Professional Documents

Culture Documents

Technic Error Codes

Technic Error Codes

Uploaded by

prajwalCopyright:

Available Formats

You might also like

- Windows Username and Password: Weight: 1Document12 pagesWindows Username and Password: Weight: 1Aamir ShaikhNo ratings yet

- Fault Code 285 SAE J1939 Multiplexing PGN Timeout Error - Abnormal Update RateDocument13 pagesFault Code 285 SAE J1939 Multiplexing PGN Timeout Error - Abnormal Update RateAhmedmah100% (2)

- Code Error RolandDocument8 pagesCode Error Rolandantonio_brasileiro_1No ratings yet

- Fault Code 286 SAE J1939 Multiplexing Configuration Error - Out of CalibrationDocument13 pagesFault Code 286 SAE J1939 Multiplexing Configuration Error - Out of CalibrationAhmedmahNo ratings yet

- Doosan Servo Drive Unit Maintenance ManualDocument22 pagesDoosan Servo Drive Unit Maintenance ManualRogerio Silva PedroNo ratings yet

- Cummins: Fault Code: 385 PID: S232 SPN: 620 FMI: 3 or 1Document6 pagesCummins: Fault Code: 385 PID: S232 SPN: 620 FMI: 3 or 1Enrrique LaraNo ratings yet

- SSt-U 5 Blink & Error CodesDocument1 pageSSt-U 5 Blink & Error CodesAzizi SamNo ratings yet

- Powerfoil X3.0 Error Codes (Delta E Series VFD) : Error Code Description and Corrective ActionDocument2 pagesPowerfoil X3.0 Error Codes (Delta E Series VFD) : Error Code Description and Corrective ActionbrayanNo ratings yet

- 19369681714Document2 pages19369681714sagarprajapati6998No ratings yet

- Vibration Excessive: This Troubleshooting Procedure Should Be Followed For The Following SymptomsDocument23 pagesVibration Excessive: This Troubleshooting Procedure Should Be Followed For The Following SymptomsMuhammad Ishfaq100% (2)

- A - Syntec Driver Alarm ManualDocument291 pagesA - Syntec Driver Alarm ManualInduk HanNo ratings yet

- A - Syntec Driver Alarm ManualDocument291 pagesA - Syntec Driver Alarm Manualphạm minh hùngNo ratings yet

- Cummins: Fault Code: 444 PID: S232 SPN: 620 FMI: 3 or 4Document7 pagesCummins: Fault Code: 444 PID: S232 SPN: 620 FMI: 3 or 4Enrrique LaraNo ratings yet

- 3 Phase Induction Motor Fault List and Solution: Problems: Like Causes: What To DoDocument3 pages3 Phase Induction Motor Fault List and Solution: Problems: Like Causes: What To DoVENKATA RAJUNo ratings yet

- Siid Siid: Electronic Venders Electronic VendersDocument7 pagesSiid Siid: Electronic Venders Electronic VenderswernerkaiNo ratings yet

- LBMC Hj5Ae: Product Introduction Key FeaturesDocument5 pagesLBMC Hj5Ae: Product Introduction Key FeaturesanjaliNo ratings yet

- 6E-104 4Ja1/4Jh1 Engine Driveability and Emissions Breaker Box Connection Type BDocument303 pages6E-104 4Ja1/4Jh1 Engine Driveability and Emissions Breaker Box Connection Type BVõ Nam PhươngNo ratings yet

- Alarm Delta VFD - E SeriesDocument4 pagesAlarm Delta VFD - E SeriesSadik HasanNo ratings yet

- ESDB AC Servo Drive User ManualDocument92 pagesESDB AC Servo Drive User ManualUsama ZaheerNo ratings yet

- ES52 User ManualDocument24 pagesES52 User ManualSylvainsfcNo ratings yet

- ES52 User ManualDocument24 pagesES52 User ManualSylvainsfcNo ratings yet

- ES52 User ManualDocument24 pagesES52 User ManualSylvainsfcNo ratings yet

- Notes For Accounting 101Document10 pagesNotes For Accounting 101revyhoheNo ratings yet

- DTC P0734 - Incorrect Gear RatioDocument4 pagesDTC P0734 - Incorrect Gear RatioHermawan 0103No ratings yet

- Kinetix Error Codes-1Document18 pagesKinetix Error Codes-1Renzo DamianNo ratings yet

- Land Rover Bosch GS8.87 Transmission Management (D2 & RR P38)Document13 pagesLand Rover Bosch GS8.87 Transmission Management (D2 & RR P38)ZM OhnNo ratings yet

- DTC P1345 Crankshaft Position (CKP) - Camshaft Position (CMP) CorrelationDocument5 pagesDTC P1345 Crankshaft Position (CKP) - Camshaft Position (CMP) CorrelationChino PlagaNo ratings yet

- Troubleshooting From I566-E1-02 G (ML2)Document25 pagesTroubleshooting From I566-E1-02 G (ML2)احمدمحمد الخياطNo ratings yet

- ENGLISH - Operation Guide SD SeriesDocument85 pagesENGLISH - Operation Guide SD Seriescatur skakNo ratings yet

- VFD EMERSON DiagnosticsDocument2 pagesVFD EMERSON Diagnosticsjuan guerreroNo ratings yet

- Maintenance & Troubleshooting: Problem IsolationDocument16 pagesMaintenance & Troubleshooting: Problem IsolationÁgost VitaNo ratings yet

- Accent P0012 Camshaft Position-Timing Over-Retarded (Bank 1)Document5 pagesAccent P0012 Camshaft Position-Timing Over-Retarded (Bank 1)flash_24014910No ratings yet

- Chapter 7. MAINTENANCE TroubleshootingDocument12 pagesChapter 7. MAINTENANCE TroubleshootingnasrunNo ratings yet

- LBMC Hk5Ap: Product Introduction Key FeaturesDocument5 pagesLBMC Hk5Ap: Product Introduction Key FeaturesanjaliNo ratings yet

- ACS580 Troubleshooting: Fault TracingDocument25 pagesACS580 Troubleshooting: Fault TracingMohamed Ayman Hefny MohamedNo ratings yet

- 8 Diagnostics: Trip Code Condition Possible CauseDocument2 pages8 Diagnostics: Trip Code Condition Possible CausePedroNo ratings yet

- 11-4 Troubleshooting: Symptom Probable Cause Items To Check MeasuresDocument1 page11-4 Troubleshooting: Symptom Probable Cause Items To Check MeasuresDominique KomeyNo ratings yet

- Problemas Con Husillo. Servicio HaasDocument5 pagesProblemas Con Husillo. Servicio Haasecaldera10100% (1)

- ATV 78 - Fault TracingDocument4 pagesATV 78 - Fault TracingHddjdjNo ratings yet

- Diagnostics and Troubleshooting Schneider ElectricDocument5 pagesDiagnostics and Troubleshooting Schneider ElectricManohar Paul Praveen MNo ratings yet

- Maintenance & TroubleshootingDocument4 pagesMaintenance & TroubleshootingJovenlou BihagNo ratings yet

- CAT - 3516H Engine Shutdown or Start Inhibit Initiated by Driven EquipmentDocument2 pagesCAT - 3516H Engine Shutdown or Start Inhibit Initiated by Driven Equipmentwagner_guimarães_1100% (1)

- FAULT CODE 1117 - Power Supply Lost With Ignition On - Data Erratic, Intermittent, or IncorrectDocument8 pagesFAULT CODE 1117 - Power Supply Lost With Ignition On - Data Erratic, Intermittent, or IncorrectAli ArdinNo ratings yet

- Fault Messages and List of FaultsDocument5 pagesFault Messages and List of FaultsAhmadNo ratings yet

- Extrait Doc Variateur GBDocument7 pagesExtrait Doc Variateur GBErick Fernando Chavez VargasNo ratings yet

- US100 Servo Manual-2018Document82 pagesUS100 Servo Manual-2018Hamed YazidiNo ratings yet

- I3500 TroubleshootingDocument14 pagesI3500 TroubleshootingAdriana Velásquez100% (2)

- Manual: Diversified Products, Inc. PowertraxDocument24 pagesManual: Diversified Products, Inc. PowertraxProyectos Trans roll, C.A. OficinaNo ratings yet

- T790 Treadmill: Customer Support Services Service ManualDocument61 pagesT790 Treadmill: Customer Support Services Service ManualtelebilNo ratings yet

- Reelmaster 5010-H Diagnostic Fault Code Quick Reference TableDocument38 pagesReelmaster 5010-H Diagnostic Fault Code Quick Reference TableValentin PiersonNo ratings yet

- Possible Solution: KNIGHT Fault # DescriptionDocument2 pagesPossible Solution: KNIGHT Fault # DescriptionFundidora UnknownNo ratings yet

- CTB Motor ManualDocument12 pagesCTB Motor ManualTibor ĎurišNo ratings yet

- 58 CBBBBBF 09 C 4Document41 pages58 CBBBBBF 09 C 4amitNo ratings yet

- SEVCON Fault Code Meanings: Message DescriptionDocument4 pagesSEVCON Fault Code Meanings: Message Descriptionmarius borcauNo ratings yet

- UniMAT Servo Set ManualDocument84 pagesUniMAT Servo Set ManualGilberto Figueroa100% (1)

- Yaskawa Alarms Faults 3735Document18 pagesYaskawa Alarms Faults 3735charlydigitalNo ratings yet

- HD785-7 SEN01274-15 Shop Manual-804-1004Document201 pagesHD785-7 SEN01274-15 Shop Manual-804-1004Muhammad RizqiNo ratings yet

- File - D - Desktop - DVD - Final - DVD - GAC Controller - Troubleshooting - PDFDocument16 pagesFile - D - Desktop - DVD - Final - DVD - GAC Controller - Troubleshooting - PDFNAVANEETHNo ratings yet

- ErrorList2004 11 24engDocument70 pagesErrorList2004 11 24englongsony2013No ratings yet

- Part 1: Commissioning: Liquiline M CM42Document36 pagesPart 1: Commissioning: Liquiline M CM42Rabah AmidiNo ratings yet

- Circuits For Hobbyists - A Collection of Schematics To Build PDFDocument1 pageCircuits For Hobbyists - A Collection of Schematics To Build PDFWilliam PacatteNo ratings yet

- Tle TVL Ict TD Module 3Document8 pagesTle TVL Ict TD Module 3MheraldyneFaith MaderaNo ratings yet

- Arcolinux Cheatsheet v2.3Document2 pagesArcolinux Cheatsheet v2.3Antonio Maria ConcepcionNo ratings yet

- Heuristic Methods To Solve Optimal Power Flow Problem: Rengin Idil CABADAG, Belgin Emre TURKAYDocument7 pagesHeuristic Methods To Solve Optimal Power Flow Problem: Rengin Idil CABADAG, Belgin Emre TURKAYhakandaghanNo ratings yet

- Unit 3 NotesDocument78 pagesUnit 3 NotesKoushiNo ratings yet

- DATA CENTER TIERS - 1, 2, 3 & 4 Explained With DownloadsDocument48 pagesDATA CENTER TIERS - 1, 2, 3 & 4 Explained With DownloadsDilip PaliwalNo ratings yet

- 2080IF4Document2 pages2080IF4Rakibul HassanNo ratings yet

- A5E44852162-ACen P320P420 HART OI en-USDocument280 pagesA5E44852162-ACen P320P420 HART OI en-USvaab11No ratings yet

- Migrating From TDM To Ip Getting The Ball RollingDocument10 pagesMigrating From TDM To Ip Getting The Ball Rollingmagdy elmasryNo ratings yet

- CKMM Change Material Price Determination PDFDocument10 pagesCKMM Change Material Price Determination PDFSurabhi Chaurasia100% (1)

- LPL Textbook PDFDocument621 pagesLPL Textbook PDFJonathan MahNo ratings yet

- Music Player REPORTDocument33 pagesMusic Player REPORTvishukephotosNo ratings yet

- 1by17cs040 Internship ReportDocument35 pages1by17cs040 Internship Reportch venkateshNo ratings yet

- Data Representation - User Defined Data Types and Mantisa and ExponentDocument7 pagesData Representation - User Defined Data Types and Mantisa and ExponentAmul BashyalNo ratings yet

- Robots Need Us More Than We Need ThemDocument18 pagesRobots Need Us More Than We Need ThemIbrahim AltkamulNo ratings yet

- Polytune Software Update Windows 7Document6 pagesPolytune Software Update Windows 7nstohlerNo ratings yet

- Chapter 4 SolutionsDocument63 pagesChapter 4 Solutionszhusen liangNo ratings yet

- RBoomer M2C95Document63 pagesRBoomer M2C95Jhancarlos Gonzales HuarangaNo ratings yet

- Chapter 10 PERT-CPM PDFDocument24 pagesChapter 10 PERT-CPM PDF6 4 8 3 7 JAYAASRI KNo ratings yet

- PLC ProgrammingDocument163 pagesPLC Programmingtshamala gaelNo ratings yet

- iVMS-4500 (Android) Mobile Client Software User Manual V1.0Document17 pagesiVMS-4500 (Android) Mobile Client Software User Manual V1.0Black-q NewmanNo ratings yet

- Booking Example of Pemsion TrojskaDocument4 pagesBooking Example of Pemsion TrojskamaruthamangalamNo ratings yet

- COCU 4 - Meeting Preparation ActivitiesDocument6 pagesCOCU 4 - Meeting Preparation ActivitiesMuhammad nazrien NizamNo ratings yet

- La Peregrinación: Arr. I.Kovalevskiy Con MotoDocument2 pagesLa Peregrinación: Arr. I.Kovalevskiy Con Motohuong trinhNo ratings yet

- Profile Company Stipend Base CTC Location: This Is Unofficial Data. Data Not To Be Relied Upon. Actual Data May VaryDocument2 pagesProfile Company Stipend Base CTC Location: This Is Unofficial Data. Data Not To Be Relied Upon. Actual Data May VaryKomal MahtoNo ratings yet

- Lesson 2 FormsDocument37 pagesLesson 2 FormsJared Patani100% (1)

- Salon Management System ThesisDocument8 pagesSalon Management System Thesismichelejohnsonfargo100% (1)

- Excel+Homework+ +Ch+4+ (ABC)Document4 pagesExcel+Homework+ +Ch+4+ (ABC)Jasurbek MadjitovNo ratings yet

Technic Error Codes

Technic Error Codes

Uploaded by

prajwalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technic Error Codes

Technic Error Codes

Uploaded by

prajwalCopyright:

Available Formats

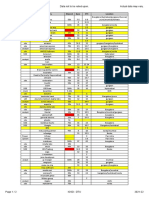

Typical safety shutdowns causes. For internal use.

Blink count Drive status output Drive status meaning MultiCam 3000 controller screen display MultiCam 5000 controller screen display See trouble shooting section in drive manual.

Rapid Enabled Drive is actively servoing.

Drive is ready to servo (not

Solid Ready, not enabled shutdown), but is disabled.

High input voltage or bus current has Over voltage/current. Incoming line voltage above 240 1) Input line voltage too high. 2) Regen circuit problem (5000). 3) Supply

Over-current/voltage (I/V) been sensed. Event could be Over voltage/current. Incoming line voltage too high for VAC or the regen resistor is disconnected - check for proper transformer not tapped for real A/C levels (3000). 4) Motor failure (phase

Three shutdown transient. current transformer tap position. seating. open). 5) Cable failure (phase open).

Drive temperature at rated limit. Check drive fans for Drive temperature at rated limit. Check drive fans for Assuming no thermostat: 1) Control box temperature excessive. 2) If using an

Drive temperature exceeding safe proper operation. Make sure air flow in or out of control proper operation. Make sure air flow in or out of control external cooling fan, drive fan off or airflow blocked. 3) Thermostat jumper

Four Over-temperature shutdown circuit limit. box is not restricted. box is not restricted. not in place. 4) Drive upside down.

Tracking limit exceeded. Confirm feed rate and cut rate OK Tracking limit exceeded. Confirm feed rate and cut rate OK 1) Command error (velocity or acceleration or both above spec). 2)

Tracking error has exceeded pre- for bit and material. Look for mechanical restrictions. for bit and material. Look for mechanical restrictions. Mechanical problem. 3) Low Voltage. 4) Motor cable problem. 5) Power

Five Tracking shutdown established limit. Check for low incoming line voltage. Check for low incoming line voltage. supply problem.

The continuous motor torque Motor torque requirement too high. Is programmed feed Motor torque requirement too high. Is programmed feed 1) Command error (velocity or acceleration or both too high). 2) Mechanical

requirement has exceeded its RMS rate within spec? Confirm cut speed OK for bit and rate within spec? Confirm cut speed OK for bit and problem/bind. 3) Load too heavy. 4) Motor cable problem. 5) Motor short

Six RMS shutdown torque limit. material. Check for mechanical bind or drag. material. Check for mechanical bind or drag. circuit.

Encoder signal problem. Confirm motor connectors are Encoder signal problem. Confirm motor connectors are

The drive has detected an illegal properly seated (especially shields) and check for visible properly seated (especially shields) and check for visible 1) Motor cable (logic side) problem. 2) Drive/Motor improperly grounded. 3)

Seven Encoder signal problem encoder state. cable damage. cable damage. Encoder failure (motor).

Eight Step failure Servo drive problem 8. Call customer service. Servo drive problem 8. Call customer service. 1) Drive failure.

Sensor signal problem. Confirm motor connectors are Sensor signal problem. Confirm motor connectors are

The drive has detected an illegal hall properly seated (especially shields) and check for visible properly seated (especially shields) and check for visible

Nine Commutation signal problem sensor state. cable damage. cable damage. 1) Motor cable problem. 2) Drive improperly grounded. 3) Motor hall failure.

Ten ADC failure Servo drive problem 10. Call customer service. Servo drive problem 10. Call customer service. 1) Drive failure.

Servo drive configuration file problem. Call customer Servo drive configuration file problem. Call customer 1) Drive problem. 2) Configuration file requires reload (due to communication

Eleven EE needs initializing service. service. problem during load).

Twelve EE hardware failure Servo drive problem 12. Call customer service. Servo drive problem 12. Call customer service. 1) Drive failure.

The drive uses the hall only upon full Vector sensor signal problem. Confirm motor connectors Vector sensor signal problem. Confirm motor connectors

reset to establish the torque vector. are properly seated (especially shields) and check for visible are properly seated (especially shields) and check for visible 1) Motor hall failure. 2) Motor cable (logic side) hall wire broken. 3) Drive

Thirteen Vector setup error An error was detected at start-up. cable damage. cable damage. problem.

Fourteen Current sensor fault Servo drive problem 15. Call customer service. Servo drive problem 15. Call customer service. 1) Drive failure.

The Drive's logic power is being

Fifteen Logic power backed-up backed up with main drive power off.

Position recovery window has

Power-up position recovery exceeded pre-defined limit, drive

Sixteen window exceeded won't recover position.

ASSUMPTIONS: 1. The drive configuration file is correct for the motor and application.

2. The DSP is running under the correct voltage.

3. The drive has been reset after any motor cable disconnect.

NOTES: 1. Blink counts Rapid, Solid, 15 and 16 are indicator states, not shutdowns.

2. Blink count 16 or 17 requires 5.5 volt back-up power and appropriate QuickSet settings to engage.

You might also like

- Windows Username and Password: Weight: 1Document12 pagesWindows Username and Password: Weight: 1Aamir ShaikhNo ratings yet

- Fault Code 285 SAE J1939 Multiplexing PGN Timeout Error - Abnormal Update RateDocument13 pagesFault Code 285 SAE J1939 Multiplexing PGN Timeout Error - Abnormal Update RateAhmedmah100% (2)

- Code Error RolandDocument8 pagesCode Error Rolandantonio_brasileiro_1No ratings yet

- Fault Code 286 SAE J1939 Multiplexing Configuration Error - Out of CalibrationDocument13 pagesFault Code 286 SAE J1939 Multiplexing Configuration Error - Out of CalibrationAhmedmahNo ratings yet

- Doosan Servo Drive Unit Maintenance ManualDocument22 pagesDoosan Servo Drive Unit Maintenance ManualRogerio Silva PedroNo ratings yet

- Cummins: Fault Code: 385 PID: S232 SPN: 620 FMI: 3 or 1Document6 pagesCummins: Fault Code: 385 PID: S232 SPN: 620 FMI: 3 or 1Enrrique LaraNo ratings yet

- SSt-U 5 Blink & Error CodesDocument1 pageSSt-U 5 Blink & Error CodesAzizi SamNo ratings yet

- Powerfoil X3.0 Error Codes (Delta E Series VFD) : Error Code Description and Corrective ActionDocument2 pagesPowerfoil X3.0 Error Codes (Delta E Series VFD) : Error Code Description and Corrective ActionbrayanNo ratings yet

- 19369681714Document2 pages19369681714sagarprajapati6998No ratings yet

- Vibration Excessive: This Troubleshooting Procedure Should Be Followed For The Following SymptomsDocument23 pagesVibration Excessive: This Troubleshooting Procedure Should Be Followed For The Following SymptomsMuhammad Ishfaq100% (2)

- A - Syntec Driver Alarm ManualDocument291 pagesA - Syntec Driver Alarm ManualInduk HanNo ratings yet

- A - Syntec Driver Alarm ManualDocument291 pagesA - Syntec Driver Alarm Manualphạm minh hùngNo ratings yet

- Cummins: Fault Code: 444 PID: S232 SPN: 620 FMI: 3 or 4Document7 pagesCummins: Fault Code: 444 PID: S232 SPN: 620 FMI: 3 or 4Enrrique LaraNo ratings yet

- 3 Phase Induction Motor Fault List and Solution: Problems: Like Causes: What To DoDocument3 pages3 Phase Induction Motor Fault List and Solution: Problems: Like Causes: What To DoVENKATA RAJUNo ratings yet

- Siid Siid: Electronic Venders Electronic VendersDocument7 pagesSiid Siid: Electronic Venders Electronic VenderswernerkaiNo ratings yet

- LBMC Hj5Ae: Product Introduction Key FeaturesDocument5 pagesLBMC Hj5Ae: Product Introduction Key FeaturesanjaliNo ratings yet

- 6E-104 4Ja1/4Jh1 Engine Driveability and Emissions Breaker Box Connection Type BDocument303 pages6E-104 4Ja1/4Jh1 Engine Driveability and Emissions Breaker Box Connection Type BVõ Nam PhươngNo ratings yet

- Alarm Delta VFD - E SeriesDocument4 pagesAlarm Delta VFD - E SeriesSadik HasanNo ratings yet

- ESDB AC Servo Drive User ManualDocument92 pagesESDB AC Servo Drive User ManualUsama ZaheerNo ratings yet

- ES52 User ManualDocument24 pagesES52 User ManualSylvainsfcNo ratings yet

- ES52 User ManualDocument24 pagesES52 User ManualSylvainsfcNo ratings yet

- ES52 User ManualDocument24 pagesES52 User ManualSylvainsfcNo ratings yet

- Notes For Accounting 101Document10 pagesNotes For Accounting 101revyhoheNo ratings yet

- DTC P0734 - Incorrect Gear RatioDocument4 pagesDTC P0734 - Incorrect Gear RatioHermawan 0103No ratings yet

- Kinetix Error Codes-1Document18 pagesKinetix Error Codes-1Renzo DamianNo ratings yet

- Land Rover Bosch GS8.87 Transmission Management (D2 & RR P38)Document13 pagesLand Rover Bosch GS8.87 Transmission Management (D2 & RR P38)ZM OhnNo ratings yet

- DTC P1345 Crankshaft Position (CKP) - Camshaft Position (CMP) CorrelationDocument5 pagesDTC P1345 Crankshaft Position (CKP) - Camshaft Position (CMP) CorrelationChino PlagaNo ratings yet

- Troubleshooting From I566-E1-02 G (ML2)Document25 pagesTroubleshooting From I566-E1-02 G (ML2)احمدمحمد الخياطNo ratings yet

- ENGLISH - Operation Guide SD SeriesDocument85 pagesENGLISH - Operation Guide SD Seriescatur skakNo ratings yet

- VFD EMERSON DiagnosticsDocument2 pagesVFD EMERSON Diagnosticsjuan guerreroNo ratings yet

- Maintenance & Troubleshooting: Problem IsolationDocument16 pagesMaintenance & Troubleshooting: Problem IsolationÁgost VitaNo ratings yet

- Accent P0012 Camshaft Position-Timing Over-Retarded (Bank 1)Document5 pagesAccent P0012 Camshaft Position-Timing Over-Retarded (Bank 1)flash_24014910No ratings yet

- Chapter 7. MAINTENANCE TroubleshootingDocument12 pagesChapter 7. MAINTENANCE TroubleshootingnasrunNo ratings yet

- LBMC Hk5Ap: Product Introduction Key FeaturesDocument5 pagesLBMC Hk5Ap: Product Introduction Key FeaturesanjaliNo ratings yet

- ACS580 Troubleshooting: Fault TracingDocument25 pagesACS580 Troubleshooting: Fault TracingMohamed Ayman Hefny MohamedNo ratings yet

- 8 Diagnostics: Trip Code Condition Possible CauseDocument2 pages8 Diagnostics: Trip Code Condition Possible CausePedroNo ratings yet

- 11-4 Troubleshooting: Symptom Probable Cause Items To Check MeasuresDocument1 page11-4 Troubleshooting: Symptom Probable Cause Items To Check MeasuresDominique KomeyNo ratings yet

- Problemas Con Husillo. Servicio HaasDocument5 pagesProblemas Con Husillo. Servicio Haasecaldera10100% (1)

- ATV 78 - Fault TracingDocument4 pagesATV 78 - Fault TracingHddjdjNo ratings yet

- Diagnostics and Troubleshooting Schneider ElectricDocument5 pagesDiagnostics and Troubleshooting Schneider ElectricManohar Paul Praveen MNo ratings yet

- Maintenance & TroubleshootingDocument4 pagesMaintenance & TroubleshootingJovenlou BihagNo ratings yet

- CAT - 3516H Engine Shutdown or Start Inhibit Initiated by Driven EquipmentDocument2 pagesCAT - 3516H Engine Shutdown or Start Inhibit Initiated by Driven Equipmentwagner_guimarães_1100% (1)

- FAULT CODE 1117 - Power Supply Lost With Ignition On - Data Erratic, Intermittent, or IncorrectDocument8 pagesFAULT CODE 1117 - Power Supply Lost With Ignition On - Data Erratic, Intermittent, or IncorrectAli ArdinNo ratings yet

- Fault Messages and List of FaultsDocument5 pagesFault Messages and List of FaultsAhmadNo ratings yet

- Extrait Doc Variateur GBDocument7 pagesExtrait Doc Variateur GBErick Fernando Chavez VargasNo ratings yet

- US100 Servo Manual-2018Document82 pagesUS100 Servo Manual-2018Hamed YazidiNo ratings yet

- I3500 TroubleshootingDocument14 pagesI3500 TroubleshootingAdriana Velásquez100% (2)

- Manual: Diversified Products, Inc. PowertraxDocument24 pagesManual: Diversified Products, Inc. PowertraxProyectos Trans roll, C.A. OficinaNo ratings yet

- T790 Treadmill: Customer Support Services Service ManualDocument61 pagesT790 Treadmill: Customer Support Services Service ManualtelebilNo ratings yet

- Reelmaster 5010-H Diagnostic Fault Code Quick Reference TableDocument38 pagesReelmaster 5010-H Diagnostic Fault Code Quick Reference TableValentin PiersonNo ratings yet

- Possible Solution: KNIGHT Fault # DescriptionDocument2 pagesPossible Solution: KNIGHT Fault # DescriptionFundidora UnknownNo ratings yet

- CTB Motor ManualDocument12 pagesCTB Motor ManualTibor ĎurišNo ratings yet

- 58 CBBBBBF 09 C 4Document41 pages58 CBBBBBF 09 C 4amitNo ratings yet

- SEVCON Fault Code Meanings: Message DescriptionDocument4 pagesSEVCON Fault Code Meanings: Message Descriptionmarius borcauNo ratings yet

- UniMAT Servo Set ManualDocument84 pagesUniMAT Servo Set ManualGilberto Figueroa100% (1)

- Yaskawa Alarms Faults 3735Document18 pagesYaskawa Alarms Faults 3735charlydigitalNo ratings yet

- HD785-7 SEN01274-15 Shop Manual-804-1004Document201 pagesHD785-7 SEN01274-15 Shop Manual-804-1004Muhammad RizqiNo ratings yet

- File - D - Desktop - DVD - Final - DVD - GAC Controller - Troubleshooting - PDFDocument16 pagesFile - D - Desktop - DVD - Final - DVD - GAC Controller - Troubleshooting - PDFNAVANEETHNo ratings yet

- ErrorList2004 11 24engDocument70 pagesErrorList2004 11 24englongsony2013No ratings yet

- Part 1: Commissioning: Liquiline M CM42Document36 pagesPart 1: Commissioning: Liquiline M CM42Rabah AmidiNo ratings yet

- Circuits For Hobbyists - A Collection of Schematics To Build PDFDocument1 pageCircuits For Hobbyists - A Collection of Schematics To Build PDFWilliam PacatteNo ratings yet

- Tle TVL Ict TD Module 3Document8 pagesTle TVL Ict TD Module 3MheraldyneFaith MaderaNo ratings yet

- Arcolinux Cheatsheet v2.3Document2 pagesArcolinux Cheatsheet v2.3Antonio Maria ConcepcionNo ratings yet

- Heuristic Methods To Solve Optimal Power Flow Problem: Rengin Idil CABADAG, Belgin Emre TURKAYDocument7 pagesHeuristic Methods To Solve Optimal Power Flow Problem: Rengin Idil CABADAG, Belgin Emre TURKAYhakandaghanNo ratings yet

- Unit 3 NotesDocument78 pagesUnit 3 NotesKoushiNo ratings yet

- DATA CENTER TIERS - 1, 2, 3 & 4 Explained With DownloadsDocument48 pagesDATA CENTER TIERS - 1, 2, 3 & 4 Explained With DownloadsDilip PaliwalNo ratings yet

- 2080IF4Document2 pages2080IF4Rakibul HassanNo ratings yet

- A5E44852162-ACen P320P420 HART OI en-USDocument280 pagesA5E44852162-ACen P320P420 HART OI en-USvaab11No ratings yet

- Migrating From TDM To Ip Getting The Ball RollingDocument10 pagesMigrating From TDM To Ip Getting The Ball Rollingmagdy elmasryNo ratings yet

- CKMM Change Material Price Determination PDFDocument10 pagesCKMM Change Material Price Determination PDFSurabhi Chaurasia100% (1)

- LPL Textbook PDFDocument621 pagesLPL Textbook PDFJonathan MahNo ratings yet

- Music Player REPORTDocument33 pagesMusic Player REPORTvishukephotosNo ratings yet

- 1by17cs040 Internship ReportDocument35 pages1by17cs040 Internship Reportch venkateshNo ratings yet

- Data Representation - User Defined Data Types and Mantisa and ExponentDocument7 pagesData Representation - User Defined Data Types and Mantisa and ExponentAmul BashyalNo ratings yet

- Robots Need Us More Than We Need ThemDocument18 pagesRobots Need Us More Than We Need ThemIbrahim AltkamulNo ratings yet

- Polytune Software Update Windows 7Document6 pagesPolytune Software Update Windows 7nstohlerNo ratings yet

- Chapter 4 SolutionsDocument63 pagesChapter 4 Solutionszhusen liangNo ratings yet

- RBoomer M2C95Document63 pagesRBoomer M2C95Jhancarlos Gonzales HuarangaNo ratings yet

- Chapter 10 PERT-CPM PDFDocument24 pagesChapter 10 PERT-CPM PDF6 4 8 3 7 JAYAASRI KNo ratings yet

- PLC ProgrammingDocument163 pagesPLC Programmingtshamala gaelNo ratings yet

- iVMS-4500 (Android) Mobile Client Software User Manual V1.0Document17 pagesiVMS-4500 (Android) Mobile Client Software User Manual V1.0Black-q NewmanNo ratings yet

- Booking Example of Pemsion TrojskaDocument4 pagesBooking Example of Pemsion TrojskamaruthamangalamNo ratings yet

- COCU 4 - Meeting Preparation ActivitiesDocument6 pagesCOCU 4 - Meeting Preparation ActivitiesMuhammad nazrien NizamNo ratings yet

- La Peregrinación: Arr. I.Kovalevskiy Con MotoDocument2 pagesLa Peregrinación: Arr. I.Kovalevskiy Con Motohuong trinhNo ratings yet

- Profile Company Stipend Base CTC Location: This Is Unofficial Data. Data Not To Be Relied Upon. Actual Data May VaryDocument2 pagesProfile Company Stipend Base CTC Location: This Is Unofficial Data. Data Not To Be Relied Upon. Actual Data May VaryKomal MahtoNo ratings yet

- Lesson 2 FormsDocument37 pagesLesson 2 FormsJared Patani100% (1)

- Salon Management System ThesisDocument8 pagesSalon Management System Thesismichelejohnsonfargo100% (1)

- Excel+Homework+ +Ch+4+ (ABC)Document4 pagesExcel+Homework+ +Ch+4+ (ABC)Jasurbek MadjitovNo ratings yet