL 60-150 seconds

Min. Peak temperature (Tp min) 235°C

Max. Peak temperature (Tp max) 260°C

Time (tp) within 5 °C of the specified classification temperature (Tc) 30 seconds max.

Ramp-down rate (Tp to TL) 6 °C/second max.

Time 25 °C to peak temperature 8 minutes max.

www.viking.com.tw For detail questions, contact:sales@viking.com.tw Edition: REV.B9

3 Revision: 15-Jun-2022

【CR..A Series】

Automotive Grade Chip Resistor

■Standard Electrical Specifications

Item Power Rating

Max. Max. Resistance Range

at 70C Operating TCR

Operating Overload

Jumper Temp. Range (PPM/C)

Voltage Voltage ±1%(E24、E96) ±5%(E24)

Type Rated Current

1/20W 1Ω - 10MΩ ±200

CR-01 (0201) -55 ~ +155C 25V 50V

Jumper: 1A - 0Ω (<50mΩ) -

1Ω - 9.76Ω ±200

1/16W 10Ω - 1MΩ ±100

CR-02 (0402) -55 ~ +155C 50V 100V 1.02MΩ - 10MΩ ±200

Jumper: 1A - 0Ω (<50mΩ) -

1Ω - 9.76Ω ±200

1/10W 10Ω - 1MΩ ±100

CR-03 (0603) -55 ~ +155C 75V 150V 1.02MΩ - 10MΩ ±200

Jumper: 1A - 0Ω (<50mΩ) -

1Ω - 9.76Ω ±200

1/8W 10Ω - 1MΩ ±100

CR-05 (0805) -55 ~ +155C 150V 300V

1.02MΩ - 10MΩ ±200

Jumper: 2A - 0Ω (<50mΩ) -

1Ω - 9.76Ω ±200

1/4W 10Ω - 1MΩ ±100

CR-06 (1206) -55 ~ +155C 200V 400V 1.02MΩ - 10MΩ ±200

Jumper: 2A - 0Ω (<50mΩ) -

1Ω - 9.76Ω ±200

1/2W 10Ω - 1MΩ ±100

CR-10 (1210) -55 ~ +155C 200V 400V 1.02MΩ - 10MΩ ±200

Jumper: 2.5A - 0Ω (<50mΩ) -

1Ω - 9.76Ω ±200

3/4W 10Ω - 1MΩ ±100

CR-0A (2010) -55 ~ +155C 200V 400V 1.02MΩ - 10MΩ ±200

Jumper: 3.5A - 0Ω (<50mΩ) -

1Ω - 9.76Ω ±200

1W 10Ω - 1MΩ ±100

CR-12 (2512) -55 ~ +155C 250V 500V 1.02MΩ - 10MΩ ±200

Jumper: 4A - 0Ω (<50mΩ) -

■High Precision Electrical Specifications

Max. Max. Resistance Range

Item Power Rating Operating (E24、E96) TCR

Operating Overload

Type at 70°C Temp. Range (PPM/°C)

Voltage Voltage ±0.5%

CR-02 (0402) 1/16W 50V 100V 10Ω - 1MΩ ±100

CR-03 (0603) 1/10W 75V 150V 10Ω - 1MΩ ±100

CR-05 (0805) 1/8W 150V 300V 10Ω - 1MΩ ±100

CR-06 (1206) 1/4W -55 ~ +155C 200V 400V 10Ω - 1MΩ ±100

CR-10 (1210) 1/3W 200V 400V 10Ω - 1MΩ ±100

CR-0A (2010) 3/4W 200V 400V 10Ω - 1MΩ ±100

CR-12 (2512) 1W 250V 500V 10Ω - 1MΩ ±100

www.viking.com.tw For detail questions, contact:sales@viking.com.tw Edition: REV.B9

4 Revision: 15-Jun-2022

【CR..A Series】

Automotive Grade Chip Resistor

■High Power Rating Electrical Specifications

Max. Max. Resistance Range

Item Power Rating Operating Temp. TCR

Operating Overload

Type at 70C Range ±0.5% ±1% ±5% (PPM/°C)

Voltage Voltage

(E24、E96) (E24、E96) (E24)

- 1Ω - 9.76Ω ±200

CR-02 (0402) 1/8W 50V 100V

10Ω - 1MΩ ±100

- 1Ω - 9.76Ω ±200

CR-03 (0603) 1/4W 75V 150V

10Ω - 1MΩ ±100

- 1Ω - 9.76Ω ±200

CR-05 (0805) 1/3W 150V 300V

10Ω - 1MΩ ±100

-55 ~ +155C

- 1Ω - 9.76Ω ±200

CR-06 (1206) 1/2W 200V 400V

10Ω - 1MΩ ±100

- 1Ω - 9.76Ω ±200

CR-0A (2010) 1W 200V 400V

10Ω - 1MΩ ±100

- 1Ω - 9.76Ω ±200

CR-12 (2512) 2W 250V 500V

10Ω - 1MΩ ±100

Operating Voltage=√(P*R) or Max. Operating Voltage listed above, whichever is lower.

Overload Voltage=2.5*√(P*R) or Max. Overload Voltage listed above, whichever is lower.

The power rating depends on the maximum temperature of the resistive element. Due to the power dissipation of the resistor, the

temperature of the resistive element will rise depending on the condition of heat dissipation from PCB. The maximum power rating in

application only applies if the temperature of the resistive element is not exceed 155 ° C.

■ Viking is capable of manufacturing the optional spec based on customer’s requirement.

■Temperature Rise

*FR4 copper board, 35µm of copper pad thickness.

www.viking.com.tw For detail questions, contact:sales@viking.com.tw Edition: REV.B9

5 Revision: 15-Jun-2022

【CR..A Series】

Automotive Grade Chip Resistor

■Environmental Characteristics

Requirement

Item Test Method

1% and Below 5% Jumper

JIS-C-5201-1 4.8

Temperature Coefficient of IEC-60115-1 4.8

As Spec.

Resistance (T.C.R.) At 25C/-55C and 25C/+125C, 25C is the

reference temperature

JIS-C-5201-1 4.13

IEC-60115-1 4.13

Short Time Overload (1.0%+0.05Ω) (2.0%+0.05Ω) <50mΩ

RCWV*2.5 or Max. Overload Voltage whichever is

lower for 5 seconds

JIS-C-5201-1 4.6

Insulation Resistance 10G IEC-60115-1 4.6

Max. Overload Voltage for 1 minute

MIL-STD-202 Method 108

Operational Life (1.0%+0.10Ω) (2.0%+0.10Ω) <100mΩ Condition D Steady State TA=125°C at derated

power.

Measurement at 24±4 hours after test conclusion.

MIL-STD-202 Method 103

Biased Humidity (1.0%+0.10Ω) (2.0%+0.10Ω) <100mΩ

1000 hrs 85C/85%RH 10% of operating power

MIL-STD-202 Method 108

High Temperature Exposure (1.0%+0.05Ω) (1.5%+0.10Ω) <50mΩ

at +155C for 1000 hrs

AEC-Q200-005

Board Flex (1.0%+0.05Ω) (1.0%+0.05Ω) <50mΩ Bending once for 60 seconds

2010, 2512 sizes: 2mm Other sizes: 3mm

JIS-C-5201-1 4.17

IEC-60115-1 4.17

Solderability 95% min. coverage

J-STD-002

2455C for 3 seconds

MIL-STD-202 Method 210

Resistance to Soldering Heat (0.5%+0.05Ω) (1.0%+0.05Ω) <50mΩ

2605C for 10 seconds

JIS-C-5201-1 4.7

Voltage Proof No breakdown or flashover IEC-60115-1 4.7

1.42 times Max. Operating Voltage for 1 minute

Individual leaching area ≦5% JIS-C-5201-1 4.18

Leaching IEC-60068-2-58 8.2.1

Total leaching area ≦ 10%

2605C for 30 seconds

JESD22 Method JA-104

Temperature Cycling (0.5%+0.05Ω) (1.5%+0.05Ω) <50mΩ

-55C to +125C, 1000 cycles

MIL-STD-202 Method 213

Mechanical Shock (0.25%+0.05Ω) (1.0%+0.05Ω) <50mΩ Wave Form: Tolerance for half sine shock pulse.

Peak value is 100g’s. Normal duration (D) is 6.

MIL-STD-202 Method 204

Vibration (0.5%+0.05Ω) (1.0%+0.05Ω) <50mΩ 5 g’s for 20 min., 12 cycles each of 3 orientations,

10-2000 Hz

AEC-Q200-002

Human body model

ESD (3%+0.05Ω) 0201: 0.5KV

0402/0603: 1KV

0805 and above: 2KV

www.viking.com.tw For detail questions, contact:sales@viking.com.tw Edition: REV.B9

6 Revision: 15-Jun-2022

【CR..A Series】

Automotive Grade Chip Resistor

Requirement

Item Test Method

1% and Below 5% Jumper

MIL-STD-202 Method 215

No visible damage on appearance and

Resistance to Solvents Add Aqueous wash chemical - OKEM Clean or

marking.

equivalent. Do not use banned solvents.

AEC-Q200-006

Terminal Strength No broken

Force of 1.8kg for 60 seconds.

UL-94

No ignition of the tissue paper or

Flammability V-0 or V-1 are acceptable. Electrical test not

scorching or the pinewood board

required.

EIA-977 (Condition A)

Sulfur Test △R1% <50mΩ

602C, no power rating for 500 hrs.

RCWV(Rated Continuous Working Voltage)=√(P*R) or Max. Operating Voltage whichever is lower.

■ Storage Temperature: 15~28°C; Humidity < 80%RH

■ Shelf Life: 2 years from production date.

▓Packaging

Reel Specifications & Packaging Quantity

Packaging Tape Reel ΦA ΦB ΦC W T

Type

Quantity Width Diameter (mm) (mm) (mm) (mm) (mm)

+1/-0

10K 8mm 7 inch 178.5±1.5 60 13.0±0.2 9.0±0.5 12.5±0.5

CR-01

Paper 20K 8mm 10 inch 254±1.0 100±0.5 13.0±0.2 9.5±0.5 13.5±0.5

CR-02

40K 8mm 13 inch 330±1.0 100±0.5 13.0±0.2 9.5±0.5 13.5±0.5

+1/-0

CR-03 5K 8mm 7 inch 178.5±1.5 60 13.0±0.2 9.0±0.5 12.5±0.5

CR-05

Paper 10K 8mm 10 inch 254±1.0 100±0.5 13.0±0.2 9.5±0.5 13.5±0.5

CR-06

CR-10 20K 8mm 13 inch 330±1.0 100±0.5 13.0±0.2 9.5±0.5 13.5±0.5

+1/-0

CR-0A 4K 12mm 7 inch 178.5±1.5 60 13.0±0.5 13.0±0.5 15.5±0.5

Embossed

CR-12 8K 12mm 10 inch 250±1.0 62±0.5 13.0±0.5 12.5±0.5 16.5±0.5

www.viking.com.tw For detail questions, contact:sales@viking.com.tw Edition: REV.B9

7 Revision: 15-Jun-2022

【CR..A Series】

Automotive Grade Chip Resistor

Paper Tape Specifications

Bottom Tape Top Tape

ψ D0

E

A

F

W

B

T P1 P2 P0 Direction of unreeling

Paper Tape Resistor

A B W E F P0 P1 P2 ΦD0 T

Type

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

CR-01 0.38±0.05 0.68±0.05 8.0±0.20 1.75±0.10 3.50±0.05 4.00±0.10 2.00±0.05 2.00±0.05 1.50+0.1,-0 0.42±0.20

CR-02 0.65±0.10 1.15±0.10 8.0±0.20 1.75±0.10 3.50±0.05 4.00±0.10 2.00±0.05 2.00±0.05 1.50+0.1,-0 0.45±0.10

CR-03 1.10±0.10 1.90±0.10 8.0±0.20 1.75±0.10 3.50±0.05 4.00±0.10 4.00±0.05 2.00±0.05 1.50+0.1,-0 0.70±0.10

CR-05 1.60±0.10 2.40±0.20 8.0±0.20 1.75±0.10 3.50±0.05 4.00±0.10 4.00±0.05 2.00±0.05 1.50+0.1,-0 0.85±0.10

CR-06 1.90±0.10 3.50±0.20 8.0±0.20 1.75±0.10 3.50±0.05 4.00±0.10 4.00±0.05 2.00±0.05 1.50+0.1,-0 0.85±0.10

CR-10 2.90±0.10 3.50±0.20 8.0±0.20 1.75±0.10 3.50±0.05 4.00±0.10 4.00±0.05 2.00±0.05 1.50+0.1,-0 0.85±0.10

Embossed Plastic Tape Specifications

Top Tape

ψ D0

E

A

F W

B

ψD11.5+0.25,-0

T Direction of unreeling

Resistor P1 P2 P0

Embossed Tape

A B W E F P0 P1 P2 ΦD0 T

Type

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

+0

CR-0A 2.8±0.10 5.40±0.20 12.0±0.30 1.75±0.10 5.5±0.05 4.00±0.10 4.00±0.10 2.00±0.05 1.50+0.1, -0 1.2

+0

CR-12 3.5±0.10 6.7±0.10 12.0±0.30 1.75±0.10 5.5±0.05 4.00±0.10 4.00±0.10 2.00±0.05 1.50+0.1, -0 1.2

www.viking.com.tw For detail questions, contact:sales@viking.com.tw Edition: REV.B9

8 Revision: 15-Jun-2022

【CR..A Series】

Automotive Grade Chip Resistor

■Marking

No Marking for 0201/0402

Jumper for all: Letter “0”

1% for 0805/0612/1206/1210/2010/2512: 4 digits marking

Example:

Resistance 100Ω 2.2KΩ 10KΩ 49.9KΩ 100KΩ

Marking 1000 2201 1002 4992 1003

5% for 0603/0805/0612/1206/1210/2010/2512: 3 digits marking in E24

st nd rd

Example: 101=100Ω 102=1KΩ (1 and 2 are E24 code and 3 code is multiplier)

E24

10 11 12 13 15 16 18 20 22 24 27 30 33 36 39 43 47 51 56 62 68 75 82 91

code

1% for 0603(E24): 3 digits marking in E24, When the E24 and E96 are the same resistance, this marking in E96

Example: 01A= 100Ω 05C=11KΩ 123=12KΩ 273=27KΩ

1% for 0603(E96): 3 digits marking in E96

14C 3 digits marking for Example: 14C=13K7Ω

68B=4K99Ω

13C=13K3Ω

68X=49.9Ω

www.viking.com.tw For detail questions, contact:sales@viking.com.tw Edition: REV.B9

9 Revision: 15-Jun-2022

【CR..A Series】

Automotive Grade Chip Resistor

Marking Table

Code E96 Code E96 Code E96 Code E96

01 100 25 178 49 316 73 562

02 102 26 182 50 324 74 576

03 105 27 187 51 332 75 590

04 107 28 191 52 340 76 604

05 110 29 196 53 348 77 619

06 113 30 200 54 357 78 634

07 115 31 205 55 365 79 649

08 118 32 210 56 374 80 665

09 121 33 215 57 383 81 681

10 124 34 221 58 392 82 698

11 127 35 226 59 402 83 715

12 130 36 232 60 412 84 732

13 133 37 237 61 422 85 750

14 137 38 243 62 432 86 768

15 140 39 249 63 442 87 787

16 143 40 255 64 453 88 806

17 147 41 261 65 464 89 825

18 150 42 267 66 475 90 845

19 154 43 274 67 487 91 866

20 158 44 280 68 499 92 887

21 162 45 287 69 511 93 909

22 165 46 294 70 523 94 931

23 169 47 301 71 536 95 953

24 174 48 309 72 549 96 976

Code A B C D E F G X Y

0 1 2 3 4 5 6 -1 -2

10 10 10 10 10 10 10 10 10

Multiplier

www.viking.com.tw For detail questions, contact:sales@viking.com.tw Edition: REV.B9

10 Revision: 15-Jun-2022

【CR..A Series】

Automotive Grade Chip Resistor

■Pulse withstanding capacity

The limit of acceptance was a shift in resistance of less than 1% from the initial value. The power applied was subject to the

restrictions of the maximum permissible impulse voltage.

2512

CR..A Series Single Pulse 2010

1210

1206

1000

0805

0603

0402

100

Pulse Power (W)

10

0.1

0.00001 0.0001 0.001 0.01 0.1 1

Pulse Duration Time(sec.)

Note: The limit of the applicable voltage is the max. overload voltage. Please consult us about the resistance characteristic when

pulse is applied continuously. This data is a reference value, please be sure to test the products on the actual circuit before you use

them.

www.viking.com.tw For detail questions, contact:sales@viking.com.tw Edition: REV.B9

11 Revision: 15-Jun-2022

【CR..A Series】

Automotive Grade Chip Resistor

REVISION HISTORY

REVISION DATE CHANGE NOTIFICATION DESCRIPTION

Version A5 Apr 30, 2015 - - Environmental Characteristics updated

Version A6 Jun 18, 2015 - - Increased 0603(E24) 1% marking description

- Remove Material Description

- Size CR-01 specifications added

- Modify Storage Temperature

Version A7 Jul 15, 2016 -

- Increased 0.5% Resistance Range

- Increased High Power Rating Electrical

Specifications

- Environmental Characteristics updated

Version A8 Jan 12, 2018 - - Modify Electrical Specifications (0R)

- Modify 2512 Land Pattern

- Modify TCR Test description

Version A9 May 20, 2019 - - Features added 100% CCD inspection

- Added Sulfur Test

Version B Jun 1, 2019 - - Modify ESD Test description & Spec.

- increase 2512 2W Specifications

Version B1 Oct 21, 2019 - - increase Special standard packaging

specifications (disc 10" & 13")

Version B2 Jan 31, 2020 - - Features added Anti-sulfur characteristics

- Added Temperature Rise

Version B3 May 22, 2020 - - Modify High Power Rating Electrical

Specifications ( added 0.5% )

Version B4 Sep 25, 2020 - - increase 0612 Specifications

- Delete 0612 size Specifications

- Modify 2010 Embossed Plastic Tape B

Version B5 Mar 10, 2021 - Specification

- Modify Soldering Condition (IPC/JEDEC

J-STD-020)

Version B6 Nov 15, 2021 - - Increase the shelf life description

Version B7 Jan 26, 2022 - - 0201 Operating temperature rises to 155℃

Version B8 Feb 15, 2022 - - Derating Curve changes the temperature

range

Version B9 Jun 15, 2022 - - Modify Soldering Condition

www.viking.com.tw For detail questions, contact:sales@viking.com.tw Edition: REV.B9

12 Revision: 15-Jun-2022

You might also like

- 2 Bill of Exchange TemplateDocument1 page2 Bill of Exchange Templatepoppadoc19594% (18)

- Chapter 09 HWDocument19 pagesChapter 09 HWSonam Mehta80% (5)

- SchleunigerDocument74 pagesSchleunigerSakshi SharmaNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Advanced Process Control Market (2014 - 2020)Document164 pagesAdvanced Process Control Market (2014 - 2020)Binny SamuelNo ratings yet

- CR SeriesDocument11 pagesCR SeriesphamNo ratings yet

- CRG..A Series PDFDocument10 pagesCRG..A Series PDFphamNo ratings yet

- SeriesDocument8 pagesSeriesArthur ChavesNo ratings yet

- CSRA Series PDFDocument15 pagesCSRA Series PDFDamian Huitzil CedilloNo ratings yet

- AR SeriesDocument8 pagesAR SeriesphamNo ratings yet

- REZistori 0603Document10 pagesREZistori 0603ivanshitov2015No ratings yet

- Viking Tech ARG03FTC2551 - C217943Document8 pagesViking Tech ARG03FTC2551 - C217943ALIRIO SOLANONo ratings yet

- Data Sheet: Kris Chen Ben Chang Ben ChangDocument7 pagesData Sheet: Kris Chen Ben Chang Ben ChangBriggitte OrtizNo ratings yet

- SMDC01005 ElectronicDocument10 pagesSMDC01005 ElectronicMariaNo ratings yet

- CSRF - Series Data Sheet (Edition REV.A5)Document9 pagesCSRF - Series Data Sheet (Edition REV.A5)Hubert OpenchowskiNo ratings yet

- High Voltage C0G Dielectric, 500 - 10,000 VDC (Commercial Grade)Document24 pagesHigh Voltage C0G Dielectric, 500 - 10,000 VDC (Commercial Grade)ndfgdfs oishdfNo ratings yet

- Multilayer Ceramic Chip Capacitors: C Series Commercial Grade General (Up To 50V)Document55 pagesMultilayer Ceramic Chip Capacitors: C Series Commercial Grade General (Up To 50V)blokolbNo ratings yet

- 1N4001 DDocument57 pages1N4001 DAbel GaunaNo ratings yet

- 3RV29012A Datasheet enDocument5 pages3RV29012A Datasheet enezeokoye4lifeNo ratings yet

- Sunon: Specification For ApprovalDocument16 pagesSunon: Specification For ApprovalManuelLentiNo ratings yet

- Series: Multilayer Ceramic Chip CapacitorsDocument34 pagesSeries: Multilayer Ceramic Chip CapacitorsralusanduNo ratings yet

- Maida Catalog Specifications Standard SeriesDocument16 pagesMaida Catalog Specifications Standard SeriesRetanaMaferNo ratings yet

- Certified Panel Builder: 19-08-2021 P1423-05-21-AD-SCH-R04Document5 pagesCertified Panel Builder: 19-08-2021 P1423-05-21-AD-SCH-R04ahmed samiNo ratings yet

- Empro® PVC WSDocument2 pagesEmpro® PVC WSm.aliNo ratings yet

- 100% Insulation Level, 28kV Rated, 3/C: Type MV-105Document1 page100% Insulation Level, 28kV Rated, 3/C: Type MV-105willytNo ratings yet

- Tantal Vishay 293dDocument22 pagesTantal Vishay 293dDakovic AleksandarNo ratings yet

- Vishay 293D475X9025C2TE3 DatasheetDocument9 pagesVishay 293D475X9025C2TE3 DatasheetMiguel VNo ratings yet

- DatasheetDocument16 pagesDatasheetErick MauricioNo ratings yet

- Multilayer Chip Capacitors X7R/B Characteristic: FeaturesDocument17 pagesMultilayer Chip Capacitors X7R/B Characteristic: FeaturesLupita Motta TobíasNo ratings yet

- C2225X104KDRAC7800Document24 pagesC2225X104KDRAC7800Fotos WD DiacoNo ratings yet

- RC1005F561CSDocument2 pagesRC1005F561CSDarwin SipayungNo ratings yet

- WW25W, WW20W, WW10W, WW12W, WW08W, WW06W 1%, 5%Document8 pagesWW25W, WW20W, WW10W, WW12W, WW08W, WW06W 1%, 5%Fazli WadoodNo ratings yet

- CFS 504 100 57 60D SL GL NSG - CLF500173 A2Document3 pagesCFS 504 100 57 60D SL GL NSG - CLF500173 A2ganesangNo ratings yet

- Kem C1010 X7R HV SMD-3316377Document25 pagesKem C1010 X7R HV SMD-3316377Faizan MalikNo ratings yet

- X7R Tip & RingDocument16 pagesX7R Tip & Ringdovesnest_inNo ratings yet

- ELECTROHMS Catalogue CT VT - 2023Document14 pagesELECTROHMS Catalogue CT VT - 2023ramarao.guruprasadNo ratings yet

- Holiday DetectorDocument7 pagesHoliday DetectorMuntadher AlbadryNo ratings yet

- X7R Dielectric, 6.3 - 250 VDC (Commercial Grade) : Surface Mount Multilayer Ceramic Chip Capacitors (SMD MLCCS)Document26 pagesX7R Dielectric, 6.3 - 250 VDC (Commercial Grade) : Surface Mount Multilayer Ceramic Chip Capacitors (SMD MLCCS)Naveed AhmedNo ratings yet

- X7R Dielectric, 6.3 - 250 VDC (Commercial Grade) : Surface Mount Multilayer Ceramic Chip Capacitors (SMD MLCCS)Document26 pagesX7R Dielectric, 6.3 - 250 VDC (Commercial Grade) : Surface Mount Multilayer Ceramic Chip Capacitors (SMD MLCCS)Alberto GonzalesNo ratings yet

- C0G Dielectric, 10Vdc-200Vdc (Automotive Grade) : Surface Mount Multilayer Ceramic Chip Capacitors (SMD MLCCS)Document18 pagesC0G Dielectric, 10Vdc-200Vdc (Automotive Grade) : Surface Mount Multilayer Ceramic Chip Capacitors (SMD MLCCS)dovesnest_inNo ratings yet

- Solder Sleeves For Coax - B-044-22-NDocument2 pagesSolder Sleeves For Coax - B-044-22-NGeeNo ratings yet

- Data Sheet: ReceivedDocument7 pagesData Sheet: ReceivedStuxnetNo ratings yet

- 3RV29211M Datasheet enDocument2 pages3RV29211M Datasheet eninfoNo ratings yet

- Cbr04c101g3gac 2Document16 pagesCbr04c101g3gac 2ahmed rafatNo ratings yet

- MF60151V1 B00u A99 PDFDocument14 pagesMF60151V1 B00u A99 PDFGustavo BorjaNo ratings yet

- ST Sub Figrc2Document2 pagesST Sub Figrc2Logistica 1No ratings yet

- Disc CapDocument33 pagesDisc CapShibu Kumar SNo ratings yet

- Hyundai Eett ResumenDocument24 pagesHyundai Eett ResumenFebo MccdNo ratings yet

- Vishay 293D107X9016D2TE3 DatasheetDocument9 pagesVishay 293D107X9016D2TE3 DatasheetAlejandro ChavarríaNo ratings yet

- Adi Artech: DescriptionDocument1 pageAdi Artech: DescriptionkumarNo ratings yet

- KCG057QV1DC-G770-Kyocera Sig GenDocument28 pagesKCG057QV1DC-G770-Kyocera Sig GenNear Mi Tech ServicesNo ratings yet

- 1101-515-2110 Datasheets USDocument3 pages1101-515-2110 Datasheets USabdulkawi alasharyNo ratings yet

- VR 10K PDFDocument3 pagesVR 10K PDFKudo ShinichiNo ratings yet

- Qoutation Offer: PDF Created With Pdffactory Pro Trial VersionDocument8 pagesQoutation Offer: PDF Created With Pdffactory Pro Trial VersionMohamad HessenNo ratings yet

- 3RV10210JA10 Datasheet enDocument5 pages3RV10210JA10 Datasheet enalexisNo ratings yet

- Viraj BookletaaDocument29 pagesViraj BookletaaSuhaib ShabandriNo ratings yet

- MetalOVD2 16 OptDocument16 pagesMetalOVD2 16 OptInajá FerreiraNo ratings yet

- ST Series Servo Motor: Beijing KND CNC Technique Co.,Ltd. 01.2012Document21 pagesST Series Servo Motor: Beijing KND CNC Technique Co.,Ltd. 01.2012Dinos ArhNo ratings yet

- "Classic Range" Aluminium Connectors - 63/220 KV: Simel ProductsDocument4 pages"Classic Range" Aluminium Connectors - 63/220 KV: Simel ProductsThành DanhNo ratings yet

- C1Z100B THRU C1Z330B Silicon Zener Diode 1 Watt, 100 Thru 330 Volts DescriptionDocument3 pagesC1Z100B THRU C1Z330B Silicon Zener Diode 1 Watt, 100 Thru 330 Volts DescriptionPelotaDeTrapoNo ratings yet

- Taj 776811Document8 pagesTaj 776811balajiboss005No ratings yet

- 1638413924Document6 pages1638413924phamNo ratings yet

- Unit 20Document6 pagesUnit 20phamNo ratings yet

- BLF10H6600P BLF10H6600PSDocument18 pagesBLF10H6600P BLF10H6600PSphamNo ratings yet

- CRG..A Series PDFDocument10 pagesCRG..A Series PDFphamNo ratings yet

- AR SeriesDocument8 pagesAR SeriesphamNo ratings yet

- CR SeriesDocument11 pagesCR SeriesphamNo ratings yet

- ElectricalDocument7 pagesElectricaldomesNo ratings yet

- PMB SiliconDocument23 pagesPMB SiliconRudi SamudraNo ratings yet

- Https Vahan - Parivahan.gov - in Vahanservice Vahan Ui Onlineservice Form 23 RC Report - XHTMLDocument1 pageHttps Vahan - Parivahan.gov - in Vahanservice Vahan Ui Onlineservice Form 23 RC Report - XHTMLzaid AhmedNo ratings yet

- Program Kredit Ultra Mikro Dan Kemiskinan Di Jawa Tengah Pada Masa PandemiDocument17 pagesProgram Kredit Ultra Mikro Dan Kemiskinan Di Jawa Tengah Pada Masa PandemiMuhammad FatahNo ratings yet

- BPP F3 KitDocument4 pagesBPP F3 KitMuhammad Ubaid UllahNo ratings yet

- Reportage Village 4 Bed 5 SepDocument1 pageReportage Village 4 Bed 5 Sepzucky1607No ratings yet

- Accounting Principles: The Recording ProcessDocument51 pagesAccounting Principles: The Recording ProcessMd. Saadman Sakib 2115420660No ratings yet

- San Antonio Businesses That Applied For, and Received, PPP LoansDocument231 pagesSan Antonio Businesses That Applied For, and Received, PPP LoansMary Claire Patton57% (7)

- Integer Programming Models Types of ModelsDocument19 pagesInteger Programming Models Types of ModelsGerard EspinaNo ratings yet

- 20210213174103D3066 - Soal Job CostingDocument3 pages20210213174103D3066 - Soal Job CostingYanti RianiNo ratings yet

- Gretchen V. CasonDocument3 pagesGretchen V. CasonGretchen VictoriaNo ratings yet

- Drafting Psda Ba BDocument21 pagesDrafting Psda Ba BNiraj Pandey0% (1)

- PolicyStatus 678709295Document1 pagePolicyStatus 678709295VENKATA KARTEEKNo ratings yet

- Chapter 3 - GEC3Document20 pagesChapter 3 - GEC3Loreen TonettNo ratings yet

- National Income Class 12 WsDocument19 pagesNational Income Class 12 WsIsha BhattNo ratings yet

- Theoretical Tools of Public Finance (Chapter 2 in Gruber's Textbook)Document45 pagesTheoretical Tools of Public Finance (Chapter 2 in Gruber's Textbook)GiuseppeNo ratings yet

- Inventory Vouchers in Tally Erp 9Document12 pagesInventory Vouchers in Tally Erp 9Subramaniam Krishnamoorthi100% (1)

- BE8-3 Date Account Titles and Explanation Debit CreditDocument4 pagesBE8-3 Date Account Titles and Explanation Debit CreditMai Phương NguyễnNo ratings yet

- Latihan 2Document25 pagesLatihan 2Muhammad Hadiyan NajibNo ratings yet

- Fuse PDFDocument1 pageFuse PDFrohit tiwariNo ratings yet

- DR - YSR Aarogyasri App Download Report As On 28.10.2023Document2 pagesDR - YSR Aarogyasri App Download Report As On 28.10.2023MeenakshiNo ratings yet

- 销售合同范本Document1 page销售合同范本jiangrenlin66No ratings yet

- The Strategy Formulation Analytical FrameworkDocument2 pagesThe Strategy Formulation Analytical Frameworkdailydoseoflaw100% (2)

- Payroll ExercisesDocument1 pagePayroll ExercisesMerry Grace EsquivelNo ratings yet

- Rizwan SB LGS CBT-LHR-544-20-2Document5 pagesRizwan SB LGS CBT-LHR-544-20-2Uzair Maqbool KhanNo ratings yet

- Small Businesses in NigeriaDocument4 pagesSmall Businesses in NigeriaMariam Oluwatoyin CampbellNo ratings yet

- (Foundations and Trends in Microeconomics) David Neumark, William Wascher - Minimum Wages and Employment - Now Publishers Inc (2007) PDFDocument197 pages(Foundations and Trends in Microeconomics) David Neumark, William Wascher - Minimum Wages and Employment - Now Publishers Inc (2007) PDFFarhan ArshadNo ratings yet