Professional Documents

Culture Documents

DocScanner Feb 21, 2023 15-52 PDF

DocScanner Feb 21, 2023 15-52 PDF

Uploaded by

ranjeet singh0 ratings0% found this document useful (0 votes)

23 views24 pagesOriginal Title

DocScanner Feb 21, 2023 15-52 (1).pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

23 views24 pagesDocScanner Feb 21, 2023 15-52 PDF

DocScanner Feb 21, 2023 15-52 PDF

Uploaded by

ranjeet singhCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 24

Sleepers :

Sleepers are the members which support the rail and are laid transverse to the rail

+ Sleepers rest on the ballast cushion and

transfer the axle load to subgrade through

ballast

* They are also called as rail road ties.

Functions of Sleeper :

+ To hold the rail to correct gauge, in proper level

+ It also facilitates adzing of the rails

+ To act as elastic medium in between ballast and rail, to absorb the shocks and

Vibrations

+ To provide longitudinal and lateral stability to the track

+ To distribute load from rail to ballast

+ Sleepers transfer point load into uniformly distributed line load.

Classification of the sleepers :

+ Classification is based on the material used. Different types of sleepers as follows,

1. Wooden sleepers

2. Metal Sleepers

(2) Cast Iron Sleepers

(b) Steel sleepers

3. Concrete sleepers

(2) Reinforced concrete sleepers

(b) Prestressed concrete sleepers

4. Timber or Wooden Sleepers :

«Wooden sleepers are regarded to be best sleepers.

Initial cost and maintenance cost are low, less!

deflection and capable of absorbing shocks and

vibrations.

+ Easy to lay, relay, pack, lift and maintain

= Sal and teak wood are most commonly used for

sleepers.

= Boxed heart or Ekka wood must be used for the!

construction of sleepers.

™

Wooden sleepers are easily subjected to wear. decay. attack of white ants, spike killing, warping any

4 ; life of ss is minimum 12 to 16 year.

i

Creosting and Burnetising (application of ZnCl, solution) are done to increase lite of wecden

sleepers. fo

Composite Sleeper Index (C.S.I.)

Raiuwav ENoWetang

C.S1_measures the mechanical s\renath of timber, derived from its composite properties of strenath ang

hardness. ae

S+10H

CS tain

S = Strength Index at 12% moisture content

H = Hardness Index at 12% moisture content

Check Sleepers :

Tie Bars

+ Serviceable portion of spike killed sleepers is cut ¢ <

and used with tie bars in station yards. za,

= They are not used on a track having running traffic, an

Check Sleepers

2. Metal Sleepers :

Metal sleeper is a inverted channel with folded ends The folded ends and edges form a bulb, which

fesist the damage caused by the packing of ballast

+ Two types of metal sleepers are used

1. Cast Iron (C.1.) Sleeper

2. Steel Sleeper

Cl Sleepers ate in areater use than steel sleeper because these are less prone to corrosion

Metal sleepers require more ballast than other types of sleepers. And it is unsuitable for bridaes and

level crossings

Metal sleepers are uniform in strength durability

The performance of fitting is better in metal sleepers. so lesser creep occurs.

Ci. Sleepers

Type of C1. Sleepers :

(2) Pot or Bow! Sleepers

(6) Plate Sleeper

(©) Box Sleeper (obsolete now)

(d) CST 9 Sleeper (

(©) Duplex sleeper

Advantages of C.l. Sleepers :

1

2

Being 9th of the series produced by central standard office)

The useful life of C.1. sleepers is about 35 to 50 years

These may be used for every type of ballast

% These provide better lateral and lonaliudinal stably to the track because of betler connectors

between rail and sleepers

RUM IES MASTER srr ons

emer Katara Sari New Oeti-110016 = Phone o11-28522084

Mobile: £010009955.5711859008 wE-mall.e

‘est Eps SATE)

| SuecPERS Ano TRACK FASTERNERS

4, Their overall cost and_cost of maintenance is low as compared to wooden sleepers and scrap value ue

is high.

Disadvantages of C.l, Sleepers

number of fastener:

hey requir

4, Their initial cost is high

ei do not provide elastic bed in between ballast and rail

oi tin

ble for tr

‘Note Track circuiting is done in order to find out the location of a train on track, it also tells the spacing between

two trains on the same track

CST-9 Sleeper :

Central Standard Trail No. 9 + CST-9

This sleeper was standarised by track

standard committee, has been

extensively used on Indian Railways for

more than last thirty years.

It_has triangular inverted pot on either

side of the rail section and a plate with

the projecting rib and a box on the top

of the plate.

The various pieces are cormnected across

the track by means of a rod. \

‘Arail seat or a chair is provided to hold booed

the FF. rail with 1 in 20 cant

Itis a speed of 130 kmph.

CST-9 Sleeper

. used

Steel Sleeper

Steel sleepers is an inverted channel with folded ends. The folded edges which form a bulb, resist the

damage caused by the packing of ballast. When placed on ballast, it takes @ grip on the ballast and

prevents escaping out tendency:

—23.35m =

he

je— 167m —

Ria at

uo ren as

tin20__1in20 eyes

2.6cm

Plan

"268m

Steel Sleeper

Advantages and disadvantages of steel sleepers:

Advantages

4. These are light weight so easily handled as compared to Cl sleepers.

2. Less no of fastenings are required, so cost of laying the track is less

Regd office

Mobile

IES MASTER

Inst Enon (ESIATEPSUH)

46 Lower Basement Katwaia Sara, New Dalh- 110016. Phone :ot1-26522068

910008885, 9711853008 « E-mall info pubications@iesmasier oxy, fo@esmaster og

‘sWeb : lesmaserpubiatons com, Yesmaster org

fae tes,

ae oe awa Evora)

4. Maintenance is easy as compare to other types of sleepers

4. The life is much more than wooden sleepers.

Disadvangates

These may by easily rusted oF corroded

Their legs get broken easily

The rounded ends of sleepers do not prevent lateral shift

tee! sleepers not suitable for electrified tracks because like wooden sleeper they do not act ag

insulators and thus interefere with track circuiting,

Steel Trough Sleepers

+ Made from rolled trough sections of stee!

In these sleepers holes are drilled and punched in the plate to accomodate modified loose jaws

«Standard 2-way keys (sometimes oversized keys for elongated holes) and Elastic rail chips are used

with modified loose jaws.

Advangates

‘+The sleeper holds the gauge firmly better than wooden and cast Iron. No widening of gauge required

at curves. And maintains the two tracks at the same level

= Good anticreep sleeper.

+ Rail cant is well maintained as it being in one piece.

‘= Good longitudinal, lateral, frame resistance

+ Occupies comparatively less storage space and being similar to the wooden sleeper in shape, the

track labour finds it easier to handle during transport and laying

= long service life about 30 to 40 years.

+ Easy and economical to manufacture

‘+ Free from fire hazard

* Good scrap value

Limitations

+ Key type fastening get loose due to high frequency heavy traffic and need frequent tightening. Use

of modified loose jaws, rubber pads and pandrol clips help to overcome this to some exter

Have a tendency to centre binding as the central portion is lower than the ends

+ Not fit for track circuiting

‘+ Excessive damage in case of derailment

+ Steel sleepers with their close spacing at the rail joints are difficult to pack To overcome this

Problem, wooden sleepers are recommended at joints of steel sleeper track

+ Ate longer in lenath thus difficult to procure and transport

Concrete Sleepers

‘+ Due to chronic shortage of timber for wooden sleeper, the concrete sleepers came into picture

+ Later it was investigated that these sleeper are very much useful for Indian railways for developing

High Speed tracks.

1 eo. omc 126, Lowe Basen) Kawa Sv New Dens 10016» Prone :01 2822004

Mobi sor0007058, 971189008 #Esmal mp pubkctonsMiesmase ag, oGeH"=s= 8

‘Web esmasierpubicatos com, easter oy

‘SLEEPERS AND TRACK FASTERNERS

Advantages of Concrete Sleepers :

These sleepers are free from Natural decay and attacks by vermin, insects etc

There is no difficulty in the track circuiting required for electrifying the track.

pre

These sleepers have higher track modulus so can with stand the stresses induced by fast and heav’

traffic. Hence also it has best shock absorbing capacity

joncrete sleepers in the elastic fastenings offers an Ideal track in respect of gauge and alignment

‘They have maximum life 40 to 60 years as compared to 15-20 years for wooden sleepers.

Disadvantages of Concrete Sleepers :

4. The weight of concrete sleepers is 2 to 3 times of wooden sleepers, so that their transportation is

difficult

2. The damage to the bottom edges during the packing

3. They have very poor scrap value

4, In case of derailment, damage to concrete sleepers is very high

Concrete sleepers are of two types :

(a) Reinforced concrete sleepers

(b) Prestressed concrete sleepers

: Reinforced Concrete Sleeper | Prestress concrete Sleeper

Prestressed Concrete Sleep

« Prestressing Technique eliminates the limitations of reinforced concrete sleepers. Here concrete is

subjected to high value of initial compression. Generally M55 and M60 are used for this purpose.

«The design is based on:

(2) Maximum permissible compressive strength of 211 kg/cm?

(b) Minimum cube crushing strength of concrete in the sleeper is 422 kg/cm? at 28 days

(c) The pre-stressed wires are stressed to a initial stress of 8.82 kg/cm?

+ tis suitable for track circuiting

Disadvantages of pre-stressed concrete sleepers:

(i) Heavy damage occurs due to derailment of trains

(ji) The design and construction procedure is complex

(ii) Ballast bed is especially prepared

(iv) Uneconomical

(v) The required standard of maintenance is high.

DEST AAAS UE a sec wscocse orion ses ve macareaeansen wesoneraren

et gs SATE) eraconsaenaniats oor ama

Railway Enna

nterlaced sleeper:

Track Fasteners :

1. Fish plate 2. Spikes 3. Chair

4 Bolts 5 Keys 6. Plates.

1. Fish Plates :

+ Fi re used at rail joints in order to

maintain continuity of rail joints.

+ Italso allows thermal contraction and thermal

expansion

= These have shape resembling to fish and

are made up of steel.

2. Spikes

+ Itis used to hold rail on wooden sleepers,

+ For holding Flat footed rails on wooden sleepers dog spikes are used

+ Example of spikes are dog spikes. screw spikes. round spikes, standard and elastic spikes.

3. Chair :

+ Cll chairs are used to support bull headed (B.H ) reils on the sleepers.

+ Slide chairs are used to hold stock rail. and tongue rail

4. Bolts :

‘+ Dog or hook bolts are used where Sleepers directly rest over the steel girders

+ Fish bolts are used to resist heavy transverse shear.

5. Keys :

+ Keys are small tapered pieces of timber, coated on steel

+ These are used to fix rails to chairs on metal sleepers.

Moraan key (18 cm long and tapered 1 in 32) is most commonly used for Cl. chairs and_

ae

Dog Spikes ee

6. Bearing Plates :

+ These are rectangular plates of either Mild stee!

(M.S) or cast iron (C.1)

+ These are used footed rails to distri

load on a larger area of timber sleepers.

© Bearing plates are not used in concrete sleeper:

and metal sleepers

+ No adzing of sleepers is required because bearing

plates are canted at 1 in 20

+ This results in uniform distribution of loads over

sleepers.

| Sueepers ano TRACK FASTERNERS | 23

‘Note: Saddle plates are used to strengthen the steel sleepers,

Sleeper Spacing and Sleeper Density

+ Sleeper spacing on a particular Railway line depends upon.

(a) The strenath of rail

(b) The type and design of sleeper

() depth of the ballast cushion and its type

(d) the bearing capacity of the formation

(e) the axle loads, volume and speed of traffic.

Sip Since cloner pron ie=leteralab 7h ear of sleepers more is the lateral

stability

The number of sleepers cannot be increased indefinitely because for convenience of packing ballast.

= No of sleepers per rail length is termed as sleeper density.

In India sleeper density is represented by (M+x) where M is rail length (meters) and x is no which

varies from 3 to 7

= For BG track sleeper density is represented by (M+5)

eg. Length of rail = 13 m

M+5=18

Therefore 18 sleepers will be used per rail length on that route,

Squaring of Sleeper

0 ring of sleepers may be defined as process

them parallel to each other

in through packing the sleepers are squared and brought to specified spacing at straight length and

on the curves ie. the ballast under the sleepers is adjusted to space them parallel to each other.

adjusting ballast under the sleepers to space

It is a maintenance process

Soom

Using sleeper

railway pack 640 m long (B.G. track).

density M + 5 find out the number of slepers required for constructing a

Bol. Length of rail on B.G. track = 12.8 m

640 Aiatz However For objective question correc?

Total no. of rails req, = sy g~ 50° | orswer may correspond to rail lergth = 13 m

sioeeseare. |b tech That ase correct

no. of sleepers per rail =

Total no. of sleepers req = 50 = 17.8

n = 890 sleepers

answer may be n = 900 sleepers

er density of n + 6. If the track is laid with welded rails of 26

‘A B.G track has a sleep

m length, find out the number of sleepers required for constructing a railway track of

1690 m.

Regd oficw F126, (Coner Basement, KatwaiaSaral New O@Hi-110016 » Phone :017-2652206%

TES MASTER “teste ssconoss sr:esnos senate pmieorsgiesmase 09 nogisnen 0

‘oti ge TERED) mo emeneptein am ato

24 Rattway Enonesy

Sol.

Length of track = 1690 m

Sleeper density = n + 6

where, n is length of one rail

26

Length of one rail, n=

As sleeper density is n + 6

5 No. of sleeper in 13 m length = 13+ 6 = 19

19

= __No. of sleeper in 1690 m length

Write a detailed note on sleeper density for railways

7971690 = 2470,

Sol._Refer to the theory of chapter.

State the reasons due to which the vertic.

caused to the sleepers in a railway traci

Write the merits and demerits oj

being extensively used in India.

‘al horizontel and transverse loadings are

‘k. Why is ballast filled between the sleepers?

f conerete-sleepers and explain the reasons of these

Sel. Sleepers are subjected to permanent stresses arising from fastenings, longitudinal forces in rails

and transient stresses due to passage of trains.

Reasons due to which the vertical loading is caused in sleeper are: |

J+ Weight of train

J+ Weight of rail

j= Dynamic effect of wheels on rail

Reasons due to which the horizontal loading is caused in sleeper are:

+ Longitudinal force of adhesion between rail and train.

+ Thermal expansion or contraction of rail

J» Wave-action

Reasons due to which transverse loading is caused in sleeper are:

‘+ Trains have the tendency to move in transver:

>On curves, due to centrifugal force, transverse loading is caused in sleeper,

TES MASTER 2.2013" tote stones sna naw on. int Prone 0 28500

te: AOT0O08ES, 8711859008 + E-mail: info publesions@esmaser or, o@ies™se' 2

‘ws Expos (ESIOATEPSU) ‘Wb leamasterpbtcations com, esmasteroy

Ballast :

Ballast is the granular material usually broken stone or brick, kankar gravel and sand, which is place

and packed below and surrounding to the sleeper such that it transmit the load from sleepers to subgrade

‘and at the same time it provides good drainage

Functions of Ballast :

+ Ittransier the load from sleepers to the subgrade and then distributes it uniformly over a larger area

of the formation.

+ Itholds the sleepers in position and prevent the longitudinal and lateral movements due to dynamic

loads.

‘+ Itimparts some dearee of elasticity to the track.

+ It also provides good drainage medium to the track.

+ On the curved track super elevation is maintained by ballast cushion and formation is levelled

Requirements of Good Ballast :

+ It should be abled to get packed properly without any disintegration that is it should have good

crushing strength.

It should make proper drainage medium and soak minimum water,

+ It should offer good resistance to wear and tear.

+ It'should be chemically inert or does not react with rail or metal sleeper

* The size of stone ballast should be 5 cm for wooden sleepers, 4 cm for metal sleepers and 25 cm

for turnouts and crossovers

Types of Ballast :

1. Broken Stone 2. Gravel or River Dabbles

3. Sand and Murum

4. Ashes 5. Brick ballast

6. Blast furnace slag

1. Broken Stone :

sis provides best material for ballast almost ell racks are covered with broken stone

+ Igneous rocks such as granite, quartzite make good baltast material

«Graded stone of size in between 1.9 cm to 5.08 cm have max stability

—

BaLiasr ANo Son Suscrae ano Survey Work. met

or Shingle :

2, Gravel or River Pebbl

River Pebbles or Gravels are broken bfore use

COthenwise packing does not hold due to smoothness of particle

+ Gravel ballast gives better performance in. formation.

ote: (I) The process of ramming the ballast underneath the sleeper is known as packing

(2) The ballast above packing which surrounds the sleeper, is loosely filled calleg Boxing

(a) The loose ballast between the two adjacent sleepers is known as Ballast Crib

3, Sand

«It provides good drainage, if free from earth and vegetation.

« lt-produces silent track and used for packing pot sleepers.

«The main draw back of sand is, it blows off due to vibration To encounter this problem the sand

ballast can be covered by stone or brick ballast.

«Steel sleepers packed with sand ballast make silent sleepers.

4, Ashes or Cinders :

Ashes has excellent drainage property due to high porosity.

It is very soft and gets reduced to powder under wheel load.

Hence makes the track very dusty, tus always used in sidings.

It is excellent ballast material for station yard, because does not retain water so track is not slippery

in rainy season

The great drawback of ashes is its corrosive quality and therefore, it corrodes steel sleepers and foot

of the rails,

5. Brick Ballast :

Where no stone or substitute is available for use as ballast, over burnt bricks are broken into small

sizes and used

= It powders easily and produces a dusty track

Rails of tracks laid on brick ballast many a time get corrugated. Brick ballast, however. is fairly good

for drainage.

Size and Section of Ballast :

+ The size of ballast varies in between 1.9 cm to 5 tem.

The packing or interlocking is better for this grading

«For different type sleeper, different size of ballast is used such as

For wooden sleepers = 5.1 cm

For steel sleepers = 3.8 cm

For switchs and crossings = 2.54 cm.

Depth of Ballast Section :

* The depth of ballast layer has important role on bearing capacity and distribution of load on subgrade.

Greater the depth of ballast, greater will be load bearing capacity

ESSAI TE res as a aes TNT

‘eta Eng OESATEPE) © Web: sesmasterpublcations con iesmaster og

2 | a

ug Prensa

+ Width of ballast layer beyond the ends of sleepers effect lateral stability of the track

+ In India this width is kept in between 38 cm to 43 cm from the end of sleeper.

+ Load distribution below the sleepers is assumed to be 45° to the vertical, so minimum, eo

calculated as follows.

Let spacing of sleepers is S and width of a sleeper is W

tan 45°

Table: Details of Ballast Section

Dimensions BG MG NG

1. Width of ballast 3.35 m 2.25 m 1.83 m

2. Depth of Ballast 20 to 25 cm 15 to 20 cm 15 cm

3. Quanity of stone ballast per | 1.036 m? 0.71 m? 0.53 m?

Meter length

— 3.35 m for BG ———+

225m for MG —

1.83 for NG

Ballast

shoulder

20t025 cmfor BG

15 to 25 cm for MG.

15 cm for NG.

Ballast Section for Railway Tracks,

3 according to Indian standards: recommerde

wider shoulder (15 cm or more) than specif

the increased lateral thrust

in table above are provided on outsid

fe curves to counter

Blanket/Sub-Ballast

+ Itis a layer of specitied coarse grained material between

purpose.

(2) Distributing the load or formation, thus reduci

{b) Eliminating mud pumping,

(©) Containing the seasonal mic content variations in subgrade

ballast and formation, It seives the follow’

Ing the subgrade stresses

Subgrade

+ It is naturally occurring soll, whichis prepared to receive ballast sleepers, rails for consttuct"?

railway track :

+ Width of formation is the width of the prepared surface to receive ballast

seni

HES MASTER “crete

OESIGATEIPSUS) - SSW bemaemeheacim amano =<

s

BALLAst ANO Son SuBoRADE AND SURVEY Work | 33]

Funetion of the Subgrade or formation :

‘+ It bears all the moving loads transmitted to it through ballast.

‘+ It should prevent the ballast from puncturing into it

+ It should provide good drainage

+ It should be stable.

Subgrade Material and its Improvement :

+ The ideal material for subgrade is soil containing gravel, sand clay and silt in equal proportion with

the moisture content slightly above the plastic limit

+ Non cohesive soils as subgrade satisfies all requirement

+ However heavy clay, peaty soil and loamy soil must be avoided.

Subgrade can be Improved by following Methods :

1. Admixture of different soils that is mixing sand and gravel to reduce plasticity.

2. Blanket - The blanket of non cohesive soil is provided above subgrade and below ballast

3. Cement Grouting - The cement sand mixture (1:1 to 1 : 12) is injected to subgrade under pressure

in order to stabilize it

Concrete mats are also provided to stabilize poor subgrade

5. Use of Sand piles to drain oui water

6. Sub-drainage system

Survey works for track alignment :

‘+ Ina railway project from beainnin end four survey works are done. These are - (In their order

of work)

1. Traffic survey

2. Reconnaissance survey

3. Preliminary Survey

4. Detailed survey or location survey.

1, Traffic Survey :

+ The object is to make accurate determination of the potential of available traffic.

«This is essential for determining the viability of new track proposed

+ It considers the future potential of both passengers and good traffic

2. Reconnaissance Survey (or Recce) :

«This is rough and rapid inspection both visual and instrumental of various physical characteristics of

the area

+ It is done to find various suitable alignment

«It collects ecological information like nature of soil, hill or pond, dip of existing rock ete

3. Preliminary Survey :

+ Detailed analysis of all suitable routes.

+ To find the best suitable route

+ Theodolite, tachometer, dumpy level etc, are used.

4, Detailed Survey or Location Survey :

+ Detailed study of final route is done.

Regd. office : F126, (Lower Basement), Karwaina Sara New Deihy-110018 # Phone : 011-26522064

‘Mobile: 8010009885, 0711853908 « mal: Voghesasterputicatons com inlogresmaster org

‘8 Web :esmasiestications com asmaster og

Railway,and Rail Joints

i Ls iam

Rails =

The rails on the track can be considered as steel girders for the purpose of carrying axle load

+ Rails transfer Axle load to the subgrade through sleepers and ballast

+ Bails convert the rolling loads (moving wheel loads of train) into point load, which acts

sleepers.

+ Sleepers convert point load into distributed load

+ Ballast convert line load is uniformly distributed load

Rails are made up of high carbon steel, to resist wear and tear.

«On points and crossing rails of medium carbon and high manganese steel is used

«In India rails are manufactured by open hearth or duplex process

Requirement of Rails :

on the

Rails act as continuous girders carrying axle loads. They should meet the following requirements

to serve intended purposes

They should be proper composition of steel and should be manufactured by open hearth or duplex

process.

The vertical stiffness should be high enough to transmit the load to several sleepers undeneath. The

height of rail should, therefore, be adequate.

Rails should be capable of with standing lateral forces. Large width of hea

with high lateral stiffness.

The head must be sufficiently deep to allow for an adequate margin of vertical wear. The wearing

surface should be hard

« Web of rails should be si

flexural rigidity in horizontal plane

Foot should be wide enough so that rails are stable against overturning especiall

= Bottom of the head and top of the foot of rails should be so shaped as to enable the fish plates to

transmit the vertical load efficiently from the head to the foot at rail joints

= Relative distribution of material of rail in head, web and foot must be balanced for smooth transmission

of loads,

« The centre

‘and compressive stresses are equal

= The fillet radii must be large to reduce the concentration of stresses.

+ To allow adequate marain of vertical wear, head of the rail must be sufficiently deep. max. wear of

head allowed is 10 mm.

© Minimum tensile strenath of rail should be 72 Ka/mm?,

tested by falling weight test or tu

.d and foot endows the rails

ufficiently thick to bear the load coming on it and should provide adequate

n_curves.

of gravity of the rail section must lie approximately at midheight so that maximum tensile

In India rails

Types of Rails :

4, Double headed rails (D.H. rails)

+ These rails were used in the beginning

+ The idea behind using these was, when the head will worn out

in course of time, the rail can be inverted and reused.

+ Inthe lower part, the indentations were so formed that smooth

running over that surface at the top was impossible, so idea

got failed.

Ce MPFeSsion

1 pom

2. Bull Headed rails (B.H.

Head

Foot Foot

+ In BH rails the head was made a little thicker and stronger than the lower part

3. Flat footed rails (F.F. rails)

+ FF rails are also called Vignole's rails after the name of the inventor

+ Bearing plates are used between the sleeper and rail at rail joints

+ These rails are designated by wt of rail per unit length

+ 52 ko/m or 52 MR and 60 kg/m or 60 MR EF. rails are used in India

+_S2-ka rail is suitable upto-speed of 130 kmph and 60 ka rail is suitable upto speed of 160 kmph

haa aes

E ¢

:

8

Neutral Honzontal axis ©,

8 8

be Ea Noe,

(0) 52g Rail section (€)60 kg Rail section

Metric Rail (HR) kgim as per indian Railway Standards a)

TES MASTER "ie ater :rt2 ve omerw watiarsoa ow oa: o01 «prone: 8

TES MASTER “ysl cmococt eno

etnen or Eognes(KSRATERS)

"Web: lesmaserpubicaton com, emasterory

Ran, RAILWAY AND Rai Jowrs

Comparison b/w Flat footed rails and Bull haded rails

Point of Comparison Flat Footed Rails Bull Headed Rails or

Double Headed

1. Strength and Stiffness These have more strength Having lesser stiffness and

and stiffness for same wt strength,

2 Laying and Relaying Fitting is simpler so, can be | Laying or relaying is difficult

easily laid or relaid,

3. Initial cost Fastenings are lesser and Fastening are more and

cheaper so initial cost is costly s0 initial cost is high

less

4, Maintenance cost Less maintenance cost it requires heavy maintenance

cost

Note: Flat footed rails is most commonly used in India

Rails of larger lengths are preferred to smaller length for more strength and economy.

Joints between Rails are weakest points of the railway track and cost of fasteners is also high

In longer rails no of joints and fish plates are less thus lesser maintenance cost

Rail's length is restricted due to transportation limitations and due to more gap required for expansion

joints.

Rail length of 12.8 m (say 13 m) for 8G tracks and rail length of 11.89 m (say 12 m) for MG tracks

are used by Indian railways

Some Other Important Points :

« Ratio of wt of rails to wt of locomotive (axle load) is 1+ 510.

«When wear of head exceeds 5% of total wt.. the rail must be replace

surves, check rails parallel to inner rail can be introduced to control wear

» On the ci

Check rail prevent the wear of outer rail

Check rail, is used if curves (degree of curves) is m

\ore than 8° for BG and more than 14° for M.G

Permanent Way or Railway Track :

Combination of rails, fitted on sleepers

and resting on ballast and subgrade is

called the railway track or permanent way.

«Some time temporary tracks are also laid

for the transportation of the material. So

to distinguish final alignment with the

temporary tracks, the term permanent

track is used

+ On the curve super elevation is

maintained by the ballast and formation

is levelled

— Ballast shoulder

Gauge

— Ballast

Sleeper

Ballast cushion

PRP PAD IS

24

Ballast base. ——*!

|< width of formation ——+1

Permanent way cross-section

Riga otice «F126, (Lower Basen) Katvaria Sool New Delhi 110016 « Phone : 01126522064

TES MASTER “oct: voronsss ses senate puncatrsgiesnase on, foes

“nti for Engineers (IESIGATESPSUS) ‘= Web : lesmasterpublications com, lesmaster org

Tara

In permanent way the ras are joined in series by fish plates and bolts and then they a

sleepers by different types of fastenings Tee

+The sleeper properly spaced and resting on the ballast are sultably packed withthe by

+The permanent way is regarded as semi-elastic in nature due to packing of ballast cug

last

Shion,

Defects on Rails :

1, Corrugated or Roaring Rails

+ The corrugation of rail consist of minute depressions on the surface of the rails

+ These are usually created at the place where either breaks are applied or trains stant

When train pass over it roaring sound occurs.

2. Kinks in rails :

When ends of adjoining rails, move slightly out of position, kinks are formed at joints

+ These occurs due to loose packing of joints and uneven wear of rail head.

3. Hogged rails :

These are created due to battering / Impact action of wheel at the end of rail, head gets bend down

‘These occurs due to loose packing of ballast or loose fish plates at the joints.

Rail

a )

aS Se C—™

ze _ ee |

=a — aa Zz

| Kinks in Rail [Top View of rail]

(a)

Seeper Hogaing of Ra |

®

4. Buckling of rail :

+ During summer due to rise in temperature

the expansion of the rail occurs, to allow this expansion

there must be certain gap in between two

rails at the end joints,

These joints are known as expansion joints,

if sufficient gap / expansion joint is not available. the thermal expansion would not be accommod

within the expansion joint which will create thermal stresses in the rail and rail will buckle.

+ Buckling also ocours if fish plates are bolted so tightly that the rail

are not allowed to slip

TES MASTER — *tt.stice:r-126 ower tatersnn avai sara Now bet 10016 « Phone 1125220

‘Mobi; 8010009855, $711859008 ¢ E-mal: info pubicaons@resmaser x, ioeesas

‘este or apners(ESGATEPSUH) ‘Web lesmaserpbseatons com, esmasier of

a

(Ran, Ranway ano Ran Jowrs

5, Scabbing of rails :

i Sea of rails occurs due to the falling of patches or chunks of metal from the rail table

Scabbing is generally seen in the shape of an elliptical depression, whose suface reveals a progressi¥&

fracture with numberous cracks around it

. Wheel burns :

«Wheel burns are caused by the slipping of the driving wheel of locomotives on the

a consequence, extra heat is generated and the surface of the rail gets affected, resulting

depression on the rail table Wheel burns are generally noticed on steep gradients or where there

are heavy incidences of braking or near water columns.

ail surface. AS

7, Shelling and black spots :

Shelling is the progressive horizontal

separation of metal that occurs on the guage

side, generally at the upper gauge comer. It

is primarily caused by heavy bearing

pressure on a small area of contact, which

produces heavy intemal shear stresses.

Requirement of an ideal permanent Way: 9 ae Wheel eons

4, The gauge should be correct and uniform.

2. The permanent way should be resilient and elastic in order to absorb shocks and vibrations of running

track.

The track should have enough lateral strength

4 Drainage system should be perfect

5. Joints should be properly designed and maintained

Gauges in Railway Track :

© Gauge of the railway track is defined as

track rails.

‘The distance between the inner faces of a pair of wheel is called wheel gauge

the clear distance between inner or running faces of two

Factors Considered Gauge Selection

Volume and Nature of Traffic

«For high volume and heavy load traffic, wider gauges are preferred whereas for low volume and low

oad traffic, narrow gauges are more suitable.

Developement of the under-developed areas:

Si Naraw gaugeelcan belused to develop the under-developed areas by joining them with developed

or urbanised areas

Topography of the area:

+ In hilly regions, where broad

«If area is plain, where high-speed is required, broad gauge Is preferred

and metre gauges are not possible, narrow gauge is preferred

‘Speed of movement:

«Speed of a train is almost proportional to the gauge Therefore, if high speed is required then broad

gouge will be preferred whereas if low-speed is required then narrow gauge is more suitable

enna

‘ots or Enginears (ESIOATEPSUS) "#Web : lesmasterpublications com, lesmaster org

a ae

je ee Rar Bye

ag

Construction

Cost uf of railway track is directly proportional to width of gauge. If a plenty of fund ig fee

. nes gauge wil be preferred whereas if fund availabe is not sufficient for broad gauge jae

gauge or metre gauge will be preferred ;

Advantages of uniformity of gauges

Gauges to be used in a particular country should be uniform throughout as far as possibje ie

has following advantages

«The delay, cost and hardship in transhipping passengers and

O0dS from the Vehicles of ong

0a

to another is avoided.

Ne

+ Surplus wagons of one gauge cannot be used on another

gauge. This problem will no

is uniform

+ Locomotives can be effectively used on all tracks if a uniform t

+ Duplication of equipment such as

of extra-expenditure

yPe of gauge is adopteg

Platforms, sanitary atrangements etc is avoided. This saves .,

Itis quite expensive to convert one gauge into a

nother at a later stage as it may req.

stock, fresh construction and widening of bridg

uire NeW roling

Jes and tunnels, :

Difficulties in loading and unloading are avoided and labour expenses are saved

During military movements, no time is wasted in changing personnel and equipment from one venice

to another if gauge is uniform

Portar charges are increased when passengers have fo change compartment due to different g

This is avoided if gauge is uniform

Different Gauges :

‘+ Broad Gauge (B.G) - 1.676 m

+ Meter Gauge (M.G) - 1.0 m

+ Narrow Gauge (N.G) - 0.762 m and 0.16 m

* Standard Gauge (S.G) - 1.435 m (U.K. and USA)

Classification of Railway

Broad Gauge Routes

All the broad gauge (BG) routes of

Indian Railways have been classified into five different grou

on speed criteria as given below.

Group A lines

‘These lines are meant for a sanctioned speed of 160

+ New Delhi to Howrah by Rajdhani route

+ New Delhi to Mumbai Central by Frontier Mail/Rajdhani route

+ New Delhi to Chennai Central by Grand Trunk route

+ Howrah to Mumbai VT via Nagpur

IES MASTER reo fe reser alsa sian Con 0016 «Pree: 011-2682

e1000988 8711869908 » Ema pubheatonsgpeemaste cy wes

neieieied aii ‘Web etastorpubieations com lesmaster org

kmh:

[Raw Ratuway AND Rai. Jonrs

Group B lines

‘These lines are meant for a sanctioned speed of 130 kmph

+ Allahabad-ltarsi-Bhusaval

~ Kalyan-Wadi Raichur-Madras

« Kharagpur-Waltair-Vijayawada

+ Wadi-Secunderabad—Kazipet

« Howrah-Bandel-Burdwan-Barharwa over Farakka-Malda town

= Barsoi—Jalpaiguri

Sitarampur-Kiul-Patna-Mughalsarai

Kiul-Sahibganj-Barharwa

+ Delhi-Ambala Cantt-Kalka

+ Ambala Cantt-Ludhiana-Pathankot

+ Ambala Cantt-Moradabad-Lucknow-Paratapgarh-Mughalsaral

+ Arkonam-Erode-Coimbatore

= Vadodara-Ahemdabad

+ Jalapet-Bangalore

Group C lines

These lines are meant for suburban sections of Mumbai, Kolkata, and Delh!

Group D and D spl lines

These lines are meant for sections where the maximum sanctioned speed is 100 km/h

Group E and E Spl lines

These lines are meant for other sections and branch lines.

D Spl and E Spl routes Based on the importance of routes, it has been decided that few selected routes

presently falling under D and! routes willbe classified as D special and E special routes. This has been

done for the purpose of track renewal and priority allotment of funds, The track standards for these routes

will be 60-kg 90 ultimate tensile strength (UTS) rails and prestressed concrete (PSC) sleepers wih

sleeper density of 1660 per km

Metre Gauge Routes

Depending upon the importance of routes, traffic carried, and maximum permissible speed, the metre

gauge (MG) tracks of Indian Railways were earlier classified into three main categories, namely, trunk

toutes, main lines, and branch lines, These track standards have since been revised and now the MG

routes have been classified as Q, R1, R2, R3, and S routes as discussed below.

Review of Track Standard for MG Routes

‘A committee of directors, chief engineers, and additional commissioner of railway safety (ACRS) was

formed in 1977 to review the track standards for MG routes. The committee submitted its report in

ee ee

S MASTER on: MIOSONA TIBSON cea epson on seen

Web jesmastepubleatlons com, lesmaster ory

| e a

RAILWAY Bg

eae SEE eae ae — aw NONE ag

December 1881, in which it recommended that MG routes be classified ito four categorieg e

Q, R, and S routes, based on speed criteria. The committee's recommendations were accept at

Railway BOard after certain modifications. The final categories are as follows, =

bY the

routes Routes wih a maximum permissible speed of more than 75 kmph The trafic ge

generally more than 2.5 GMT (gross million tonne(s) per km/anum), eNSiy ig

S routes Routes wih a speed potential of less than 75 kmph and a traffic density of less than

These consist of routes that are not covered in Q, R1, R2, and RS routes, S routes have beer ga!

Subclassified into three routes, namely, $1, S2 and $3. S1 routes are used for the through movem, ss

Of freight traffic. $3 routes are uneconomical branch lines, and $2 routes are those whisy, are page

S1 nor S3 routes. fe

Advantages of B.G. over MG. and N.G.

1. Stability of Train Movements :

On BG gauge the stability of train operations is more than on M.G. and NG.

2. Speed of the Tr

‘The speed of train allowed on B.G. track is more than the speed on the M.G. and N.G

The speed more than 100 kmph is allowed only on BG. track

3. Axle Load :

Greater axle load is permitted on BG. track.

4. Economy of B.G. track :

Operations and control of train movement on the B.G. track is economical as compare to M.G. and NC

Coning of the Wheel :

The distance between the inside edges of wheel flanges

's generally kept less than the gauge of the track

Normally, the tread of wheels is absolutely dead centre

Of the head of the rail, as the wheel is coned to keep it

in the central position automatically. These wheels are

coned at a slope of 1 in 20,

‘The advantages of coning the wheels are

()) To reduce the wear and tear of the wheel flanges

‘and rails which is due to rubbing action of flanges

with inside faces of the rail head

121

0

20 al

Ef

1

Adzing of 4 fa Ral

sleeper

20 Sleeper

Behaviour of coning of wheels

sb

(ii) To provide a possibility of lateral movement of the

axle with its wheels

(ili) To prevent the wheels from slipping to some extent

eso

126 (et Bassi Katara Saal New Dubii0%e «Phone 012050

90009955, 9711859908 « -mall ino pubicatons Geass. WiO@™

Wed :lesmasterputcalons com, esmateroro

Ra, RALWAY AND Rai Jowrs

Purposes :

4, On a straight track ;

It keeps the train just in central

* position duri th nce travelled by two

wheels are alwavs same, ing_movement so that the distal

+ ILihe tain moves side way in any direction. the diameter of wheel on that direction increases and

on other rail in decreases so distance travelled by two wheel becomes unequal, it directs back the

rail in_central position. So coning of wheels acts as automatic handle for the train

2, On Curved Track :

= When train moves on curved track, the distance of

the outer rail is more than the inner rail

= Oncurves due to centrifugal force, the train is forced

to move outward direction, thus the diameter of wheel

‘on the outer rail become more than dia of wheel on.

the inner rail so distance travelled by outer wheel is,

more than inner wheel

+ So,more length of outer rail is partly adjusted due to

coning of wheel, remaining length is adjusted due to

skid of outer wheel and slip of inner wheel.

«The slip or skid distance is 0.029 m per 1° of central

angle

Adzing of Sleepers :

« For the effective use of coning of wheels, the rails are not laid horizontal, these are laid at a slope

‘of 1 in 20 on the sleepers. Thus is known as adzing of sleepers or tilting of rails

« Oncurves due to centrifugal force, the outer wheels are pushed outwards, the flange of wheel ma

start touching the rail which would have resulted in wear and tear of rail, to prevent this rails are tilted

at slope of 1 in 20 on curve.

«On the curves, advantage of coning of wheel is not effectively utilized.

+ If may exceed the pressure on outer rail

Rail Joints :

«Rail joints are necessary to hold together the adjoining ends of the rails in the correct position both

in horizontal and vertical

«Rails joints from the weaket part of the track, its strength is only 50% of the strength of rai

Types of Rail Joints : Fish plate joint

4. Supported rail joint :

When the rail ends rest on a single sleeper called a

“Joint Sleeper’, the joint is termed as supported joint Sippeealreau ait

MSIE “SSI eee

M Ce Eee

emelss Sees

Suspended Rail Joints :

When rail ends are projected beyond sleepers called

“Shoulder Sleepers’, the joint is termed as suspended

rail joint

3. Bridge Rail Joint :

When rail ends are projected beyond sleepers as in

case of suspended joint and they are connected by

a flat or corrugated plate, the joints are termed as

bridge rail joint

Bridge Plate

Bridge Rail Joint

4. Compromise Joint :

Where two different rail sections are jointed by fish

plate, the joint is termed as compromise joint.

5. Expansion Joint :

+ Toallow the thermal expansion at the end joints of rail so gap is provided, thus type ot joins termes

as expansion joint.

+ The gap of 2.2 cm in case of mitered rail! and 7.2 cm in case of halved joint is provided

6. Welded Joints :

+ Welded joints are considered as the most perfect and strongest type of joints.

Note: Fish plates are used for connecting one rail to the next rail

Purpose of Welding of Rail or Advantages of Welded Rail :

1. To increase the lenath of the rail by joining two or more rails and thus to reduce the number of joints

and requirement of costly fasteners like fish plats etc. Thus leads to economy and strenath of !

track.

2. Some rails at the beginning and at end of track are welded in order to omit the requirement cf

expansion joint

3. To reduce the creep of rail in order to maintain proper gauge and alignment

4. To increase the life of the railway track and to reduce maintenance cost of the track.

5.

Welded rails have very few expansion joints

Concept of Welded Rai

to resist

+ Innon welding rails the sufficient amount of resistance is available due to sleeper fasteners t0 ©

swelded

the thermal stresses, but at the rail ends no sufficient restraining force is available so non-wel

rail may buckle.

4 better

The idea behind using the welding rail is to provide sufficient restraint at the ends of rail and be

degree of fixity of rail to the sleeper so that the stresses [Both thermal and Creep] produced

resisted by sleeper fasteners.

etter

. f welded rail nds better dearee of fixity of rails with the sleepers ="

measure against buckling of rail and regular maintenance

esr!

Fen F265 Ln a Was ost Pee: 2 S

__ ions aay ma enna

il scamrar-oneens sanrontoetaues tray

Ye C—O

[Ra RAway aNo Rat. Jowns 11

Types of Welded Rail ;

4, Short Welded Rail (SWR) :

+ If 3, 5 oF 10 rail lengths are welded together at the both ends of the track, the rails are known 28

short welded rails

« Due to temperature variation SWR contracts or expands through its entire lenath

+ SWR of 3 rail length is standardized by Indian Railway.

2, Long Welded Rail (LWR) :

+ {minimum rail lenath of 200 m (for BG) or 300 m (for MG) is welded at the both ends. The rail 's

known as long welded rail

+ LWR is one whose central part does not undergo any longitudinal movement and only end portions

are effected due to temperature variation

+ The maximum LWR length allowed is 1000 m

3. Continuous Welded Rail :

«The welded rail longer than 1 km and extending from 1 station to other with switch expansion joint

are called CWR

Length of Welded Rail :

1 = length of rail

a = coefficient of thermal expansion

t = rise in temp,

E = modulus of elasticity

Increase in length of rail due to temp. rise

al = loT

Strain in rails

Thermal stress produced, if this exp. is not allowed

oy = aTEs

The Thermal force developed in rail due t0 oy

Fo =aTEsAs IA

10 be resisted by sleepers, let resisting force per sleeper is R

Cross section of rail]

«The internal force F, has t

UuTEsAs

+ No. of sleepers req Des

S|

Length of welded rail

where S = sleeper spacing

IES MASTER Regi te F126 (we Bader) Kawai Sara New Dai 110018 Phone : 01126522064

) Nobile; 8010008055, 9711859508 ¢ mall: nf publeatens@esmaser ox, nfogesmaser op

npn (ESEATEPBN) © # Web: iesmasepubleations com, esmaste org

Breathing Length :

+ Incase of LWR, the minimum lenath of

Tail, required to be welded at the end of

the portion i en

welded rail _does not undergo any

therm nsion_oF contraction, is

0 thing lenath

Breathing length at the both ends = (n - 1)S

Total breathing length = 2(n -1 )S

Theoretical length of LWR beyond which central portion of

z 52 kg rail would not 6,

subjected to any longitudinal movement due to 30°C temperature increase, |

Given Data :

As = 66.15 cm?

a = 115 «106

Eg = 21*108 kg/em?

Spacings = 60 cm

Resistance (R) = 300 kg

Rise in temperature (t) = 30°C

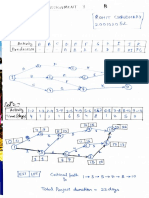

Sol.

‘The Internal force developed due to rise in temperature

Fs = alsAg

Fs = 44. 5x10°% «30x 21% 108 x66.15

Fs = 479256 kg

No. of steeper 8 required |

n = FIR |

47925.6

ee 6

DE 300 3

LwR at an end = (n-4)S = (160-1) x 60= 954m

Breathing length required = 2 x 95.4 |

= 190.8 m |

I Breathing length 90.8 m

a

What are the factors to be considered in selection of a gauge? Write advantages

uniformity of gauges.

Sol. Refer Theory S

yt 200

‘Rega. oie : F125 (Lower Basement), Katara Sarl Naw Deh 10016 «Prone a

‘Mobile 8010008858, 9711883008 + E-mail no publewlonsgesmai

ae: "SY: fesmasirgubiatons com, east’ 19

_at

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SA Assignment 2Document11 pagesSA Assignment 2ranjeet singhNo ratings yet

- OR Assignment PDFDocument11 pagesOR Assignment PDFranjeet singhNo ratings yet

- Design of RCC Structure PDFDocument24 pagesDesign of RCC Structure PDFranjeet singhNo ratings yet

- Assignment - OR (CPM, PERT) PDFDocument3 pagesAssignment - OR (CPM, PERT) PDFranjeet singhNo ratings yet

- Assignment - 4Document2 pagesAssignment - 4ranjeet singhNo ratings yet

- 10.1201 9780429505980-39 Chapterpdf PDFDocument7 pages10.1201 9780429505980-39 Chapterpdf PDFranjeet singhNo ratings yet

- Banda PDFDocument15 pagesBanda PDFranjeet singhNo ratings yet

- CONM Hbtu End Sem 2017 18Document2 pagesCONM Hbtu End Sem 2017 18ranjeet singhNo ratings yet

- CONM Hbtu Mid Sem 2017 18 2Document1 pageCONM Hbtu Mid Sem 2017 18 2ranjeet singhNo ratings yet

- Assignment 1 - Maths IIIDocument2 pagesAssignment 1 - Maths IIIranjeet singhNo ratings yet

- Complex Assignment IIDocument2 pagesComplex Assignment IIranjeet singhNo ratings yet

- 425 ch2 PDFDocument32 pages425 ch2 PDFranjeet singhNo ratings yet