Professional Documents

Culture Documents

Stair Design

Stair Design

Uploaded by

Angelika Caguioa BiayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stair Design

Stair Design

Uploaded by

Angelika Caguioa BiayCopyright:

Available Formats

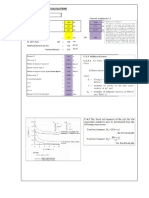

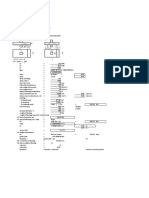

DESIGN OF CONCRETE STAIRS

Specifications:

fy = 275 MPa s = 100 mm CC = 20 mm

f'c = 27.6 MPa r = 300 mm L = 4170 mm

LL = 4.8 MPa t = 200 mm

ꝺ Concrete = 23.6 kN/m³ B = 1000 mm

Minimum Thickness of Slab (s) = L/20

= 208.5 mm

𝑠

Weight of Slab = 𝑡

(ɣConcrete)√𝑟 2 +𝑡 2

= 2.836367 kN/m

𝑟

Weight of Step = (ɣConcrete)

2

= 3.54 kN/m

Total Weight = Wt. LL + Wt. Slab + Wt. Step

= 11.17637 kN/m

𝑊𝑡𝑜𝑡𝑎𝑙(𝐿2 )

Mmax =

8

= 24.29309 kN.m

subs:

𝑀𝑚𝑎𝑥 = φ𝑓 ′ 𝑐(𝑏𝑑2 )(ω)(1 − 0.59ω)

ω = 0.1094

subs:

ρ𝑓𝑦

ω=

𝑓 ′𝑐

ρ = 0.01098

check in ρmin

ρmin = 1.4/fy

0.0051 ρmin > ρ, therefore use ρmin.

Solve for Area of Steel

As = ρbd

= 3293.935 mm²

Use 16mm Ø RSB (Main Bars)

Area of Steel = 201.062 mm²

No. of Bars = As/Asteel

= 17 pcs

Spacing = 59 mm

Spacing of 10mm Ø Temperature Bars

Ast = 0.002bd

= 600 mm²

Use 10mm Ø RSB (Temp Bars)

Area of Steel = 78.5398 mm²

No. of Bars = As/Asteel

= 8 pcs

Spacing = 125 mm

Therefore:

Use 12mm Ø RSB spaced @ 72 mm O.C. for Main Bars

Use 10mm Ø RSB spaced @ 125 mm O.C. forTemp Bars

You might also like

- BCO Specification For OfficesDocument8 pagesBCO Specification For OfficesKev Whyte100% (1)

- Design One Way SlabDocument22 pagesDesign One Way Slabjohn rey toledoNo ratings yet

- Pile Design Cal - Rev-1Document9 pagesPile Design Cal - Rev-1Nitin SakpalNo ratings yet

- Design of Outlet ChamberDocument7 pagesDesign of Outlet ChamberHemant SonawadekarNo ratings yet

- Lorai (Foundation Program)Document15 pagesLorai (Foundation Program)Loremae Masong JusgaNo ratings yet

- 1.2 ประมาณราคาศูนย์เด็ก ใส่ ประตู หน้าต่าง อิฐแก้ว แล้วDocument18 pages1.2 ประมาณราคาศูนย์เด็ก ใส่ ประตู หน้าต่าง อิฐแก้ว แล้วsarafan leewan0% (1)

- Design of Staging of 19 M (Span) Bridge of Jorabat Flyover Assam Road Project (As-03)Document5 pagesDesign of Staging of 19 M (Span) Bridge of Jorabat Flyover Assam Road Project (As-03)Masud Amin100% (1)

- SLABDocument1 pageSLABNick OperarioNo ratings yet

- Slab DesignDocument11 pagesSlab DesignCarmel Buniel Sabado100% (22)

- PERHITUNGAN BALOK ATAPFIX - REiDocument8 pagesPERHITUNGAN BALOK ATAPFIX - REiRainhard PurbaNo ratings yet

- Design of Floor BeamDocument4 pagesDesign of Floor Beamycmjdb79m9No ratings yet

- Stairway 1Document10 pagesStairway 1Anissah ManialaNo ratings yet

- Slab Design-RajDocument6 pagesSlab Design-Rajankit kadamNo ratings yet

- Two-Way Slab Design UIDocument1 pageTwo-Way Slab Design UIpobre3nga3bataNo ratings yet

- Timber Column Design: Mark Diameter 200mmDocument4 pagesTimber Column Design: Mark Diameter 200mmFarly VergelNo ratings yet

- One-Way Slab Design UIDocument1 pageOne-Way Slab Design UIpobre3nga3bataNo ratings yet

- Two Way Slab Distributed LoadDocument9 pagesTwo Way Slab Distributed LoadJujemar GujeldeNo ratings yet

- Aljon RCD ExcelDocument10 pagesAljon RCD Excelaj domingoNo ratings yet

- Desing of 200 Cubic Metre Reinforced Rectangular Clear Water Storage Tank For Rumphi Tank Geometry and DimensionsDocument23 pagesDesing of 200 Cubic Metre Reinforced Rectangular Clear Water Storage Tank For Rumphi Tank Geometry and DimensionsWjz WjzNo ratings yet

- Design of Box CulvertDocument34 pagesDesign of Box CulvertAl Patrick Dela CalzadaNo ratings yet

- Calculation For 1.4m X 1.5m RCC Box CulvertDocument4 pagesCalculation For 1.4m X 1.5m RCC Box CulvertManish BhatkarNo ratings yet

- Bibi Design of SlabsDocument16 pagesBibi Design of SlabsMICHAEL MAHINAYNo ratings yet

- Stair Case CalcuationsDocument2 pagesStair Case CalcuationsraghavendraNo ratings yet

- Top Bar Slab CheckingDocument6 pagesTop Bar Slab CheckingJamie MartinezNo ratings yet

- E.naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - V2.0.2Document2 pagesE.naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - V2.0.2Max100% (1)

- Coba JembatanDocument28 pagesCoba JembatanAbdi Septia PutraNo ratings yet

- Design Constants: Load On SlabDocument5 pagesDesign Constants: Load On Slabkiran raghukiranNo ratings yet

- Design of Box CulvertDocument24 pagesDesign of Box CulvertAl Patrick Dela CalzadaNo ratings yet

- PLIDCO Riser Stress AnalysisDocument2 pagesPLIDCO Riser Stress AnalysisMahamad Azi Bin IshakNo ratings yet

- Footing Slab PurlinsDocument5 pagesFooting Slab PurlinsMichael RojasNo ratings yet

- Pad Foundation DesignDocument4 pagesPad Foundation DesignNaison StanleyNo ratings yet

- Steel Beam NSCP2015Document307 pagesSteel Beam NSCP2015Sherwin CairoNo ratings yet

- Design of Slabs: Input DataDocument6 pagesDesign of Slabs: Input Datagewegw3gNo ratings yet

- FC' 20.68 Mpa Cement Finish 1.53 Kpa Ceiling Suspended Loads 0.48 Kpa Fy 230.00 MpaDocument19 pagesFC' 20.68 Mpa Cement Finish 1.53 Kpa Ceiling Suspended Loads 0.48 Kpa Fy 230.00 Mparamel sigueNo ratings yet

- Design of RC Rectangular Section NSCP ACI 318Document5 pagesDesign of RC Rectangular Section NSCP ACI 318Nicko Jay BajaoNo ratings yet

- Penulangan PelatDocument16 pagesPenulangan Pelatzaenal AbidinNo ratings yet

- Design of Rectangular Is0Lated Footings 1: F2: Footing MarkDocument2 pagesDesign of Rectangular Is0Lated Footings 1: F2: Footing MarkFarly VergelNo ratings yet

- Water TankDocument4 pagesWater Tankraghu kiranNo ratings yet

- Slab DesignDocument11 pagesSlab DesignHanafiahHamzahNo ratings yet

- One Way SlabDocument3 pagesOne Way SlabMuhammad Sulaiman100% (1)

- Flight 1: Main Staircase DesignDocument17 pagesFlight 1: Main Staircase DesignSatwik SantoshNo ratings yet

- Lifting CalculationDocument7 pagesLifting CalculationAsaru DeenNo ratings yet

- Base Ring Fillet Size CalculationDocument4 pagesBase Ring Fillet Size Calculationmiteshpatel191No ratings yet

- Base Design (Blocks) - Commented On 26.09.2017Document4 pagesBase Design (Blocks) - Commented On 26.09.2017tsinghal_19No ratings yet

- Pool AnalysisDocument5 pagesPool Analysisnemat1233No ratings yet

- Perhitungan Pelat Versi 2 M22Document11 pagesPerhitungan Pelat Versi 2 M22zaenal AbidinNo ratings yet

- Pile 4.5 MDocument2 pagesPile 4.5 MRAJAT SHARMANo ratings yet

- 6.3 Staircase Waist SlabDocument2 pages6.3 Staircase Waist SlabEr Mohd NoshadNo ratings yet

- Design of Roof BeamDocument4 pagesDesign of Roof Beamycmjdb79m9No ratings yet

- 2 Flight Stair CaseDocument4 pages2 Flight Stair CaseMaaz OsmanNo ratings yet

- AiscDocument13 pagesAiscsteven bianesNo ratings yet

- Over Head Tank - Circular Flat SlabDocument14 pagesOver Head Tank - Circular Flat SlabVi Jay100% (1)

- Culvert Design Using Staad As Per IrsDocument171 pagesCulvert Design Using Staad As Per IrsTanvir Shahrier MahmudNo ratings yet

- Pad Foundation DesignDocument4 pagesPad Foundation Designg4goharNo ratings yet

- Column K PDFDocument27 pagesColumn K PDFAngelika Caguioa BiayNo ratings yet

- Design and Const2Document20 pagesDesign and Const2ramel sigueNo ratings yet

- Isolated Footing (R or S)Document19 pagesIsolated Footing (R or S)Shaniha kkNo ratings yet

- Fy 276 Mpa: Formula For Transferring The Weight of Slab To BeamDocument19 pagesFy 276 Mpa: Formula For Transferring The Weight of Slab To Beamraymark mendozaNo ratings yet

- Feynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterFrom EverandFeynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Basic Civil and Mechanical Engineering - Lecture Notes, Study Material and Important Questions, AnswersDocument5 pagesBasic Civil and Mechanical Engineering - Lecture Notes, Study Material and Important Questions, AnswersM.V. TVNo ratings yet

- NYSDOT Bridge Manual US 2017Document595 pagesNYSDOT Bridge Manual US 2017Ayoub Zekraoui100% (1)

- CH7 - Design of Footing and Pile Cap (2014!04!20)Document24 pagesCH7 - Design of Footing and Pile Cap (2014!04!20)Lee Tin Yan100% (2)

- Tunnel FormworkDocument7 pagesTunnel FormworkApoorv Srivastava ce 42No ratings yet

- HIRA For Road ConstructionDocument5 pagesHIRA For Road ConstructionPrabhath TharakaNo ratings yet

- Analysis Report Anju MallaDocument43 pagesAnalysis Report Anju Mallasibu_bhusalNo ratings yet

- Santhakumar A R and Uma Rao Santhakumar A R and Uma RaoDocument6 pagesSanthakumar A R and Uma Rao Santhakumar A R and Uma RaoVirat DesaiNo ratings yet

- Samsara VilasaDocument19 pagesSamsara VilasaAdarsh PawarNo ratings yet

- Hart Cooley 2206GS CatalogDocument142 pagesHart Cooley 2206GS Catalogyapoh91026No ratings yet

- Berlins Hotels Fun Activities Games Reading Comprehension Exercis - 37634Document2 pagesBerlins Hotels Fun Activities Games Reading Comprehension Exercis - 37634frade1980No ratings yet

- Module 05 - Notes PDFDocument13 pagesModule 05 - Notes PDFcrazyyygodNo ratings yet

- MHD Ramadhan Daulay LDD ESSAYDocument2 pagesMHD Ramadhan Daulay LDD ESSAYramadhanNo ratings yet

- SuSD.1.I.004 - Contents of Plans and Documents To Be Submitted (For Application of Permit Under NBC)Document5 pagesSuSD.1.I.004 - Contents of Plans and Documents To Be Submitted (For Application of Permit Under NBC)MeowthemathicianNo ratings yet

- cvg4145 Assignment 1 - SolutionDocument8 pagescvg4145 Assignment 1 - Solutiontajiw17001No ratings yet

- Visual Communication Design and Urban Design As Tool For Urban Regeneration: Case Study of KolkataDocument11 pagesVisual Communication Design and Urban Design As Tool For Urban Regeneration: Case Study of KolkatarahilkelaNo ratings yet

- MUSAC - Contemporary Art Museum of Castilla y León: Architecture Mansilla+Tuñón Arquitectos MiesvanderroheDocument10 pagesMUSAC - Contemporary Art Museum of Castilla y León: Architecture Mansilla+Tuñón Arquitectos MiesvanderroheRenae LewisNo ratings yet

- TCS - 3Document1 pageTCS - 3Ravindra singh TanwarNo ratings yet

- Lite ReportDocument12 pagesLite Reportshakeellashkaria1893No ratings yet

- Influence of Fibers On Drying Shrinkage in Restrained ConcreteDocument3 pagesInfluence of Fibers On Drying Shrinkage in Restrained ConcreteIcha FarisaNo ratings yet

- Attributes Nirma University, Ahmedabad Site AnalysisDocument30 pagesAttributes Nirma University, Ahmedabad Site AnalysisLisha NurgisNo ratings yet

- Good Industry Practices Guide BookDocument108 pagesGood Industry Practices Guide Booklim kang hai100% (1)

- Shunyam House, Jodhpur: Presented byDocument2 pagesShunyam House, Jodhpur: Presented byManasi Sonar100% (1)

- Bangalore HotelsDocument1 pageBangalore HotelsJoydeep BanerjeeNo ratings yet

- DETAILED ESTIMATES OF Two Storey BuildingDocument7 pagesDETAILED ESTIMATES OF Two Storey BuildingfreelineNo ratings yet

- Electrical Wirings-Ground FloorDocument1 pageElectrical Wirings-Ground FloordrajkumarceNo ratings yet

- MR - Vivak Malik LayoutDocument1 pageMR - Vivak Malik LayoutvivekNo ratings yet

- Adx 999 SM PDFDocument10 pagesAdx 999 SM PDFSusana KhoNo ratings yet

- PNOCVA - BLANK - BOQ - Slope ProtectionDocument4 pagesPNOCVA - BLANK - BOQ - Slope ProtectionEdmar BangayanNo ratings yet

- 4.FSD C22048 Ele 101Document1 page4.FSD C22048 Ele 101mhazarath murariNo ratings yet