Professional Documents

Culture Documents

Receiving of Raw Materials

Receiving of Raw Materials

Uploaded by

muhammad amirul mukmininCopyright:

Available Formats

You might also like

- Non-Conforming Product ProcedureDocument3 pagesNon-Conforming Product ProcedureHamzah Abbass SibaiNo ratings yet

- S:No Name of The Company Company Address Phone Number 1 Phone Number 2 Phone Number 3Document14 pagesS:No Name of The Company Company Address Phone Number 1 Phone Number 2 Phone Number 3Buvan Balu50% (2)

- 2020 GR 7 Ems Term 1 ManualDocument38 pages2020 GR 7 Ems Term 1 ManualSamuel Thembinkosi HermansNo ratings yet

- JSA For Foundation Concrete RepairDocument6 pagesJSA For Foundation Concrete RepairOvais FarooqNo ratings yet

- Sample SOP RM Stores PDFDocument2 pagesSample SOP RM Stores PDFRosiana Amelia Sari100% (3)

- Store Inventory Management Sop: CoverageDocument19 pagesStore Inventory Management Sop: CoverageBebe Berry100% (1)

- Materials Receipt and InspectionDocument6 pagesMaterials Receipt and InspectionMj AndresNo ratings yet

- WH SOPsDocument6 pagesWH SOPsMuhammad Khalid Mushtaq Mayo100% (1)

- N-00-PQ-5011-PR - R0A (Material Receiving Procedure) PDFDocument10 pagesN-00-PQ-5011-PR - R0A (Material Receiving Procedure) PDFRaziKhanNo ratings yet

- Standard Operation Procedure Store ProcessDocument2 pagesStandard Operation Procedure Store ProcessHarits As SiddiqNo ratings yet

- 23 Rejected Material Handling ProcedureDocument9 pages23 Rejected Material Handling ProcedureQAD LotusNo ratings yet

- CSS - TGDocument150 pagesCSS - TGJenniferBanogonNo ratings yet

- Verefaction ProcessDocument7 pagesVerefaction ProcessSaid ElsamnaNo ratings yet

- Procedure For Importation - AOCDocument4 pagesProcedure For Importation - AOCMohamed EzzatNo ratings yet

- Receive and Store Stock: D2.TGA - CL6.11 Assessor ManualDocument60 pagesReceive and Store Stock: D2.TGA - CL6.11 Assessor ManualPhttii phttiiNo ratings yet

- SOP Material RecivingDocument4 pagesSOP Material Recivingsatish hNo ratings yet

- Turtle Diagram StoreDocument1 pageTurtle Diagram StoreRiyu Rathod0% (1)

- AV-ST-WI-01 Material Receipt Inspection Storage Issue and Recovery Iss 1Document6 pagesAV-ST-WI-01 Material Receipt Inspection Storage Issue and Recovery Iss 1Kevin DeLimaNo ratings yet

- Sample SOPDocument1 pageSample SOPkishorehrmmiNo ratings yet

- Receiving Material ProcedureDocument5 pagesReceiving Material Proceduregst ajah100% (1)

- TG Receive Store Stock 190312 V2V2Document174 pagesTG Receive Store Stock 190312 V2V2Phttii phttiiNo ratings yet

- GR - HR Training - V. 1.1Document108 pagesGR - HR Training - V. 1.1RoseAfnyNo ratings yet

- Pm3 - Mat & Equip PurchaseDocument1 pagePm3 - Mat & Equip PurchaseMohammed EyazNo ratings yet

- Receive and Store Stock: D2.TGA - CL6.11 Trainee ManualDocument88 pagesReceive and Store Stock: D2.TGA - CL6.11 Trainee ManualPhttii phttiiNo ratings yet

- Inventory-SOP-Policy & FormsDocument25 pagesInventory-SOP-Policy & FormsSaad Khan100% (2)

- SOP H-100 Receiving Materials - Rev.1Document2 pagesSOP H-100 Receiving Materials - Rev.1iplaruffNo ratings yet

- Property & Supply Unit FlowDocument8 pagesProperty & Supply Unit FlowEmmanuel EndrigaNo ratings yet

- AV-OP-05 Goods Inwards Storage and Release Iss 1Document3 pagesAV-OP-05 Goods Inwards Storage and Release Iss 1Kevin DeLimaNo ratings yet

- Basic Flowchart of Incoming & Outgoing of Stock Indent Non-Conforming MaterialsDocument1 pageBasic Flowchart of Incoming & Outgoing of Stock Indent Non-Conforming MaterialsMichael Ang100% (1)

- Work FlowDocument2 pagesWork FlowSupriya Sain RanaNo ratings yet

- Store ProcessDocument5 pagesStore ProcessGAMALAT ELSAYED100% (1)

- StockYard Conveyor System Overhauling JSA HADEED MODULE A-BDocument8 pagesStockYard Conveyor System Overhauling JSA HADEED MODULE A-Bammar mughalNo ratings yet

- Supplier Evaluation FormDocument1 pageSupplier Evaluation Formwaseem mohammadNo ratings yet

- Inspection and Acceptance ReportDocument35 pagesInspection and Acceptance Reportarnel100% (1)

- Purchasing ProcedureDocument3 pagesPurchasing ProcedureMark Roger Huberit IINo ratings yet

- 5-6. Overhauling of TGS & CGS JSA HADEED MODULE A-BDocument8 pages5-6. Overhauling of TGS & CGS JSA HADEED MODULE A-Bammar mughalNo ratings yet

- DCP Handbook GuideDocument31 pagesDCP Handbook GuideBrian MaryNo ratings yet

- Procedure For Material Requirement Planning & PurchasingDocument1 pageProcedure For Material Requirement Planning & PurchasingHarkesh KumarNo ratings yet

- Body 1Document76 pagesBody 1Rommel sauraNo ratings yet

- Kewaunee Labway India PVT LTD: Material Handling & StorageDocument5 pagesKewaunee Labway India PVT LTD: Material Handling & Storagesatish hNo ratings yet

- ACMV Hirac - Tipping RoomDocument19 pagesACMV Hirac - Tipping RoomNethiyaaRajendranNo ratings yet

- Materialapprovalprocedure 210113201728Document15 pagesMaterialapprovalprocedure 210113201728Mohamed AliNo ratings yet

- SOP Asset Acceptance & InstallationDocument2 pagesSOP Asset Acceptance & InstallationNasser AnapparaNo ratings yet

- UG Piping InstallationDocument5 pagesUG Piping InstallationZubair Ahmed KhaskheliNo ratings yet

- 004 - QMS - Inspection DivisionDocument18 pages004 - QMS - Inspection DivisionSittie Fatma ReporsNo ratings yet

- Study Text Cma Caf 3Document606 pagesStudy Text Cma Caf 3Muhammad KashifNo ratings yet

- JD - Spares Warehouse HeadDocument2 pagesJD - Spares Warehouse HeadJayprakash BamboleNo ratings yet

- Project Handling ProcedureDocument8 pagesProject Handling ProcedurePk NimiwalNo ratings yet

- Standard Operating Procedure (SOP) For Store: (Procurement of Material)Document9 pagesStandard Operating Procedure (SOP) For Store: (Procurement of Material)TASHIDINGNo ratings yet

- Learner Guide: Front-End Loader/BackhoeDocument17 pagesLearner Guide: Front-End Loader/BackhoeOwen PerrinNo ratings yet

- 26.RG Cooler Overhauling, Pipe Work and Seal Leg Replacement JSA HADEED MODULE A-BDocument8 pages26.RG Cooler Overhauling, Pipe Work and Seal Leg Replacement JSA HADEED MODULE A-Bammar mughalNo ratings yet

- JSA Unloading & SHIFTING by Manually 10-01-2017Document16 pagesJSA Unloading & SHIFTING by Manually 10-01-2017PAVANKUMAR100% (1)

- Purchase SOPDocument1 pagePurchase SOPnrupika solankiNo ratings yet

- Singapore SOP 602 - Receipt & Storage of ChemicalsDocument2 pagesSingapore SOP 602 - Receipt & Storage of ChemicalsKings NoyNo ratings yet

- MTP-PR-004-QUC Material Recieving Inspection (R0)Document5 pagesMTP-PR-004-QUC Material Recieving Inspection (R0)parwoto100% (1)

- GDGDocument1 pageGDGrahulgehlot2008No ratings yet

- VAMerchan - Supply Chain FlowchartDocument10 pagesVAMerchan - Supply Chain FlowchartVladimir adolfo MerchánNo ratings yet

- Costing and Pricing PrelimDocument6 pagesCosting and Pricing PrelimJV EstanislaoNo ratings yet

- JSA For RadiographyDocument5 pagesJSA For RadiographyViron BaxhiaNo ratings yet

- Document Claim Umobile (PAKO)Document34 pagesDocument Claim Umobile (PAKO)muhammad amirul mukmininNo ratings yet

- Ibs Sungai Buloh 1 31/12/22Document10 pagesIbs Sungai Buloh 1 31/12/22muhammad amirul mukmininNo ratings yet

- HRM Ain's AssignmentDocument5 pagesHRM Ain's Assignmentmuhammad amirul mukmininNo ratings yet

- 10.3 HDD ProfileDocument13 pages10.3 HDD Profilemuhammad amirul mukmininNo ratings yet

- Claim Form: TERABAND SMART SOLUTION SDN BHD (2021010083320) (1408631-K)Document200 pagesClaim Form: TERABAND SMART SOLUTION SDN BHD (2021010083320) (1408631-K)muhammad amirul mukmininNo ratings yet

- UntitledDocument1 pageUntitledmuhammad amirul mukmininNo ratings yet

- Assignment - I - Case II - UpdateDocument2 pagesAssignment - I - Case II - Updatetheingi linnNo ratings yet

- TWf2020.03 - Rebar Guide - Part 1 Management - October 2020 - FINALDocument38 pagesTWf2020.03 - Rebar Guide - Part 1 Management - October 2020 - FINALkamilrak2317No ratings yet

- Understanding RCEF and Implication To Rice FarmersDocument51 pagesUnderstanding RCEF and Implication To Rice FarmersCLARIZZE JAINE MANALONo ratings yet

- Job Advert - Assistant Field Agronomist Intern (Kagera)Document2 pagesJob Advert - Assistant Field Agronomist Intern (Kagera)Swalau OmaryNo ratings yet

- Nasm3036 (MS35489)Document7 pagesNasm3036 (MS35489)Bogdan RusuNo ratings yet

- Reliance RetailDocument12 pagesReliance RetailFalansh JainNo ratings yet

- Vegifresh Profile Export Profile PDFDocument9 pagesVegifresh Profile Export Profile PDFsantoshtaydeNo ratings yet

- Piao Proposed Structure 2023Document5 pagesPiao Proposed Structure 2023me.I.onlyNo ratings yet

- Types of Screw Conveyors - Engineering Guide: Traducir Esta PáginaDocument8 pagesTypes of Screw Conveyors - Engineering Guide: Traducir Esta PáginaDIEGO FERNANDO CADENA ARANGONo ratings yet

- A Study On Production and Marketing of Poultry Products in Namakkal District, Tamil Nadu StateDocument5 pagesA Study On Production and Marketing of Poultry Products in Namakkal District, Tamil Nadu StatevisalakshitexmillsNo ratings yet

- Sop For Manual DaybookDocument2 pagesSop For Manual DaybookAudit helpNo ratings yet

- PTT Annual Report 2551 - 2008 - ENGDocument159 pagesPTT Annual Report 2551 - 2008 - ENGPhan SNo ratings yet

- How To Invoice AddressesDocument40 pagesHow To Invoice AddressesShield ShieldNo ratings yet

- Tugasan Amali 1Document25 pagesTugasan Amali 1Norelyana SyakirahNo ratings yet

- Zara -Apparel Manufacturing and RetailDocument1 pageZara -Apparel Manufacturing and RetailSahil AgrawalNo ratings yet

- QTN22392Document2 pagesQTN22392Haitham AlhomaideNo ratings yet

- Job Order Costing SystemDocument3 pagesJob Order Costing SystemPung Xin YaoNo ratings yet

- Moos Motaihein, Lodha Hoihein Na Hathi, Na Ghoda Hoihein-1Document9 pagesMoos Motaihein, Lodha Hoihein Na Hathi, Na Ghoda Hoihein-1Abhishek GauravNo ratings yet

- Skin Care in Vietnam: Euromonitor International July 2020Document17 pagesSkin Care in Vietnam: Euromonitor International July 2020Nguyễn TrangNo ratings yet

- PM Sunway Test July-Sept 2023 PTDocument11 pagesPM Sunway Test July-Sept 2023 PTFarahAin FainNo ratings yet

- BPD en UsDocument32 pagesBPD en Usramakrishna4pNo ratings yet

- 5.ast - Installment & FranchisingDocument12 pages5.ast - Installment & FranchisingElaineJrV-IgotNo ratings yet

- AME1501 Study GuideDocument164 pagesAME1501 Study GuideKwazi MalazaNo ratings yet

- DLF LimitedDocument14 pagesDLF LimitedC P In IndiaNo ratings yet

- Chapter 2. VatDocument97 pagesChapter 2. VatVu Thi ThuongNo ratings yet

- Unit 6 Drought: Case Studies: 6.0 Learning OutcomeDocument13 pagesUnit 6 Drought: Case Studies: 6.0 Learning OutcomeJack PNo ratings yet

- List of Important Mergers and Acquisitions in India 2022 - Download PDFDocument7 pagesList of Important Mergers and Acquisitions in India 2022 - Download PDFPrerna PardeshiNo ratings yet

- สัญญาแร่เหล็ก-เวียดนาม-แปลง (AutoRecovered)Document3 pagesสัญญาแร่เหล็ก-เวียดนาม-แปลง (AutoRecovered)Note BuriNo ratings yet

Receiving of Raw Materials

Receiving of Raw Materials

Uploaded by

muhammad amirul mukmininOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Receiving of Raw Materials

Receiving of Raw Materials

Uploaded by

muhammad amirul mukmininCopyright:

Available Formats

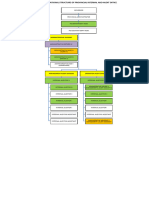

PROCESS FLOW CHART FOR RECEIVING OF MATERIALS

ACTIVITY / RESPONSIBILITY REMARKS/DETAILS

Store Personnel

1.1 Upon receiving of incoming purchased materials

Receive of purchased from external provider, the store personnel shall

materials be responsible to verify & check the materials

received with external provider’s D/O against

Store Personnel Teraband’s P/O and actual quantity received.

Check materials against to 1.2 After completed the verification, the store

D/O personnel shall acknowledge the external

provider’s D/O with stamp and sign, then submit

to Purchasing personnel to key into SQL system

Store Personnel for payment processing.

Unload purchased materials

from truck / container 1.3 The store personnel shall return 1 copy of

acknowledged D/O to the transporter.

1.4 Store personnel shall unload the purchased

materials from the container / truck and arrange

Project / Site the materials at the incoming area with proper

No Engineer

Project / labeling.

Site On Hold Materials

Engineer with Reject Sticker 1.5 Then, Project / Site Engineer shall conduct

Check Incoming Quality Inspection on:

Quality?

i) Raw material for machining

Yes

ii) Packaging material for shipping

1.6 The materials that passed the Project / Site

Store Personnel Engineer will be deliver to store.

Deliver to store 1.7 Store personnel update the stock card.

1.8 If the purchased materials are found to be not in

Store Personnel conformance with the product specification or

Update stock card quality requirement, Project / Site Engineer shall

on hold the materials with On-hold stickers.

You might also like

- Non-Conforming Product ProcedureDocument3 pagesNon-Conforming Product ProcedureHamzah Abbass SibaiNo ratings yet

- S:No Name of The Company Company Address Phone Number 1 Phone Number 2 Phone Number 3Document14 pagesS:No Name of The Company Company Address Phone Number 1 Phone Number 2 Phone Number 3Buvan Balu50% (2)

- 2020 GR 7 Ems Term 1 ManualDocument38 pages2020 GR 7 Ems Term 1 ManualSamuel Thembinkosi HermansNo ratings yet

- JSA For Foundation Concrete RepairDocument6 pagesJSA For Foundation Concrete RepairOvais FarooqNo ratings yet

- Sample SOP RM Stores PDFDocument2 pagesSample SOP RM Stores PDFRosiana Amelia Sari100% (3)

- Store Inventory Management Sop: CoverageDocument19 pagesStore Inventory Management Sop: CoverageBebe Berry100% (1)

- Materials Receipt and InspectionDocument6 pagesMaterials Receipt and InspectionMj AndresNo ratings yet

- WH SOPsDocument6 pagesWH SOPsMuhammad Khalid Mushtaq Mayo100% (1)

- N-00-PQ-5011-PR - R0A (Material Receiving Procedure) PDFDocument10 pagesN-00-PQ-5011-PR - R0A (Material Receiving Procedure) PDFRaziKhanNo ratings yet

- Standard Operation Procedure Store ProcessDocument2 pagesStandard Operation Procedure Store ProcessHarits As SiddiqNo ratings yet

- 23 Rejected Material Handling ProcedureDocument9 pages23 Rejected Material Handling ProcedureQAD LotusNo ratings yet

- CSS - TGDocument150 pagesCSS - TGJenniferBanogonNo ratings yet

- Verefaction ProcessDocument7 pagesVerefaction ProcessSaid ElsamnaNo ratings yet

- Procedure For Importation - AOCDocument4 pagesProcedure For Importation - AOCMohamed EzzatNo ratings yet

- Receive and Store Stock: D2.TGA - CL6.11 Assessor ManualDocument60 pagesReceive and Store Stock: D2.TGA - CL6.11 Assessor ManualPhttii phttiiNo ratings yet

- SOP Material RecivingDocument4 pagesSOP Material Recivingsatish hNo ratings yet

- Turtle Diagram StoreDocument1 pageTurtle Diagram StoreRiyu Rathod0% (1)

- AV-ST-WI-01 Material Receipt Inspection Storage Issue and Recovery Iss 1Document6 pagesAV-ST-WI-01 Material Receipt Inspection Storage Issue and Recovery Iss 1Kevin DeLimaNo ratings yet

- Sample SOPDocument1 pageSample SOPkishorehrmmiNo ratings yet

- Receiving Material ProcedureDocument5 pagesReceiving Material Proceduregst ajah100% (1)

- TG Receive Store Stock 190312 V2V2Document174 pagesTG Receive Store Stock 190312 V2V2Phttii phttiiNo ratings yet

- GR - HR Training - V. 1.1Document108 pagesGR - HR Training - V. 1.1RoseAfnyNo ratings yet

- Pm3 - Mat & Equip PurchaseDocument1 pagePm3 - Mat & Equip PurchaseMohammed EyazNo ratings yet

- Receive and Store Stock: D2.TGA - CL6.11 Trainee ManualDocument88 pagesReceive and Store Stock: D2.TGA - CL6.11 Trainee ManualPhttii phttiiNo ratings yet

- Inventory-SOP-Policy & FormsDocument25 pagesInventory-SOP-Policy & FormsSaad Khan100% (2)

- SOP H-100 Receiving Materials - Rev.1Document2 pagesSOP H-100 Receiving Materials - Rev.1iplaruffNo ratings yet

- Property & Supply Unit FlowDocument8 pagesProperty & Supply Unit FlowEmmanuel EndrigaNo ratings yet

- AV-OP-05 Goods Inwards Storage and Release Iss 1Document3 pagesAV-OP-05 Goods Inwards Storage and Release Iss 1Kevin DeLimaNo ratings yet

- Basic Flowchart of Incoming & Outgoing of Stock Indent Non-Conforming MaterialsDocument1 pageBasic Flowchart of Incoming & Outgoing of Stock Indent Non-Conforming MaterialsMichael Ang100% (1)

- Work FlowDocument2 pagesWork FlowSupriya Sain RanaNo ratings yet

- Store ProcessDocument5 pagesStore ProcessGAMALAT ELSAYED100% (1)

- StockYard Conveyor System Overhauling JSA HADEED MODULE A-BDocument8 pagesStockYard Conveyor System Overhauling JSA HADEED MODULE A-Bammar mughalNo ratings yet

- Supplier Evaluation FormDocument1 pageSupplier Evaluation Formwaseem mohammadNo ratings yet

- Inspection and Acceptance ReportDocument35 pagesInspection and Acceptance Reportarnel100% (1)

- Purchasing ProcedureDocument3 pagesPurchasing ProcedureMark Roger Huberit IINo ratings yet

- 5-6. Overhauling of TGS & CGS JSA HADEED MODULE A-BDocument8 pages5-6. Overhauling of TGS & CGS JSA HADEED MODULE A-Bammar mughalNo ratings yet

- DCP Handbook GuideDocument31 pagesDCP Handbook GuideBrian MaryNo ratings yet

- Procedure For Material Requirement Planning & PurchasingDocument1 pageProcedure For Material Requirement Planning & PurchasingHarkesh KumarNo ratings yet

- Body 1Document76 pagesBody 1Rommel sauraNo ratings yet

- Kewaunee Labway India PVT LTD: Material Handling & StorageDocument5 pagesKewaunee Labway India PVT LTD: Material Handling & Storagesatish hNo ratings yet

- ACMV Hirac - Tipping RoomDocument19 pagesACMV Hirac - Tipping RoomNethiyaaRajendranNo ratings yet

- Materialapprovalprocedure 210113201728Document15 pagesMaterialapprovalprocedure 210113201728Mohamed AliNo ratings yet

- SOP Asset Acceptance & InstallationDocument2 pagesSOP Asset Acceptance & InstallationNasser AnapparaNo ratings yet

- UG Piping InstallationDocument5 pagesUG Piping InstallationZubair Ahmed KhaskheliNo ratings yet

- 004 - QMS - Inspection DivisionDocument18 pages004 - QMS - Inspection DivisionSittie Fatma ReporsNo ratings yet

- Study Text Cma Caf 3Document606 pagesStudy Text Cma Caf 3Muhammad KashifNo ratings yet

- JD - Spares Warehouse HeadDocument2 pagesJD - Spares Warehouse HeadJayprakash BamboleNo ratings yet

- Project Handling ProcedureDocument8 pagesProject Handling ProcedurePk NimiwalNo ratings yet

- Standard Operating Procedure (SOP) For Store: (Procurement of Material)Document9 pagesStandard Operating Procedure (SOP) For Store: (Procurement of Material)TASHIDINGNo ratings yet

- Learner Guide: Front-End Loader/BackhoeDocument17 pagesLearner Guide: Front-End Loader/BackhoeOwen PerrinNo ratings yet

- 26.RG Cooler Overhauling, Pipe Work and Seal Leg Replacement JSA HADEED MODULE A-BDocument8 pages26.RG Cooler Overhauling, Pipe Work and Seal Leg Replacement JSA HADEED MODULE A-Bammar mughalNo ratings yet

- JSA Unloading & SHIFTING by Manually 10-01-2017Document16 pagesJSA Unloading & SHIFTING by Manually 10-01-2017PAVANKUMAR100% (1)

- Purchase SOPDocument1 pagePurchase SOPnrupika solankiNo ratings yet

- Singapore SOP 602 - Receipt & Storage of ChemicalsDocument2 pagesSingapore SOP 602 - Receipt & Storage of ChemicalsKings NoyNo ratings yet

- MTP-PR-004-QUC Material Recieving Inspection (R0)Document5 pagesMTP-PR-004-QUC Material Recieving Inspection (R0)parwoto100% (1)

- GDGDocument1 pageGDGrahulgehlot2008No ratings yet

- VAMerchan - Supply Chain FlowchartDocument10 pagesVAMerchan - Supply Chain FlowchartVladimir adolfo MerchánNo ratings yet

- Costing and Pricing PrelimDocument6 pagesCosting and Pricing PrelimJV EstanislaoNo ratings yet

- JSA For RadiographyDocument5 pagesJSA For RadiographyViron BaxhiaNo ratings yet

- Document Claim Umobile (PAKO)Document34 pagesDocument Claim Umobile (PAKO)muhammad amirul mukmininNo ratings yet

- Ibs Sungai Buloh 1 31/12/22Document10 pagesIbs Sungai Buloh 1 31/12/22muhammad amirul mukmininNo ratings yet

- HRM Ain's AssignmentDocument5 pagesHRM Ain's Assignmentmuhammad amirul mukmininNo ratings yet

- 10.3 HDD ProfileDocument13 pages10.3 HDD Profilemuhammad amirul mukmininNo ratings yet

- Claim Form: TERABAND SMART SOLUTION SDN BHD (2021010083320) (1408631-K)Document200 pagesClaim Form: TERABAND SMART SOLUTION SDN BHD (2021010083320) (1408631-K)muhammad amirul mukmininNo ratings yet

- UntitledDocument1 pageUntitledmuhammad amirul mukmininNo ratings yet

- Assignment - I - Case II - UpdateDocument2 pagesAssignment - I - Case II - Updatetheingi linnNo ratings yet

- TWf2020.03 - Rebar Guide - Part 1 Management - October 2020 - FINALDocument38 pagesTWf2020.03 - Rebar Guide - Part 1 Management - October 2020 - FINALkamilrak2317No ratings yet

- Understanding RCEF and Implication To Rice FarmersDocument51 pagesUnderstanding RCEF and Implication To Rice FarmersCLARIZZE JAINE MANALONo ratings yet

- Job Advert - Assistant Field Agronomist Intern (Kagera)Document2 pagesJob Advert - Assistant Field Agronomist Intern (Kagera)Swalau OmaryNo ratings yet

- Nasm3036 (MS35489)Document7 pagesNasm3036 (MS35489)Bogdan RusuNo ratings yet

- Reliance RetailDocument12 pagesReliance RetailFalansh JainNo ratings yet

- Vegifresh Profile Export Profile PDFDocument9 pagesVegifresh Profile Export Profile PDFsantoshtaydeNo ratings yet

- Piao Proposed Structure 2023Document5 pagesPiao Proposed Structure 2023me.I.onlyNo ratings yet

- Types of Screw Conveyors - Engineering Guide: Traducir Esta PáginaDocument8 pagesTypes of Screw Conveyors - Engineering Guide: Traducir Esta PáginaDIEGO FERNANDO CADENA ARANGONo ratings yet

- A Study On Production and Marketing of Poultry Products in Namakkal District, Tamil Nadu StateDocument5 pagesA Study On Production and Marketing of Poultry Products in Namakkal District, Tamil Nadu StatevisalakshitexmillsNo ratings yet

- Sop For Manual DaybookDocument2 pagesSop For Manual DaybookAudit helpNo ratings yet

- PTT Annual Report 2551 - 2008 - ENGDocument159 pagesPTT Annual Report 2551 - 2008 - ENGPhan SNo ratings yet

- How To Invoice AddressesDocument40 pagesHow To Invoice AddressesShield ShieldNo ratings yet

- Tugasan Amali 1Document25 pagesTugasan Amali 1Norelyana SyakirahNo ratings yet

- Zara -Apparel Manufacturing and RetailDocument1 pageZara -Apparel Manufacturing and RetailSahil AgrawalNo ratings yet

- QTN22392Document2 pagesQTN22392Haitham AlhomaideNo ratings yet

- Job Order Costing SystemDocument3 pagesJob Order Costing SystemPung Xin YaoNo ratings yet

- Moos Motaihein, Lodha Hoihein Na Hathi, Na Ghoda Hoihein-1Document9 pagesMoos Motaihein, Lodha Hoihein Na Hathi, Na Ghoda Hoihein-1Abhishek GauravNo ratings yet

- Skin Care in Vietnam: Euromonitor International July 2020Document17 pagesSkin Care in Vietnam: Euromonitor International July 2020Nguyễn TrangNo ratings yet

- PM Sunway Test July-Sept 2023 PTDocument11 pagesPM Sunway Test July-Sept 2023 PTFarahAin FainNo ratings yet

- BPD en UsDocument32 pagesBPD en Usramakrishna4pNo ratings yet

- 5.ast - Installment & FranchisingDocument12 pages5.ast - Installment & FranchisingElaineJrV-IgotNo ratings yet

- AME1501 Study GuideDocument164 pagesAME1501 Study GuideKwazi MalazaNo ratings yet

- DLF LimitedDocument14 pagesDLF LimitedC P In IndiaNo ratings yet

- Chapter 2. VatDocument97 pagesChapter 2. VatVu Thi ThuongNo ratings yet

- Unit 6 Drought: Case Studies: 6.0 Learning OutcomeDocument13 pagesUnit 6 Drought: Case Studies: 6.0 Learning OutcomeJack PNo ratings yet

- List of Important Mergers and Acquisitions in India 2022 - Download PDFDocument7 pagesList of Important Mergers and Acquisitions in India 2022 - Download PDFPrerna PardeshiNo ratings yet

- สัญญาแร่เหล็ก-เวียดนาม-แปลง (AutoRecovered)Document3 pagesสัญญาแร่เหล็ก-เวียดนาม-แปลง (AutoRecovered)Note BuriNo ratings yet