Professional Documents

Culture Documents

CN-DT-004 - ENG - Riprap vs. Mattresses - Rev. 0 PDF

CN-DT-004 - ENG - Riprap vs. Mattresses - Rev. 0 PDF

Uploaded by

szemianOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CN-DT-004 - ENG - Riprap vs. Mattresses - Rev. 0 PDF

CN-DT-004 - ENG - Riprap vs. Mattresses - Rev. 0 PDF

Uploaded by

szemianCopyright:

Available Formats

COMPARISON NOTE

Ref: INT / CN_DT_004 - Rev. 00, Nov 2018

GABIONS AND MATTRESS vs. RIPRAP

1- PREFACE

This Technical Note is aimed to compare RenoTM mattresses to loose stone rip rap revetments.

The study called “Hydraulic Tests to Develop Design Criteria for the Use of Reno Mattresses” is the

reference study for the application of Maccaferri Reno mattress/gabion in the river engineering. It gives

indeed the reference knowledge about the behavior of mattresses under hydraulic loads and gives

reference design criteria for mattresses and gabions as well. The tests have been conducted at the

Hydraulics Laboratory of the Engineering Research Center, Colorado State University in USA.

These tests, conducted in 1984, covered the following points:

• The distribution of speed and pressure in the current section and under the Reno mattresses.

• The determination of roughness coefficient.

• Analysis of the turbulence phenomena.

• Evaluation of the stability of revetments subjected to different flow conditions.

• Identification of incipient motion of mattresses as well as understand mattresses deformations when

subjected to very high flow currents.

• Development of design criteria suitable to mattress protection designs.

The structures tested are gabions and RenoTM mattresses manufactured by the Maccaferri factories in

accordance with the European standard EN 10223-3.

2 – CARRIED OUT TEST

The tests were performed on RenoTM mattresses having double diaphragms obtained by folding a

continuous hexagonal double twist wire mesh, whereas the tested gabions (50cm and 1m thick) had a

single diaphragm.

Gabions and Reno mattresses

The tests were conducted on a test bench to vary:

• The flow rate through the structures

• The angle of the longitudinal slope

Officine Maccaferri S.p.A. Global Headquarters

Via JF Kennedy 10, 40069 Zola Predosa (BO) - Italy

T: (+39) 051 6436000 F: (+39) 051 236507

www.maccaferri.com

For each test, the hydraulic speeds and stresses applied to structures were reported.

It was then possible to distinguish two states: Critical conditions for which there is a triggering in the motion

of the stones and a limit condition for which the movement of the stones inside the revetment is no longer

allowed and for which the revetment fulfills its protective role. This limit state occurs for speeds and flow

rates about 20% higher than those for the critical state.

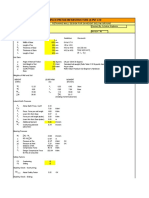

The diagram below defines the thickness Dz for which the limit state is reached.

3 – RESULTS

The results of these tests are presented in the two tables below which provide speeds and allowable

stresses depending on the thicknesses of the structures.

Stone filling Limit velocity

Type Thickness (m)

Dimension [mm] D50 (m) (m/s)

0.17 70 to 100 0.085 4.2

0.17 70 to 150 0.110 4.5

Reno 0.23 70 to 100 0.085 4.5

mattress 0.23 70 to 150 0.110 4.9

0.30 70 to 120 0.100 4.7

0.30 100 to 150 0.125 5.0

0.50 100 to 200 0.150 5.8

Gabions

0.50 120 to 250 0.190 6.4

Table 1 - Gabion and Reno mattress performances in terms of allowable velocities

Officine Maccaferri S.p.A. Global Headquarters

Via JF Kennedy 10, 40069 Zola Predosa (BO) - Italy

T: (+39) 051 6436000 F: (+39) 051 236507

www.maccaferri.com

Allowable shear stress

Type Thickness (m)

(N/m2)

0.17 224

Reno

0.23 268

mattress

0.30 336

Gabions 0.50 470

Table 2 - Gabion and Reno mattress performances in terms of allowable shear forces

4 – COMPARISON BETWEEN THE TWO SOLUTIONS IN TERMS OF REVETMENT THICKNESS

Tests have established a comparison chart of thicknesses depending on the velocity. The thickness of a

gabion revetment is 3 to 4 times lower than a loose stone rip rap revetment.

Comparative example for a flow rate of 5 m/s

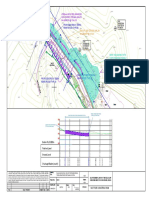

5 – HORIZONTAL EXTENSION AND DEPTH INCREASE AT TOE BASE

The stability at the toe can be guaranteed either by increasing the lining depth (Δy) or by extending it

horizontally (Δx), depending on scour depth (Δz). Standard design practice for rip-rip requires a minimum

thickness of 0.30 m and a thickness/d50 ratio equal to 1.5-2. In permanent underwater conditions the

thickness of loose revetment must be doubled. Unlike rip-rap linings, Reno mattress and gabion linings can

be very thin (0.17 m).

Toe protection for riprap (above) and mattresses (below)

Officine Maccaferri S.p.A. Global Headquarters

Via JF Kennedy 10, 40069 Zola Predosa (BO) - Italy

T: (+39) 051 6436000 F: (+39) 051 236507

www.maccaferri.com

6 – CARBON FOOTPRINT AND CARBON SEQUESTRATION

Double twist steel wire products have shown an extraordinary capability for regeneration of the natural

environment, since gabions and mattresses are filled with stones, soil and roots which eventually provide

favorable developmental conditions. At the same time vegetation uses these structures as shelter during

the initial growth phase, thus allowing these solutions to provide adequate structural and hydraulic

performances even when plants are not fully developed yet.

A recent study has demonstrated how the use of gabions and Reno mattresses is a solution which reduces

the impact on climate change, having a lower carbon footprint than the one of the equivalent traditional

engineering solutions in terms of CO2 emissions.

Another important aspect for gabion and mattress solutions is related to their capability to offer a good

substrate to the vegetation, eventually playing the role of carbon sinks: by capturing atmospheric CO2

through photosynthesis (biosequestration), plants store large amounts of organic C in above and

belowground biomass.

6.1 Evaluation of carbon footprint of DT products

A comparison (APMC, 2012) has been made between a bank lining with 0.3 m thick mattress filled in with

local river stones and a riprap lining 1 m thick: mattresses lead to savings in terms of emissions up to 80%

of the riprap emissions. Further details can be found in the TN-DT-018.

Emissions of CO2 for riprap and mattresses

6.2 Evaluation of the CO2 sequestered with wire mesh solutions

The research (Sauli, 2014) has evaluated the absorption of CO2 by the vegetation grown on soil-bio

engineering structures made with gabions and mattresses. The absorption rate values are similar to those

found in natural plant formation comparable to the average value of a high beech forest or a beech forest

coppice or to a high turkey oak forest. The positive results in terms of both a reduced carbon footprint and

of a high carbon sequestration are a clear evidence of the capability of wire mesh solutions to contribute to

the reduction of CO2 emissions. Further details can be found in the TN-DT-019.

BIBLIOGRAPHY

APMC, 2012. Carbon Footprint dei Gabbioni e Materassi Maccaferri e confronto con soluzioni tradizionali”

(Unpublished).

Sauli G., Pellizzari L. 2014. Assorbimento del carbonio da parte della vegetazione arboreo-arbustiva presente su

strutture in rete metallica (Unpublished)

Officine Maccaferri S.p.A. Global Headquarters

Via JF Kennedy 10, 40069 Zola Predosa (BO) - Italy

T: (+39) 051 6436000 F: (+39) 051 236507

www.maccaferri.com

COMPARATIVE TABLE

ITEM

RIP-RAP RENO MATTRESSES & GABIONS

Rock Dimensions Because of the low value of Shield’s coefficient, With the same hydraulic conditions, the

the stone to be used is very large even at small average dimension of the rocks to be used

values of Hydraulic forces. in the Reno mattress or in the Gabions is

half that of rip rap lining.

Thickness of For works under water, the thickness must be There is no need to increase the depth or

revetment increased by 50% causing considerable increase to reduce the slope of the banks

in the material at the toe and careful design and (permissible slope is 1:1.5, nor it is

execution. The slope should not be steeper than necessary to increase the revetment

1:2 which leads to more space consumption. thickness at the toe)

Thickness of For Scouring depth of “d”, horizontal extension For Scouring depth of “d” horizontal

lining based on will be ‘2d’ to ‘3d’ and increase in depth will be extension will be ‘1.5d’ to ‘2d’ and increase

stability at the (d+2t) in rip rap; where t is thickness of rip rap. in depth will be ‘d’ in case of Reno

base of the toe mattresses.

International The international regulations governing the The Reno mattresses lining can be as thin

regulations on design of rip rap provide for a minimum depth as 0.17m.

thickness of of 0.3m and the relationship between this

lining and size of depth and the average dimension of the rocks is

stones 1.5 to 2.

Behavior of The condition for initial movement for rip rap is After the “initial movement” the

lining against a limit condition. A small force beyond this may containment offered by the mesh

forces higher cause the destruction of lining progressively. continues. The mesh may deform slightly,

than the design but it will allow more severe conditions

forces without compromising the resistance.

Effect on The large stones will reduce the channel The possibility to use smaller stones will

capacity of capacity. Also the increase in roughness will enhance higher discharge capacity of the

channel reduce the efficiency to carry high discharges. channel.

Differential Rip rap system do not tolerate any deferential Due their flexibility, Gabions and

settlement settlement. Mattresses tolerate differential settlement

without undergoing a failure.

Economy This system tends to be expensive as it requires Cost effective in most of the cases as it can

the need of very heavy stones which will be be filled with locally available good stones

seldom available in most of the sites. with moderate sizes.

Solid transport Practically not affected by solid transport Large sized solid materials carried by the

stream may eventually abrade the wire

mesh

Carbon footprint Characterized by high emission CO2 emissions Leads to savings in terms of emissions up

and to 80% of riprap emissions and allow for

sequestration the vegetation growth (biosequestration)

Officine Maccaferri S.p.A. Global Headquarters

Via JF Kennedy 10, 40069 Zola Predosa (BO) - Italy

T: (+39) 051 6436000 F: (+39) 051 236507

www.maccaferri.com

You might also like

- Science Grade 4: Learning Activity Sheet Lesson 3: Materials That Undergo Decay Activity 1: "Document10 pagesScience Grade 4: Learning Activity Sheet Lesson 3: Materials That Undergo Decay Activity 1: "Lhenzky Palma BernarteNo ratings yet

- Problems PDFDocument9 pagesProblems PDFEduarGelvezNo ratings yet

- M&D Foundations & Building Services Limited: SHOREHAM - 79-81 Brighton Road, BN43 6RHDocument10 pagesM&D Foundations & Building Services Limited: SHOREHAM - 79-81 Brighton Road, BN43 6RHNitaiGauranga108No ratings yet

- Sans 10049:2019: Food Safety Management - Requirements For Prerequisite Programmes (PRPS)Document5 pagesSans 10049:2019: Food Safety Management - Requirements For Prerequisite Programmes (PRPS)Mark D Villanueva100% (1)

- Panyam Cements and Mineral Industries (Mining) - Combined CFO & HWA - VerDocument7 pagesPanyam Cements and Mineral Industries (Mining) - Combined CFO & HWA - Verapi-3809359100% (1)

- 1997 Ortigao & Palmeira Optimised Design For Soil Nailed Walls London PDFDocument6 pages1997 Ortigao & Palmeira Optimised Design For Soil Nailed Walls London PDFCescyle CostaNo ratings yet

- Masada PGS 2015Document38 pagesMasada PGS 2015Nayara BelfortNo ratings yet

- C. Milewskietal.2020Shearingresistanceofroughpolymer-sandinterfacesDocument11 pagesC. Milewskietal.2020Shearingresistanceofroughpolymer-sandinterfacesJaime SeguraNo ratings yet

- Shwan Unsat18 118Document7 pagesShwan Unsat18 118Amir BakhtiarNo ratings yet

- Evaluation of Undrained Shear Strength of Soft Soils Using CPT and VSTDocument4 pagesEvaluation of Undrained Shear Strength of Soft Soils Using CPT and VSTFrancolt41No ratings yet

- Flexural Behaviour of Precast Slab Made of Ops Lightweight ConcreteDocument8 pagesFlexural Behaviour of Precast Slab Made of Ops Lightweight ConcreteArtemis EnteriNo ratings yet

- Assessing Quarry Dust As A Possible Replacement of River Sand in Hollow BlocksDocument3 pagesAssessing Quarry Dust As A Possible Replacement of River Sand in Hollow BlocksNuruddeen MuhammadNo ratings yet

- Experimental Study of Crushed Palmyra PaDocument4 pagesExperimental Study of Crushed Palmyra PaJohn Tomas AtalNo ratings yet

- Comparison of Subgrade Reaction and FEM For D Wall DesignDocument7 pagesComparison of Subgrade Reaction and FEM For D Wall DesignCEG BangladeshNo ratings yet

- Paperpdf 1367 Mir PDFDocument8 pagesPaperpdf 1367 Mir PDFJose Ismael Fernandez SilvaNo ratings yet

- Basic SpecificationDocument5 pagesBasic SpecificationArunpandiyanNo ratings yet

- Soil Descriptions - Figure 1 and 2 Revised ISSMFE - Rev. Oct, 2012Document2 pagesSoil Descriptions - Figure 1 and 2 Revised ISSMFE - Rev. Oct, 2012Terobau111No ratings yet

- L01 - TDS - ID - Matren Plus ZN+Polymer - Rev02 - 2021Document2 pagesL01 - TDS - ID - Matren Plus ZN+Polymer - Rev02 - 2021Wika SentiongNo ratings yet

- Draft Ethiopian Standard Fdes 4050 DES 6613-3: Lightweight Aggregates For Masonry Nits and Structural ConcreteDocument11 pagesDraft Ethiopian Standard Fdes 4050 DES 6613-3: Lightweight Aggregates For Masonry Nits and Structural ConcretebiniNo ratings yet

- Soil Report 4Document5 pagesSoil Report 4rekzziNo ratings yet

- Designing Stone Columns To Control Horizontal and Vertical PDFDocument6 pagesDesigning Stone Columns To Control Horizontal and Vertical PDFZOUABINo ratings yet

- Use of Nanoparticles For Enhancing The Interlaminar Properties of Fiber-Reinforced Composites and Adhesively Bonded Joints-A ReviewDocument29 pagesUse of Nanoparticles For Enhancing The Interlaminar Properties of Fiber-Reinforced Composites and Adhesively Bonded Joints-A Reviewmkumar_234155No ratings yet

- The Reinforced Concrete Beam Deflection and Cracking Behavior With Additional Fiber SteelDocument5 pagesThe Reinforced Concrete Beam Deflection and Cracking Behavior With Additional Fiber SteelNamaku AndaNo ratings yet

- Spe 151770 MS PDocument20 pagesSpe 151770 MS PjbetancourtNo ratings yet

- Irene UbaywwDocument11 pagesIrene Ubaywwskdelacruz.djdengrNo ratings yet

- GEO11 Paper 185Document6 pagesGEO11 Paper 185Safak BooksNo ratings yet

- Filter Media Characteristics2Document5 pagesFilter Media Characteristics2EduarGelvezNo ratings yet

- S BmittedDocument13 pagesS Bmittedhayel elnaggarNo ratings yet

- Finite Element Analyses of Granular Pile Anchors As A Foundation Option For Reactive SoilsDocument6 pagesFinite Element Analyses of Granular Pile Anchors As A Foundation Option For Reactive SoilshamefNo ratings yet

- Analysis and Design Study of Concrete Paver Blocks With Feedback LoopDocument7 pagesAnalysis and Design Study of Concrete Paver Blocks With Feedback LoopMaestro ConstructionNo ratings yet

- Ert 03 02Document14 pagesErt 03 02S A KaleNo ratings yet

- MM 551 Instruction Sheets FinalDocument9 pagesMM 551 Instruction Sheets FinalNaval vermaNo ratings yet

- Simplex Prefab Infrastructure (I) PVT LTD: Project Name: Retaining Wall Design For 2M Height Below GroundDocument2 pagesSimplex Prefab Infrastructure (I) PVT LTD: Project Name: Retaining Wall Design For 2M Height Below GroundAnonymous cG5MyHMNo ratings yet

- Exhibit 4Document1 pageExhibit 4Arjun Chitradurga RamachandraRaoNo ratings yet

- 1986, K. Fabian; Performance of Geotextile-reinforced Clay Samples in Undrained Triaxial Tests.Document11 pages1986, K. Fabian; Performance of Geotextile-reinforced Clay Samples in Undrained Triaxial Tests.kommanamanchi.vamsiNo ratings yet

- A - Substructure 1. Excavation & EarthworksDocument4 pagesA - Substructure 1. Excavation & Earthworkstofikkemal100% (1)

- BEFIB EduardoEtAl 2004 PDFDocument10 pagesBEFIB EduardoEtAl 2004 PDFsandyNo ratings yet

- Bamboo As Structural Reinforcement Final 22222Document32 pagesBamboo As Structural Reinforcement Final 22222Saurav ChoudhuryNo ratings yet

- Soil Mechanics and Foundation Design TheoryDocument172 pagesSoil Mechanics and Foundation Design Theorykingraja93No ratings yet

- Plate Load Test - Chapter 16 - The Use of Alternative and Improved Construction Materials and Geosynthetics For PavementsDocument22 pagesPlate Load Test - Chapter 16 - The Use of Alternative and Improved Construction Materials and Geosynthetics For PavementsCharles MakozaNo ratings yet

- Pile Foundation Spacing and Skin Fraction in Pile GroupDocument4 pagesPile Foundation Spacing and Skin Fraction in Pile GroupJustin MusopoleNo ratings yet

- TDS MATREN PLUS POLIMAC - Rev. 00 - 31072020 PDFDocument1 pageTDS MATREN PLUS POLIMAC - Rev. 00 - 31072020 PDFSuntharathevan RamasamyNo ratings yet

- Back AnalysisDocument7 pagesBack AnalysisBiren ShethNo ratings yet

- Contoh RAP - Ida Made Dwi PayanaDocument2 pagesContoh RAP - Ida Made Dwi PayanajanfridayNo ratings yet

- Effect of Ceria Particle-Size Distribution and Pressure Interactions in Chemo-Mechanical Polishing (CMP) of Dielectric MaterialsDocument8 pagesEffect of Ceria Particle-Size Distribution and Pressure Interactions in Chemo-Mechanical Polishing (CMP) of Dielectric MaterialsAverage JoeNo ratings yet

- Plastering PDFDocument6 pagesPlastering PDFTheOne YasirNo ratings yet

- An Experimental Investigation On Steel Fiber Reinforced Concrete With Quarry Dust As A Partial Replacement of Fine AggregateDocument5 pagesAn Experimental Investigation On Steel Fiber Reinforced Concrete With Quarry Dust As A Partial Replacement of Fine AggregateIJRASETPublicationsNo ratings yet

- Effect of Finenesses of Fly Ash On Expansion of Mortars in Magnesium SulfateDocument7 pagesEffect of Finenesses of Fly Ash On Expansion of Mortars in Magnesium SulfaterazNo ratings yet

- AAC LeichtBric 2020Document10 pagesAAC LeichtBric 2020Jared Josef GomezNo ratings yet

- Design Note of Lvup CH-115+837Document61 pagesDesign Note of Lvup CH-115+837vishal bhardwaj100% (1)

- Data Collection and AnalysisDocument10 pagesData Collection and AnalysisChris ArtecoNo ratings yet

- Box Culvert Estimate 3/53/0Document69 pagesBox Culvert Estimate 3/53/0veevimalNo ratings yet

- IADC SPE 128728 Wellbore Stability in FRDocument8 pagesIADC SPE 128728 Wellbore Stability in FRDanubio Dallamna Sordo AguilarNo ratings yet

- SS PolandDocument11 pagesSS Polandseret GideyNo ratings yet

- Memo 3. Confirmatory Geotechnical Tests For Treatment Plant Site, Dawa Water Supply ProjectDocument3 pagesMemo 3. Confirmatory Geotechnical Tests For Treatment Plant Site, Dawa Water Supply ProjectEphrem GalNo ratings yet

- A Study On Bearing Capacity of Skirted Square Footings On Different SandsDocument17 pagesA Study On Bearing Capacity of Skirted Square Footings On Different Sandsveenau 1100% (1)

- Some Pipe Bedding SpecificationsDocument3 pagesSome Pipe Bedding SpecificationsTarek KhallafNo ratings yet

- ProgresDocument3 pagesProgresindra allureNo ratings yet

- Numerical Investigation On The Performance of Stone Columns Under Raft Foundation in Soft Clayey SoilsDocument9 pagesNumerical Investigation On The Performance of Stone Columns Under Raft Foundation in Soft Clayey Soilstekla gom-lua groupNo ratings yet

- Internal Curing Improves Concrete Perfor PDFDocument16 pagesInternal Curing Improves Concrete Perfor PDFgonzalez_m_aNo ratings yet

- Internal Curing Improves Concrete Perfor PDFDocument16 pagesInternal Curing Improves Concrete Perfor PDFgonzalez_m_aNo ratings yet

- 41 - 43 Double TeeDocument3 pages41 - 43 Double TeeRavinesh SinghNo ratings yet

- TDS Jumbo Gabion P8+2.2 PVC - PubDocument2 pagesTDS Jumbo Gabion P8+2.2 PVC - PubszemianNo ratings yet

- Tender Specification HEA Panels 300 X 300 10 ZnAL10Document1 pageTender Specification HEA Panels 300 X 300 10 ZnAL10szemianNo ratings yet

- CN-DT-009 - ENG - Green Terramesh vs. Concrete Panel MSEW - Rev. 0 PDFDocument2 pagesCN-DT-009 - ENG - Green Terramesh vs. Concrete Panel MSEW - Rev. 0 PDFszemianNo ratings yet

- Mactube DesignDocument2 pagesMactube DesignszemianNo ratings yet

- CEPC - YPPH - POND - 002 - R0 Cooling & Buffer Pond Cross Section - R2Document1 pageCEPC - YPPH - POND - 002 - R0 Cooling & Buffer Pond Cross Section - R2szemianNo ratings yet

- CN-DT-007 - ENG - Stone Pitching vs. Mattresses - Rev. 0 PDFDocument2 pagesCN-DT-007 - ENG - Stone Pitching vs. Mattresses - Rev. 0 PDFszemianNo ratings yet

- DOP HEA DK PANEL GL10 300 10mmDocument1 pageDOP HEA DK PANEL GL10 300 10mmszemianNo ratings yet

- CN-DT-006 - ENG - Geocells vs. Mattresses - Rev. 0Document1 pageCN-DT-006 - ENG - Geocells vs. Mattresses - Rev. 0szemianNo ratings yet

- 1-Wave Ht-Part of Hydraulic Study ReportDocument10 pages1-Wave Ht-Part of Hydraulic Study ReportszemianNo ratings yet

- Mactube CalculationDocument6 pagesMactube CalculationszemianNo ratings yet

- Sustainability 2022 - Master PDFDocument49 pagesSustainability 2022 - Master PDFszemianNo ratings yet

- CN-DT-003 - ENG - RC Walls vs. Terramesh System - Rev. 0 PDFDocument2 pagesCN-DT-003 - ENG - RC Walls vs. Terramesh System - Rev. 0 PDFszemianNo ratings yet

- Mac Brochure-OM GeosyntheticsDocument12 pagesMac Brochure-OM GeosyntheticsszemianNo ratings yet

- Environmental Aspects of Double Twist Solutions PDFDocument86 pagesEnvironmental Aspects of Double Twist Solutions PDFszemianNo ratings yet

- CN-DT-002 - ENG - Concrete Lining Vs Mattresses - Rev. 0 PDFDocument2 pagesCN-DT-002 - ENG - Concrete Lining Vs Mattresses - Rev. 0 PDFszemianNo ratings yet

- Mac Brochure-OM MacGuide - CompressedDocument14 pagesMac Brochure-OM MacGuide - CompressedszemianNo ratings yet

- CN-DT-005 - ENG - ACBM vs. Mattresses - Rev. 0 PDFDocument2 pagesCN-DT-005 - ENG - ACBM vs. Mattresses - Rev. 0 PDFszemianNo ratings yet

- Mac Brochure-Soil - Stabilisation - and - PavementsDocument16 pagesMac Brochure-Soil - Stabilisation - and - PavementsszemianNo ratings yet

- TN-DT-019 - ENG - Carbon Footprint of DT Products - Rev. 4 PDFDocument11 pagesTN-DT-019 - ENG - Carbon Footprint of DT Products - Rev. 4 PDFszemianNo ratings yet

- Design AnalysesDocument6 pagesDesign AnalysesszemianNo ratings yet

- Analysis Report - Soil Nail SGHR100 MacMatDocument2 pagesAnalysis Report - Soil Nail SGHR100 MacMatszemianNo ratings yet

- Mac Brochure-OM Rockfall Prot and Snow BarriersDocument16 pagesMac Brochure-OM Rockfall Prot and Snow BarriersszemianNo ratings yet

- Kundasang DWG Design FinalDocument14 pagesKundasang DWG Design FinalszemianNo ratings yet

- TDS ERDOX TERRA - Rev.01 - 20210312 - EngDocument2 pagesTDS ERDOX TERRA - Rev.01 - 20210312 - EngszemianNo ratings yet

- TDS FLEXIBLE ANCHOR SYSTEM T-FAST - Rev00 - 20210211Document1 pageTDS FLEXIBLE ANCHOR SYSTEM T-FAST - Rev00 - 20210211szemianNo ratings yet

- Water Quality ModelDocument4 pagesWater Quality ModelĐịa TiênNo ratings yet

- 800 MMDocument1 page800 MMPRAMODH CHELLURUNo ratings yet

- 4.1.4 PollenAnalysisDocument11 pages4.1.4 PollenAnalysisAhmed Al-fitouriNo ratings yet

- Steps To Process Palm Efb PelletDocument9 pagesSteps To Process Palm Efb PelletBahtiar YoganaNo ratings yet

- History of Environment Protection in IndiaDocument5 pagesHistory of Environment Protection in IndiaSadhika SharmaNo ratings yet

- Sustainable SourcingDocument30 pagesSustainable SourcingNguyen Thi Thoai AnhNo ratings yet

- Chapter Two: The Geology of Ethiopia and The HornDocument63 pagesChapter Two: The Geology of Ethiopia and The HornAbineh TilahunNo ratings yet

- Roads Works PricedDocument5 pagesRoads Works PricedMwesigwa DaniNo ratings yet

- DIDI PDS 7 Client Briefs 2022-23Document20 pagesDIDI PDS 7 Client Briefs 2022-23jasmineNo ratings yet

- 8 Quiz WorksheetDocument7 pages8 Quiz WorksheetOğuzhan OlgunNo ratings yet

- Case Studies For Large Span Roofing StructureDocument1 pageCase Studies For Large Span Roofing StructureASHWIN BNo ratings yet

- Chapter 4 ForestsDocument12 pagesChapter 4 ForestsYousuf hafeezNo ratings yet

- Reducing The Effects of Climate Change Using Building-Integrated and Building-Applied Photovoltaics in The Power Supply Ali SayighDocument70 pagesReducing The Effects of Climate Change Using Building-Integrated and Building-Applied Photovoltaics in The Power Supply Ali Sayighgerald.moore649100% (8)

- MSC Thesis - Final CopyDocument188 pagesMSC Thesis - Final CopyJohn TauloNo ratings yet

- Gemini Corporation N.V., Antwerp, BelgiumDocument24 pagesGemini Corporation N.V., Antwerp, BelgiumD AstableNo ratings yet

- Greenwoods Cendana - Sales KitsDocument24 pagesGreenwoods Cendana - Sales KitsAmBeeNo ratings yet

- Drainage LinesDocument27 pagesDrainage LinesFritzie Sheena ZipaganNo ratings yet

- Group 06 Assignment 2Document28 pagesGroup 06 Assignment 2Amna ArifNo ratings yet

- Exploring San Jose Farm TourismDocument16 pagesExploring San Jose Farm TourismNolly Franco HaliliNo ratings yet

- Architectural Design - 6: Hyderabad Case StudyDocument20 pagesArchitectural Design - 6: Hyderabad Case StudyHannah Mrudulyn50% (2)

- Katakamuna: The World You See Is Just The Tip of The IcebergDocument8 pagesKatakamuna: The World You See Is Just The Tip of The IcebergThomas100% (1)

- Lesson and Learning Task Mod 10Document2 pagesLesson and Learning Task Mod 10Dylan AngelesNo ratings yet

- Smart Bulb PDFDocument16 pagesSmart Bulb PDFriya jariwalaNo ratings yet

- Low Density Polyethylene (Ldpe) Pada Suhu 250 °C Dan 300 °C Soelarso Pani, Heribertus Sukarja, Yustinus Sigit PDocument7 pagesLow Density Polyethylene (Ldpe) Pada Suhu 250 °C Dan 300 °C Soelarso Pani, Heribertus Sukarja, Yustinus Sigit PAndi DulungNo ratings yet

- Master Check List - DesignDocument2 pagesMaster Check List - DesignKhewin tonleeNo ratings yet

- Environmental Sustainability Action PlanDocument15 pagesEnvironmental Sustainability Action PlanIvana NikolicNo ratings yet

- Earthfill Dam Breach AnalysisDocument1 pageEarthfill Dam Breach AnalysisjnfNo ratings yet