Professional Documents

Culture Documents

US6581308

US6581308

Uploaded by

PUVAN TST0 ratings0% found this document useful (0 votes)

15 views5 pagesThe patent describes a high capacity bucket arrangement for work machines. The bucket has a moldboard attached between opposite side plates, and a base plate attached to the top of the moldboard. The leading portion of the base plate is curved outwardly relative to the bottom of the moldboard, which allows for greater bucket capacity and breakout force compared to conventional straight base plates.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe patent describes a high capacity bucket arrangement for work machines. The bucket has a moldboard attached between opposite side plates, and a base plate attached to the top of the moldboard. The leading portion of the base plate is curved outwardly relative to the bottom of the moldboard, which allows for greater bucket capacity and breakout force compared to conventional straight base plates.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

15 views5 pagesUS6581308

US6581308

Uploaded by

PUVAN TSTThe patent describes a high capacity bucket arrangement for work machines. The bucket has a moldboard attached between opposite side plates, and a base plate attached to the top of the moldboard. The leading portion of the base plate is curved outwardly relative to the bottom of the moldboard, which allows for greater bucket capacity and breakout force compared to conventional straight base plates.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

USOO6581308B1

(12) United States Patent (10) Patent No.: US 6,581,308 B1

Woerman et al. (45) Date of Patent: Jun. 24, 2003

(54) HIGH CAPACITY BUCKET ARRANGEMENT 2,063,698. A 12/1936 Roe

2,336,729 A 12/1943 Harris et al. ................ 228/182

(75) Inventors: Gary R. Woerman, Wamego, KS (US); 3,860,131 A * 1/1975 Borowski et al. ............. 37/444

Philip M. Ciofi, Canadaigua, NY (US) 4,077,140 A 3/1978 Branconi

4,108,561 A 8/1978 Kelley et al.

(73) Assignee: Caterpillar Inc., Peoria, IL (US) 4,304,058 A

4,858,346 A * 12/1981 Schwappach ................ 37/444

8/1989 Schulte

(*) Notice: Subject to any disclaimer, the term of this to: A RS SE,

patent is extended or adjusted under 35 5,172.498 A 12/1992 Wack

U.S.C. 154(b) by 358 days. 5.992,062. A 11/1999 Evans et al.

6,108,951 A * 8/2000 Renfrow et al. .............. 37/403

(21) Appl. No.: 09/905,705 * cited by examiner

(22) Filed: Jul. 25, 2000

Primary Examiner Robert E. Pezzuto

Related U.S. Application Data (74) Attorney, Agent, or Firm-James R Smith

(60) givisional application No. 60/220,801, filed on Jul. 25, (57) ABSTRACT

51) Int. Cl." ................................................... E02F 3/40 A high

9. capacitv

pacily bucket arrangement

9. for a work machine

(52) U.S. Cl. ......................................................... 37/444 having a pair of opposite side plates and a moldboard

(58) Field of Search ................................. 172/272,273; extending between, and attached to, the side plates. The

37/403, 404, 405, 444, 466, 468; 414/697, trailing portion of a base plate is attached to the top portion

724, 723 of the moldboard, while the leading portion of the base plate

is outwardly curved, relative to the bottom portion of the

(56) References Cited moldboard, which allows for a greater bucket capacity as

U.S. PATENT DOCUMENTS

well as the generated bucket breakout force.

829,829 A 8/1906 D'Artenay 13 Claims, 1 Drawing Sheet

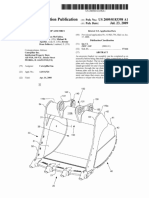

U.S. Patent Jun. 24, 2003 US 6,581,308 B1

US 6,581,308 B1

1 2

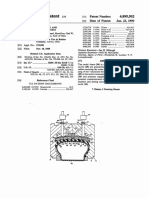

HIGH CAPACITY BUCKET ARRANGEMENT ally shown at 20 for an excavating machine (not shown),

Such as a hydraulic excavator, loader, backhoe or the like.

This application claims the benefit of U.S. Provisional The bucket arrangement 20 includes a moldboard 21

Application No. 60/220,801 filed Jul. 25, 2000. having a bottom portion 24 and top portion 25. The mold

board 21 is attached to and extends between a pair of

TECHNICAL FIELD opposite side plates 28.29. The bucket arrangement 20 also

includes a base plate 32, preferably made of a rigid material,

The present invention relates generally to a high capacity having a leading portion 33 and a trailing portion 36. AS

bucket arrangement. More particularly, this invention con shown in FIG. 2, the base plate 32 has a length sufficient to

cerns a high capacity bucket for work machines and the like Substantially span the distance between the opposite side

in which the base plate is provided with at least one plates 28.29. In addition, the trailing portion 36 is attached,

curvilinear portion. preferably by welding, to the top portion 25 of moldboard

21. The side plates 28.29, moldboard 21 and base plate 32

BACKGROUND ART define, when arranged in the aforementioned manner, a

Typically, buckets for work machines Such as hydraulic 15 bucket 37 having an opening 40. Also shown are outer and

middle torque tubes 41,44 attached, preferably by welding,

excavators, loaders, backhoes and the like typically utilize to the top surface 45 of the base plate 32.

base plates to form, in part, a coupling juncture between the Also shown are a pair of hinge plates 48 attached,

bucket and the hinge plates and also to form the upper preferably by welding, with the base plate 32. Each hinge

leading portion of the bucket. The remaining upper portion plate 48 is adapted to receive a Stick pin 49, having a Stick

of the bucket is typically attached to the trailing edge of the pin center 50, and a link pin 52, both of a well-known type,

base plate the shape and orientation of which defines the which are used to couple the bucket arrangement 20 to, for

shape and orientation of the remaining upper and rear example, an excavator Stick (not shown). According to an

portions of the bucket. The bucket shape constrains the base embodiment of this invention, the leading portion 33 of base

plate configurations and directly affects operating param

eterS Such as bucket payload capacity. Other parameters 25 plate 32 is outwardly curved, relative to the bottom portion

which may be constrained by the base plate shape also 24 of the moldboard 21, and has a preferred predetermined

include the ability to retain material in the bucket, the radius of curvature (designated herein as R) Such that the

amount of breakout force generated, and the height of the radius of curvature R defines a Substantially concentric inner

torque tube in relation to the bucket which may hamper circle 53 (shown in phantom detail) which is substantially

coupling of the hinge plates to the excavator Stick. tangent to both the stick pin 49 and link pin 52.

Prior base plates typically comprise a planar Straight The bottom portion 24 of the moldboard 21 may also

Structure which, when the bucket is coupled to the Stick, is include a Substantially planar Straight, in transverse croSS

oriented at an angle greater than horizontal. Orienting the Section, forward bottom portion 54 and a Substantially

entire base plate at the aforementioned angle limits the size upwardly curving bottom portion 57. As used herein,

and shape of the remaining upper rear portion of the bucket. 35 “upwardly curving defines the shape of the moldboard 21

This results in the payload capacity being limited to the base substantially between the forward bottom portion 54 and the

plate-defined bucket shape. The present invention is directed moldboard rear portion 58, relative to the ground (not

to overcome one or more of the problems as Set forth above. shown), when the forward bottom portion 54 is substantially

adjacent to and parallel with the ground. Also shown is a

DISCLOSURE OF THE INVENTION 40 cutting edge 61 which may be attached, in well-known

ways, to the forward bottom portion 54. A plurality of teeth

In accordance with one aspect of the present invention, a 62, each having a tip 63, may be attached with the cutting

bucket arrangement for a work machine is provided. The edge 61. AS should be appreciated by those skilled in Such

bucket arrangement includes a pair of opposite side plates, art, providing the moldboard 21 with the aforementioned

a moldboard, and a base plate. The moldboard extends 45 contour reduces contact between the bottom portion 24 and

between the Side plates and has a bottom portion and a top the ground which may result in reduced wear and longer

portion. The base plate has a leading portion and a trailing Service life of the moldboard 21. In accordance with an

portion with the trailing portion attached with the top portion embodiment of the present invention, and as shown in FIG.

of the moldboard. The leading portion is constructed to be 1, to provide the bucket 37 with increased capacity, it is

curved, relative to the bottom portion of said moldboard, 50 preferred that the trailing portion 36 of the base plate 32 be

with a predetermined radius of curvature. substantially parallel with the forward bottom portion 54.

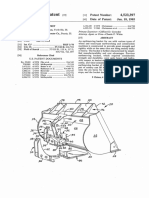

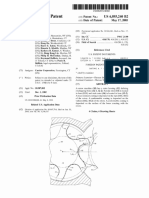

FIG. 3 shows an alternate embodiment of the bucket

BRIEF DESCRIPTION OF THE DRAWINGS

arrangement of the present invention base designated herein

FIG. 1 is a diagrammatic Side elevation view of an by reference numeral 65. Shown is a base plate 66 having the

embodiment of the bucket arrangement of the present inven 55 aforementioned radius of curvature R provided on the lead

tion. ing portion 69. The trailing portion 70 of the base plate 66

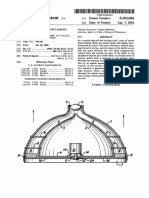

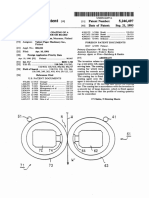

FIG. 2 is a diagrammatic top view of the bucket arrange is formed to be angled outward, relative to the bottom

ment embodiment shown in FIG. 1. portion 24, at a predetermined angle 0 from the horizontal

FIG. 3 is a diagrammatic side elevation view of another when the base plate 66 is attached to the moldboard 21 in the

embodiment of the bucket arrangement of the present inven

60 above-described manner. It is preferred that this angle 0 be

tion. greater than Zero (0) degrees from horizontal. As should also

be appreciated by those skilled in Such art, by providing the

BEST MODE FOR CARRYING OUT THE base plate 66 with an angled trailing portion 70, the top

INVENTION portion 25 of the moldboard 21 may be provided with a

65 Substantially upwardly bulging top portion 73, relative to the

Referring to FIGS. 1 and 2, a bucket arrangement bottom portion 24, thereby effectively increasing the pay

embodying the principles of the present invention is gener load capacity of the bucket 37.

US 6,581,308 B1

3 4

INDUSTRIAL APPLICABILITY 5. The bucket arrangement of claim 4 wherein Said angle

With reference to the drawings, and in operation, the base is greater than Zero degrees from horizontal.

plate 32,66 couples a bucket 37 (defined by a moldboard 21, 6. The bucket arrangement of claim 1 wherein:

having a substantially straight forward bottom portion 54, said bottom portion of said moldboard includes a Sub

and side plates 28.29) to the hinge plates 48. Providing the Stantially Straight forward bottom portion; and

base plate 32 with a trailing portion 36 which is substantially Said trailing portion of Said base plate is Substantially

parallel with the forward bottom portion 54 allows for a parallel with said forward bottom portion.

moldboard 21 having a deeper and higher (relative to the

ground) moldboard top portion 25. By increasing bucket portion ofbucket

7. The

said

arrangement of claim 1 wherein said bottom

moldboard includes:

Volume in this manner, the bottom portion 24 of the mold- 10 a Substantially Straight forward bottom portion; and

board 21 may be provided with an upwardly curving bottom

portion 57, thereby effectively increasing the useful life of a Substantially upwardly curving bottom portion, relative

the bucket 37 by minimizing the amount of abrasive contact to the ground, when said forward bottom portion is

between the moldboard 21 and the ground. Substantially adjacent to and parallel with the ground.

Furthermore, providing the base plate 32,66 with a lead 15 8. The bucket arrangement of claim 1 wherein said top

ing portion 33,69 that is outwardly curved, relative to the portion of Said moldboard includes a Substantially upwardly

bottom portion 24 of the moldboard 21, allows for nesting bulging top portion, relative to Said bottom portion.

of the stick pin 49 closer to the bucket opening 40. This, in 9. Abucket arrangement for a work machine, comprising:

turn, may assist in maintaining material within the bucket 37 a pair of opposite Side plates,

and increasing the generated bucket breakout force by a moldboard extending between and attached to Said Side

effectively decreasing the tip radius (defined herein as the plates, Said moldboard having a bottom portion and a

distance between the stick pin center 50 and tips 63). top portion;

Additional useful advantages would include increased bend a base plate having a leading portion and a trailing

ing Strength of the base plate 32,66 allowing for Smaller

torque tubes 41,44 and lower nesting of the middle torque portion, Said trailing portion attached with Said top

tube 44 allowing for easier stick and link pins 49.52 cou 25 portion of Said moldboard and Said leading portion

pling to, for example, an excavator Stick (not shown). To being outwardly curved, relative to Said bottom portion

further increase the payload capacity of the bucket 37, the of Said moldboard, and having a predetermined radius

base plate 32,66 may be provided with a trailing portion 70 of curvature; and

that is angled outward, relative to the bottom portion 24 of a pair of hinge plates attached with Said base plate, Said

the moldboard 21, at an angle greater than Zero (0) degrees. hinge plate adapted to receive a Stick pin and a link pin;

Such an orientation of the trailing portion 70 may allow for said bottom portion of said moldboard includes a Sub

a substantially upwardly bulging top portion 73 of mold Stantially Straight forward bottom portion;

board 21 providing for an even greater bucket payload said trailing portion of Said base plate is Substantially

capacity.

AS should be appreciated by those skilled in Such art, an 35 10.parallel with said forward bottom portion.

The bucket of claim 9 wherein said radius of curvature

advantage of increasing the bucket payload capacity is that

the time required for the work machine to move a Set amount of Said base plate defines a Substantially concentric inner

circle Substantially tangent to both Said Stick pin and Said

of material is decreased resulting in Savings both in time and link pin.

cost to complete a task. Other aspects, objects and advan

tages of this invention can be obtained from a study of the 40 ing:11. A bucket arrangement for a work machine, compris

drawings, the disclosure and the appended claims.

What is claimed is: a pair of opposite Side plates,

1. Abucket arrangement for a work machine, comprising: a moldboard extending between Said Side plates, Said

a pair of opposite side plates, moldboard having a bottom portion and a top portion;

a moldboard extending between and attached to Said Side 45 a base plate having a leading portion and a trailing

plates, Said moldboard having a bottom portion and a portion, Said trailing portion attached with Said top

top portion; portion of Said moldboard and Said leading portion

a base plate having a leading portion and a trailing being outwardly curved, relative to Said bottom portion

portion, Said trailing portion attached with Said top of Said moldboard, and having a predetermined radius

portion of Said moldboard and Said leading portion 50 of curvature; and

being outwardly curved, relative to Said bottom portion a pair of hinge plates attached with Said base plate, Said

of Said moldboard, and having a predetermined radius hinge plate adapted to receive a Stick pin and a link pin;

of curvature; and Said trailing portion of Said base plate is angled outward,

Said bucket arrangement including a mouth, and Said relative to Said bottom portion, at a predetermined

leading portion is Structured and arranged for place 55 angle from horizontal.

ment between Said mouth and Said trailing portion. 12. The bucket of claim 11 wherein said radius of curva

2. The bucket arrangement of claim 1 further comprising ture of Said base plate defines a Substantially concentric

at least one hinge plate attached with Said base plate, Said inner circle Substantially tangent to both Said Stick pin and

hinge plate adapted to receive a Stick pin and a link pin. Said link pin.

3. The bucket arrangement of claim 2 wherein Said radius 60 ing:13. A bucket arrangement for a work machine, compris

of curvature of Said base plate defines a Substantially con

centric inner circle Substantially tangent to both Said Stick a pair of opposite Side plates,

pin and Said link pin. a moldboard extending between and attached to Said Side

4. The bucket arrangement of claim 1 wherein Said plates, Said moldboard having a bottom portion and a

trailing portion of Said base plate is angled outward, relative 65 top portion;

to Said bottom portion, at a predetermined angle from a base plate having a leading portion and a trailing

horizontal. portion, Said trailing portion attached with Said top

US 6,581,308 B1

S 6

portion of Said moldboard and Said leading portion a pair of hinge plates attached with Said base plate, Said

being outwardly curved, relative to Said bottom portion hinge plate adapted to receive a Stick pin and a link pin.

of Said moldboard, and having a predetermined radius

of curvature; and k . . . .

You might also like

- Laryngo Broncho EsophagologyDocument94 pagesLaryngo Broncho EsophagologyFrederick Mars UntalanNo ratings yet

- Siemens J Press Sidebar Filter Press PDFDocument12 pagesSiemens J Press Sidebar Filter Press PDFTrần Khánh Duy100% (1)

- USRE29603Document7 pagesUSRE29603PUVAN TSTNo ratings yet

- United States Patent (10) Patent No.: US 8.246,240 B2Document19 pagesUnited States Patent (10) Patent No.: US 8.246,240 B2Xuan Phuong HuynhNo ratings yet

- United States PatentDocument6 pagesUnited States PatentDaikinllcNo ratings yet

- Vernier Caliper PatentDocument9 pagesVernier Caliper Patentmeinard angelesNo ratings yet

- US4523397Document6 pagesUS4523397PUVAN TSTNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,214,135 B2 Laskey Et Al. (45) Date of Patent: May 8, 2007Document6 pagesUnited States Patent: (12) (10) Patent No.: US 7,214,135 B2 Laskey Et Al. (45) Date of Patent: May 8, 2007Keval Kamani100% (1)

- Centri Cobra TattooDocument9 pagesCentri Cobra TattooJeremy BloodNo ratings yet

- US10029802 Tiltrotor Aircraft Having Pillow Block Mounted Pylon AssembliesDocument23 pagesUS10029802 Tiltrotor Aircraft Having Pillow Block Mounted Pylon Assemblies雷黎明No ratings yet

- US6378265Document19 pagesUS6378265brandon padillaNo ratings yet

- Us6230368 PDFDocument9 pagesUs6230368 PDFSantoshNo ratings yet

- United States Patent: Reid (45) Date of Patent: Jun. 26, 2007Document16 pagesUnited States Patent: Reid (45) Date of Patent: Jun. 26, 2007raj kishoreNo ratings yet

- United States Patent (10) Patent No.: US 6,237,387 B1: Yoshizawa Et Al. (45) Date of Patent: May 29, 2001Document7 pagesUnited States Patent (10) Patent No.: US 6,237,387 B1: Yoshizawa Et Al. (45) Date of Patent: May 29, 2001tajshah283No ratings yet

- United States Patent (19) : Gazalel, 72 8Document7 pagesUnited States Patent (19) : Gazalel, 72 8Mihai RobertNo ratings yet

- 1980 - Precision Closed-Die Forging MethodDocument11 pages1980 - Precision Closed-Die Forging MethodNguyen Hoang DungNo ratings yet

- US4753444Document5 pagesUS4753444Hadi KoraniNo ratings yet

- United States Patent (19) 11 Patent Number: 6,058,893: Pate (45) Date of Patent: May 9, 2000Document8 pagesUnited States Patent (19) 11 Patent Number: 6,058,893: Pate (45) Date of Patent: May 9, 2000qamarVEXNo ratings yet

- United States Patent (10) Patent No.: US 6,453,528 B1Document9 pagesUnited States Patent (10) Patent No.: US 6,453,528 B1MahnooshNo ratings yet

- United States PatentDocument7 pagesUnited States Patentwmgb249529No ratings yet

- PATENTDocument8 pagesPATENTHeavy Construction EquipmentNo ratings yet

- US9981750 Tiltrotor Aircraft Having Spherical Bearing Mounted Pylon AssembliesDocument23 pagesUS9981750 Tiltrotor Aircraft Having Spherical Bearing Mounted Pylon Assemblies雷黎明No ratings yet

- United States Patent (10) Patent No.: US 6,880,220 B2: Gandy (45) Date of Patent: Apr. 19, 2005Document8 pagesUnited States Patent (10) Patent No.: US 6,880,220 B2: Gandy (45) Date of Patent: Apr. 19, 2005Erin GokNo ratings yet

- United States Patent (10) Patent No.: US 8.414,195 B2Document6 pagesUnited States Patent (10) Patent No.: US 8.414,195 B2Anshumaan Pratap BhagatNo ratings yet

- 59 0f1-,-,,é - 1,, M 13,553 $525113ei Iiii?if III Fifit 21811101511121.1118Document22 pages59 0f1-,-,,é - 1,, M 13,553 $525113ei Iiii?if III Fifit 21811101511121.1118Qwerty UiopNo ratings yet

- United States Patent: (45) July 4, 1972Document4 pagesUnited States Patent: (45) July 4, 1972Lidya SimatupangNo ratings yet

- Ta Co Chceme - US7134255Document5 pagesTa Co Chceme - US7134255hana.hovorkovaNo ratings yet

- Us4252504 PDFDocument7 pagesUs4252504 PDFAhmed EltemsahNo ratings yet

- Threaded Connections With High and Low Friction CoatingsDocument14 pagesThreaded Connections With High and Low Friction CoatingsysuyycNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,322,545 B2Document13 pagesUnited States Patent: (12) (10) Patent No.: US 7,322,545 B2rakkaNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument10 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentPriyankaNo ratings yet

- Us 7845574Document10 pagesUs 7845574Hossein Hosseini RadNo ratings yet

- US4103849Document5 pagesUS4103849Zhu LeeNo ratings yet

- United States Patent (19) : Chupka Et Al. 11) Patent Number: 5,078,275 (45) Date of PatentDocument10 pagesUnited States Patent (19) : Chupka Et Al. 11) Patent Number: 5,078,275 (45) Date of PatentClaudinei MayerNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,109,625 B1Document34 pagesUnited States Patent: (12) (10) Patent No.: US 7,109,625 B1Paul D. GenoveseNo ratings yet

- (12 Ulllted States Patent (10) Patent N0.: US 6,360,830 B1Document53 pages(12 Ulllted States Patent (10) Patent N0.: US 6,360,830 B1Cường Nguyễn QuốcNo ratings yet

- US10421541Document51 pagesUS10421541gorgiNo ratings yet

- US9197965Document50 pagesUS9197965Morena SlpNo ratings yet

- United States Patent: Kizhakkepat Et AlDocument32 pagesUnited States Patent: Kizhakkepat Et Al雷黎明No ratings yet

- US3921555Document6 pagesUS3921555Muhammad TalhaNo ratings yet

- United States Patent (10) Patent No.: US 6,793,224 B2: Stratton (45) Date of Patent: Sep. 21, 2004Document14 pagesUnited States Patent (10) Patent No.: US 6,793,224 B2: Stratton (45) Date of Patent: Sep. 21, 2004Dagger HashimotoNo ratings yet

- Reducing The Core-End Heating in Large Power GeneratorsDocument12 pagesReducing The Core-End Heating in Large Power GeneratorsMichal KowalczykNo ratings yet

- US7849623 Rolling Block Trigger PDFDocument25 pagesUS7849623 Rolling Block Trigger PDFE MakinenNo ratings yet

- United States Patent (10) Patent No.: US 7.587,842 B2: Tajiri Et Al. (45) Date of Patent: Sep. 15, 2009Document11 pagesUnited States Patent (10) Patent No.: US 7.587,842 B2: Tajiri Et Al. (45) Date of Patent: Sep. 15, 2009emre yıldırımNo ratings yet

- US4160132Document6 pagesUS4160132majid.javadi.1993No ratings yet

- United States Patent (19) : (54) Coating Device For Coating OfaDocument10 pagesUnited States Patent (19) : (54) Coating Device For Coating OfaNiccolast Adnandito SaputraNo ratings yet

- Us6924931 PDFDocument10 pagesUs6924931 PDFja2ja1No ratings yet

- United States PatentDocument8 pagesUnited States PatentClaudinei MayerNo ratings yet

- US4681285 Main Gear DeflectorDocument8 pagesUS4681285 Main Gear DeflectorkippcamNo ratings yet

- US20090183398A1Document9 pagesUS20090183398A1PUVAN TSTNo ratings yet

- United States Patent: (10) Patent No.: US 9,393,739 B2Document31 pagesUnited States Patent: (10) Patent No.: US 9,393,739 B2Yu YangNo ratings yet

- US6804943Document6 pagesUS6804943Abdullah KhanNo ratings yet

- 2013 - Us8365841b2 - Sectional Back Reamer Apparatus and Method For Horizontal Directional DrillingDocument11 pages2013 - Us8365841b2 - Sectional Back Reamer Apparatus and Method For Horizontal Directional DrillingCường Nguyễn QuốcNo ratings yet

- Us 6497296Document15 pagesUs 6497296JUAN MORANNo ratings yet

- United States Patent (10) Patent No.: US 7,681,342 B2: Choi (45) Date of Patent: Mar. 23, 2010Document20 pagesUnited States Patent (10) Patent No.: US 7,681,342 B2: Choi (45) Date of Patent: Mar. 23, 2010Ronan RojasNo ratings yet

- Us 7628347Document6 pagesUs 7628347Pooria1989No ratings yet

- US8075772 失效Document35 pagesUS8075772 失效Steven CHENNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument25 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentXuan Phuong HuynhNo ratings yet

- Us5584264 PDFDocument4 pagesUs5584264 PDFMiguel Kühnert FrichenbruderNo ratings yet

- Us8371532 PDFDocument12 pagesUs8371532 PDF雷黎明No ratings yet

- US6189197Document11 pagesUS6189197Simon VotteroNo ratings yet

- Ammunition, Demystified: The (non) Bubba's Guide to How Ammo Really WorksFrom EverandAmmunition, Demystified: The (non) Bubba's Guide to How Ammo Really WorksNo ratings yet

- ExcavatorschecklistDocument4 pagesExcavatorschecklistPUVAN TSTNo ratings yet

- DozerchecklistDocument4 pagesDozerchecklistPUVAN TSTNo ratings yet

- Wheel Loaders Checklist PDFDocument4 pagesWheel Loaders Checklist PDFPUVAN TSTNo ratings yet

- US8069593Document9 pagesUS8069593PUVAN TSTNo ratings yet

- USRE29603Document7 pagesUSRE29603PUVAN TSTNo ratings yet

- US4523397Document6 pagesUS4523397PUVAN TSTNo ratings yet

- US20090183398A1Document9 pagesUS20090183398A1PUVAN TSTNo ratings yet

- US3523621Document8 pagesUS3523621PUVAN TSTNo ratings yet

- Advanced Recon CommandosDocument12 pagesAdvanced Recon CommandosRaymar WaltonNo ratings yet

- Biotechnology - Principles and Processes - Mind Map - Lakshya NEET 2024Document7 pagesBiotechnology - Principles and Processes - Mind Map - Lakshya NEET 2024Test UserNo ratings yet

- UTS ENGLISH - 112011192 - Netta Delyana PutriDocument2 pagesUTS ENGLISH - 112011192 - Netta Delyana Putrinetta delyana putriNo ratings yet

- BEC ChemDocument7 pagesBEC ChemSka dooshNo ratings yet

- Active Certificates: A Framework For DelegationDocument39 pagesActive Certificates: A Framework For DelegationBruno CrispoNo ratings yet

- Unit 3 Prepare and Interpret Technical DrawingDocument20 pagesUnit 3 Prepare and Interpret Technical Drawingtracert_atanNo ratings yet

- Final Seats Matrix Ss Counelling - 2022 D.M M.CHDocument55 pagesFinal Seats Matrix Ss Counelling - 2022 D.M M.CHMinerva Medical Treatment Pvt LtdNo ratings yet

- Aspen Plus NMP ModelDocument24 pagesAspen Plus NMP ModelGodstandNo ratings yet

- Introduction To Strategic Management: Topic OutlineDocument7 pagesIntroduction To Strategic Management: Topic OutlineJoyce DuaNo ratings yet

- Competitive Rivalry and Competitive Dynamics: Strategic ManagementDocument42 pagesCompetitive Rivalry and Competitive Dynamics: Strategic ManagementnessieanatashaNo ratings yet

- Angprm 2xx PDFDocument437 pagesAngprm 2xx PDFHalász AttilaNo ratings yet

- JEE Main 2023 11 April Shift 2Document37 pagesJEE Main 2023 11 April Shift 2Madhu RathNo ratings yet

- PA - StocksDocument36 pagesPA - Stocksikolev57No ratings yet

- Franchise PackageDocument3 pagesFranchise PackageJayson Nonan100% (1)

- Digital Booklet - V (Deluxe Version)Document7 pagesDigital Booklet - V (Deluxe Version)Aldo Jesus Reyes CortesNo ratings yet

- Đề Cương TA 10 - Unit 6 7 8Document10 pagesĐề Cương TA 10 - Unit 6 7 8Su SanNo ratings yet

- (Dry Type Transformer)Document23 pages(Dry Type Transformer)togirishsharmaNo ratings yet

- Tổng hợp đề thi HSK2Document5 pagesTổng hợp đề thi HSK2Tran My HanhNo ratings yet

- Problem Solving ActivitiesDocument6 pagesProblem Solving ActivitiesreginafernNo ratings yet

- PW Unit 8 PDFDocument3 pagesPW Unit 8 PDFac5sro1No ratings yet

- Green Bedding Separator FAN - Parts List - 2017Document9 pagesGreen Bedding Separator FAN - Parts List - 2017Centrifugal SeparatorNo ratings yet

- Cigre2012 - Power System Energy EfficiencyDocument10 pagesCigre2012 - Power System Energy EfficiencyFernando De MarcoNo ratings yet

- Answers To Specific Heat ProblemsDocument5 pagesAnswers To Specific Heat ProblemsSiraj AL sharifNo ratings yet

- Evolution-of-Management-Theory 02 PDFDocument42 pagesEvolution-of-Management-Theory 02 PDFsafiqulislamNo ratings yet

- Splintered Truths Splintered Promises Duet Book One M George All ChapterDocument49 pagesSplintered Truths Splintered Promises Duet Book One M George All Chaptermarcus.culnane57883% (6)

- 'NEXtCARE Corporate Profile 5Document1 page'NEXtCARE Corporate Profile 5Rajesh PotluriNo ratings yet

- Sample Applications For .NET DevelopersDocument2 pagesSample Applications For .NET Developersreena jadhavNo ratings yet

- 7 PDFDocument6 pages7 PDFjoseNo ratings yet