Professional Documents

Culture Documents

Oxy-Acetelyne Regulation SIRE Vessel Inspection Questionnaire - VIQ 7 PDF

Oxy-Acetelyne Regulation SIRE Vessel Inspection Questionnaire - VIQ 7 PDF

Uploaded by

Tolias EgwOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oxy-Acetelyne Regulation SIRE Vessel Inspection Questionnaire - VIQ 7 PDF

Oxy-Acetelyne Regulation SIRE Vessel Inspection Questionnaire - VIQ 7 PDF

Uploaded by

Tolias EgwCopyright:

Available Formats

Hot Work Procedures:

5.24 Are officers aware of the requirements for hot work and are hot work procedures in

accordance with the recommendations of ISGOTT and OCIMF guidelines?

There have been a number of fires and explosions due to Hot Work in, on, or near cargo tanks or other

spaces that contain, or that have previously contained, flammable substances or substances that emit

flammable vapours. Hot Work should only be considered if there are no practical alternative means of

repair. (ISGOTT 9.4)

The SMS should include adequate guidance on control of Hot Work and should be robust enough to

ensure compliance. (See Fig 9.2) Absence of guidance should be regarded as prohibition rather than

approval (IMO MSC/Circ. 1084). (ISGOTT 9.4.1)

The OCIMF Guidelines on Safety Management Systems for Hot Work and Entry into Enclosed Spaces

(1st Ed September 2008) information paper must be taken into account in the development of hot

work procedures.

.

5.25 Are officers aware of safety guidelines for electric welding equipment, are written guidelines

posted and equipment in good order?

Welding and other equipment used for Hot Work should be carefully inspected before each occasion

of use to ensure that it is in good condition. Where required, it must be correctly earthed. Special

attention must be paid when using electric arc equipment to ensure that:

- Electrical supply connections are made in a gas free space.

- Existing supply wiring is adequate to carry the electrical current demand without overloading,

causing heating.

- Insulation of flexible electric cables is in good condition.

- The cable route to the work site is the safest possible, only passing over gas free or inerted spaces.

- The welding return lead should be connected as near as practicable to the welding arc; metal rails,

pipes and frames should not be used as part of the welding circuit unless they are a part of the work

piece itself.

(ISGOTT 9.5)

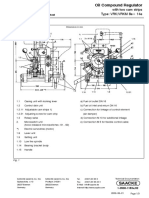

5.26 Is gas welding and burning equipment in good order and spare oxygen and acetylene

cylinders stored apart in a well-ventilated location outside of the accommodation and

engine room?

Piping should be of steel welded construction and bolted flanges are prohibited. Copper, rubber or

braided lines should not be used, except that braided lines may be used for the short length from the

cylinder heads to the manifolds within the storage space. Pipework and fittings should be free of

grease.

Pipe joints on the low-pressure side of the regulators shall be welded. (46 CFR 56.50-103)

Note. In open air locations it may be acceptable for a short length of piping from the bottle to an

isolation valve to be flanged. This is the only exception however.

Flashback arrestors should be fitted at both the cylinders and workstation as recommended by the USA

Operational Safety and Health Admin (OSHA), the UK Health and Safety Executive and other national

safety authorities where long lengths of piping between the cylinders and the blowtorch are involved.

Regulators should be inspected annually and replaced or refurbished on a 5-year basis. (British

Compressed Gases Association Code of Practice CP7)

Oxygen will not burn or explode, it only supports combustion; however, a small amount of excess

oxygen will allow materials which are not normally combustible to burn with ferocity. Industrial oxygen

cylinders are painted blue. Acetylene is 92.3% carbon and 7.7% hydrogen, is lighter than air and is

highly flammable with a LEL of 2.5%. Acetylene cylinders are painted maroon.

Oxygen and Acetylene should be kept in separate compartments except in the case of the cylinders

that are in use, which may be stored in the same compartment. Cylinders should be stowed away

from heat sources and should not be in heavy traffic areas to prevent accidental knocking over or

damage from passing or failing objects. Valve caps should remain on cylinders not connected for use.

Full and empty cylinders should be segregated. Cylinders should be stored with the valve end up.

Storage areas should be free of combustible material and not exposed to salt or other corrosive

chemicals. The use of propane in gas burning and welding systems is prohibited.

© Copyright OCIMF 2018. All rights reserved. VIQ 7 – 17 September 2018

54

You might also like

- Technical Proposal: The Seller Jinan Senfeng Technology Co.,Ltd The BuyerDocument23 pagesTechnical Proposal: The Seller Jinan Senfeng Technology Co.,Ltd The BuyerjuanNo ratings yet

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocument9 pagesHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- Hot Tap Procedures ExonDocument17 pagesHot Tap Procedures ExonDian Ardiansyah67% (3)

- Safe Use of Oxygen Fuel Gas EquipmentDocument4 pagesSafe Use of Oxygen Fuel Gas Equipmentzam110No ratings yet

- OA Cutting and WeldingDocument24 pagesOA Cutting and WeldingJames Hale0% (1)

- MCQ Workshop Engg: Workshop Technology Objective Questions With Answers - Set 07Document5 pagesMCQ Workshop Engg: Workshop Technology Objective Questions With Answers - Set 07l8o8r8d8s8i8v8100% (2)

- SOP For Gas Cutting Amp WeldingDocument12 pagesSOP For Gas Cutting Amp WeldingRmr ReyesNo ratings yet

- Safety Standard On Storage, Handling & Use of Gas Cylinders in Steel IndustryDocument8 pagesSafety Standard On Storage, Handling & Use of Gas Cylinders in Steel Industrylajpat mehraNo ratings yet

- Maz - PRJ - Hse - PRC 17 Safe Use of Compressed Gases 001Document10 pagesMaz - PRJ - Hse - PRC 17 Safe Use of Compressed Gases 001ghazi kallelNo ratings yet

- Safetyin Welding Gas Cutting OperationsDocument12 pagesSafetyin Welding Gas Cutting OperationsSantanu Kumar SahuNo ratings yet

- Safe Operating Procedure: (Revised 11/11)Document10 pagesSafe Operating Procedure: (Revised 11/11)Sandeep ShettyNo ratings yet

- SOP Welding, Cutting and Gas CylinderDocument7 pagesSOP Welding, Cutting and Gas Cylindertengku hafizNo ratings yet

- Gas Cylinder Rules, 2004Document16 pagesGas Cylinder Rules, 2004Madhuri Gauba100% (1)

- Section 9 - Compressed Gases/Cylinders: Basic H&S GuidelinesDocument1 pageSection 9 - Compressed Gases/Cylinders: Basic H&S GuidelinesnguyenthinhvinhkhaNo ratings yet

- Design and Fitting of Oxygen SystemsDocument10 pagesDesign and Fitting of Oxygen Systemsasjadullah1No ratings yet

- Safety in Work Place Safety in WeldingDocument25 pagesSafety in Work Place Safety in WeldingRahul SiwakotiNo ratings yet

- Sop Welding & Gas CuttingDocument9 pagesSop Welding & Gas CuttingvinodsnNo ratings yet

- Welding SopDocument7 pagesWelding Sopttdost0% (1)

- Compressed Gases SOP FinalDocument9 pagesCompressed Gases SOP FinalSandeep ShettyNo ratings yet

- Purpose: Handling CylindersDocument3 pagesPurpose: Handling Cylindersdaburto2No ratings yet

- Welding, Cutting and BrazingDocument66 pagesWelding, Cutting and BrazingSohail AnjumNo ratings yet

- Welding, Cutting and Brazing: NOAA Web Based TrainingDocument66 pagesWelding, Cutting and Brazing: NOAA Web Based TrainingRauf HuseynovNo ratings yet

- Compressed Gas SafetyDocument28 pagesCompressed Gas SafetyDiaa Gab-AllahNo ratings yet

- 06.24.037 - Welding and CuttingDocument3 pages06.24.037 - Welding and Cuttingdaan me teanNo ratings yet

- T 1839 F Welding OperationDocument44 pagesT 1839 F Welding OperationrubelNo ratings yet

- Airworthiness Advisory Circular: Director General of Civil AviationDocument4 pagesAirworthiness Advisory Circular: Director General of Civil AviationksmohsinNo ratings yet

- Sop For Storage, Handling & Use of Gas CylindersDocument8 pagesSop For Storage, Handling & Use of Gas Cylinderssuvojitroy2000No ratings yet

- Layouts FOR Oil and Gas InstallationsDocument21 pagesLayouts FOR Oil and Gas Installationsashishntpc1309No ratings yet

- E0900048-V4 LIGO UHV Welding SpecDocument7 pagesE0900048-V4 LIGO UHV Welding SpecBenjamin BrownNo ratings yet

- Compressed Gas SafetyDocument12 pagesCompressed Gas SafetyRavi Sankar VenkatesanNo ratings yet

- Welding, Cutting and Brazing: NOAA Web Based TrainingDocument66 pagesWelding, Cutting and Brazing: NOAA Web Based TrainingninibangashNo ratings yet

- Schlenk Line Technique ChandraDocument21 pagesSchlenk Line Technique ChandraAustin LaneNo ratings yet

- Safe Use of Cylinder Gases: ©consultnet LimitedDocument29 pagesSafe Use of Cylinder Gases: ©consultnet LimitedAhmad Mensa100% (1)

- Oxy Acetylene Welding Cutting Use and StorageDocument6 pagesOxy Acetylene Welding Cutting Use and Storagekenoly123No ratings yet

- Welding SafetyDocument43 pagesWelding Safetyjefmohd100% (3)

- Safety ChecklistDocument1 pageSafety ChecklistSvetoslav StoimenovNo ratings yet

- Welding and Cutting InstructionDocument2 pagesWelding and Cutting InstructioncaptaincadenaNo ratings yet

- Reference 1 PDFDocument10 pagesReference 1 PDFJanicka Palencia AgaNo ratings yet

- Senr0512 01Document46 pagesSenr0512 01Pauk HseinNo ratings yet

- CGC SafetyDocument9 pagesCGC SafetySOLY_POP_10No ratings yet

- BCGA Code of PracticeDocument18 pagesBCGA Code of PracticeSivakumar NatarajanNo ratings yet

- O2 SafetyDocument3 pagesO2 Safetyrajpatil0007No ratings yet

- SOP Compressed GasDocument4 pagesSOP Compressed GasSandeep ShettyNo ratings yet

- Welding: Subpart QDocument65 pagesWelding: Subpart QRathnakrajaNo ratings yet

- Above Ground Oil Storage TanksDocument8 pagesAbove Ground Oil Storage TanksTarjo SutedjoNo ratings yet

- WeldingDocument66 pagesWeldingNilton LuisNo ratings yet

- Safety in Welding and Cutting Operations.Document9 pagesSafety in Welding and Cutting Operations.MANOJ KUMARNo ratings yet

- 50x70-Poster SafetyChecklist LowresDocument1 page50x70-Poster SafetyChecklist LowresMuhd Khir RazaniNo ratings yet

- Safe Gas Cylinders ManagementDocument5 pagesSafe Gas Cylinders ManagementdnmuleNo ratings yet

- AMCA Standard 99-0401-86 Classification For Spark Resistant ConstructionDocument1 pageAMCA Standard 99-0401-86 Classification For Spark Resistant Constructionhardik033No ratings yet

- SM-Contents Week 10-13Document38 pagesSM-Contents Week 10-13May Ann RiveraNo ratings yet

- Compressed Gas Cylinder Storage and Handling - UCLADocument7 pagesCompressed Gas Cylinder Storage and Handling - UCLAtaibkNo ratings yet

- Bunds For Above Ground TanksDocument8 pagesBunds For Above Ground TanksAlf HorsemanNo ratings yet

- Guide-to-Compressed-or-Liquefied-Gases-in-Laboratories ACETYLENEDocument10 pagesGuide-to-Compressed-or-Liquefied-Gases-in-Laboratories ACETYLENEvermaravi11449922No ratings yet

- The Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingFrom EverandThe Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingNo ratings yet

- The Art of Lead Burning: A practical treatisening the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatisening the apparatus and processesNo ratings yet

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- The Art of Lead Burning: A practical treatise explaining the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatise explaining the apparatus and processesNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- 3.1.4 - EM CK 01 D - Fire in EngineroomDocument1 page3.1.4 - EM CK 01 D - Fire in EngineroomTolias EgwNo ratings yet

- Jacob LadderDocument1 pageJacob LadderTolias EgwNo ratings yet

- 2T10-12mHSGK220-160-2400-1755 ModelDocument1 page2T10-12mHSGK220-160-2400-1755 ModelTolias EgwNo ratings yet

- 2 Threshold Voltage PDFDocument8 pages2 Threshold Voltage PDFTolias EgwNo ratings yet

- 2 Ballast Level Flowchart PDFDocument1 page2 Ballast Level Flowchart PDFTolias EgwNo ratings yet

- 3.6 - EM CK 06 - Man Overboard and Recovery From WaterDocument1 page3.6 - EM CK 06 - Man Overboard and Recovery From WaterTolias EgwNo ratings yet

- 2.PC Jotun Chart1011 PDFDocument3 pages2.PC Jotun Chart1011 PDFTolias EgwNo ratings yet

- 3.1.2 - EM CK 01 B - Fire On Deck - in Cargo SpaceDocument1 page3.1.2 - EM CK 01 B - Fire On Deck - in Cargo SpaceTolias EgwNo ratings yet

- 1 3638 5012a 02 PDFDocument2 pages1 3638 5012a 02 PDFTolias EgwNo ratings yet

- 1 3638 5049 02 PDFDocument1 page1 3638 5049 02 PDFTolias EgwNo ratings yet

- 1..FLOW DRAW MT CHER SW600 Kalooo PDFDocument1 page1..FLOW DRAW MT CHER SW600 Kalooo PDFTolias EgwNo ratings yet

- 1-DD-Akron-CORA-9519705-PROP-60 Months Technical Specification 2018-07-18 PDFDocument8 pages1-DD-Akron-CORA-9519705-PROP-60 Months Technical Specification 2018-07-18 PDFTolias EgwNo ratings yet

- 1-DD-Akron-CORA-9519705-PROP-60 Months Commercial Paint Delivery 2018-07-18 PDFDocument3 pages1-DD-Akron-CORA-9519705-PROP-60 Months Commercial Paint Delivery 2018-07-18 PDFTolias EgwNo ratings yet

- 02.1 - HSE - Policy-01 03 16 PDFDocument1 page02.1 - HSE - Policy-01 03 16 PDFTolias EgwNo ratings yet

- 1 3500 4109a 02 PDFDocument3 pages1 3500 4109a 02 PDFTolias EgwNo ratings yet

- 1.unimarine Equivalent List PDFDocument3 pages1.unimarine Equivalent List PDFTolias EgwNo ratings yet

- 1 3638 3074a 02 PDFDocument1 page1 3638 3074a 02 PDFTolias EgwNo ratings yet

- 1.apexior 3 PDFDocument1 page1.apexior 3 PDFTolias EgwNo ratings yet

- 1 Cot Slop Level Flowchart PDFDocument1 page1 Cot Slop Level Flowchart PDFTolias EgwNo ratings yet

- 1 3638 1204a 02 PDFDocument1 page1 3638 1204a 02 PDFTolias EgwNo ratings yet

- #405 Maintenance of Emergency GeneratorDocument2 pages#405 Maintenance of Emergency GeneratorTolias EgwNo ratings yet

- 01-6 Complaint Procedures-R0-15 05 13-Ud 01 07 13 - RINA - PDFDocument5 pages01-6 Complaint Procedures-R0-15 05 13-Ud 01 07 13 - RINA - PDFTolias EgwNo ratings yet

- 02.2 - D&A Policy-01 03 16 PDFDocument1 page02.2 - D&A Policy-01 03 16 PDFTolias EgwNo ratings yet

- 0service Bulletin List ForDocument3 pages0service Bulletin List ForTolias Egw100% (1)

- 00 ContentsDocument6 pages00 ContentsTolias EgwNo ratings yet

- 01 General Conditions PDFDocument5 pages01 General Conditions PDFTolias EgwNo ratings yet

- #408 Steering Gear Overhaul or MaintenanceDocument3 pages#408 Steering Gear Overhaul or MaintenanceTolias EgwNo ratings yet

- 1st Page PDFDocument1 page1st Page PDFTolias EgwNo ratings yet

- 1 3500 1183a 02 PDFDocument3 pages1 3500 1183a 02 PDFTolias EgwNo ratings yet

- #404 Emergency Fire Pump Maintenance (Revised)Document4 pages#404 Emergency Fire Pump Maintenance (Revised)Tolias EgwNo ratings yet

- Fabrication of Process Analyzer Packages-MSDocument24 pagesFabrication of Process Analyzer Packages-MSAhmed ElghmatiNo ratings yet

- RTG Kalmar MainternanceDocument356 pagesRTG Kalmar MainternanceMIKELAM09No ratings yet

- IS 10987 (1992) - Above & Under Ground Tanks For SolventsDocument17 pagesIS 10987 (1992) - Above & Under Ground Tanks For SolventsNishith100% (1)

- MIG Flux-Cored Welding CalculatorDocument2 pagesMIG Flux-Cored Welding CalculatorKhamdi AfandiNo ratings yet

- Astm A54Document6 pagesAstm A54rgi178No ratings yet

- Sekuen Fabrikasi TopsiteDocument2 pagesSekuen Fabrikasi TopsiteAnonymous FHkX0ANo ratings yet

- TOFD Inspection With Phased Arrays: 17th World Conference On Nondestructive Testing, 25-28 Oct 2008, Shanghai, ChinaDocument7 pagesTOFD Inspection With Phased Arrays: 17th World Conference On Nondestructive Testing, 25-28 Oct 2008, Shanghai, ChinafizanlaminNo ratings yet

- When Is SPC-SP3 Power Tool Cleaning Used?Document2 pagesWhen Is SPC-SP3 Power Tool Cleaning Used?HennieNo ratings yet

- Location and Layout Analysis of MARUTI SUZUKIDocument19 pagesLocation and Layout Analysis of MARUTI SUZUKIsonu sah100% (1)

- Recom. de Soldadura XARDocument4 pagesRecom. de Soldadura XARelias667No ratings yet

- Manufacturing Considerations in DesignDocument6 pagesManufacturing Considerations in DesignKRISHNA KANT GUPTANo ratings yet

- Steel Girder Bridge - ChecklistDocument2 pagesSteel Girder Bridge - ChecklistMahmud ShalehudinNo ratings yet

- GP 04-10 22 Feb 2006Document58 pagesGP 04-10 22 Feb 2006mailmaverick8167No ratings yet

- Electrode Qualification TestDocument5 pagesElectrode Qualification TestAbhishek Kumar VishwakarmaNo ratings yet

- Determining The Short Term Tensile Weld Strength of Chemical-Resistant ThermoplasticsDocument4 pagesDetermining The Short Term Tensile Weld Strength of Chemical-Resistant ThermoplasticsFernando Da RosNo ratings yet

- Good Fabrication in Architectural Stainless Steel: ISBN 2-87997-062-8Document10 pagesGood Fabrication in Architectural Stainless Steel: ISBN 2-87997-062-8tonyNo ratings yet

- 3814 GY VD AC - 901 - 2101 IS01 Structural Calculation NotesDocument272 pages3814 GY VD AC - 901 - 2101 IS01 Structural Calculation Notesgchaves504No ratings yet

- QW 483 - PQR (Gtaw+smaw) 04.01.17Document8 pagesQW 483 - PQR (Gtaw+smaw) 04.01.17Srikant GanjiNo ratings yet

- C89520 (Sebiloy Ii (Envirobrass Ii) ) : Last Updated: Jan 27, 2006Document1 pageC89520 (Sebiloy Ii (Envirobrass Ii) ) : Last Updated: Jan 27, 2006박준용No ratings yet

- Cswip QueDocument28 pagesCswip QueJigar PrajapatiNo ratings yet

- Thermal Hazards PDFDocument19 pagesThermal Hazards PDFEvert W. VanderBergNo ratings yet

- ESAB 6010: Safety Data SheetDocument14 pagesESAB 6010: Safety Data SheetHusam AhmedNo ratings yet

- Inspection and Maintenance of Steel Girders-1Document10 pagesInspection and Maintenance of Steel Girders-1vpmohammedNo ratings yet

- ASME I Part PMB Requirements For Miniature BoilersDocument2 pagesASME I Part PMB Requirements For Miniature BoilersAmanda Ariesta ApriliaNo ratings yet

- Manual For Surface Treatment of Stainless Steels: Lasting ConnectionsDocument40 pagesManual For Surface Treatment of Stainless Steels: Lasting ConnectionsAsgard Sanchez100% (1)

- Vol I BCD Patratu Rev 16 2279 2280Document199 pagesVol I BCD Patratu Rev 16 2279 2280Prince AnejaNo ratings yet

- Welding Weldox or RQT or (Generic) S690 Steels: Home MIG TIG Arc Paint ForumDocument2 pagesWelding Weldox or RQT or (Generic) S690 Steels: Home MIG TIG Arc Paint ForumFilipe CordeiroNo ratings yet