Professional Documents

Culture Documents

S-0200-1654-001 - 0-Permit To Work System Procedure-R1 PDF

S-0200-1654-001 - 0-Permit To Work System Procedure-R1 PDF

Uploaded by

okba labdiCopyright:

Available Formats

You might also like

- BEC-HSE-L2 - Lock Out Tag Out ProceduresDocument12 pagesBEC-HSE-L2 - Lock Out Tag Out ProceduresZakariyaNo ratings yet

- Plywood Shear Wall DesignDocument7 pagesPlywood Shear Wall DesignmlamourNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument11 pagesSafety Data Sheet: Section 1. IdentificationSanthosh GowthamNo ratings yet

- Tanjung Manis HowDocument7 pagesTanjung Manis Howramen28No ratings yet

- HPCL Disaster MGMT Control PlanDocument64 pagesHPCL Disaster MGMT Control PlanKiran BhattNo ratings yet

- Annexure IV - EL - Warehouse Operation Model (v1)Document81 pagesAnnexure IV - EL - Warehouse Operation Model (v1)Maged gmailNo ratings yet

- JSA Confined Space To Carryout Manual Cleaning, Inspection, Grit Blasting and Painting Rev-00Document42 pagesJSA Confined Space To Carryout Manual Cleaning, Inspection, Grit Blasting and Painting Rev-00Syed Ahmed manzoor100% (1)

- Manzoor Ali H.S.E Engineer Updated CVDocument5 pagesManzoor Ali H.S.E Engineer Updated CVManzoor AliNo ratings yet

- Site Visit ReportDocument4 pagesSite Visit Reporta.hasan670No ratings yet

- CRW For Shell Tanks (SP - 18 & SP - 21) Refurbishment WorksDocument32 pagesCRW For Shell Tanks (SP - 18 & SP - 21) Refurbishment WorksTALHA AHMAD FAROOQINo ratings yet

- 1028-2009 - Volume 2Document137 pages1028-2009 - Volume 2Ifkar ApriadiNo ratings yet

- Hazard Identification and Risk AssessmenDocument6 pagesHazard Identification and Risk AssessmenEric-peterEkumNo ratings yet

- LPG Gas Leakage Detection and Alert SystemDocument6 pagesLPG Gas Leakage Detection and Alert SystemIJRASETPublicationsNo ratings yet

- Metro Hse Plan 01Document49 pagesMetro Hse Plan 01Wasique Nesar100% (1)

- Risk Assessment - ExcavationDocument6 pagesRisk Assessment - Excavationganesh gbNo ratings yet

- ESE Method Statement Underground Utility Survey Rev3Document22 pagesESE Method Statement Underground Utility Survey Rev3بسام عوضNo ratings yet

- Zubair Mishrif SS Medical EmergencyDocument19 pagesZubair Mishrif SS Medical Emergencyhussein aliNo ratings yet

- Job Description - Baûng Moâ Taû Coâng VieäcDocument8 pagesJob Description - Baûng Moâ Taû Coâng VieäcquycoctuNo ratings yet

- Emergency Preparedness Plan For Marketing Loc of Oil Ind GDN-168Document34 pagesEmergency Preparedness Plan For Marketing Loc of Oil Ind GDN-168Good KnightnkNo ratings yet

- 07 - Tata Power OH&S - Legal Compliance - ProcedureDocument5 pages07 - Tata Power OH&S - Legal Compliance - ProcedureloganathanNo ratings yet

- Objectives: CareerDocument14 pagesObjectives: CareerHedi Ben MohamedNo ratings yet

- 2 - Hazards Indentification PlanDocument27 pages2 - Hazards Indentification PlanasanNo ratings yet

- Risk Procurement Assignment - 090164Document11 pagesRisk Procurement Assignment - 090164srvshNo ratings yet

- QS049-P09 Progress MOM No 31of 05 Sept 2021Document5 pagesQS049-P09 Progress MOM No 31of 05 Sept 2021ahmed khalil100% (1)

- 8015 0151 CK01 00 000 HS RP 06201 - 00Document12 pages8015 0151 CK01 00 000 HS RP 06201 - 00Saleem AkhtarNo ratings yet

- Ohs-Pr-09-03-F11 (A) Ra & JSP Daily Briefing - TBT RecordDocument1 pageOhs-Pr-09-03-F11 (A) Ra & JSP Daily Briefing - TBT RecordShafie ZubierNo ratings yet

- Risk Assessment: Site Facilities Larsen & Toubro Limited PT&D (I) (Africa)Document4 pagesRisk Assessment: Site Facilities Larsen & Toubro Limited PT&D (I) (Africa)Naveen GladsonNo ratings yet

- Discharge Rod 11kv 3phaseDocument1 pageDischarge Rod 11kv 3phasewaytobhushan100% (1)

- Logistic Plan Example Good 1Document8 pagesLogistic Plan Example Good 1Arrow LazarusNo ratings yet

- Enifix 150 MSDSDocument6 pagesEnifix 150 MSDSYASHICA VAITTIANATHANNo ratings yet

- Sr. Manager Weekly H&S Walkthrough Report 005Document11 pagesSr. Manager Weekly H&S Walkthrough Report 005abdelaziz.a.zakariaNo ratings yet

- SITRUST Brochure PDFDocument8 pagesSITRUST Brochure PDFÐôùxBébê Ðê MãmäñNo ratings yet

- GGC-HSEF 037 Site Daily ObservationDocument1 pageGGC-HSEF 037 Site Daily ObservationAmjadNo ratings yet

- Fire Safety ProgramDocument11 pagesFire Safety ProgramfayeNo ratings yet

- MEC HO-HIRAC Update As of May 10, 2023Document27 pagesMEC HO-HIRAC Update As of May 10, 2023Judes BayleNo ratings yet

- Delivery of ConcreteDocument5 pagesDelivery of Concretesikandar1234No ratings yet

- WQP012 - Spill Response 20220628Document89 pagesWQP012 - Spill Response 20220628Kevin RimmerNo ratings yet

- ZEESHAN ALI RESUME 2021 Safety AdvisorDocument4 pagesZEESHAN ALI RESUME 2021 Safety AdvisorShahid BhattiNo ratings yet

- CHDG13631 PDFDocument127 pagesCHDG13631 PDFjingning2929No ratings yet

- Mt-El-020 - Installation of Earthing & BondingDocument19 pagesMt-El-020 - Installation of Earthing & BondingkevinNo ratings yet

- Work Procedure For The Concrete Pouring of Remaining Operating Deck SlabDocument28 pagesWork Procedure For The Concrete Pouring of Remaining Operating Deck SlabResearcherNo ratings yet

- HSE Inspection Report - BlankDocument11 pagesHSE Inspection Report - BlankMohammed HamedNo ratings yet

- QSP Quality and Safety Plan For Railway Civil WorksDocument43 pagesQSP Quality and Safety Plan For Railway Civil Worksvinodshukla25No ratings yet

- A-One Consultant - Methanol & Other LicensesDocument12 pagesA-One Consultant - Methanol & Other LicensesWasim PathanNo ratings yet

- SP 2329Document119 pagesSP 2329Santosh ThakurNo ratings yet

- Bellary Off Site Emergency PlanDocument36 pagesBellary Off Site Emergency PlanVishal BarveNo ratings yet

- Handbook-Uae enDocument233 pagesHandbook-Uae enJYOTI TALUKDARNo ratings yet

- Pre-Qualification Questionnaires MBDDocument7 pagesPre-Qualification Questionnaires MBDDede ThailandNo ratings yet

- Confined Space 05Document8 pagesConfined Space 05Royal RoyNo ratings yet

- PSSR Rotating Group B Urea p2b Update 07 Agt 2015Document34 pagesPSSR Rotating Group B Urea p2b Update 07 Agt 2015cecep sumiratna hadiNo ratings yet

- Job Design & Job EvaluationDocument29 pagesJob Design & Job Evaluation428SHUBHASHEESH SAXENANo ratings yet

- HSSE Plan SATORP To Install Piping at Unit 102 Bypass Feed To Stripper in Jet SeviceDocument42 pagesHSSE Plan SATORP To Install Piping at Unit 102 Bypass Feed To Stripper in Jet SeviceOvais FarooqNo ratings yet

- 2021 PTTEP Annual SSHE PerformanceDocument44 pages2021 PTTEP Annual SSHE PerformanceBradley Moxon-HoltNo ratings yet

- HSE-P-018 - 0 Materials Handling ProcedureDocument4 pagesHSE-P-018 - 0 Materials Handling ProcedurevladNo ratings yet

- SF 1000 310 0000 FRM 002 - Prequalification HSSE Questionaire - R3Document3 pagesSF 1000 310 0000 FRM 002 - Prequalification HSSE Questionaire - R3Mohamad HafizNo ratings yet

- Day 4 PresentationDocument23 pagesDay 4 PresentationEgbin TransmissionNo ratings yet

- 390-CDM-T-00225-02.pdf (HSE M Plan Rev.2) Code 1 PDFDocument194 pages390-CDM-T-00225-02.pdf (HSE M Plan Rev.2) Code 1 PDFSumairBrohiNo ratings yet

- 16 HIRA N ERADocument19 pages16 HIRA N ERAriyazaliNo ratings yet

- Water Managment PlanDocument31 pagesWater Managment Planmehmal malikNo ratings yet

- Emergency Response PlanDocument22 pagesEmergency Response PlanJake McKeeNo ratings yet

- 2.30 S-000-1310-002 - Wind CriteriaDocument39 pages2.30 S-000-1310-002 - Wind CriteriaPravinNo ratings yet

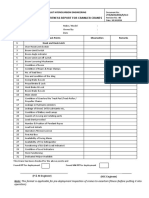

- Abrasive Blasting Inspection Checklist - Rev 00Document1 pageAbrasive Blasting Inspection Checklist - Rev 00okba labdiNo ratings yet

- Vehicle - Equipment Inspection Report - Rev 00Document1 pageVehicle - Equipment Inspection Report - Rev 00okba labdiNo ratings yet

- Pre-Use & Daily Inspection Checklist - Rev 00Document2 pagesPre-Use & Daily Inspection Checklist - Rev 00okba labdiNo ratings yet

- Equipment Fitness Report For Crawler Cranes - Rev 00Document1 pageEquipment Fitness Report For Crawler Cranes - Rev 00okba labdiNo ratings yet

- Confined Space Insection ChecklistDocument1 pageConfined Space Insection Checklistokba labdiNo ratings yet

- Heavy Equipment & Vehcile Movement - Rev 00Document13 pagesHeavy Equipment & Vehcile Movement - Rev 00okba labdiNo ratings yet

- Supplemental DocumentsDocument95 pagesSupplemental DocumentsNone None NoneNo ratings yet

- BS 6100 5 3 PDFDocument12 pagesBS 6100 5 3 PDFShaik AbdullaNo ratings yet

- Astm A 420-2020Document7 pagesAstm A 420-2020Mohammed AliNo ratings yet

- Silabo - BRIDGES AND ART WORKSDocument5 pagesSilabo - BRIDGES AND ART WORKSLuis Fernando García-zapatero BarahonaNo ratings yet

- Sl. No. Description of Equipment Equipment Code Air CompressorDocument17 pagesSl. No. Description of Equipment Equipment Code Air CompressorsivathegrateNo ratings yet

- Stainless Steel Butt Weld FittingsDocument34 pagesStainless Steel Butt Weld Fittingsmichael_mic99No ratings yet

- RCD2Document59 pagesRCD2Bobby AguilarNo ratings yet

- Petronas TowersDocument11 pagesPetronas TowersArunCoolNo ratings yet

- CTR MH Estimate-Piping-MasterDocument5 pagesCTR MH Estimate-Piping-MasterSumantra ChattopadhyayNo ratings yet

- Vertical Garden - Project ReportDocument4 pagesVertical Garden - Project ReportSubhadeep MitraNo ratings yet

- 20th Century Industrial Architectural SceneDocument117 pages20th Century Industrial Architectural Sceneद्भििय न्भिषयलNo ratings yet

- App Note PCB vs. PBT vs. Urea Comparison PDFDocument3 pagesApp Note PCB vs. PBT vs. Urea Comparison PDFcatiav5r18No ratings yet

- Business Plan Zambia - Individual InvestorsDocument11 pagesBusiness Plan Zambia - Individual InvestorsMelvin D'SouzaNo ratings yet

- Manual Compresor 1812Document76 pagesManual Compresor 1812Juan Diego Tovar MorenoNo ratings yet

- Block ShearDocument17 pagesBlock ShearDeepmalaJayeshNo ratings yet

- Workplan - Raichur PMCDocument1 pageWorkplan - Raichur PMCabhishek5810No ratings yet

- Sec613 - FalseworkDocument6 pagesSec613 - FalseworkAmr Adel HameedNo ratings yet

- DPWH MATERIALS ENGINEERING EXAM REVIEWER FOR ITEM 300 WITH NOTES FROM A MATERIALS ENGINEER LLDocument76 pagesDPWH MATERIALS ENGINEERING EXAM REVIEWER FOR ITEM 300 WITH NOTES FROM A MATERIALS ENGINEER LLWillard Apeng97% (38)

- Calculation of Bearing Plate Dimension:: Beam SectionDocument3 pagesCalculation of Bearing Plate Dimension:: Beam Sectionk.m.ariful islam100% (1)

- Bourdillon Presentation PowerpointDocument41 pagesBourdillon Presentation PowerpointAdedoyin LasisiNo ratings yet

- Tutor - Chap 6 - Analysis of StructuresDocument10 pagesTutor - Chap 6 - Analysis of StructuresMUHAMMAD AQIM MOHD SUHAIMINo ratings yet

- Tyre GripDocument2 pagesTyre GripjoebriffaNo ratings yet

- Environmental Impact Assessment and Their Mitigation Measures of Irrigation ProjectDocument8 pagesEnvironmental Impact Assessment and Their Mitigation Measures of Irrigation ProjectInternational Journal of Innovative Science and Research Technology100% (1)

- 18 Screens HouseDocument14 pages18 Screens HouseAkshay PipadaNo ratings yet

- PBA Therm Clad BrochureDocument2 pagesPBA Therm Clad BrochureJames DickinsonNo ratings yet

- 3 4 PDFDocument3 pages3 4 PDFMarjoko SantosoNo ratings yet

- Tutorial Material For Mandatory Basic Safety Training Course (Construction Work)Document22 pagesTutorial Material For Mandatory Basic Safety Training Course (Construction Work)Nirajan MarwaitNo ratings yet

- 300kVA XFMR Installation Project DrawingsDocument5 pages300kVA XFMR Installation Project Drawingsnitroxx7No ratings yet

- What Is Back PressureDocument3 pagesWhat Is Back Pressurecepong89No ratings yet

S-0200-1654-001 - 0-Permit To Work System Procedure-R1 PDF

S-0200-1654-001 - 0-Permit To Work System Procedure-R1 PDF

Uploaded by

okba labdiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S-0200-1654-001 - 0-Permit To Work System Procedure-R1 PDF

S-0200-1654-001 - 0-Permit To Work System Procedure-R1 PDF

Uploaded by

okba labdiCopyright:

Available Formats

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 1 of 45

LTHE DOCUMENT NO : S-0200-1654-001

PROJECT NAME : SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

COMPANY NAME : Sonatrach, Algeria

CONTRACT No. : CT-EPC/011/SH-EPM/EP-G/18

CONTRACTOR : L&T Hydrocarbon Engineering (LTHE)

ISSUE DATE CLOSED DATE RETURN CODE

DOCUMENT SUBMISSION STATUS – L&T HE 17-OCT-2019 DD-MMM-YY X

CA REVIEW STATUS

DOC. CATEGORY: (USE TICK MARK)

DISCIPLINE NAME E-SIGN

A R I

DELIVERABLE REVIEW LEVELS

A - Issued for Approval (IFA)

This is the highest level of review reserved for high impact deliverables or

those, which may result in financial commitment (e.g. requisitions, work

scope etc.). At this level, the reviewer must take great care to ensure that the

deliverable is indeed correct. Only one person will actually approve a

Deliverable and by signing it off the reviewer will be accountable for the

technical content of the deliverable. The design process will be on hold until

approval is granted. The CA engineer collates all the comments and returns

them to the originator

No approval = DESIGN STAYS ON HOLD

R - Issued for Review (IFR)

This is one step up the review ladder and the reviewer is expected to take

the time to thoroughly review the deliverable. The design process will be on

hold for the comment period. Project engineer collates all the comments at

the end and returns them to the originator.

No Response Within the comment Period = DESIGN PROCESS

CONTINUES

I - Issued for Information (IFI)

Documents issued for Information have in many cases been issued to assist

with the review of other documents and for general awareness of what is

proposed. Review of the documents need not necessarily be required and

failure to review will impede the design process by the design contractor.

No Response = No comment

REVIEW RETURN CODES

[CODE A] FINAL

Document accepted. Do not re-submit except modified

[CODE B] REVISE AND RE-ISSUE (RE-SUBMIT)

Incorporate comments and re-issue for review. Work may proceed.

[CODE C] REVIEW NOT REQUIRED (NOT TO RE-SUBMIT)

Incorporate comments and proceed. Do not re-issue for review

[CODE D] REJECTED.

Incorporate comments and re-issue for review. Work may( shall )

NOT proceed

01 Issued for Approval PP PP NS 17-OCT-2019

00 Issued for review PP PP NS 27-SEP-2019

Rev. Description Prepared By Reviewed By Approved By Approved Date

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 2 of 45

LTHE DOCUMENT NO : S-0200-1654-001

ISSUE RECORD / REVISION HISTORY

Rev Date Section/ Pages Description

00 27-SEP-2019 First Issue First submission to CA for review.

Section-2 Replaced SWGSP with SWGFD

Section 3.0

Added the decrees.

References and

Documents

As per PTW Procedure, the Permits are of only two types

Section 7.1 Cold (Cold Work Permit & Hot Work Permit) remaining all are

Work Permit (CWP) certificates in support of Permit. Hence, it is not specifically

01 17-OCT-2019 mentioned in PTW Flow Chart.

Section 7.1 Cold

Added the comment.

Work Permit (CWP)

The second copy of the PTW shall be retained with PTW

Coordinator, who is directly reporting to HSE Manager. The

Section11.3

PTW Coordinator will have always a copy with him and

Distribution of Permit

maintains log of all the PTWs, which can be referred in case

And Certificates

of any Emergency or any such situations. All closed PTW

are archived for future reference and Audits.

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 3 of 45

LTHE DOCUMENT NO : S-0200-1654-001

TABLE OF CONTENTS

1.0 PURPOSE: ......................................................................................................................................... 5

2.0 SCOPE: .............................................................................................................................................. 5

3.0 REFERENCES AND DOCUMENTS ................................................................................................... 5

4.0 ABBREVIATION AND DEFINITIONS: ................................................................................................ 6

5.0 ROLES AND RESPONSIBILITIES: .................................................................................................. 10

6.0 PERMIT TO WORK SYSTEM COMPONENT: .................................................................................. 15

7.0 PERMIT TO WORK FORMS AND CERTIFICATES: ........................................................................ 15

8.0 VALIDITY AND EXTENSION OF THE PERMIT: .............................................................................. 21

9.0 CLOSURE OF THE PERMIT: ........................................................................................................... 22

10.0 TRAINING AND AUTHORIZATION: ........................................................................................... 22

11.0 OPERATIONAL PROCEDURE FOR CONTRACTOR PTW SYSTEM: ....................................... 23

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 4 of 45

LTHE DOCUMENT NO : S-0200-1654-001

12.0 EMERGENCY AND CHANGING CONDITIONS: ........................................................................ 24

13.0 PTW AUDIT AND REVIEW: ........................................................................................................ 24

14.0 ACTIVITIES DO NOT REQUIRE PTW: ....................................................................................... 25

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 5 of 45

LTHE DOCUMENT NO : S-0200-1654-001

1.0 PURPOSE:

A Permit to Work system is a formal documented system used to control work, which has been

identified as potentially dangerous. It is also a means of communication between site management,

supervisors, operators and those who carry out the work.

The purpose of this procedure is to establish a controlled system of work for non-routine activities

during construction and commissioning to ensure that all the precautionary measures have been taken

prior that execution of works, which may potentially cause injuries or property damage.

2.0 SCOPE:

This PTW System will be applicable to the areas under full control of Larsen & Toubro Hydrocarbon

Engineering Limited (LTHE) and formally declared as “Green Field” by Contracting Authority (CA).

The area under SWGFD, where the PTW System procedure will be applicable includes:

• Hassi Ba Hamou and Reg Mouaded (HBH & RM) fields

• Hassi Tidjerane (HTJ & HTJW) fields

• Tinerkouk (TNK & TNKW) fields

It is the responsibility of the Resident Construction Manager to ensure that all concern personnel’s are

made fully aware of the contents of the PTW procedures and that they receive information and training

as necessary. The induction and the training shall be documented. This PTW procedure for

construction and commissioning works for SWGFD shall be followed by all CONTRACTOR and

Subcontractors personnel.

3.0 REFERENCES AND DOCUMENTS

• 11EPG18-0000-AP-X-00 OO 001 - Project HSE Plan

• Annex – 11 of SWGSP Contract.

• Law 88-07 relating to health, Safety and Occupational medicine.

• Executive decree N 91-05

• Executive decree No 02-427

• Executive decree No-05-08

• Permit to Work Procedure of the group Sonatrach.

• Executive Decree No. 01-342

• Executive Decree No. 05-117

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 6 of 45

LTHE DOCUMENT NO : S-0200-1654-001

4.0 ABBREVIATION AND DEFINITIONS:

ABBREVIATIONS:

AEP - Authorized Electrical Person

AGT - Authorized Gas Tester

ALARP - As Low As Reasonably Practicable

ARH - Hydrocarbons Regulatory Agency

CA - CONTRACTING AUTHORITY

CPF - Central Processing Facility

CRA - Commissioning Restricted Area

CSE - Confined Space Entry

CWP - Cold Work Permit

ELCB - Earth Leakage Circuit Breaker

EPC - Engineering Procurement & Construction

ERP - Emergency Response Plan

GSR - Golden Safety Rules

HWP - Hot Work Permit

HSE - Health Safety & Environment

HSEMS - Health Safety Environment Management System

HEMP - Hazard and Effect Management Process

IA - Issuing Authority

LEL - Lower Explosive Limit

LOTO - Lock Out and Tag Out

LTHE - L&T Hydrocarbon Engineering

MSDS - Material Safety Data Sheet

PA - Permit Applicant

PC - Permit Coordinator

PPE - Personal Protective Equipment

PSV - Pressure Safety Valve

KPI - Key Performance Indicators

RCM - Resident Construction Manager

PA - Permit Applicant

PD - Project Director

PPM - Parts Per Million

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 7 of 45

LTHE DOCUMENT NO : S-0200-1654-001

PTW - Permit to Work

RPE - Respiratory Protection Equipment

RPS - Radiation Protection Supervisor

SCBA - Self-Contained Breathing Apparatus

SIMOPs - Simultaneous Operations

STEL - Short Term Exposure Limit

STOP - Safety Training & Observation Program

SWGFD - South West Gas Fields Development

TBT - Tool Box Talk

TCF - Temporary Construction Facility

TRA - Task Risk Assessment

TLV - Threshold Limit Value

TWA - Time Weighted Average

DEFINITIONS:

As Low as Reasonably Practicable (ALARP)

Acronym of As Low As Reasonably Practicable ALARP is a demonstration that the risk of a favorite

option, are acceptable and/or comparable to other similar developments.

It requires consideration of all the hard and soft issues related to the range of options and a judgment

decision with the full knowledge of all the option and their associated risks

and costs. Represents the level or risk reduction at which the time, trouble, difficulty and cost of further

reduction measures become unreasonable disproportionate to the additional risk reduction to be

obtained. ALARP is determined through cost benefit analysis).

Authorized Electrical Person

A competent Contractor electrical person who is having sufficient technical knowledge and has been

authorized by the Contractor Resident Construction Manager to carry out an Isolation/ De-Isolation

work on electrical systems, apparatus and equipment.

Authorized Gas Tester

A Contractor or Subcontractor employee of supervisory level other than the Permit Accepter at the

discretion of Permit Issuer, who is authorized by CONTRACTOR after satisfactory completion of the

Gas Testing Training and Certification.

Cold Work

Cold works are frequently used to cover a variety of activities which are not a type covered by the more

specific activities such as opening lines or equipment, painting, insulating work, equipment inspection

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 8 of 45

LTHE DOCUMENT NO : S-0200-1654-001

involving energy isolation or guard removal and the use of non-spark producing hand tools require cold

work permit,

Confined Space:

Any area that has:

• Limited access or egress,

• Not designed for normal human occupancy;

• Large enough for at least one person and work inside;

• Because of design or hazards present, can hamper the ability of a person to escape

• May posse hazards like accumulation of flammable or toxic gases or vapours, oxygen deficient

or enriched environment, inadequate lighting, ventilation etc.

Contractor

L&T Hydrocarbon Engineering Ltd.

Excavation

Any man-made cut, cavity, trench, or depression in the earth’s surface formed by earth removal.

Fabrication Shop

Any work shop that produces hot work as part of its normal duties. Fabrication Shops will be inspected

and Audited by the HSE department prior to use and regularly thereafter.

Fire Watch

A CONTRACTOR or Subcontractor individual who is trained in firefighting and who is responsible for

monitoring the working area, normally under hot work conditions and particularly when high-energy

sources of ignition are applied.

Hazard

Hazard is the potential to cause harm, including ill health and injury, damage to property, products or

the environment, production losses or increased liabilities.

Hot Work

Any job within the Contractor area of work, wherein the heat generated is of sufficient magnitude and

intensity to cause ignition of any flammable liquids, gases or any other material. Common sources of

ignition are internal combustion engines, gas-cutting torches, welding machines, non-flame proof

electrical equipment, grinders, annealing blankets, jackhammers, Radiography activities, etc.

Isolation

Means of rendering electrical circuits, plant, equipment and/or process systems, as detached from

potential sources of energy

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 9 of 45

LTHE DOCUMENT NO : S-0200-1654-001

Lock Out & Tag Out (LOTO)

A mean to partially or entirely isolate a piece of equipment, plant or process to allow work to proceed

safely on an alternative section of the equipment, plant or process.

Non Routine Works

Activities carried out as a part of and / or combination of works during construction at work at TNK, HTJ

& HBH areas and Pre commissioning / Commissioning which are required to be controlled through an

appropriate & authorized Permit to Work.

Permit to Work

The means of providing the formal written instructions, and authorization to the personnel carrying out

the hazardous job or a defined job in a hazardous environment, or both.

Permit Applicant

A trained & competent person authorized by the Resident Construction Manager to apply for the permit

and be responsible for planning, supervising & executing the work safely.

PTW Coordinator

A CONTRACTOR employee who is qualified in CONTRACTOR PTW System and who administers the

Permits; he has no formal signing role on the CONTRACTOR PTW System. The Work Permit

Coordinator is responsible to insure that the PTW Procedure is followed, permits are distributed,

opened and closed as to procedural requirements, insuring that permits are correctly completed by the

Issuing and Permit Applicant/Job Originator and finally archived.

Permit Issuing Authority (Permit Issuer)

A trained & competent person authorized by the Resident Construction Manager to validate / issue the

permit.

Permit Office

It is a designated location from where Permits are issued and recorded. All the permits to be applied

and issued from permit Office.

Radiography

Work involving radioactive sources.

Routine Works

Activities carried out as a part of day-to-day Camp, Warehouse, Workshop and Batching Plant

operational requirement. A routine work activity would not normally require a work permit; but must be

carried out under general supervision with the recognized trade skills and competency in place.

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 10 of 45

LTHE DOCUMENT NO : S-0200-1654-001

Stand by Person (Confined Space Attendant)

A person whether Contractor or Subcontractor (other than the Permit Applicant) who is trained in

confined space, rescue procedures, communications and B.A use.

Sub-contractor

Firm awarded with a Subcontract by CONTRACTOR to provide Services for the PROJECT.

Task Risk Assessment (TRA)

It is a systematic approach conducted by a team of Permit Applicant, Permit Issuer, HSE

Representative, Work Supervisor and other members (as required) to identify hazards and the

necessary control measures required prior to issuing PTW/ Certificate for any high risk jobs. The TRA

must be prepared in advance, documented and attached to PTW.

The key risks and precautions identified during the TRA shall be considered as part of in the PTW and

communicated to the Permit Issuer. Permit Applicant or Work Supervisor should communicate hazards

and precautions to his work crew during the TBT and prior commencing the task.

Tool Box Talk

It is a short safety briefing which must be given at the work site to all personnel involved in the work

controlled by the PTW/Certificate immediately prior to commencing the job.

Supplementary Certificates

Additional certificate that has to be issued together with the “Permit to Work”.

Supplementary certificates include:

• Confined Space Entry Certificate

• Radiography Certificate

• Excavation Certificate

• First Energization Certificate

• Road Closure Certificate

• Lifting Certificate

• Pressure Testing Certificate

• Electrical Isolation/ De-Isolation Certificate

5.0 ROLES AND RESPONSIBILITIES:

RESIDENT CONSTRUCTION MANAGER (RCM):

The RCM will be responsible for ensuring the effective administration of this procedure within

Construction site activities and shall ensure that this procedure is properly implemented at site.

• He shall ensure that all work is carried out under the controls of Permit to Work System.

• To ensure that sufficient funds and recourses are made available to ensure the continuity of this

procedure for the duration of the works;

• Verify that providing the correct information and equipment for the scope of work;

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 11 of 45

LTHE DOCUMENT NO : S-0200-1654-001

• Ensure training and testing are given to all concern persons requiring to use a Permit to Work;

• Nominate personnel and authorize them to perform the duties of permit to Work Signatories;

• He shall empower all the personals involve in this project to stop the work if it’s not safe,

HSE MANAGER:

HSE Manager shall:

• Monitor that proper instruction, training is provided at all times;

• Monitor that suitable and sufficient inspections / audits are carried out by competent personnel,

and that proper records are maintained;

• Monitor that work is carried out in accordance with this procedure;

• Monitor that the conditions are satisfactory for the work to proceed;

• Monitor that each item on the permit is accurately filled out and covered;

• Monitor that personnel understands the requirements on the permit and any unusual conditions

connected with the job;

• Continue monitoring of the work area conditions and to stop, the environment and/or equipment

to convey pertinent information about the work to the relievers;

• Advise the contractor Project Manager/construction manager for any irregularities or areas of

concern in order to identify any necessary corrective action;

PERMIT APPLICANT (PA):

Permit Applicant is the person responsible for applying the PTW and supervising the work specified in

the PTW. For the majority of works on the Project, the PA will be the Work Supervisor of the

Subcontractor directly responsible for the work stated in the permit.

The PA must be able to speak, read and write English at a level sufficient to understand the

requirements of the permit. PA shall be appropriately trained in the requirements of Contractor’s permit

to work procedure and authorized by Contractor’s HSE Department.

The Permit Applicant shall responsible for:

• Involvement in preparation of Task Risk Assessment (TRA) as required by CONTRACTOR.

• Apply for required PTW & Supplementary certificates.

• Shall attach the Signed TRA, Work Method Statement and other supporting document- if

applicable- with the submission of the permits.

• Communicate his work crew about the requirements stated in the permit through daily TBT and

attendance is completed for every permit.

• Ensure the requirements specified in the permit are implemented prior to the commencement

of the work.

• Shall remain at the work location to supervise the work at all times while the work is in progress.

• Request a new permit in the event a change in the scope, location or equipment / machineries

of the work. The new permit shall be obtained before work required by the new scope is

undertaken.

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 12 of 45

LTHE DOCUMENT NO : S-0200-1654-001

• Whenever site conditions are drastically changed such as to create a hazard, the Permit

Applicant shall immediately stop the work and inform the Permit Issuer (Issuing Authority) of the

change and await further instruction from him.

• Upon the occurrence of an emergency, the Permit Applicant shall immediately stop the work

and follow emergency procedures.

• Upon resolution of the emergency, the Permit Applicant shall have the PTW revalidated before

resuming work.

• Report the completion of the work or the expiration of the validity of the permit to the Permit

Issuer (Issuing Authority) and ensure that the site is duly reinstated without any remaining risks.

• If the work in progress extends beyond the validity stated in the permit, the Permit Applicant

shall request the issue of a new permit before the expiry of the original permit.

• Closed and suspended work permits & certificates shall return to the PTW Coordinator for

record keeping.

During the validity of a permit, in circumstances Permit Applicant may require leaving the work location

and need to be replaced. In such cases; responsibility shall be transfer to new incoming Permit

Applicant and permit shall be signed off by incoming Permit Applicant, Permit Issuer (Issuing Authority).

The incoming Permit Applicant then takes over the responsibility to ensure the work permit

requirements are adhered to.

Whenever Gas Test is required, Permit Applicant on the same permit / certificate CANNOT be an AGT.

PERMIT ISSUER / ISSUING AUTHORITY (IA):

Permit Issuer or Issuing Authority is person authorized to Issue the Permit. For green field areas under

CONTRACTOR’s control, the RCM, Area In-charge / Discipline Engineer can be the Issuing Authority.

All Issuing Authority shall successfully complete the Contractor’s Permit to Work Training and to be

authorized to sign the permits in his areas of responsibility by RCM and CONTRACTOR HSE Manager.

CONTRACTOR will develop and maintain a list of nominated personnel allowed to sign permits. The

list of Issuing Authorities shall be provided to CA Representative, when requested.

Issuing Authorities role & responsibilities are as follows:

• Review the PTW applications, Certificate and supporting document such as Work Method

Statement, TRA & drawings.

• The Issuing Authority has the sole authority to issue/, approve, and cancel the permit.

• The Issuing Authority shall be fully aware of site conditions, the type of work to be carried out

and all the requirements stated in the permit.

• Ensures that gas tests and precautions are acceptable for the job to start/ continue safely.

• Whenever required, the Issuing Authority shall consult with the CONTRACTOR’s HSE Lead at

site to ensure all required safety precautionary measures are stated in the permit are adequate.

• Prior to approving a permit, the Issuing Authority shall conduct an onsite inspection jointly

together with the Permit Applicant to ensure that the Site conditions are safe to conduct the

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 13 of 45

LTHE DOCUMENT NO : S-0200-1654-001

work; that there are no interferences either to or from other work groups near the vicinity and

ensure that all the requirements stated in the permit are implemented.

• The Issuing Authority shall withhold approval of the permit & certificates if the requirements are

not met, or Site conditions are not safe for the work to be carried out.

• Ensures that Permit Applicant conducted effective Tool Box Talks for work team and people are

aware of emergency procedure.

• Once informed that the work is complete, the Issuing Authority shall visit the Site jointly with the

Permit Applicant to ensure that the work has ceased, area has been cleaned and the site is duly

reinstated without any remaining risks prior to closing the permit as per the requirements of this

procedure.

Note:

• Both Issuing Authority and Permit Applicant are responsible for the safe execution of the work.

• The Permit Applicant shall under no circumstance, either by his own discretion, or that of his

work crew, change the original scope of the work, which is described in the permit.

• The Permit Applicant cannot be the Issuing Authority or the Gas Tester for his own job.

• The numbers of the work crew within one PTW shall be limited as possible. However,

consideration should be given to worksite location, visibility of work crew and the area covered.

RCM and CONTRACTOR HSE Manager shall jointly decide the number of permit that can be

issued to a single Permit Applicant.

PERMIT COORDINATOR (PC):

The designated CONTRACTOR’s Permit Coordinator reports to the CONTRACTOR Site HSE Manager

or his delegate about the work permits including review/ verification of the permits forms, supporting

document such as Work Method Statement & TRA submitted by Permit Applicant.

He is responsible for clerical control of the permit to work system including retention of the closed out

Work Permits until the end of the Project and notification of expired permits that have not been closed

out.

The PC will be holder of the Work Permit & Certificates Register. All Permits shall be registered daily

before they are handed over to the Permit Applicant.

When a Permit & Certificate is closed / suspended the Permit Coordinator must update the Permit

Register database accordingly.

• The PTW Coordinator shall maintain an up to date register of Permit Signatories (Permit

Applicant, Issuing Authority, AGTs, Authorized Electrical Person).

• The PTW Coordinator shall maintain an up to date register of Permit Violations.

• Review the TRA submitted by Subcontractors/ Disciplines.

• Participate in TRA Review session/ workshop.

• Maintain up to date register of approved TRA’s.

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 14 of 45

LTHE DOCUMENT NO : S-0200-1654-001

AUTHORIZED GAS TESTER (AGT):

Authorized Gas Testers (AGT) shall specifically be trained and certified by CONTRACTOR HSE

Trainer. He shall be authorized to use portable gas testing equipment like multi gas detector to measure

the atmospheric concentration of Toxic Gas, Flammable Gas (LEL), Oxygen Level, Carbon Monoxide

etc. and interpret the results.

A list of the trained and authorized AGT’s must be maintained CONTRACTOR HSE Department. The

AGT after completion of training and successfully passing the assessment shall be issued with an

Authorization Card by CONTRACTOR HSE Manager.

Subcontractors shall not perform gas tests for another Subcontractor’s activity.

All gas detectors shall be tested and calibrated in accordance with the manufacturer’s guidelines. A

copy of the valid certificate shall be available with equipment for reference.

In case the concentration of any gas is detected outside of the permissible level of concentration, the

AGT shall withhold the permit and immediately inform the Issuing Authority and conduct retesting.

Should the re-test also show levels in excess of these concentrations then additional means of

ventilation shall be deployed, fans, air movers etc.

Gas tests shall be carried out:

• Before any entry into a Confined Space and before re-validation of main work permits. The

Issuing Authority shall decide the frequency.

• Before any Hot Work (if recommended by Issuing Authority or HSE Lead)

• Works near any live facility, well heads etc.

All AGT personnel must successfully complete the CONTRACTOR’s PTW Training before they will be

permitted to sign permits.

Gases to be checked Permissible range

H2S Concentration Below 10 ppm (if available)

LEL (Lower Explosive Limit) Below 5%

Oxygen (O2) 19.5 – 22.5 %

AUTHORIZED ELECTRICAL PERSON (AEP):

A person from Contractor’s Electrical Discipline who either applies the locks and tags on Energized

Electrical systems/ Equipment in order to perform servicing or maintenance on specific Electrical

System/ sub-system or equipment requested by Permit Applicant and authorized to sign the Electrical

Isolation/ De-Isolation Certificate.

Only CONNTRACTOR HSE approved Padlocks & Tags shall be used for Isolation purpose and a

minimum of two padlocks shall be installed when the isolation is required for work.

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 15 of 45

LTHE DOCUMENT NO : S-0200-1654-001

HSE LEAD / ENGINEER / OFFICER (HSE PERSONNEL):

HSE Personnel assigned in an area shall conduct an inspection of the job site to verify that the all safety

precautions detailed in the permit and supporting documents are implemented prior to endorse the

PTW.

He shall assess the adequacy of safety precautions mentioned in permit, TRA and certificates and

provides specialized safety advice to the Permit Applicant and Issuing Authority, if required.

HSE Personnel is not an Issuing Authority at any circumstances for permits and certificates.

Daily permit checks & Permit to work compliance audits on a regular basis (minimum 3 permits a week

by each CONTRACTOR’s area HSE Personnel) shall be performed and communicate findings and

lessons learned to respective Issuing Authority & Subcontractors for corrective action. Records shall

be maintained by Permit Coordinator.

6.0 PERMIT TO WORK SYSTEM COMPONENT:

Under this procedure individual Permit to Work forms and certificates are issued for works as described

in Section- 7.0.

The permit to work consists of a document which:

• Details the work to be done;

• Location and dates and time of work to be done;

• Details of equipment and tools to be used; States that all foreseeable

• hazards have been noted;

• Details the precautions to be taken;

• States the control measures to be implemented;

• Identify person responsible.

Permit to work do not itself make a job free from risk: they rely upon effective control and Coordination

in order that hazards are identified and risks are suitably and sufficiently assessed and eliminated/

controlled.

7.0 PERMIT TO WORK FORMS AND CERTIFICATES:

The activities covered by the PTW are managed by Two (2) main types of Work Permits Forms.

• Hot Work Permit

• Cold Work Permit

In addition to the work permits required by this procedure, the activities requiring Confined Space Entry,

Excavations, Radiography, Heavy /Critical Lifting, Energization, Isolation/ de-isolation of energized

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 16 of 45

LTHE DOCUMENT NO : S-0200-1654-001

systems, Pressure Testing, Road Closure shall be conducted utilizing a Certificate attached to the

permit to work.

• Confined Space Entry Certificate

• Radiography Certificate

• Excavation Certificate

• First Energization Certificate

• Road Closure Certificate

• Lifting Certificate

• Pressure Testing Certificate

• Electrical Isolation/ De-Isolation Certificate

Each PTW and Certificates shall be uniquely and individually numbered for identification purposes and

shall comprise Three (3) multi-sheet forms.

Every application for a PTW must have attached to it as a minimum the following supporting

documentation:

Work Method Statement (WMS)

Task Risk Assessment (TRA)

Marked up Drawings showing the work area (if required)

Material Safety Data Sheet (MSDS) where applicable

Other items that may be required include but are not limited to:

o Isolation details, LOTO

o Rigging / Lifting Plan

o Pressure testing risk dossier

o Decay Chart

No certificates will authorize to proceed with an activity therefore; all certificates shall be used in

conjunction with one of the Main Work Permit form (CWP or HWP).

COLD WORK PERMIT (CWP):

A cold work permit is required for all construction and maintenance work where no open flames are

introduced.

Some typical examples are, but not limited to:

• Spading and de-spading of systems under pressure or which contain substances which

are flammable, toxic or corrosive

• Scaffolding Erection, Dismantling and modification;

• Chemical cleaning

• Handling of hazardous substances e.g., radioactive sources, toxic corrosive/flammable

chemicals.

• Painting operations.

• Working at Height

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 17 of 45

LTHE DOCUMENT NO : S-0200-1654-001

• Work on isolated electrical equipment.

As part of the work activity usages of portable diesel engines, vehicles and cranes in any green field

areas does not required a separate Cold Work Permit, but it shall be mentioned in work permit form

Section-1 “Tools and Equipment To Be Used”. However, a formal Risk Assessment shall be carried out

for such activities and based on the risk level, control and mitigation measures shall be ensured.

Attachment - 2. Cold Work Permit Form

HOT WORK PERMIT (HWP):

A Hot Work permit is required for all work involving explosive devices, and all open flame activities (i.e.:

welding, cutting, grinding etc.).

Tasks that would require a hot work permit are as below examples, which include but are not limited

to:

• Welding

• Flame cutting

• Grinding / Cutting

• Grit blasting

• Use of powered steel wire brushes

• Metal cutting, chipping

• Heat treatment using electrical coils,

Use of powder-actuated tool cartridges for fixing or drilling operations requires a Hot Work Permit. The

activity shall be appropriately risk assessed and operators of such equipment shall be trained in the

operation of the equipment by the vendor / supplier or CONTRACTOR HSE Trainer.

As part of the work activity usages of portable diesel engines, vehicles and cranes in any green field

areas does not required a separate Hot Work Permit, but it shall be mentioned in work permit form

Section-1 “Tools and Equipment To Be Used”.

Attachment 3. Hot Work Permit Form

CONFINED SPACE ENTRY (CSE) CERTIFICATE:

A confined space is defined as an area that:

• Has limited or restricted means of entry or exit

• Is large enough for an employee to enter and perform assigned work, and

• Is not designed for continuous occupancy by the employee.

These spaces may include, but are not limited to, underground vaults, tanks, storage bins, pits and

diked areas, vessels, sewers, and silos.

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 18 of 45

LTHE DOCUMENT NO : S-0200-1654-001

A Confined Space Entry certificates is required for the protection of personnel entering vessels, tanks,

furnaces, sewers, pits over 1.2 meter deep and other confined spaces within the Construction areas.

A Confined Space Entry Permit must be issued in all areas if personnel are to work in excavations over

2 meters deep and narrow width (width to depth ratio less than 2).

Entering into a confined space for visual inspection is not exempted from the requirement of this

procedure.

Attachment- 4. Confined Space Entry Certificate

Attachment- 5. Confined Space Entry Log Sheet

Attachment- 6. Supplementary Log Sheet for Gas Test

EXCAVATION CERTIFICATE (EXV):

All excavations, regardless of depth, require an Excavation Certificate and a Work Permit. Excavation

means any breaking of ground or cutting into floors.

Excavation Certificate (Attachment - 7) shall be obtained when working inside the areas controlled by

CONTRACTOR. This also includes any cutting into ground or floors below surrounding level where

there is the risk of damage to existing services or harm to personnel.

Where an excavation is deeper than 2 meters deep and narrow width (width to depth ratio less than 2)

and personnel to be enter, a confined space entry certificate shall be obtained in addition to Excavation

Certificate.

Review of underground services shall be completed by Contractor Civil / Mechanical & E&I Department

and to be signed on the Excavation Certificate.

HEAVY / CRITICAL LIFT CERTIFICATE (HCL):

Heavy and Critical Lifts shall be conducted under a Lifting Certificate.

Heavy and Critical lifts are defined as:

• Heavy Lifts: Any lift where the payload weight is 10 tons or greater.

• Critical Lifts:

− Any lift that exceeds 80 percent of crane’s chart capacity;

− Any multiple-crane lift;

− Any lift over operating plant or occupied facilities, process pipe racks, or near power

lines.

− Any lift involving a complex rigging arrangement or that requires specialty rigging.

Note: - CONTRACTOR Project management may classify any lift that involves sensitive or costly

equipment as critical.

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 19 of 45

LTHE DOCUMENT NO : S-0200-1654-001

Attachment-13- Heavy & Critical Lift Certificate

Attachment-14- Simple Lift Plan

All lifting activities shall be suspended, if the wind exceeds 32 km/h (20mph, 9 m/s, 17 knots), or the

crane limitation due to manufacturer specifications.

RADIOGRAPHY CERTIFICATE (RC):

Any work requiring the use of radioactive sources or x-ray machines for NDE works requires a

Radiography Form.

The Radiography Certificate shall be used in conjunction with a Hot Work Permit.

Attachment-8: Radiography Certificate

Precautions prior to issuing Radiography Certificate & Safe Work Practices:

Before issuing the Radiography Form, the following precautions shall be taken:

• Barriers erected and radiation signs posted at all access points to the radiation work area.

• Area cleared of all non-essential personnel.

• Amber flashing lights sited at barriers.

• Red flashing light sited at source.

• Communication made available/provided.

• Safe access and egress provided to/from source.

FIRST ENERGIZATION CERTIFICATE (FEC):

The First Energization Certificate is required any time that an electrical item, such as panel boards,

cabinet, transformer or equipment is to be energized for the first time.

Re-starting an electrical equipment/ system/ subsystem after the first energization; do not required First

Energization Certificate.

The First Energization Certificate shall be used in conjunction with a Hot Work Permit.

Precautions prior to issuing First Energization Certificate & Safe Work Practices:

Before issuing the First Energization Certificate, the following precautions shall be taken:

• Discipline clearance must be obtained prior to energization of any electrical installations

• Earthing connected to the equipment shall be tested. Test results to be cross verified

• Affected area shall be cordon-off and signage to be in place

• Firefighting equipment shall be in place & in operational.

Attachment-9: First Energization Certificate

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 20 of 45

LTHE DOCUMENT NO : S-0200-1654-001

ROAD CLOSURE CERTIFICATE (RCC):

Any activity that require to closure of an existing or/ and common access road regardless of the full

road closures or partial road closures, within the Contractor’s premises shall require a Road Closure

Certificate.

Partial road closure involves the closure of one side of the freeway during the construction activities,

movement of the heavy cranes or transportation of the heavy loads through a common/ existing access

road. Traffic is shifted to the other side of the freeway, rather than detoured, which distinguishes this

type of closure from full closure.

Closing of the road other than the common access road, which will not affect to the normal movement

of the vehicles/ construction equipment shall not require a Road Closure Certificate.

All the road closure shall co-ordinate with Area In-charge and to be verified by CONTRACTOR’s HSE

Lead prior to approve the road closure.

A detour for vehicles and pedestrians shall be made available when require a full road closure.

Attachment-12. Road Closure Certificate

PRESSURE TEST CERTIFICATE (PTC):

All hydraulic or pneumatic pressurization activities shall be carried out under Pressure Test Certificate.

Strict controls are to be implemented, including but not limited to:

• Risk Management Dossier (Containing all technical details of equipment to be used,

systems to be pressurized, SIMOPS, flange certificates, equipment certificates, etc.)

• Approved Method of statement and TRA,

• Valid Certificate for PSVs,

• Correct barriers and exclusion zones are in place.

• A comprehensive pre-test checklist is prepared and complied.

• Advance notifications to all parties, which could be affected.

• Critical systems to be tested to be identified (i.e. analyzer systems)

• Trained Technicians,

CONTRACTOR personnel shall directly accountable and responsible for all tests. The system/

subsystem/ tubing to be tested shall be marked with RED and WHITE marker tape. A signboard shall

prominently display at the test site indicating “Hydraulic/ Pneumatic Pressure Testing in Progress, Do

Not Enter or Authorized Access Only”.

Wherever possible, pneumatic tests shall be conducted on Fridays and / or during night shift to reduce

the exposure of personnel.

Attachment-11: Pressure Test Certificate

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 21 of 45

LTHE DOCUMENT NO : S-0200-1654-001

ELECTRICAL ISOLATION / DEISOLATION CERTIFICATE (EIC):

Any work requiring the isolation or de-isolation of energized electrical systems under the construction

within the Contractor’s premises shall be completed under an isolation/ de-isolation certificate. This

includes any work on any system/ subsystem/ equipment capable of being electrically charged or

activated.

Electrical Isolation / De-Isolation Certificate is a supporting document that requires to complete an

activity on an energized system, therefore it does not required to use in conjunction with a Main Work

Permit.

Following sequent shall follow when obtaining the Electrical Isolation.

• Part 1 in Electrical Isolation Certificate shall be completed by Permit Applicant and shall hand

over to PTW Coordinator.

• Contractor’s PTW Coordinator shall verify the certificate and to be handed over to the

Contractor’s Authorized Electrical Person.

• When the Isolation completed and relevant section signed-off by Contractor’s Authorized

Electrical Person, Isolation/ De-Isolation Certificate shall handed-over to the Permit Applicant.

• When job completed & requesting for De-Isolation, Part-5 of Isolation Certificate shall be signed

off by Permit Applicant and handed-over to Contractor’s Authorized Electrical Person.

• Contractor’s Authorized Electrical Person shall complete De-Isolation and certificate shall be

closed along with Main Work Permit.

Attachment-10: Electrical Isolation/ De-Isolation Certificate

8.0 VALIDITY AND EXTENSION OF THE PERMIT:

A PTW is normally issued on a daily basis (maximum 12 hrs.), i.e. a new permit must be issued or

extension must be obtained in the event of shift changeover.

A Certificate which shall be used in conjunction with a Main Work Permits does not required

revalidation, as Certificates are supported by Main Work Permit therefore revalidation shall obtain in

main work permits.

The date and time of the permit will be clearly specified on the form. If the validity of the permit extends

beyond one shift, then the permit shall be re-validated by the Issuing Authority, Permit Applicant and

AGT as required at the start of the oncoming shift.

Main work permits are valid for SEVEN (7) consecutive days and requires revalidation if work extends

more than one shift. On completion of seven days, the permit shall be closed if the work is completed

else transferred to new permit. The old permit number shall be mentioned in the new permit.

No one should authorize/ issue a work permit for work they will carry out themselves.

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 22 of 45

LTHE DOCUMENT NO : S-0200-1654-001

Re-validation is also required:

• Before work is resumed after a verified actual Emergency Alarm

• When there is a significant change in the conditions as specified on the permit

• If work is continued into the extended hours, the permit must be re-validated

In order to improve the re-validation process, persons involved shall be requested to perform all

necessary re-validation tasks in a timely manner.

Note: Where a transfer of responsibilities takes place; in “PERMIT REVALIDATION” of the work permit

form shall be signed off by incoming Permit Applicant & Issuing Authority. The incoming Permit

Applicant then takes over the responsibility to ensure the work permit requirements are adhered to.

9.0 CLOSURE OF THE PERMIT:

On completion of the work, the Permit Applicant shall signify that the work is complete and that he wish

to close the permit & certificate, by signing in the correct space on the permit and certificate and

returning the permit to the Issuing Authority. The permit is only considered closed when signed by the

Issuing Authority and after the Issuing Authority has visited the Site and confirmed that the worksite

has been left in a safe condition.

The closed permit must be returned to the CONTRACTOR’s PTW Coordinator before the end of the

day of its closure.

10.0 TRAINING AND AUTHORIZATION:

All Permits to Work Signatories are required to attend the CONTRACTOR’s Permit to Work Training

courses and shall pass an accompanying written assessment with minimum of 80% marks.

Further, signatories qualified in Contractor’s PTW system will be assessed by CONTRACTOR HSE

Manager and RCM or their delegates.

All signatories must be sufficiently conversant with written and spoken English to enable them to

understand the requirements that the CONTRACTOR places on them and their workers.

Individuals violating Work Permit, Certificate, and Method Statement, Task Risk Assessment or Hazard

Identification Process conditions may be subject to disciplinary actions.

Individuals who have not complied with the PTW procedures must undergo refresher training before

they are allowed to sign further permits. No signatory will be permitted to undergo more than two

refresher courses before he is removed from the authorized list permanently.

Attachment- 16. PTW Signatories Assessment Form

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 23 of 45

LTHE DOCUMENT NO : S-0200-1654-001

11.0 OPERATIONAL PROCEDURE FOR CONTRACTOR PTW SYSTEM:

GUIDANCE ON PREPARING THE PERMIT:

All permits will be serially numbered and have one (1) Original and two (2) Copies.

PTW is initiated by filling the Work Permit Form of a Work Permit (Hot Work Permit or Cold Work

Permit).

This shall be done in advance at the planned time for the commencement of the work, ideally within

14.00 O’clock of day before to the CONTRACTOR’s PTW Coordinator. This will enable the Issuing

Authority to review the work permits, visit the work site, and arrange for work site preparation and to

lay down conditions/ limitations when preparing the permit.

CONTRACTOR’s Work Permit Approval Flow Chart is represented in Attachment – 1

RULES ON PERMIT TO WORK PROCEDURE:

• Permit Applicant prepares the PTW request and shall produce the permits to the

CONTRACTOR PTW Coordinator.

− The description of the work shall be a precise statement of the planned activity and

the location of the work by identification of the area or equipment to be worked upon.

− Equipment used must be clearly mentioned (stated) on the Work Permit. It must be

specific.

− Multiple scopes of work, which are not relevant, are not acceptable. Example- a cold

work permit for Scaffolding Erection and Excavation cannot be requested in a single

permit.

− Approved copies of Method Statements, Task Risk Assessments shall be attached

to form part of the permit

• The Permit Applicant shall then submit the permits to the PTW Coordinator & Issuing

Authority in advance maximum by 14:00 hrs. day before the planned activity.

• Issuing Authority reviews the PTW request.

• PTW Coordinator review and registers the permit in the PTW database.

• On the day of the work, the Issuing Authority visits the work location to ensure that all

requirements in the permit are met before issuing the permit.

• The Work Permit must remain on the job site in a conspicuously visible place while work is

ongoing.

• If emergency occurs, the permit must be withdrawn immediately and all works must be

stopped without any question.

• When extension of permit is required; permit shall be signed off by Permit Applicant, Issuing

Authority and Contractor’s Field HSE Personnel.

• To extend time Work Permit and/or certificate beyond one shift, the incoming shift Issuing

Authority and Permit Applicant shall inspect the job site and sign the work permit;

• The Work Permit and certificate, if any must be closed out after a job is completed. Issuing

Authority and Permit Applicant shall inspect the job site and sign off the work permit.

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 24 of 45

LTHE DOCUMENT NO : S-0200-1654-001

• Permit Applicant is not authorized to sign/ receive multiple permits in various areas of the

site at a time.

• Permit Applicant shall always be at work location during the job covered by a work permit.

DISTRIBUTION OF PERMIT AND CERTIFICATES:

Original : With Permit Applicant (On work site)

First Copy : To be retained by Issuing Authority throughout the duration of the work.

Second Copy : It remains in the Contractor’s PTW Coordinator (Permit Office).

12.0 EMERGENCY AND CHANGING CONDITIONS:

In the event of an emergency such as activation of site/ plant alarm or a fire/ explosion incident, the

Permit Applicant shall, on hearing the alarms, immediately stop all works and shut down all equipment

before moving to the appropriate Assembly Point/ Safe Area.

All the permits will be suspended. Once the emergency is over, the permit shall be closed and handover

to PTW Coordinator. A new PTW shall be issued. Prior to the issuance of a new permit, the Issuing

Authority shall visit the worksite to ensure that there is no imminent hazard/ risk present and that the

work site is safe to work

All workers have the right to stop work should they find after inspection of the work site and work

methods that the conditions listed in the permit are not being followed or that a significant hazard exists.

Should the work conditions change significantly e.g., underground services being found where not

expected, a positive gas reading in excess of the levels mentioned above, or other such circumstances,

the work must be immediately stopped and the Issuing Authority informed. In such cases, the permit

will be reviewed and if necessary cancelled and a new PTW issued taking account of new

circumstances.

13.0 PTW AUDIT AND REVIEW:

The Permit to Work System is subject to continuous re-assessment and regular review. The permit

audit should be performed to identify lapses in the permit system and rectification shall be advised by

the auditor and necessary actions for rectification must be taken by Permit Applicant & Issuing Authority

in Coordination with CONTRACTOR HSE Department.

The permit audit form shall be established and provided for such audits. Contractor shall develop

reporting & Tracking system and audit main or significant findings shall be recorded in the tracking

system to ensure that the auditor considers and reviews all aspects of a permit and allow comparison

with company or/and external audit results.

ALL RIGHTS RESERVED

THIS DOCUMENT IS DEVELOPED BY LTHE AND INFORMATION CONTAINED IS PROPERTY OF SONATRACH-ENC. IT SHALL NOT BE USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT

WAS SUPPLIED, CONFIDENTIAL - NOT TO BE DISCLOSED WITHOUT AUTHORIZATION

SOUTH WEST GAS FIELDS DEVELOPMENT PROJECT, ALGERIA

Realization of Gas Treatment Units (EPC 2 – Phase 1)

DOCUMENT NAME : PERMIT TO WORK SYSTEM PROCEDURE DATE : 17-OCT-2019

JOB CODE : CA DOCUMENT NO : 11EPG18-0200-AP-X-00 OO 013

SWGFD PAGE NO: Page 25 of 45

LTHE DOCUMENT NO : S-0200-1654-001

The audit results shall be considered as one of the KPI. Permit violations, which could have had a

serious consequence, should be considered serious and violator shall be subject to disciplinary actions

as per project disciplinary procedure.

Attachment- 15. Permit To Work Audit Checklist

AUDIT REGISTER:

The Contractor Reporting & Tracking system shall be utilized as audit register and to ensure tracking

of actions and recommendations through to close out. Each permit audited will have its findings