Professional Documents

Culture Documents

Welding On Sheet Metal

Welding On Sheet Metal

Uploaded by

Debabrata Misra [DME6369]Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding On Sheet Metal

Welding On Sheet Metal

Uploaded by

Debabrata Misra [DME6369]Copyright:

Available Formats

8Discuss

AnSwer:

rious classification of Joininwelding.

gProcessees

Welding processes MT.181

Fusion

or

n o n - p r e s s u r e

weldino

ng WesCTE 2006)

Heat obtained from

Plastuc or

preswure welding

Low

Energy Heat obtained from

Energy Temperature Arc Chemical

Ray Energy Smith's

Forge Electrical

Energy Mechanical

Laser

Atomic (resistance) Energy

Electron

beam

Welding

Hydrogen (Pressut)

Welding Welding Chemical

Reaction

Brasing Brase Gas flame

Thermit Welding

Soldering

Welding

Oxy-Acetylene (without pressure)

Welding

Carbon Tungsten Argon Electro

Metal Arc Arc

Submerged Inert gas

Slag

LArc

Welding

Arc

Welding

Arc

Welding

Spot Seam Projection Butt or Flash Percussion

Welding Welding Welding upset Welding Welding

Welding

Friction Ultra Sonic Explosive

Welding Welding Welding

Water gas

Thermit Welding

Welding

with pressure)

2008, 2019]

WBSCTE 2007,

Brazing

Distinguish between soldering and

Answer BRAZING

temperature ot

temperature

of tiller

ter

point than the

SOLDERING The

melting

430°C

but less

1. . .

filler1 than material.

The melting e m p e r a t u r e

of material

is more basemarernl.

otbase

of

is also less

temperature

t e m p e r a t u r e

material is less than 430°C and it melting

m elting

point

copper and

hatan melting point temperature

o f base

is an

alloy of

and

aluminum.

material.

material

copper

Filler

silver;

2.

tin, and

er material is an alloy of lead and zinc.

Zinc.

Cu

known

as

spelter.

and

boric

acids

known as solder This is

The flux

used

is

borax

You might also like

- Handy-Tig 210 AcdcDocument80 pagesHandy-Tig 210 AcdcEdin Edin100% (1)

- Electrode Selection As Per Base Metal With Preheat, Postheat and Hardness DetailsDocument1 pageElectrode Selection As Per Base Metal With Preheat, Postheat and Hardness DetailsJlkKumar100% (1)

- AWS A5.23 Specification For Low Alloy Steel Electrodes and Fluxes For Submerged Arc Welding PDFDocument44 pagesAWS A5.23 Specification For Low Alloy Steel Electrodes and Fluxes For Submerged Arc Welding PDFRUDY ALONSO CASTRO IGNACIONo ratings yet

- Welding Rod SelectionDocument1 pageWelding Rod Selectionbikas_sahaNo ratings yet

- Welding For 2023 GATE ESE PSUs by S K MondalDocument84 pagesWelding For 2023 GATE ESE PSUs by S K MondalRaj SinhaNo ratings yet

- Welding For 2022 GATE ESE PSUs by S K MondalDocument84 pagesWelding For 2022 GATE ESE PSUs by S K MondalNabin MukherjeeNo ratings yet

- TIG Welding and Plasma Arc WeldingDocument14 pagesTIG Welding and Plasma Arc Weldingswapnil pandeNo ratings yet

- Week 7 - Resistance WeldingDocument25 pagesWeek 7 - Resistance WeldingameerakeemNo ratings yet

- The Welding Journal 1958 8Document152 pagesThe Welding Journal 1958 8AlexeyNo ratings yet

- Aws A5.22-95Document51 pagesAws A5.22-95AdriánOrtiz0% (1)

- Consumables For The Welding of Hardox, Strenx™, Toolox and Armox Techsupport #60Document8 pagesConsumables For The Welding of Hardox, Strenx™, Toolox and Armox Techsupport #60MONo ratings yet

- Centrifuged and Bimetallic Cast Iron Rolls: Chemical CompositionDocument1 pageCentrifuged and Bimetallic Cast Iron Rolls: Chemical CompositionBhupendraNo ratings yet

- List of welding processes - WikipediaDocument5 pagesList of welding processes - Wikipediakalaga43No ratings yet

- Product Catalog & Design Guide: Gas Discharge Tube (GDT) ProductsDocument60 pagesProduct Catalog & Design Guide: Gas Discharge Tube (GDT) ProductsMisko PiskoNo ratings yet

- Prima Catalouge 6 Pgs-MinDocument6 pagesPrima Catalouge 6 Pgs-MinVarun KapoorNo ratings yet

- Anshu Welding PDFDocument45 pagesAnshu Welding PDFAnshu SourabhNo ratings yet

- ABC of Welding For Robot - EnglishDocument66 pagesABC of Welding For Robot - EnglishAnubhavNo ratings yet

- Lecture 11 (Mems) Thermal SensorsDocument3 pagesLecture 11 (Mems) Thermal SensorsMANUDEYNo ratings yet

- Welding 6TH SemDocument15 pagesWelding 6TH SemIshan VermaNo ratings yet

- The Influence of Oxygen Additions On Argon-Shielded Gas Metal Arc Welding ProcessesDocument11 pagesThe Influence of Oxygen Additions On Argon-Shielded Gas Metal Arc Welding ProcesseszoombadosNo ratings yet

- Principle of Tig Welding: Arc Welding Pro-CessesDocument22 pagesPrinciple of Tig Welding: Arc Welding Pro-CesseszsmithNo ratings yet

- Basics of WeldingDocument70 pagesBasics of Weldingamit kumarNo ratings yet

- W Section 2 Tig Welding Saf Fro General Catalogue3005009245853932523Document18 pagesW Section 2 Tig Welding Saf Fro General Catalogue3005009245853932523ravi00098No ratings yet

- Materials Electrodes SelectionDocument1 pageMaterials Electrodes SelectionjineshNo ratings yet

- Material With Electrode SelectionDocument3 pagesMaterial With Electrode SelectionpmkarNo ratings yet

- Destacador - Ejetor Misumi PJHDocument1 pageDestacador - Ejetor Misumi PJHMarcus ViniciusNo ratings yet

- List of Welding Processes - Wikipedia, The Free EncyclopediaDocument6 pagesList of Welding Processes - Wikipedia, The Free EncyclopediasumitNo ratings yet

- How To Select ElectrodeDocument2 pagesHow To Select Electrodesbmmla100% (1)

- Electrode SelectionDocument1 pageElectrode SelectionVijayabaraniNo ratings yet

- AWS Specification For Surfacing Electrodes For Shielded Metal Are WeldingDocument27 pagesAWS Specification For Surfacing Electrodes For Shielded Metal Are WeldingJuan Carlos Fernandez LoveraNo ratings yet

- Aws A5.28-96 PDFDocument43 pagesAws A5.28-96 PDFlouisdabooisNo ratings yet

- Joining Processes Chapter OutlineDocument7 pagesJoining Processes Chapter OutlineAjyant SuryaNo ratings yet

- List of Welding Processes: Name N AWS Characteristics ApplicationsDocument5 pagesList of Welding Processes: Name N AWS Characteristics ApplicationsCalcgen Engineering0% (1)

- Anshu WeldingDocument46 pagesAnshu WeldingAnshu SourabhNo ratings yet

- Selection of Materials For WeldingDocument1 pageSelection of Materials For WeldingUNNIKRISHNAN NAIRNo ratings yet

- Product Catalog & Design Guide: Gas Discharge Tube (GDT) ProductsDocument76 pagesProduct Catalog & Design Guide: Gas Discharge Tube (GDT) ProductsSantiago BNo ratings yet

- Adobe Scan 31 Jul 2021Document1 pageAdobe Scan 31 Jul 2021arnabNo ratings yet

- Electrode SelectionDocument1 pageElectrode SelectionRachel ThompsonNo ratings yet

- Tool Steel - Material Selection Guide: High Speed SteelsDocument1 pageTool Steel - Material Selection Guide: High Speed SteelsAlok Rawat NLMKNo ratings yet

- Safety in Welding, Cutting and Allied Processes, © CSADocument14 pagesSafety in Welding, Cutting and Allied Processes, © CSAkakaNo ratings yet

- TALAT Lecture 4500: Resistance WeldingDocument23 pagesTALAT Lecture 4500: Resistance WeldingCORE MaterialsNo ratings yet

- Welding AND Gas Metal Arc Welding (Gmaw) : Teknik Kendaraan Ringan Semester 2 Class X Kompetensi Kejuruan SK-KD 2Document14 pagesWelding AND Gas Metal Arc Welding (Gmaw) : Teknik Kendaraan Ringan Semester 2 Class X Kompetensi Kejuruan SK-KD 2Prisma RianNo ratings yet

- Chloride: Vapour Deposition Hard-Facing Miscellaneous TechniquesDocument2 pagesChloride: Vapour Deposition Hard-Facing Miscellaneous TechniquessandeepNo ratings yet

- Lesson 6 - Carbon & Low Alloy Steel Filler Metals For The GMAW, GTAW and SAW Welding ProcessesDocument1 pageLesson 6 - Carbon & Low Alloy Steel Filler Metals For The GMAW, GTAW and SAW Welding ProcessesAjaj AnsariNo ratings yet

- Nickel Alloys: Alloy 825 (UNS N08825)Document1 pageNickel Alloys: Alloy 825 (UNS N08825)joceth3632No ratings yet

- Selection of Materials For WeldingDocument1 pageSelection of Materials For WeldingmohammedetaNo ratings yet

- Pohon Industri Tembaga Dan BajaDocument3 pagesPohon Industri Tembaga Dan BajakevinNo ratings yet

- LT - Power - Cable Schedule For Garret Line (Danieli)Document3 pagesLT - Power - Cable Schedule For Garret Line (Danieli)zibraltan1No ratings yet

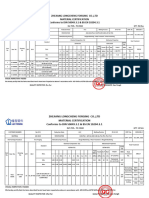

- Certificados - Mtc-Po 23040-Req 14989Document98 pagesCertificados - Mtc-Po 23040-Req 14989MissionPetroleum InfoNo ratings yet

- Ansi-Aws A5.23-A5.23mDocument44 pagesAnsi-Aws A5.23-A5.23mSugiharnoNo ratings yet

- 4weldingprocess 170312145054Document25 pages4weldingprocess 170312145054farooqueNo ratings yet

- Book of Welding 2007 PDFDocument80 pagesBook of Welding 2007 PDFravi00098100% (1)

- RM01 - Arc Weld ProcessesDocument53 pagesRM01 - Arc Weld ProcessesAnonymous cgcKzFtXNo ratings yet

- Applications and Benefits of Adaptive Pulsed GMAWDocument140 pagesApplications and Benefits of Adaptive Pulsed GMAWroostercockburnNo ratings yet

- Tig - Mig Welding ConsumablesDocument2 pagesTig - Mig Welding ConsumablesandyhaggerNo ratings yet

- Filler Metals For Anti-WearDocument1 pageFiller Metals For Anti-WearSlavisaGNo ratings yet

- A5 9 PDFDocument42 pagesA5 9 PDFCesar Fernando BenavidesNo ratings yet

- Ice 1.1 Steam Welding PrincipleDocument82 pagesIce 1.1 Steam Welding PrincipleThilagavathy SethuramahNo ratings yet

- CH 05Document41 pagesCH 05pravyramNo ratings yet

- Group 4 - Assignment 4 - MoonChemDocument5 pagesGroup 4 - Assignment 4 - MoonChemdipraj.dhuri22No ratings yet

- Toaz - Info Bata Project PRDocument46 pagesToaz - Info Bata Project PRPRITAM PATRANo ratings yet

- I. Purchasing Management IntroductionDocument5 pagesI. Purchasing Management IntroductionCLAUDIA RIVERA GARCIANo ratings yet

- Wa0001Document22 pagesWa0001Adarsh KashyapNo ratings yet

- Risk-Based Auditing 2015Document164 pagesRisk-Based Auditing 2015Vicente Enteng Jr.75% (4)

- FMEA Training TextDocument54 pagesFMEA Training TextCHULYUN JUNGNo ratings yet

- Pbbi Data Warehousing Keys To Success WP UsaDocument16 pagesPbbi Data Warehousing Keys To Success WP UsasubramanyamsNo ratings yet

- Third Party Procedure For Heat Exchanger TestingDocument10 pagesThird Party Procedure For Heat Exchanger TestingVarun MalhotraNo ratings yet

- Ravi Lead AuditorDocument11 pagesRavi Lead AuditorRonanki RaviNo ratings yet

- Objectives of Supply Chain ManagementDocument2 pagesObjectives of Supply Chain ManagementRavi KumarNo ratings yet

- Blast Furnace Processing and It's OperationsDocument20 pagesBlast Furnace Processing and It's OperationsRaghava Chari Koilkonda100% (1)

- AR DJP 2014-Eng - 2Document192 pagesAR DJP 2014-Eng - 2HenryNo ratings yet

- MTE Project of MPOB (MBA-101) : Comparative Analysis of H&M and ZARADocument15 pagesMTE Project of MPOB (MBA-101) : Comparative Analysis of H&M and ZARAamankumar 2k21dmba23No ratings yet

- Herbalife Products (M) SDN BHD - Writing Reports (DRAFT)Document14 pagesHerbalife Products (M) SDN BHD - Writing Reports (DRAFT)Nor Saadiah Mat DaliNo ratings yet

- Client Certification PackageDocument24 pagesClient Certification PackageWahyu RahmadNo ratings yet

- ECO111 Progress Test Fall2021Document4 pagesECO111 Progress Test Fall2021Ha raNo ratings yet

- Flotation FlowsheetsDocument6 pagesFlotation FlowsheetsRodrigo GarcíaNo ratings yet

- A Strategic Analysis Project of Target CorporationDocument8 pagesA Strategic Analysis Project of Target CorporationJam EsNo ratings yet

- VSynergize Outsourcing PVT LTD (Company Profile)Document21 pagesVSynergize Outsourcing PVT LTD (Company Profile)VSynergize Outsourcing0% (1)

- Managing Demand and Supply of ServicesDocument18 pagesManaging Demand and Supply of ServicesHimanshu KheraNo ratings yet

- Mekelle University College of Business and EconomicsDocument50 pagesMekelle University College of Business and Economicsayele eshete100% (1)

- Enovia Basic PDFDocument48 pagesEnovia Basic PDFkhiladi2No ratings yet

- " Work Experience in Ishan Equipments Pvt. LTD.": Internship Presentation OnDocument20 pages" Work Experience in Ishan Equipments Pvt. LTD.": Internship Presentation OnrajivNo ratings yet

- Sip ReportDocument33 pagesSip ReportSanskar saxena33% (3)

- Irjet V7i7824Document5 pagesIrjet V7i7824HRUSHIKESH MANENo ratings yet

- Albandia, Ken Joshua - Chapter 1Document4 pagesAlbandia, Ken Joshua - Chapter 1Mary Joy AlbandiaNo ratings yet

- Inspection Report Po 450557730Document1 pageInspection Report Po 450557730Saqib KhanNo ratings yet

- Week 6-11 Pre-Tut Quiz Ans.Document83 pagesWeek 6-11 Pre-Tut Quiz Ans.Samiha RashidNo ratings yet

- BBA - Sales-Management SlidesDocument87 pagesBBA - Sales-Management Slidesazeem rayaduramNo ratings yet