Professional Documents

Culture Documents

Tank Foundation PDF

Tank Foundation PDF

Uploaded by

Noel Elivert0 ratings0% found this document useful (0 votes)

17 views7 pagesOriginal Title

2. TANK FOUNDATION.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

17 views7 pagesTank Foundation PDF

Tank Foundation PDF

Uploaded by

Noel ElivertCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 7

Annex B

(informative)

Recommendations for Design and Construction of Foundations for

Aboveground Oil Storage Tanks.

B.1 Scope

B.1.1 This Annex provides important considerations for the design and construction of oases for aboveground

tic

steel oll storage tanks with flat bottoms, Recommendations are offered to outline good pract point out some

precautions that should be considered in the design and construction of storage tank fout

BA1.2. Since there is a wide variety of surface, subsurface, and climatic conditig Nt practical to establish

design data to cover all situations. The allowable soil loading and the exact type of st e construction to be used

must be decided for each individual case after careful consideration. The same rules and precautions shall be used in

selecting foundation sites as would be applicable in designing and constru undations for other structures of

‘comparable magnitude. oS

B.2 Subsurface Investigation and Construction

B.2.1 At any tank site, the subsurface conditions must be knowio estimate the soil bearing capacity and

settlement that will be experienced. This information is ger obtained from soil borings, load tests, sampling,

laboratory testing, and analysis by an experienced geotec! jeer familiar wth the history of similar structures

in the vicinity, The subgrade must be capable of supportifg,ie load ofthe tank and its contents, The total settlement

rust not strain connecting piping or produce gaug ae is, and te stement shoud not continue to a pont

at which the tank bottom is below the surrounding surface. The estimated setlement shall be within the

aoceplabe tolerances forthe tank shel and bo

B.2.2_ When actual experience with simlatfaits and foundations ata particular sit is not avaliable, the following

ranges for factors of safety should be eonskiered for use inthe foundation design crea for determining the

dllowable sol bearing pressures, (The;Swqeror geotechnical engineer responsible forthe project may use factors of

safety ouside these anges.)

a) From2.0103.0 women faire fornormal operating conditons.

b) From 1.5 to 2.25 againeMbilinte bearing failure during hydrostatic testing,

©) From 1.5 to 2. st ultimate bearing failure for operating conditions plus the maximum effect of wind or

seismic log

B.2.3 Some\éf the many conditions that require special engineering consideration are as follows:

4) sites on hillsides, where part of a tank may be on undisturbed ground or rock and part may be on fil or another

construction or where the depth of required fils variable,

b) sites on swampy or filed ground, where layers of muck or compressible vegetation are at or below the surface or

Where unstable or corrosive materials may have been deposited as fil

©) sites underlain by soils, such as layers of plastic clay or organic clays, that may support heavy loads temporarily

but settle excessively over long periods of time.

4d) sites adjacent to water courses or deep excavations, where the lateral stability of the ground is questionable.

4

82 [API Sranparo 650

) sites immediately adjacent to heavy structures that distribute some of their load to the subsoil under the tank sites,

thereby reducing the subsoils capacity to carry additional loads without excessive settlement.

1) sites where tanks may be exposed to flood waters, possibly resulting in uplif, displacement, or scour.

49) sites in regions of high seismicity that may be susceptible to liquefaction.

h) sites with thin layers of soft clay solls that are directly beneath the tank bottom and that can cause lateral ground

stabilty problems,

a) Removing the objectionable material and replacing it wth suitable, compacted mal

b) Compacting the soft material with short piles.

‘c) Compacting the soft material by preloading the area with an overbu Gaxy Strip or sand drains may be used

in conjunction with this method

4) Stabilizing the soft material by chemical methods or injection of cemaReGrout.

the load intensity will be within allowable limi ‘cessive settlement will not occur.

bottom,

* ~»

{Constructing a slab foundation that wil mee fd over a sufficiently large area of the soft material so that

4g) Improving soil properties by vibro-comy

ibro-replacement, or deep dynamic-compaction.

h) Slow and controlled filing of the ta

may be compromised by excessive saitlements of the shell or bottom, For this reason, the settlements of the tank

shall be closely monitores

stopped and the tank rele\

B25. The fil material whe 0 replace muck or other objectionable material orto build up the grade to a sultable

height shall be adeayAl@Yob the support of the tank and product after the material has been compacted. The fil

malerial shall bp“ree\al yegetation, organic matter, cinders, and any material that wil cause corrosion ofthe tank

bottom. The gfadefénd fype of fil material shall be capable of being compacted with standard industry compaction

techniques to a dengiy suficient to provide appropriate bearing capacity and acceptable settlements. The placement

ofthe fil material shal be in accordance wit the project specifications prepared by a qualifed geotechnical engineer.

B.3. Tank Grades

B.3.1 The grade or surface on which a tank bottom will rest should be constructed at least 0.3 m (1 fl) above the

‘surrounding ground surface. This will provide suitable drainage, help keep the tank bottom dry, and compensate for

‘some small settlement that is likely to occur. If a large settlement is expected, the tank bottom elevation shall be

raised so that the final elevation above grade will be a minimum of 160 mm (6 in.) after settlement.

B.3.2_ There are several different materials that can be used for the grade or surface on which the tank bottom will

rest. To minimize future corrosion problems and maximize the effect of corrosion prevention systems such as

WeLpeD TANKS FoR OIL SroRAGE Bs

cathodic protection, the material in contact with the tank bottom should be fine and uniform. Gravel or large particles

shall be avoided. Clean washed sand 75 mm to 100 mm (3 in. 4 in.) deep is recommended as a final layer because

itcan be readily shaped to the bottom contour of the tank to provide maximum contact area and wil protect the tank

bottom from coming into contact with large particles and debris. Large foreign objects or point contact by gravel or

rocks could cause corrosion cells that wil cause piting and premature tank bottom failure

During construction, the movement of equipment and materials across the grade will mar the graded surface. These

irregularties should be corrected before bottom plates are placed for welding.

Adaqt roe, sch a raking sega nutayr progatssvalaremgotetNo sot bo

raise phe rt nactgscm rage aah agi! eater

Me ia el mit ons eld

NOTE For more information on tank bottom corrosion and corrosion prevention that,

API 651

B.3.3_Uniess otherwise specified by the Purchaser, the fnished tank grade spatpbe crowned from its outer periphery

to its center at a slope of 1 in. in 10 ft. The crown will parly compensate fohgfight settlement, which is likely to be

‘greater at the center. It will also facilitate cleaning and the removal of watt and Sludge through openings in the shell

‘or from sumps situated near the shell. Because crowning will affe ths of roof-supporting colurmns, it is

‘essential thatthe tank Manufacturer be fully informed of this fe nly in advance. (For an allemative to this

paragraph, see B3.4)

undation of @ tank, see

B.4 Typical Foundation Types wy

B.4.1 Earth Foundations Without a

B.4.1.1_ When an engineering evaluat

work has shown that the subgrad

satisfactory foundations may b

foundations are identical to thase

the following,

bsurface conditions that is based on experience and/or exploratory

‘adequate bearing capacity and that settlements will be acceptable,

ieted from earth materials. The performance requirements for earth

re extensive foundations. Specifically, an earth foundation should accomplish

4) provide a stable <" ‘support of the tank;

b) limit overall se

connecting Pipi

©) provide adeQyate drainage;

‘of the tank grade to values compatible with the allowances used in the design of the

4) not settle excessively at the perimeter due to the weight of the shell wall

B.4.1.2. Many satisfactory designs are possible when sound engineering judgment is used in their development,

‘Three designs are referred to in this Annex on the basis of their satisfactory long-term performance. For smaller

tanks, foundations can consist of compacted crushed stone, screenings, fine gravel, clean sand, or similar material

placed directly on virgin soil, Any unstable material must be removed, and any replacement material must be

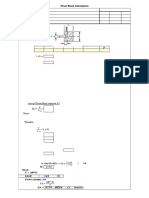

thoroughly compacted. Two recommended designs that include ringwalls are illustrated in Figure B.1 and Figure B.2

and described in B.4.2 and B.4.3.

es AP smoano 680

Catering ot nga

. j NY Tine

flere /

som ks i// ayer

Gin) | @iny {If

eae {

NUFF AL {Sp

~ \ \\\

~ \\\ ’

f | ~ \

4 ~ soe \\ i

me \ H

i 2 a a

ewan 75.nm (in) min of cect, dean sara

NX -

eng fal foie wi sable hen

— suraipgeg : ‘thoroughly compact il

“ 300 mm (12 in.) min

mao

NOTE 1 Se08.423forrequtemens oe hen

NOTE 2 The top of the concrete, be smooth and level. The concrete strength shall be at least 20 MPa (3000 tofiin.2)

Meat days Recemaat sa Sib cso nd hah So tupre cs covobp fl svongn bbe Wsaggeang ape ©

fot posable, se ACI 318 for ad lopment requirements

NOTES Ringwals that excogs 300 F912 in.) in widh shall have rears cistriouted on both faces,

NOTE4 See B4.2.2forthélfgstion of the tank shel on the rngwall

jure B.1—Example of Found:

B.4.2_ Earth Foundations With a Concrete Ringwall

BAA.2.1 Large tanks and tanks with heavy or tall shells and/or self-supported roofs impose a substantial load on the

foundation under the shell. This is particularly important with regard to shell distortion in floating-roof tanks. When

there is some doubt whether a foundation will be able to carry the shell load directly, a concrete ringwall foundation

should be used. As an altemative to the concrete ringwall noted in this section, a crushed stone ringwall (see B.4.3)

ion with Concrete Ringwall

may be used, A foundation with a concrete ringwall has the following advantages.

4) It provides better distribution of the concentrated load of the shell to produce a more nearly uniform soil loading

under the tank,

b) It provides a level, solid starting plane for construction of the shell

WeLpeD TANKS FoR OIL SroRAGE Bs

tien —itewmn

‘Slope to9 of ringwal

‘way rom tank

paved lA 1

\ As

1

Thoroughly compacted fof

Crushed stone or gravel {fine gravel coarse sand.

rote stable materia

75mm (in) min

compacted

eur so

4.

NOTE _Any unsuitable materal shall be removed ard replaced with

‘Sutable fi the fl shal then be thoroughly compacted,

©) It provides a better means of leveling the tank grade, and it is capatilp of preserving its contour during

construction,

4) It retains the fill under the tank bottom and prevents loss of| > of erosion

) It minimizes moisture under the tank.

A disadvantage of concrete ringwalls is that they may CRaoooy conform to differential settlements. This

disadvantage may lead to high bending stresses inthe Oj 3s adjacent tothe ringwall

B.A22_ When a concrete ringwal is designedy ning ‘proportioned so that the allowable sol bearing fs not

exceeded. The ringwall shall not be less than Pa 12 in.) thick. The centerline diameter of the ringwall should

quel tre nominel dameter ofthe tank: Row¥epethe ringwal certeine may vary fequted to flats the

placeront of archot bls oto satst sl aging ts for seismic loads or excesive pli forces The dept of te

Weal wil depend on local contre, bu must be suffcentfo place the bom of fe ringwal below the

Srticpated Fost penevaton and witmdhewsecfed bearing seta, As 2 rinimum, te bottom of te Fingal

founded on Sl, sha be located Or (@ % below the lowest adjacent fish grade Tank foundations must be

Corsi win te tolerances flees in 755, Recess shal be paved ite wal for fush-ype deanouts,

drawoff sumps, and any otk PT lances that require recesses.

B423 A ringwall shoul forced against temperature changes and shrinkage and reinforced to resist the

lateral pressure of the gonfined fill wth its surcharge from product loads. ACI 318 is recommended for design stress.

values, material spegifiCations, and rebar development and cover. The following items conceming a ringwall shall be

considered.

1a) The ringwaifShall be reinforced to resist the direct hoop tension resulting from the lateral earth pressure on the

ringwal's inside face. Unless substantiated by proper geotechnical analysis, the lateral earth pressure shall be

assumed to be at least 50 % of the vertical pressure due to fluid and soil weight. Ifa granular backfil is used, a lateral

earth pressure coefficient of 30 % may be used.

b) The ringwall shall be reinforced to resist the bending moment resulting from the uniform moment load. The

uniform moment load shall account for the eccentricities of the applied shell and pressure loads relative to the

centroid of the resulting soil pressure. The pressure load is due to the fluid pressure on the horizontal projection of

the ringwall inside the shell

6). The ringwall shall be reinforced to resist the bending and torsion moments resulting from lateral, wind, or seismic

loads applied eccentrically to it, A rational analysis, which includes the effect of the foundation stiffness, shall be

used to determine these moments and soil pressure distributions,

Bs [API Sranparo 650

4d) The total hoop steel area required to resist the loads noted above shall not be less than the area required for

temperature changes and shrinkage. The hoop steel area required for temperature changes and shrinkage is

0.0026 times the vertical cross-sectional area of the ringwall or the minimum reinforcement for walls called for in

ACI 318, Chapter 14,

) For ringwalls, the vertical steel! area required for temperature changes and shrinkage is 0.0015 times the

horizontal cross-sectional area of the ringwall or the minimum reinforcement for walls called for in ACI 318,

Chapter 14. Additional vertical steel may be required for uplift or torsional resistance. If the ring foundation is wider

than its depth, the design shall consider its behavior as an annular slab with flexure in the sadial direction

‘Temperature and shrinkage reinforcement shall meet the AC! 318 provisions for slabs. (See ACI 348, Chapter 7.)

1) When the ringwall width exceeds 460 mm (18 in.), using a footing beneath the wall bd) considered.

Footings may also be useful for resistance to uplift forces.

undergo minimal settlement.

h) Ifthe tank is designed and constructed for elevated temperature Seyvice pee B.6.

B.4.2.4 Options under the shell. Considerations shall be given toe trapping of moisture under the tank bottom that

‘can lead to underside corrosion. Refer to E.7.1 for additional sei§gifc fonsiderations.

we

a) Place steel directly on concrete.

b) 13 mm ('/2 in.) asphalt impregnated fiber board,

B.4.3. Earth Foundations Wit hed Stone and Gravel Ringwall

BA43.1_ A crushed stone of{gravelringwall will provide adequate support for high loads imposed by a shell. A

foundation with a crushed stor ravel ringwall has the following advantages.

2) It provides beter ros ofthe concentrated lod ofthe shel to produce @ more neal uniform soil loading

ur tela

¢) Hretains theft une the anicbotom and prevents loss of mater a a elo erosion

6) lean more smoot acconmadate diferent! etlement because os exit

Adisadvantage of the crushed stone or gravel ringwall is that itis more difficult to construct it to close tolerances and

achieve a flat, level plane for construction of the tank shell

WeLpeD TANKS FoR OIL SroRAGE e7

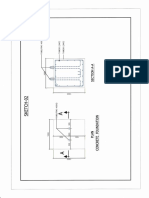

4.3.2. For crushed stone or gravel ringwalls, careful selection of design details is necessary to ensure satisfactory

performance. The type of foundation suggested is shown in Figure B.2. Significant details include the following

a) The 0.9 m (3 ft) shoulder and berm shall be protected from erosion by being constructed of crushed stone or

covered with a permanent paving material

) Care shall be taken during construction to prepare and maintain a smooth, level surface for the tank bottom plates.

c) The tank grade shall be constructed to provide adequate drainage away from the tank foundation.

) The tank foundation must be true to the specified plane within the tolerances specified in

B.4.4 Slab Foundations &

BA4.4.1 When the soil bearing loads must be distributed aver an area larger tank area or when it is

specified by the owner, a reinforced concrete slab shall be used. Piles beneath the Slat may be required for proper

tank support

BA.4.2 The structural design of the slab, whether on grade or on piles, Feperly account forall loads imposed

Upon the slab by the tank. The reinforcement requirements and # In details of construction shall be in

accordance with ACI 318.

BA.4.3. Refer to B.4.2.4 for options under the shell @

B.5 Tank Foundations for Leak Detection

‘Annex | provides recommendations on the conan ‘Yank and foundation systems for the detection of leaks

through the bottoms of storage tanks,

B.6 Tank Foundations for Elevat perature Service

‘The design and construction of foundations Yer tanks operating at elevated temperatures [> 93 °C (200 °F)] should

address the following considerations.

a) When subjected to ele ing temperatures, a self-anchored tank may tend to move in one or more

directions over time. THis movement must be accommodated in the design of the tank fitings and attachments.

b) Elevated temperatuye service may evaporate moisture in the soil supporting the tank and lead to increased, and

possibly non-unifor settlement. Such settlement may include differential settlement between the ringwall and

soil under the fom immediately adjacent to the ringwall resulting from non-uniform shrinkage of the soll

with respéét ne oF concrete ringwall

) In cases wh8te there is high groundwater table, elevated temperatures may vaporize groundwater and generate

undesirable steam.

4d) Attachments between the tank and the foundation must accommodate the thermal expansion and contraction of

the tank without resulting in unacceptable stress levels.

2) The elevated temperature must be accounted for in the design of concrete ringwall foundations. The ringwall is

subject to a moment due to the higher temperature at the top of the ringwall with respect to the temperature at the

bottom of the ringwall, If not adequately accounted for in the design of the ringwall, this moment can lead to

cracking of the concrete foundation and loss of tank support.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Kerbstone FixingDocument3 pagesKerbstone FixingNoel ElivertNo ratings yet

- 1 Sectional ViewDocument2 pages1 Sectional ViewNoel ElivertNo ratings yet

- Sulphate ContentsDocument2 pagesSulphate ContentsNoel ElivertNo ratings yet

- BS 8500 ExtractDocument5 pagesBS 8500 ExtractNoel ElivertNo ratings yet

- ADM Standard Specs - Nov 2014Document3 pagesADM Standard Specs - Nov 2014Noel ElivertNo ratings yet

- CoeffDocument1 pageCoeffNoel ElivertNo ratings yet

- 23MY PAJERO SPORT - Eng1Document4 pages23MY PAJERO SPORT - Eng1Noel ElivertNo ratings yet

- Empirical Pavement Design ExamDocument5 pagesEmpirical Pavement Design ExamNoel ElivertNo ratings yet

- Annex 1Document3 pagesAnnex 1Noel ElivertNo ratings yet

- Low Volume RoadDocument6 pagesLow Volume RoadNoel ElivertNo ratings yet

- Pavement Design ComponentsDocument15 pagesPavement Design ComponentsNoel ElivertNo ratings yet

- Box of Odd Size ModelDocument1 pageBox of Odd Size ModelNoel ElivertNo ratings yet

- Izza Volume CalculationsDocument1 pageIzza Volume CalculationsNoel ElivertNo ratings yet

- Fencing Layout ModelDocument1 pageFencing Layout ModelNoel ElivertNo ratings yet

- Thrust Block-End CapDocument1 pageThrust Block-End CapNoel ElivertNo ratings yet

- Concrete BlockDocument1 pageConcrete BlockNoel ElivertNo ratings yet