Professional Documents

Culture Documents

Clock Grade Sheet 2022-23

Clock Grade Sheet 2022-23

Uploaded by

Dustin Coleman (CHMS)Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Clock Grade Sheet 2022-23

Clock Grade Sheet 2022-23

Uploaded by

Dustin Coleman (CHMS)Copyright:

Available Formats

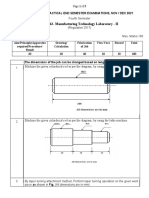

2022-23 Name:

8th Grade Tech Ed - Clock Project Grade Sheet

Date of Possible Points

Procedure Completion Points Earned

1. Glue up strips of wood to between 10 1/2" and 12 1/2"

2. Scrape and hand plane to remove excess glue and to level your wood.

3. Use the surface planer to clean each side of your wood. 10

4. Have Mr. Coleman use the Sliding Miter Saw to cut your wood into square blocks.

5. Find the center of your block by drawing diangle lines from the corners.

6. Centerpunch the center of your wood square.

7. Drill a 3/8" hole all the way through the center. 10

8. Using the pattern, mark then centerpunch the eight holes for the wood plugs. Make

sure that you do NOT mark the 12, 3, 6, and 9.

9. Measure 3" from each corner and draw a straight line

10. Drill the 3" hole in the back so it is a 1/4" away from the front face. 10

11. Drill the eight 1/2" plug holes 1/2" deep into the face of the clock. 10

12. Have Mr. Coleman cut the corners on the Table Saw.

13. Use the CNC Router to carve the numbers 12,3,6 and 9

14. Seal and paint your numbers

15. Glue in the eight wood plugs then let them dry.

16. Use the Drum Sanding Machine to sand down the plugs.

17. With your clock face down, use the Router Table to rout your clocks edge. Move right

to left. 10

18. Sand with rough (100) grit sandpaper with the grain. After you get Mr. Coleman's

initials, raise the grain with a clean damp sponge. Let it dry. 10

19. Sand with medium (150) grit sandpaper with the grain.After you get Mr. Coleman's

initials, raise the grain with a clean damp sponge.

20. Sand with fine (220) grit sandpaper with the grain. After you get Mr. Coleman's

initials, Do NOT raise the grain. 5

21. Saturate the clock with sealer. After the clock does not hold any more sealer, wipe

off the excess and let it dry. 5

22. Rub the clock down with 0000 steel wool. Wipe off the dust with a tack rag.

23. Apply a very light coat of finish with a foam brush. Be careful of runs and let it dry. 10

24. IF NEEDED -Rub the clock down with 0000 steel wool so there is no shiny spots left.

Wipe off the dust with a tack rag.

25. IF NEEDED Apply another coat of finish. Be very careful with dust and runs.

26. Rub on a coat of paste wax. Let it dry for 10 minutes then rub it off.

27. Attach the saw tooth hanger to the back of the clock.

28. Assemble the clock components and put on the hands and numbers.

29. I'm all finished with my clock and I am finished with this silly procedure sheet too!!!! 20

Total: 100

You might also like

- High School Clayforweeblypart2Document62 pagesHigh School Clayforweeblypart2api-293964578100% (1)

- Simmons Pads ReconditioningDocument5 pagesSimmons Pads ReconditioningAnonymous cdQSIU03AQNo ratings yet

- Sculpting and HandbuildingDocument9 pagesSculpting and Handbuildingcyberkike75% (4)

- Getting Started with Handplanes: How to Choose, Set Up, and Use Planes for Fantastic ResultsFrom EverandGetting Started with Handplanes: How to Choose, Set Up, and Use Planes for Fantastic ResultsRating: 1 out of 5 stars1/5 (1)

- Navy m16 Nko Course AnswersDocument1 pageNavy m16 Nko Course Answerschiefboats100% (14)

- The Art of Woodworking - Sharpening and Tool Care 1994Document148 pagesThe Art of Woodworking - Sharpening and Tool Care 1994Zorila Dan93% (14)

- Here's How ... Ceramic Tile PDFDocument98 pagesHere's How ... Ceramic Tile PDFRaghu100% (2)

- Pottery: Global Action Programme On Education For All Youth ProjectDocument28 pagesPottery: Global Action Programme On Education For All Youth ProjectJoao DuarteNo ratings yet

- Ceramics Work Sheet 1 Grade 8Document9 pagesCeramics Work Sheet 1 Grade 8Chris-Ann EdwardsNo ratings yet

- 3 - Foundry&Casting - Shop 1Document9 pages3 - Foundry&Casting - Shop 1Mansi NegiNo ratings yet

- DIY#11 Build Your Own ClayBrick Braai BDocument4 pagesDIY#11 Build Your Own ClayBrick Braai BteboviNo ratings yet

- Report Bengkel (Mold & Slip Casting)Document7 pagesReport Bengkel (Mold & Slip Casting)fatinzalila0% (1)

- Black & Decker Here's How Ceramic TileDocument98 pagesBlack & Decker Here's How Ceramic TileRade Mladenovic100% (12)

- How To Design, Make, and Install and Murals: Ceramic TilesDocument19 pagesHow To Design, Make, and Install and Murals: Ceramic TilesChanrathNo ratings yet

- Report Politeknik Brickwork Wall PlasteringDocument7 pagesReport Politeknik Brickwork Wall PlasteringMuhammad MuazzamNo ratings yet

- Take Notes: Practical Guideline For Internal and External Plastering WorkDocument19 pagesTake Notes: Practical Guideline For Internal and External Plastering WorkVelmurugan BalasubramanianNo ratings yet

- GREEN FOUNDRY INITIATIVES For Sustainability and Value CreationDocument232 pagesGREEN FOUNDRY INITIATIVES For Sustainability and Value CreationiluNo ratings yet

- Carl Church Bird Taxidermy - Breakthrough Magazine Issue 89Document4 pagesCarl Church Bird Taxidermy - Breakthrough Magazine Issue 89rebootisNo ratings yet

- Shop Parctice No. 6.2 Molding Practice 2Document8 pagesShop Parctice No. 6.2 Molding Practice 2Patrick James RoseteNo ratings yet

- Seminar On Case Study of Investment Casting by Manish PujaraDocument39 pagesSeminar On Case Study of Investment Casting by Manish PujaraNikunj PatelNo ratings yet

- Workshop Practice Lab Manual PDFDocument47 pagesWorkshop Practice Lab Manual PDFAKULA DINESHNo ratings yet

- Fg16 Ceramic TilesDocument22 pagesFg16 Ceramic Tilesgabiconminuscula100% (1)

- CeramicTiles4 PDFDocument22 pagesCeramicTiles4 PDFRoberto MarottaNo ratings yet

- FIMO Liquid Beach GlassDocument5 pagesFIMO Liquid Beach Glasslhoche100% (3)

- Experiment No. 1. EmptyDocument1 pageExperiment No. 1. EmptyDenny FrancaNo ratings yet

- Juniper Marshall - Intro To Clay - Reading Questions 2023Document2 pagesJuniper Marshall - Intro To Clay - Reading Questions 2023api-750288251No ratings yet

- Build On A Slope To Save Effort. of Course, An Igloo Can Be Built On Flat Land WithoutDocument17 pagesBuild On A Slope To Save Effort. of Course, An Igloo Can Be Built On Flat Land Withoutsurendar17_raj3406No ratings yet

- Micro-Concrete Roofing Tile ProductionDocument6 pagesMicro-Concrete Roofing Tile ProductionzulizwxnNo ratings yet

- Making A Multicolor EtchingDocument19 pagesMaking A Multicolor EtchingsyderterranNo ratings yet

- T-Nuts in FoamDocument6 pagesT-Nuts in Foamscribd4uall100% (1)

- Casting Expt 2Document5 pagesCasting Expt 2Shashank PhansikarNo ratings yet

- MCQ BhimaDocument8 pagesMCQ BhimaShruti ShahNo ratings yet

- Section - 09 30 00 - TilingDocument3 pagesSection - 09 30 00 - TilingEliseo LagmanNo ratings yet

- Tandoori OvenDocument5 pagesTandoori OvenosmanajmalNo ratings yet

- Bulking of SandDocument10 pagesBulking of SandAK RajNo ratings yet

- DL50 Discus Launch GliderDocument16 pagesDL50 Discus Launch GliderAri SutiknoNo ratings yet

- Making A Fiberglass Mold: It's Easy!Document4 pagesMaking A Fiberglass Mold: It's Easy!Roxana Hincu100% (1)

- Investment Casting: How The Process WorksDocument15 pagesInvestment Casting: How The Process Worksvikas2510No ratings yet

- BEGINNER’S GUIDE TO HANDBUILDING: Learn how to create slab pots, mugs, pinch pots, coiled pots and other amazing ceramic art work like a proFrom EverandBEGINNER’S GUIDE TO HANDBUILDING: Learn how to create slab pots, mugs, pinch pots, coiled pots and other amazing ceramic art work like a proNo ratings yet

- Accelerated Curing TestDocument8 pagesAccelerated Curing Testvempadareddy100% (1)

- Ceramics Vocabulary!!!!Document4 pagesCeramics Vocabulary!!!!anaNo ratings yet

- Jewelry Box: Woodworks: Beginner Project 2009-2010Document7 pagesJewelry Box: Woodworks: Beginner Project 2009-2010Sal GNo ratings yet

- How To Repoint Brick MortarDocument2 pagesHow To Repoint Brick MortarRi SovannaphumiNo ratings yet

- DIY#16 Build Your Own UnderGround Wine CellarDocument3 pagesDIY#16 Build Your Own UnderGround Wine CellarBrian PierceNo ratings yet

- Micro Concrete RoofingtilesDocument6 pagesMicro Concrete RoofingtilesWP 2-1-PR Katubedda-CESLNo ratings yet

- Microconcrete Roofing Tiles PDFDocument5 pagesMicroconcrete Roofing Tiles PDFPietrus Nimbus100% (1)

- Micro-Concrete Roofing Tile Production: Quality ControlDocument4 pagesMicro-Concrete Roofing Tile Production: Quality ControlPietrus NimbusNo ratings yet

- Session 7 PlasterDocument43 pagesSession 7 PlasterlavNo ratings yet

- 49 February 2014 SupplementDocument43 pages49 February 2014 SupplementArtisans in Miniature97% (35)

- Technical Brochure Gruntec BlocksDocument5 pagesTechnical Brochure Gruntec BlockspatnipranayNo ratings yet

- Constructing A DOMEDocument28 pagesConstructing A DOMEvigyanashram50% (2)

- UnaboxDocument3 pagesUnaboxChristian MoffattNo ratings yet

- OSI Floortek Anti-Static Vinyl Installation MethodologyDocument10 pagesOSI Floortek Anti-Static Vinyl Installation MethodologyBernanRolandCelisNo ratings yet

- MCJM F12 BLAD WebDocument2 pagesMCJM F12 BLAD WebInterweaveNo ratings yet

- A Guide to Making a Leather Purse - A Collection of Historical Articles on Designs and Methods for Making PursesFrom EverandA Guide to Making a Leather Purse - A Collection of Historical Articles on Designs and Methods for Making PursesNo ratings yet

- Family Handyman Handy HintsFrom EverandFamily Handyman Handy HintsFamily HandymanRating: 5 out of 5 stars5/5 (1)

- Basic Mosaics: All the Skills and Tools You Need to Get StartedFrom EverandBasic Mosaics: All the Skills and Tools You Need to Get StartedRating: 2 out of 5 stars2/5 (1)

- TraderConfig EditDocument22 pagesTraderConfig EditMarc GallantNo ratings yet

- Repairing Logitech Driving Force Pro PedalsDocument5 pagesRepairing Logitech Driving Force Pro PedalsJuan Pablo D StsNo ratings yet

- ME8462-Manufacturing Technology Laboratory - IIDocument5 pagesME8462-Manufacturing Technology Laboratory - IIBala AbimanyuNo ratings yet

- Dna Power Tools Register-Oct - Nov - DecDocument11 pagesDna Power Tools Register-Oct - Nov - DecQarib KazmiNo ratings yet

- North Sector: MountsDocument2 pagesNorth Sector: MountsSwarupendra BhattacharyyaNo ratings yet

- Alpha PhysicsDocument19 pagesAlpha PhysicsTurbo GamingNo ratings yet

- Instrument ScheduleDocument3 pagesInstrument ScheduleChad TrombatoreNo ratings yet

- Armatix Baselock - Multi-Gun Safety Storage DeviceDocument2 pagesArmatix Baselock - Multi-Gun Safety Storage DevicegilaloanNo ratings yet

- Notes On Anti-Aircraft-guns in WWI 1917Document32 pagesNotes On Anti-Aircraft-guns in WWI 1917Jose Luis CastilloNo ratings yet

- KIT10 21257 AP v03-110 04-2013Document6 pagesKIT10 21257 AP v03-110 04-2013albertoNo ratings yet

- Untitled PDFDocument124 pagesUntitled PDFNarra Vivek168No ratings yet

- BH-60 Fixed Gas Detector Operation ManualDocument8 pagesBH-60 Fixed Gas Detector Operation ManualTan KokkiangNo ratings yet

- Furniture Multiple Choice Activity Picture Description Exercises Picture Dictionaries - 78199Document1 pageFurniture Multiple Choice Activity Picture Description Exercises Picture Dictionaries - 78199Ariunjargal RagchaabazarNo ratings yet

- Gun Range Safety and Standard CommandsDocument2 pagesGun Range Safety and Standard CommandsRobNo ratings yet

- A Series I Tech Spares CatalogueDocument115 pagesA Series I Tech Spares CatalogueMinh DangNo ratings yet

- Pneumatic Rotary Actuator, Single-Acting and Double-ActingDocument4 pagesPneumatic Rotary Actuator, Single-Acting and Double-Actingrema irmaNo ratings yet

- SP PDFDocument7 pagesSP PDFVikram JainNo ratings yet

- Workshop TechnologyDocument105 pagesWorkshop Technologymuneebimran0% (1)

- Manual Service Instructions Disassembly Reassembly For G GC GH GHC Series Pneumatic Actuators Bettis en 84628Document72 pagesManual Service Instructions Disassembly Reassembly For G GC GH GHC Series Pneumatic Actuators Bettis en 84628Andrew MellorNo ratings yet

- Loose-Tenon Options: Spend A Little, Spend A Lot: Three Great Ways To Make Loose-Tenon JointsDocument6 pagesLoose-Tenon Options: Spend A Little, Spend A Lot: Three Great Ways To Make Loose-Tenon JointsFausto Martin Vicente MoralesNo ratings yet

- Innofill DMG Filling PhasesDocument10 pagesInnofill DMG Filling PhasesdingobkNo ratings yet

- Pitot TubeDocument2 pagesPitot TubeJinco JoseNo ratings yet

- D&D 3.5 Range Weapon Penalty ChartDocument2 pagesD&D 3.5 Range Weapon Penalty ChartJoe SchmidtNo ratings yet

- Ciat Aquaciat 700v 1100v Power 1200v 1800v Free Cooling Modules Na08668aDocument12 pagesCiat Aquaciat 700v 1100v Power 1200v 1800v Free Cooling Modules Na08668aAR&MENDES ENGENHARIANo ratings yet

- Tool TrolleyDocument17 pagesTool TrolleysanjeevvangeNo ratings yet

- PalbitDocument369 pagesPalbitBalmos Claudiu100% (1)

- Maryland MetricsDocument19 pagesMaryland MetricsKurt VaughnNo ratings yet

- Kalgoorlie Boulder (YPKG)Document18 pagesKalgoorlie Boulder (YPKG)Xavier MannersNo ratings yet