Professional Documents

Culture Documents

PNGRB - Electrical Safety Audit Checklist

PNGRB - Electrical Safety Audit Checklist

Uploaded by

Kritarth SrivastavCopyright:

Available Formats

You might also like

- Ultimate Guide: Wiring, 8th Updated EditionFrom EverandUltimate Guide: Wiring, 8th Updated EditionRating: 3.5 out of 5 stars3.5/5 (4)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Compliance Inspection Test SheetDocument3 pagesCompliance Inspection Test SheetFlorin PanazanNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Gree Service ManualDocument57 pagesGree Service Manualtheskyishigh33% (3)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- M542Document3 pagesM542xhaneriNo ratings yet

- ZN1 ManualDocument40 pagesZN1 Manualpkgoyal1983No ratings yet

- Early Hot Spot Detection Enabling Condition-Based MaintenanceDocument4 pagesEarly Hot Spot Detection Enabling Condition-Based Maintenancesridhar30481647No ratings yet

- Power Meter DPM-C530 User ManualDocument114 pagesPower Meter DPM-C530 User ManualPablo CallaNo ratings yet

- AirConditioner-Sanyo-Service KS (L) 18-24 72 Series Rev C-3285512Document117 pagesAirConditioner-Sanyo-Service KS (L) 18-24 72 Series Rev C-3285512raymihregNo ratings yet

- Buku Perbaikan PanasonicDocument108 pagesBuku Perbaikan PanasonicSahida HaryantoNo ratings yet

- Trade of Electrician: Standards Based ApprenticeshipDocument25 pagesTrade of Electrician: Standards Based ApprenticeshipSebastienNoumsiNo ratings yet

- Lafarge Thermography ProgramDocument17 pagesLafarge Thermography ProgramDiego AlejandroNo ratings yet

- BEKO PDP CH L6BDocument129 pagesBEKO PDP CH L6BvideosonNo ratings yet

- BEKO L6B PDP Service ManualDocument121 pagesBEKO L6B PDP Service Manualvideoson100% (2)

- Beko P7 PDPDocument125 pagesBeko P7 PDPwajkNo ratings yet

- Chigo DX ManualDocument19 pagesChigo DX Manualmurat100% (1)

- Conductors & Terminations: Application ConsiderationsDocument3 pagesConductors & Terminations: Application ConsiderationsizzyonNo ratings yet

- Electric Heater Company Operating and Maintenance Manual For Immersion Heating ElementsDocument8 pagesElectric Heater Company Operating and Maintenance Manual For Immersion Heating Elementsnavi_0403No ratings yet

- Panasonic WH-TD20B3E5 Domestic Hot Water SystemDocument18 pagesPanasonic WH-TD20B3E5 Domestic Hot Water SystemPravin MevadaNo ratings yet

- BSEE Safety Alert 478 - Inadequately Maintained Electrical Connections and Compromised Wiring IntegrityDocument3 pagesBSEE Safety Alert 478 - Inadequately Maintained Electrical Connections and Compromised Wiring IntegrityReda MashalNo ratings yet

- 0.5A 125V AC Qualified TypeDocument4 pages0.5A 125V AC Qualified TypeshyhuNo ratings yet

- Panasonic CS-A7GKD CS-A9GKD CS-A12GKD Series Service Manual Repair GuideDocument81 pagesPanasonic CS-A7GKD CS-A9GKD CS-A12GKD Series Service Manual Repair GuideevangalosNo ratings yet

- Department of Education PUBLIC TECHNICAL-VOCATIONAL High SchoolsDocument32 pagesDepartment of Education PUBLIC TECHNICAL-VOCATIONAL High SchoolsReinier Paclibar FederizoNo ratings yet

- IDC - HV Conf - Perth 2015 - Condition Monitoring of High Voltage Switchgear - KHDocument58 pagesIDC - HV Conf - Perth 2015 - Condition Monitoring of High Voltage Switchgear - KHbmwr1100s_055542No ratings yet

- Module 3 Building ServicesDocument62 pagesModule 3 Building ServicesAr. Soumya P SNo ratings yet

- Ac Split Inverter PDFDocument69 pagesAc Split Inverter PDFjewd100% (1)

- Inspection of Electrical Installations in HomesDocument10 pagesInspection of Electrical Installations in HomesHans De KeulenaerNo ratings yet

- K-MCD200R SMDocument66 pagesK-MCD200R SMAurelio Gómez aguilarNo ratings yet

- Inspection of Electrical Installations in Home Part 2Document7 pagesInspection of Electrical Installations in Home Part 2Tani100% (2)

- Intrinsic Safety - The Appropriate Technique For Zone 2Document8 pagesIntrinsic Safety - The Appropriate Technique For Zone 2Omprakash_janaNo ratings yet

- Installation Instructions Type C Boilers: Leave These Instructions With The End-UserDocument24 pagesInstallation Instructions Type C Boilers: Leave These Instructions With The End-UserDaniel James KimmonsNo ratings yet

- CS RE912HKE Manual PDFDocument45 pagesCS RE912HKE Manual PDFZika StojanovicNo ratings yet

- Laboratory Manual Course Code: Ece 130 Course Title: Electrical and Electronics WorkshopDocument36 pagesLaboratory Manual Course Code: Ece 130 Course Title: Electrical and Electronics WorkshopDebashis PaulNo ratings yet

- 2006 19 Summer Wiring Matters Periodic Inspection of Critical SystemsDocument5 pages2006 19 Summer Wiring Matters Periodic Inspection of Critical Systemsaxia_films256No ratings yet

- LGE - PDP42V7xxxx RM 15590 PDFDocument34 pagesLGE - PDP42V7xxxx RM 15590 PDFadolfoc261100% (1)

- Minor Works Cert 2023-5517217898615673120Document4 pagesMinor Works Cert 2023-5517217898615673120James SmithNo ratings yet

- Pca - IomDocument15 pagesPca - IomwavehayiathNo ratings yet

- OCP 02 Electrical SafetyDocument3 pagesOCP 02 Electrical Safetyanon_647217551No ratings yet

- Rmas 20 e - Rad - Ing - Man - Inst - 0809B - Digitech PDFDocument54 pagesRmas 20 e - Rad - Ing - Man - Inst - 0809B - Digitech PDFBotnaru AurelNo ratings yet

- AHU KIT IOM_20200731Document29 pagesAHU KIT IOM_20200731felipeNo ratings yet

- Method of StatementDocument14 pagesMethod of Statementharigopalk12No ratings yet

- Electro Industries ES-24-BR Electronic Slab Thermostat For Electric BoilersDocument10 pagesElectro Industries ES-24-BR Electronic Slab Thermostat For Electric Boilerse-ComfortUSANo ratings yet

- Technical Service Manual DC INVERTER SPLIT SYSTEM AIR CONDITIONERDocument109 pagesTechnical Service Manual DC INVERTER SPLIT SYSTEM AIR CONDITIONEREliel Olivere100% (2)

- Split Type Aircon Installation ManualDocument30 pagesSplit Type Aircon Installation Manualfreddie reyesNo ratings yet

- Diagnostic ExaminationDocument3 pagesDiagnostic ExaminationJoshua CarlNo ratings yet

- 0150511191-A-MH2VYHAS - 150506 Standard Ambinent Outdoor 380-3-50&60 PDFDocument52 pages0150511191-A-MH2VYHAS - 150506 Standard Ambinent Outdoor 380-3-50&60 PDFArshad Mahmood100% (1)

- Presentation - Non-Domestic Electrical Installation Safety CodeDocument39 pagesPresentation - Non-Domestic Electrical Installation Safety CodeTommy YapNo ratings yet

- H2su 14tk r2 DB Out User Manual Aaaa55e0e00Document56 pagesH2su 14tk r2 DB Out User Manual Aaaa55e0e00Adam BELAISNo ratings yet

- Samsung PDP TV Ps58p96fdxxee Chassis F30a P Europe 58fhd Saffron SMDocument71 pagesSamsung PDP TV Ps58p96fdxxee Chassis F30a P Europe 58fhd Saffron SMLuděk CsibaNo ratings yet

- Technical & Service Manual: CS-KE12NB41 & CZ-18BT1U + CU-KE12NK1 CS-KE18NB4UW & CZ-18BT1U + CU-KE18NKUDocument69 pagesTechnical & Service Manual: CS-KE12NB41 & CZ-18BT1U + CU-KE12NK1 CS-KE18NB4UW & CZ-18BT1U + CU-KE18NKUMalay K GhoshNo ratings yet

- Luna Installation ManualDocument16 pagesLuna Installation Manualcmorley5057No ratings yet

- Samsung P2050 - P2250 - P2350Document47 pagesSamsung P2050 - P2250 - P2350boroda241050% (2)

- Im Puhz-Rp200-250yha Bg79u638h01Document16 pagesIm Puhz-Rp200-250yha Bg79u638h01limlianpengNo ratings yet

- SFG20 - 01-07 Power Fail - Motor Return ActuatorDocument4 pagesSFG20 - 01-07 Power Fail - Motor Return Actuatoreclimaco.snclgroupNo ratings yet

- Nibe Install Manual f2300Document52 pagesNibe Install Manual f2300Zo NetNo ratings yet

- Basic Electronic Circuits Explained - Beginner's Guide To Electronics - Homemade Circuit ProjectsDocument85 pagesBasic Electronic Circuits Explained - Beginner's Guide To Electronics - Homemade Circuit ProjectsJuan fernando RoldanNo ratings yet

- V500 / V700 Raceway: Installation InstructionsDocument1 pageV500 / V700 Raceway: Installation InstructionsJhaeZa Sangcap GarridoNo ratings yet

- LTC Library Components List PDFDocument56 pagesLTC Library Components List PDFAna SixNo ratings yet

- Vdocument - in Ntpc-InternshipDocument20 pagesVdocument - in Ntpc-InternshipParnika UpadhyayNo ratings yet

- Att 1001PDocument1 pageAtt 1001PRamtelNo ratings yet

- Zip Light Linear 4 18 SpecificationsDocument3 pagesZip Light Linear 4 18 SpecificationsbjpwongNo ratings yet

- 2SK2195 2Document11 pages2SK2195 2miloud1911No ratings yet

- ComPact NS 33310Document2 pagesComPact NS 33310ivanandresfdezNo ratings yet

- Track Busway Plug in Units - Domestic 6Document68 pagesTrack Busway Plug in Units - Domestic 6TBS Máy Phát ĐiệnNo ratings yet

- Type Coordination Siemens PDFDocument58 pagesType Coordination Siemens PDFvishal.nitham100% (2)

- Untitled 1Document2 pagesUntitled 1Samiul IslamNo ratings yet

- Industrial New Dol 11 55kwand Asd 22 55kw Operating InstructionDocument8 pagesIndustrial New Dol 11 55kwand Asd 22 55kw Operating InstructionRinda_RaynaNo ratings yet

- Technical Guide: Category: Arc Flash Subcategory: Load/Line SideDocument5 pagesTechnical Guide: Category: Arc Flash Subcategory: Load/Line SideEmmanuel EntzanaNo ratings yet

- ENG - PGD 239 - 4.7 Tehnicki OpisDocument3 pagesENG - PGD 239 - 4.7 Tehnicki OpiszdravkocolicNo ratings yet

- Price List Veloce LBS, COS & ATS (Email) - 1Document4 pagesPrice List Veloce LBS, COS & ATS (Email) - 1Rengga PrasetyoNo ratings yet

- Ultra Low Output Voltage Linear N-FET Controller: Global Mixed-Mode Technology IncDocument1 pageUltra Low Output Voltage Linear N-FET Controller: Global Mixed-Mode Technology IncDaniel Norberto DemariaNo ratings yet

- vl160xDocument6 pagesvl160xHuy Dao QuangNo ratings yet

- Power Electronics Ned Mohan Slides Ch28Document26 pagesPower Electronics Ned Mohan Slides Ch28Anoop MathewNo ratings yet

- Full Wave RectifierDocument5 pagesFull Wave RectifierAmulya TengNo ratings yet

- HT8950 Voice Modulator: FeaturesDocument10 pagesHT8950 Voice Modulator: FeatureszvaNo ratings yet

- Ca Series: Proven ReliabilityDocument7 pagesCa Series: Proven ReliabilityHari NurcahyadiNo ratings yet

- As SeriesDocument52 pagesAs SeriesZulfikar FahmiNo ratings yet

- Electrical Cable SpecificationsDocument2 pagesElectrical Cable Specificationsguven dalgaNo ratings yet

- Rural Electrification (2) : Multiple ChoiceDocument6 pagesRural Electrification (2) : Multiple ChoiceAlfredo CondeNo ratings yet

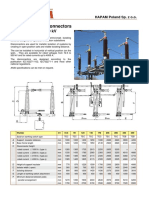

- Centre-Break Disconnectors: Types SGF 72.5Document2 pagesCentre-Break Disconnectors: Types SGF 72.5Ionut - CristianNo ratings yet

- TICO732Document3 pagesTICO732edueu21No ratings yet

- Teleme XS618 DatasheetDocument2 pagesTeleme XS618 Datasheetfajar ssNo ratings yet

- Bts 442 eDocument13 pagesBts 442 eiqdam94No ratings yet

- RSC Electrical SafetyDocument15 pagesRSC Electrical SafetyEftakher Alam WasiNo ratings yet

PNGRB - Electrical Safety Audit Checklist

PNGRB - Electrical Safety Audit Checklist

Uploaded by

Kritarth SrivastavOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PNGRB - Electrical Safety Audit Checklist

PNGRB - Electrical Safety Audit Checklist

Uploaded by

Kritarth SrivastavCopyright:

Available Formats

PNGRB_2018_Checklist

Annexure –IV

System Document for Electrical Safety Audit

SL. No. Item Observation

A. Deviation from laid down procedure:

Deviation from statutory Requirements as laid down.

1 in the law in force relating to electricity and

petroleum

Equipments enclosure mis- match with

1.1

correspondingzone of application

1.2 Clearances not maintained as per guideline

1.3 Material not as per respective Indian Standards

1.4 Inappropriate illumination levels

B. Insulation, Grounding and Lightning Protection:

Grounding and Lightning Protection Systems are not

2

as per IS-3043 and IS -2309

Electrical equipments are not earthed as per the

2.1

recommendation

2.2 Neutral point of transformer and DG set are not earthed

The lightning or surge arrestors are in not in place

2.3

and/or not connected to earth, or both

2.4 High Earth Resistance

2.5 Insulation resistance low, less than 1 Mega Ohm

All panel doors are not earthed with flexible braided

2.6

connection

The electrical room is not clean, and there is water

2.7

accumulation inside the room or cable trenches

C. Protection and Metering System:

3 Protection System is not operating

3.1 Emergency push button jammed

Under-voltage, over-voltage, phase unbalance protection

3.2

not working

3.3 Neutral snap, phase failure protection not working

3.4 Meters not indicating or recording properly

D. Loose connection and overheating:

4.1 Loose connection in cable termination

Equipments running in overload condition, heating and

4.2

burning smell

E. Safety:

Non-functioning of lighting fixtures, especially in

5.1 critical zones viz. near the dispenser, tank farm area,

front and rear of sales room, electrical room

Safety equipments, viz. rubber mat, CO2 fire

5.2 extinguisher, shock treatment chart, flameproof torch are

not in designated places

Repairing work being carried out without any authorized

5.3

work-permit

Components material used are of poor sub-standard

5.4

quality

Labels or tag-marking or ferruling on equipments,

5.5

cables, feeders, cable cores are missing

5.6 Drawing or documents not available in panels

F. Repair and Maintenance:

6.1 Dirt and dust accumulation inside panel

6.2 Spare holes in electrical panel

cklist

fety Audit

Action Needed

Immediate attention needed to rectify the

issue and comply with statutory

requirements

Equipment with appropriate enclosure,to

be installed.

Minimum clearance to be ensured.

Replaced with IS approved materials.

Modify to meet the recommendation.

“Earth” connection to be provided as per

recommendation

“Neutral” points have to be grounded as

per recommendation

Lightning or surge arrestor to be properly

placed and connected

Salt and water to be added to earth pit to

reduce earth resistance.

Damaged portion of insulation to be

repaired, insulation resistance to be

beyond 1 Mega Ohm.

Missing flexible earth links to be put at the

earliest.

Room to be cleaned, water wiped out, all

holes for water entry, to be blocked.

Push button to be replaced, safety

checked by simulation

Relay to be properly set and fault

condition to be simulated to check and

ensure healthiness of the protection

system.

Meter, its C.T. and P.T., as required, to be

replaced immediately.

Termination to be tightened properly

Load must be restricted within the design

limits, loose connection, if any, shall be

set right.

Lighting fixtures and its associated

circuits to be checked and rectified.

To be put at their designated places

immediately and persons trained on

procedure for shock treatment

Immediately work authorization procedure

to be implemented

Standard good quality components to be

used

Missing labels or tag- marks or ferrules to

be put as per drawing.

Drawing or documents to be kept in the

dedicated pockets in panels

Clean periodically.

Spare holes to be blocked.

You might also like

- Ultimate Guide: Wiring, 8th Updated EditionFrom EverandUltimate Guide: Wiring, 8th Updated EditionRating: 3.5 out of 5 stars3.5/5 (4)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Compliance Inspection Test SheetDocument3 pagesCompliance Inspection Test SheetFlorin PanazanNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Gree Service ManualDocument57 pagesGree Service Manualtheskyishigh33% (3)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- M542Document3 pagesM542xhaneriNo ratings yet

- ZN1 ManualDocument40 pagesZN1 Manualpkgoyal1983No ratings yet

- Early Hot Spot Detection Enabling Condition-Based MaintenanceDocument4 pagesEarly Hot Spot Detection Enabling Condition-Based Maintenancesridhar30481647No ratings yet

- Power Meter DPM-C530 User ManualDocument114 pagesPower Meter DPM-C530 User ManualPablo CallaNo ratings yet

- AirConditioner-Sanyo-Service KS (L) 18-24 72 Series Rev C-3285512Document117 pagesAirConditioner-Sanyo-Service KS (L) 18-24 72 Series Rev C-3285512raymihregNo ratings yet

- Buku Perbaikan PanasonicDocument108 pagesBuku Perbaikan PanasonicSahida HaryantoNo ratings yet

- Trade of Electrician: Standards Based ApprenticeshipDocument25 pagesTrade of Electrician: Standards Based ApprenticeshipSebastienNoumsiNo ratings yet

- Lafarge Thermography ProgramDocument17 pagesLafarge Thermography ProgramDiego AlejandroNo ratings yet

- BEKO PDP CH L6BDocument129 pagesBEKO PDP CH L6BvideosonNo ratings yet

- BEKO L6B PDP Service ManualDocument121 pagesBEKO L6B PDP Service Manualvideoson100% (2)

- Beko P7 PDPDocument125 pagesBeko P7 PDPwajkNo ratings yet

- Chigo DX ManualDocument19 pagesChigo DX Manualmurat100% (1)

- Conductors & Terminations: Application ConsiderationsDocument3 pagesConductors & Terminations: Application ConsiderationsizzyonNo ratings yet

- Electric Heater Company Operating and Maintenance Manual For Immersion Heating ElementsDocument8 pagesElectric Heater Company Operating and Maintenance Manual For Immersion Heating Elementsnavi_0403No ratings yet

- Panasonic WH-TD20B3E5 Domestic Hot Water SystemDocument18 pagesPanasonic WH-TD20B3E5 Domestic Hot Water SystemPravin MevadaNo ratings yet

- BSEE Safety Alert 478 - Inadequately Maintained Electrical Connections and Compromised Wiring IntegrityDocument3 pagesBSEE Safety Alert 478 - Inadequately Maintained Electrical Connections and Compromised Wiring IntegrityReda MashalNo ratings yet

- 0.5A 125V AC Qualified TypeDocument4 pages0.5A 125V AC Qualified TypeshyhuNo ratings yet

- Panasonic CS-A7GKD CS-A9GKD CS-A12GKD Series Service Manual Repair GuideDocument81 pagesPanasonic CS-A7GKD CS-A9GKD CS-A12GKD Series Service Manual Repair GuideevangalosNo ratings yet

- Department of Education PUBLIC TECHNICAL-VOCATIONAL High SchoolsDocument32 pagesDepartment of Education PUBLIC TECHNICAL-VOCATIONAL High SchoolsReinier Paclibar FederizoNo ratings yet

- IDC - HV Conf - Perth 2015 - Condition Monitoring of High Voltage Switchgear - KHDocument58 pagesIDC - HV Conf - Perth 2015 - Condition Monitoring of High Voltage Switchgear - KHbmwr1100s_055542No ratings yet

- Module 3 Building ServicesDocument62 pagesModule 3 Building ServicesAr. Soumya P SNo ratings yet

- Ac Split Inverter PDFDocument69 pagesAc Split Inverter PDFjewd100% (1)

- Inspection of Electrical Installations in HomesDocument10 pagesInspection of Electrical Installations in HomesHans De KeulenaerNo ratings yet

- K-MCD200R SMDocument66 pagesK-MCD200R SMAurelio Gómez aguilarNo ratings yet

- Inspection of Electrical Installations in Home Part 2Document7 pagesInspection of Electrical Installations in Home Part 2Tani100% (2)

- Intrinsic Safety - The Appropriate Technique For Zone 2Document8 pagesIntrinsic Safety - The Appropriate Technique For Zone 2Omprakash_janaNo ratings yet

- Installation Instructions Type C Boilers: Leave These Instructions With The End-UserDocument24 pagesInstallation Instructions Type C Boilers: Leave These Instructions With The End-UserDaniel James KimmonsNo ratings yet

- CS RE912HKE Manual PDFDocument45 pagesCS RE912HKE Manual PDFZika StojanovicNo ratings yet

- Laboratory Manual Course Code: Ece 130 Course Title: Electrical and Electronics WorkshopDocument36 pagesLaboratory Manual Course Code: Ece 130 Course Title: Electrical and Electronics WorkshopDebashis PaulNo ratings yet

- 2006 19 Summer Wiring Matters Periodic Inspection of Critical SystemsDocument5 pages2006 19 Summer Wiring Matters Periodic Inspection of Critical Systemsaxia_films256No ratings yet

- LGE - PDP42V7xxxx RM 15590 PDFDocument34 pagesLGE - PDP42V7xxxx RM 15590 PDFadolfoc261100% (1)

- Minor Works Cert 2023-5517217898615673120Document4 pagesMinor Works Cert 2023-5517217898615673120James SmithNo ratings yet

- Pca - IomDocument15 pagesPca - IomwavehayiathNo ratings yet

- OCP 02 Electrical SafetyDocument3 pagesOCP 02 Electrical Safetyanon_647217551No ratings yet

- Rmas 20 e - Rad - Ing - Man - Inst - 0809B - Digitech PDFDocument54 pagesRmas 20 e - Rad - Ing - Man - Inst - 0809B - Digitech PDFBotnaru AurelNo ratings yet

- AHU KIT IOM_20200731Document29 pagesAHU KIT IOM_20200731felipeNo ratings yet

- Method of StatementDocument14 pagesMethod of Statementharigopalk12No ratings yet

- Electro Industries ES-24-BR Electronic Slab Thermostat For Electric BoilersDocument10 pagesElectro Industries ES-24-BR Electronic Slab Thermostat For Electric Boilerse-ComfortUSANo ratings yet

- Technical Service Manual DC INVERTER SPLIT SYSTEM AIR CONDITIONERDocument109 pagesTechnical Service Manual DC INVERTER SPLIT SYSTEM AIR CONDITIONEREliel Olivere100% (2)

- Split Type Aircon Installation ManualDocument30 pagesSplit Type Aircon Installation Manualfreddie reyesNo ratings yet

- Diagnostic ExaminationDocument3 pagesDiagnostic ExaminationJoshua CarlNo ratings yet

- 0150511191-A-MH2VYHAS - 150506 Standard Ambinent Outdoor 380-3-50&60 PDFDocument52 pages0150511191-A-MH2VYHAS - 150506 Standard Ambinent Outdoor 380-3-50&60 PDFArshad Mahmood100% (1)

- Presentation - Non-Domestic Electrical Installation Safety CodeDocument39 pagesPresentation - Non-Domestic Electrical Installation Safety CodeTommy YapNo ratings yet

- H2su 14tk r2 DB Out User Manual Aaaa55e0e00Document56 pagesH2su 14tk r2 DB Out User Manual Aaaa55e0e00Adam BELAISNo ratings yet

- Samsung PDP TV Ps58p96fdxxee Chassis F30a P Europe 58fhd Saffron SMDocument71 pagesSamsung PDP TV Ps58p96fdxxee Chassis F30a P Europe 58fhd Saffron SMLuděk CsibaNo ratings yet

- Technical & Service Manual: CS-KE12NB41 & CZ-18BT1U + CU-KE12NK1 CS-KE18NB4UW & CZ-18BT1U + CU-KE18NKUDocument69 pagesTechnical & Service Manual: CS-KE12NB41 & CZ-18BT1U + CU-KE12NK1 CS-KE18NB4UW & CZ-18BT1U + CU-KE18NKUMalay K GhoshNo ratings yet

- Luna Installation ManualDocument16 pagesLuna Installation Manualcmorley5057No ratings yet

- Samsung P2050 - P2250 - P2350Document47 pagesSamsung P2050 - P2250 - P2350boroda241050% (2)

- Im Puhz-Rp200-250yha Bg79u638h01Document16 pagesIm Puhz-Rp200-250yha Bg79u638h01limlianpengNo ratings yet

- SFG20 - 01-07 Power Fail - Motor Return ActuatorDocument4 pagesSFG20 - 01-07 Power Fail - Motor Return Actuatoreclimaco.snclgroupNo ratings yet

- Nibe Install Manual f2300Document52 pagesNibe Install Manual f2300Zo NetNo ratings yet

- Basic Electronic Circuits Explained - Beginner's Guide To Electronics - Homemade Circuit ProjectsDocument85 pagesBasic Electronic Circuits Explained - Beginner's Guide To Electronics - Homemade Circuit ProjectsJuan fernando RoldanNo ratings yet

- V500 / V700 Raceway: Installation InstructionsDocument1 pageV500 / V700 Raceway: Installation InstructionsJhaeZa Sangcap GarridoNo ratings yet

- LTC Library Components List PDFDocument56 pagesLTC Library Components List PDFAna SixNo ratings yet

- Vdocument - in Ntpc-InternshipDocument20 pagesVdocument - in Ntpc-InternshipParnika UpadhyayNo ratings yet

- Att 1001PDocument1 pageAtt 1001PRamtelNo ratings yet

- Zip Light Linear 4 18 SpecificationsDocument3 pagesZip Light Linear 4 18 SpecificationsbjpwongNo ratings yet

- 2SK2195 2Document11 pages2SK2195 2miloud1911No ratings yet

- ComPact NS 33310Document2 pagesComPact NS 33310ivanandresfdezNo ratings yet

- Track Busway Plug in Units - Domestic 6Document68 pagesTrack Busway Plug in Units - Domestic 6TBS Máy Phát ĐiệnNo ratings yet

- Type Coordination Siemens PDFDocument58 pagesType Coordination Siemens PDFvishal.nitham100% (2)

- Untitled 1Document2 pagesUntitled 1Samiul IslamNo ratings yet

- Industrial New Dol 11 55kwand Asd 22 55kw Operating InstructionDocument8 pagesIndustrial New Dol 11 55kwand Asd 22 55kw Operating InstructionRinda_RaynaNo ratings yet

- Technical Guide: Category: Arc Flash Subcategory: Load/Line SideDocument5 pagesTechnical Guide: Category: Arc Flash Subcategory: Load/Line SideEmmanuel EntzanaNo ratings yet

- ENG - PGD 239 - 4.7 Tehnicki OpisDocument3 pagesENG - PGD 239 - 4.7 Tehnicki OpiszdravkocolicNo ratings yet

- Price List Veloce LBS, COS & ATS (Email) - 1Document4 pagesPrice List Veloce LBS, COS & ATS (Email) - 1Rengga PrasetyoNo ratings yet

- Ultra Low Output Voltage Linear N-FET Controller: Global Mixed-Mode Technology IncDocument1 pageUltra Low Output Voltage Linear N-FET Controller: Global Mixed-Mode Technology IncDaniel Norberto DemariaNo ratings yet

- vl160xDocument6 pagesvl160xHuy Dao QuangNo ratings yet

- Power Electronics Ned Mohan Slides Ch28Document26 pagesPower Electronics Ned Mohan Slides Ch28Anoop MathewNo ratings yet

- Full Wave RectifierDocument5 pagesFull Wave RectifierAmulya TengNo ratings yet

- HT8950 Voice Modulator: FeaturesDocument10 pagesHT8950 Voice Modulator: FeatureszvaNo ratings yet

- Ca Series: Proven ReliabilityDocument7 pagesCa Series: Proven ReliabilityHari NurcahyadiNo ratings yet

- As SeriesDocument52 pagesAs SeriesZulfikar FahmiNo ratings yet

- Electrical Cable SpecificationsDocument2 pagesElectrical Cable Specificationsguven dalgaNo ratings yet

- Rural Electrification (2) : Multiple ChoiceDocument6 pagesRural Electrification (2) : Multiple ChoiceAlfredo CondeNo ratings yet

- Centre-Break Disconnectors: Types SGF 72.5Document2 pagesCentre-Break Disconnectors: Types SGF 72.5Ionut - CristianNo ratings yet

- TICO732Document3 pagesTICO732edueu21No ratings yet

- Teleme XS618 DatasheetDocument2 pagesTeleme XS618 Datasheetfajar ssNo ratings yet

- Bts 442 eDocument13 pagesBts 442 eiqdam94No ratings yet

- RSC Electrical SafetyDocument15 pagesRSC Electrical SafetyEftakher Alam WasiNo ratings yet