Professional Documents

Culture Documents

m0043 003 1 PDF

m0043 003 1 PDF

Uploaded by

ajarekarga ajarekarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

m0043 003 1 PDF

m0043 003 1 PDF

Uploaded by

ajarekarga ajarekarCopyright:

Available Formats

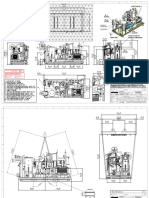

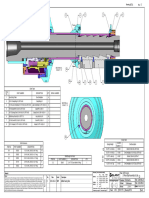

JOB: C1683 PKG: 55 CNTRL NO: M0043-003 RCPT: 1

DWG NO. SHT 3 OF 3 REV

8 7 6 5 4 3 6A 0 1

PARTITION TO PARTITION, PARTITION TO END PLATES

A12M TUBE AND PLUG SHEET TO TOP AND BOTTO M PLATE B END PLATES TO ALL OTHER OUTSIDE PLATES C TUBE & PLUG SHEET, TOP

D

(SEAL WELD)

(TOP OR BTM PLATE) END PL THK. ANG. "b" & BOTTOM PLATE (PLUG HEADER)

(SEAL WELD)

16 "

UP TO 1 1/2" = 30

1

1 5/8" TO 2" = 25

2 1/8" TO 2 1/2" = 20

8"

b

PARTITION

1

4"

1

D (TUBE OR D

PLUG SHT)

45 30

1/4" MIN.

WELD SIZE

FILLET WELD

JOINT PREPARATION END PLATE

+ 81 " MIN.

WELD DETAIL 1/4

NOTES: JOINT PREPARATION WELD DETAIL ALL WELD SIZES ARE CORROSION

MAX.

1. CARBON ARC GOUGING FOOR P1A-4 ONLY, IF REQ'D.

ALLOWANCE +1/8"

WELD PROC. NO.: P1TMA-4(R1); P1G-1 (R3); P1G-1 (R3);

WELD PROC. NO.: P1A-4(APP.28) P1TM-1(R7) WELD PROC. NO.: P1TM-1 (R7) WELD PROC. NO.: P1TM-1(R7)

EM SHOULDER PLUG TAP F1 TUBE HOLE GROOVING 3 H6 WELD NECK FLANGE, PIPE K TRANSITION OR PIPE TO

WELD NECK FLANGE

R6M STIFFENER OR PARTITION

USED AS STIFFENER TO

DOUBLE GROOVE IF TUBESHEET > 4 " OR TRANSITION TO HEADER

OUTSIDE FACE 3" 1 1/4" TUBE & PLUG SHEET

1" 8 8" FILLET

OF SHEET (MIN) FLANGE

THK. TUBE OR PLUG SHEET

+15 +15

30 45

+1/16

-7.5 30 -7.5

SPOT FACE:

-0

63-125 AARH

& GREATER

GENERAL NOTES

16 "

FINISH +15

1

OUTSIDE

8" THK

30 -7.5

-1/16"

FACE OF

8"

1

TUBE SIZE

+0

1" TUBESHEET 1. APPLICABLE ASME CODE PARAGRAPH FOR MDMT: EXEMPT FROM CHARPY IMPACT TESTING PER UG-20(f).

1

3

4"

CHAMFERED OR

1

1 1 1 4 " THK. 2 +15 2. API-661 REQUIRED: YES (7TH EDITION, 2013).

1" = TAP 1 8" -12UNF,SPOT FACE=1 2" ROUNDED

& OVER TOP OR BTM PLATE 30 -7.5

1 3 3 3. NATIONAL BOARD REGISTRATION REQUIRED: YES.

TUBE OR PLUG SHEET 1

1 4 " = TAP 1 8" -12UNF,SPOT FACE=1 4" GROOVE TO BE APPROXIMATELY 16 " 4. CERTIFIED MILL TEST REPORTS REQUIRED FOR ALL PRESSURE RETAINING PARTS.

1 5 1 1 "NO UT REQ'D."

1 2 " = TAP 1 8" -12UN,SPOT FACE=2" 8 " WIDE X 64 " DEEP JOINT EFFICIENCY = 70% 5. HYDROTEST PRESSURE BASED ON 1.3 X MAP (NEW & COLD).

C 1 1 TUBE HOLES: PER API-661 WELD PROC. NO.: P1TFC-2M; P1TMA-4 (R1) C

6. MAWP (HOT & CORRODED) LIMITED BY FLANGE RATING.

2" = TAP 2 8" -12UN,SPOT FACE=2 2"

STANDARD FIT P1TM-1(R7) WELD PROC. NO.: P1GA-STT WELD PROC. NO.: P1A-4 7. MAP (NEW & COLD) = 283 PSIG, LIMITED BY FLANGE RATING.

8. PLATE SHALL BE EXAMINED BEFORE AND AFTER WELDING BY MT PER UG-93(d)(3).

9. MAWP REDUCED BY 2 PSIG FOR STATIC HEAD.

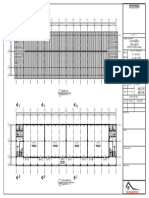

SHOP NOTES

1. ALL ACCESSORY PLATES (NAMEPLATE BRACKET, SHIPPING LUGS, ETC.) TO BE 3/16 SEAL WELDED UNLESS NOTED.

2. PLATES INCLUDE ADDITIONAL LENGTH AT EACH END FOR SAWING.

3. PLATES INCLUDE ADDITIONAL WIDTH FOR MACHINING.

4. ALL PLUG AND HEADER THREADS SHALL BE COATED WITH LOC-TITE C5A LUBRICANT.

5. ALL CARBON STEEL MACHINED SURFACES, FLANGE FACES, AND/OR STUDS, TO BE COATED WITH TECTYL 891 RUST

PREVENTATIVE.

6. PLUG TORQUE = 142 FT-LB MIN, 272 FT-LB MAX.

7. PWHT AT 1125-1175 F FOR ONE-HOUR MIN.

8. NOZZLE HEADER WEIGHT (DRY) = 2234 LB.

9. RETURN HEADER WEIGHT (DRY) = 1784 LB.

10. PRESSURIZE BUNDLE TO 15 PSIG WITH DRY NITROGEN.

11. BUNDLES TO BE DRAINED AND DRIED WITH SHOP AIR AFTER HYDRO.

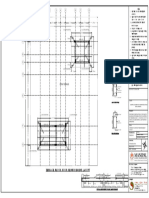

12. MT NOZZLE CUT OUT, PLATE EDGES, EXTERNAL HEADER FINAL WELDS, NOZZLE TO HEADER ROOT PASS AND FINAL

B WELDS, AND FLANGE TO PIPE FINAL WELDS.

B

DWG NO.

13. SPOT RT ALL BUTT WELDS.

14. WFMPT PLATE EDGES 1 AND THICKER.

15. BASELINE UT THICKNESS MEASUREMENTS REQUIRED.

16. LONG SEAM WELDS DO NOT NEED TO BE GROUND FLUSH AT HEADER SUPPORT ANGLES, HEADER TIE-DOWN ANGLES,

SPACER PLATES, OR SLIDE PAD PLATES.

17. COATING: SEE DWG. C1.

6A

18. SPOT RT PER THE REQUIREMENTS OF API 661.

SHT 3 OF 3

19. HARDNESS TESTING PER THE REQUIREMENTS OF API 661.

REV

0

0 2/6/2019 INITIAL RELEASE CV GJH

REV DATE DESCRIPTION DRAWN APPR'D

ISSUE AND REVISION HISTORY

PURCHASE ORDER CUSTOMER

C1683-M0043 S&B ENGINEERS AND CONSTRUCTORS

BANK ITEM PHILLIPS 66

A ~ SWY-4900-GRP-24-201 OLD OCEAN, TX A

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES.

TOLERANCES ARE:

HUDSON PRODUCTS CORPORATION

X.

DECIMALS

: .06 X.

ANGLES

: 2

Beasley, Texas

.X : .03 .X : 1

.XX : .015 .XX : .5 TITLE

.XXX : .005 FRACTIONS

ALL : 1/16

THIS DOCUMENT IS THE PROPERTY OF HUDSON PRODUCTS

CORPORATION AND SHALL BE RETURNED ON DEMAND. IT SHALL NOT

BE TRADED, REPRODUCED, OR USED IN ANY WAY, DIRECTLY OR

CONSTRUCTION DETAIL

INDIRECTLY, THAT IS DETRIMENTAL TO THE INTERESTS OF HUDSON

PRODUCTS CORPORATION. COPYRIGHT HUDSON PRODUCTS

CORPORATION - ALL RIGHTS RESERVED. SIZE PROJECT DRAWING NUMBER SHEET 3 OF 3 REV

MATERIAL:

D K931 6A 0

COATING: DO NOT MANUALLY EST. THIRD ANGLE

ALTER OR SCALE WT: lbs PROJECTION:

SCALE NTS

8 7 6 5 4 3 2 1

You might also like

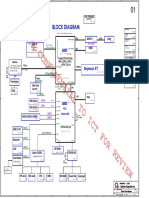

- Dell Inspiron 15 3567 Wistron Vegas Turis SKL KBL U Rev A00 15341 1 SchematicDocument105 pagesDell Inspiron 15 3567 Wistron Vegas Turis SKL KBL U Rev A00 15341 1 Schematicredis1973100% (2)

- GCS Interview Questions GuideDocument14 pagesGCS Interview Questions GuideAnkita ManchandaNo ratings yet

- Design Build and Assess Composite Hub Bar For Gyroplane Application GYRATEDocument30 pagesDesign Build and Assess Composite Hub Bar For Gyroplane Application GYRATEvictorNo ratings yet

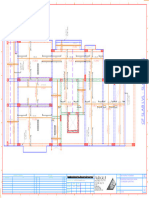

- Maintenance/clearance Area: Dimensions Could Be Change +/-5 MMDocument2 pagesMaintenance/clearance Area: Dimensions Could Be Change +/-5 MMZander MctrevorNo ratings yet

- Detail A: Assembly and Detail Shipping Lug Detail 54" Steam Drum FM 120-124 LH BOILERDocument1 pageDetail A: Assembly and Detail Shipping Lug Detail 54" Steam Drum FM 120-124 LH BOILERmorrisonNo ratings yet

- Esquema Elétrico D6T CATERPILLARDocument1 pageEsquema Elétrico D6T CATERPILLARKardean AlvesNo ratings yet

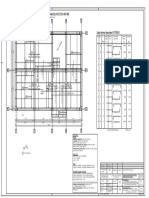

- Yashpalbhai GF Slab R0 12.01.24 BDocument1 pageYashpalbhai GF Slab R0 12.01.24 BGyayak BhutaNo ratings yet

- Quanta LZ3C Rev 2a - Lenovo Ideapad z585Document51 pagesQuanta LZ3C Rev 2a - Lenovo Ideapad z585Raj kishorNo ratings yet

- Th255c Cat Hyd SchemDocument4 pagesTh255c Cat Hyd SchemKevine KhaledNo ratings yet

- BMRCL 32M 003Document1 pageBMRCL 32M 003DOMNo ratings yet

- Power Schematic Diagram: (TV MT PCB)Document1 pagePower Schematic Diagram: (TV MT PCB)alanNo ratings yet

- PennDOT NEXT Beam StandardDocument2 pagesPennDOT NEXT Beam StandardProfessor Puppies100% (1)

- BSG1018 - Rev 3Document1 pageBSG1018 - Rev 3Xu DuaNo ratings yet

- Durabrand DBTV1901 Orion TV-1934ADocument63 pagesDurabrand DBTV1901 Orion TV-1934Aelectronicatotal100% (1)

- Block Diagram: DDR IiiDocument51 pagesBlock Diagram: DDR Iiijoe wiillsonNo ratings yet

- Sump Discharge Piping - ISOMETRIC DrawingDocument9 pagesSump Discharge Piping - ISOMETRIC DrawingIlham KelanaNo ratings yet

- Material List - Fabrication: - / - A1ZA-1 2 PMDocument2 pagesMaterial List - Fabrication: - / - A1ZA-1 2 PMMallela Sampath KumarNo ratings yet

- 1 2 3 4 5 Plan Armare Planseu Peste Parter: Gol ScaraDocument1 page1 2 3 4 5 Plan Armare Planseu Peste Parter: Gol ScaraGeorge EnacheNo ratings yet

- Parikalp: Reference Drawings RevisionsDocument1 pageParikalp: Reference Drawings RevisionsGyayak BhutaNo ratings yet

- Flow Pattern: OUT INDocument1 pageFlow Pattern: OUT INrs755No ratings yet

- BLIND FLANGE 28 IN 150 RF - SERIES A Rev.01 PDFDocument1 pageBLIND FLANGE 28 IN 150 RF - SERIES A Rev.01 PDFdhani projectoNo ratings yet

- Arranque Smar Key 1Document1 pageArranque Smar Key 1almeidajuarezjuancarlosNo ratings yet

- Wistron Sapporo-GLK (Gemini Lake) 4PD0E6010001 17891-1MDocument104 pagesWistron Sapporo-GLK (Gemini Lake) 4PD0E6010001 17891-1Misai ramos sotoNo ratings yet

- Security Record ShopsDocument38 pagesSecurity Record ShopsMulti PhaseNo ratings yet

- BLDG. - D1 - 16.11.23-ModelDocument1 pageBLDG. - D1 - 16.11.23-Modelincogtrader8No ratings yet

- 44 SbsDocument1 page44 SbsCampel SilvaNo ratings yet

- (Cont. Next Page) 26 HiluxDocument4 pages(Cont. Next Page) 26 HiluxautocomtrucksNo ratings yet

- 26 PDFDocument4 pages26 PDFautocomtrucksNo ratings yet

- (Cont. Next Page) 26 HiluxDocument4 pages(Cont. Next Page) 26 HiluxautocomtrucksNo ratings yet

- (Cont. Next Page) 26 HiluxDocument4 pages(Cont. Next Page) 26 HiluxautocomtrucksNo ratings yet

- (Cont. Next Page) 26 HiluxDocument4 pages(Cont. Next Page) 26 HiluxautocomtrucksNo ratings yet

- (Cont. Next Page) 26 HiluxDocument4 pages(Cont. Next Page) 26 HiluxautocomtrucksNo ratings yet

- 26 PDFDocument4 pages26 PDFautocomtrucksNo ratings yet

- Roundrock MLK (15203-1 JM7HC) (Rev A00) PDFDocument69 pagesRoundrock MLK (15203-1 JM7HC) (Rev A00) PDFCarlosNo ratings yet

- Dell N5040 DV15 - CP 10263-1 48.4ip01.011 - A00 - MB - 0422 - InsDocument99 pagesDell N5040 DV15 - CP 10263-1 48.4ip01.011 - A00 - MB - 0422 - InsSadiq Al-MohandisNo ratings yet

- Dell Latitude 3350 Wistron Round Rock MLK MB 15203-A00 Rev A00Document110 pagesDell Latitude 3350 Wistron Round Rock MLK MB 15203-A00 Rev A00MihohohoNo ratings yet

- Single Analog Output Option Card: Synergy SeriesDocument4 pagesSingle Analog Output Option Card: Synergy Seriesmetalcernaw rodriguezNo ratings yet

- Andika Shirt A0Document1 pageAndika Shirt A0Anonymous tIhcNRlpSnNo ratings yet

- Mytee 8400P Air Lite Upholstery Tool Parts ManualDocument1 pageMytee 8400P Air Lite Upholstery Tool Parts ManualJOSE ARRTURO0% (1)

- T400, T700 Temp. Switch Installation and Maintenance ManualDocument2 pagesT400, T700 Temp. Switch Installation and Maintenance ManualHuan Trinh VanNo ratings yet

- RENR4046Document2 pagesRENR4046Cecilia Gomez.contrerasNo ratings yet

- Leaf Side Clamp HEX NUT M5: Parts ListDocument2 pagesLeaf Side Clamp HEX NUT M5: Parts ListPrabhat HambireNo ratings yet

- 008-4th Floor & Roof PlanDocument1 page008-4th Floor & Roof Planmrhtoo119No ratings yet

- Drawbar Prox Sensor States Prox Sensor No Tool Tool in Tool ReleaseDocument1 pageDrawbar Prox Sensor States Prox Sensor No Tool Tool in Tool Releasejorge varNo ratings yet

- 81731E CRTi 8.63 2piecDocument1 page81731E CRTi 8.63 2piecUmar IkramNo ratings yet

- Hoist Beam & Connection SketchDocument2 pagesHoist Beam & Connection SketchJuan Misael Astudillo SteppesNo ratings yet

- 5368 (Diagramas - Com.br)Document106 pages5368 (Diagramas - Com.br)Davy AtilaNo ratings yet

- General Installation Notes: Bell 407 Rotorcraft Installation, G500H SystemDocument39 pagesGeneral Installation Notes: Bell 407 Rotorcraft Installation, G500H SystemJudhi C ArdyantoNo ratings yet

- Bill of Material - 3105538: QTY Description Part No. ItemDocument3 pagesBill of Material - 3105538: QTY Description Part No. ItemluisNo ratings yet

- 2 Ton Steering SystemDocument1 page2 Ton Steering SystemArnie SaysonNo ratings yet

- This Is New PDFDocument1 pageThis Is New PDFAnonymous BZQOJwWIh6No ratings yet

- 13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Document1 page13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Anonymous BZQOJwWIh6No ratings yet

- Door Lock Control RHDDocument2 pagesDoor Lock Control RHDskNo ratings yet

- Catalogo 2018 DIODocument133 pagesCatalogo 2018 DIOSamara Maya100% (1)

- Aluminum Body DetailsDocument26 pagesAluminum Body DetailsVinod YbNo ratings yet

- Architecture DrawingDocument3 pagesArchitecture DrawingDwiki SetiabudiNo ratings yet

- Niigata Airport: ELEV 1.40m (4.6ft)Document23 pagesNiigata Airport: ELEV 1.40m (4.6ft)張允執No ratings yet

- Naik Associates: ProjectDocument1 pageNaik Associates: Projectshivraj naikNo ratings yet

- Contact Us: Prestressed SpunDocument2 pagesContact Us: Prestressed Spunconcrete engineeringNo ratings yet

- 3.podium Level 1-NF-SD-FF-PLN-102Document1 page3.podium Level 1-NF-SD-FF-PLN-102mirfan10053No ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- Advances Photonic CrystalsDocument348 pagesAdvances Photonic CrystalsMuhammad Shemyal NisarNo ratings yet

- Negotiations 5 - Clinching The Deal - WorksheetDocument7 pagesNegotiations 5 - Clinching The Deal - WorksheetNatalia InsuaNo ratings yet

- Historical Development of Human RightsDocument3 pagesHistorical Development of Human RightsHazel UsanaNo ratings yet

- Final Chapter 4Document19 pagesFinal Chapter 4Jhanelyn V. InopiaNo ratings yet

- UPSE Discussion Paper On Maharlika FundDocument28 pagesUPSE Discussion Paper On Maharlika FundjosnixNo ratings yet

- TDC Book Parte6Document44 pagesTDC Book Parte6QUARCISSUSNo ratings yet

- Dangers of Social Networking 1Document4 pagesDangers of Social Networking 1Kerri McFarlaneNo ratings yet

- RCPI OBE BST Paediatrics Curriculum Final PilotDocument40 pagesRCPI OBE BST Paediatrics Curriculum Final PilotBharat Kumar SharmaNo ratings yet

- Module 1Document140 pagesModule 1naitik S TNo ratings yet

- Eu Law ExamDocument14 pagesEu Law ExamOla PietruszewskaNo ratings yet

- Project Report On Ulip & Mutual FundDocument55 pagesProject Report On Ulip & Mutual FundGovind BhakuniNo ratings yet

- Week4.Individual AssignmentDocument6 pagesWeek4.Individual AssignmentFrederickPaigeIIINo ratings yet

- MoM Team Review 14-3-2024Document1 pageMoM Team Review 14-3-2024krupuk.kricikNo ratings yet

- CAPITALGAINS 3rdsep PDFDocument202 pagesCAPITALGAINS 3rdsep PDFPhani Kumar SomarajupalliNo ratings yet

- LTD Palabrica NotesDocument20 pagesLTD Palabrica NotesDarla Grey0% (1)

- C. Health Problems Common in ToddlerDocument72 pagesC. Health Problems Common in ToddlerRika MaeNo ratings yet

- Peralatan KantorDocument47 pagesPeralatan KantorEva SiswantiNo ratings yet

- PGL FIN 2006 01 Subrecipient Financial ProceduresDocument45 pagesPGL FIN 2006 01 Subrecipient Financial ProceduresAilec FinancesNo ratings yet

- Effective Removal of Phosphorus From High Phosphorus Steel Slag Using Carbonized Rice HuskDocument9 pagesEffective Removal of Phosphorus From High Phosphorus Steel Slag Using Carbonized Rice HuskApto SubaNo ratings yet

- Vedic Multiplier DesignDocument39 pagesVedic Multiplier DesignVeena Sridhar100% (1)

- Traverse Adjustment ReportDocument3 pagesTraverse Adjustment Reportpopovicib_2No ratings yet

- Zwcad Cost ComparisonDocument1 pageZwcad Cost ComparisonVishvam Vishu 26No ratings yet

- Wartsila Brochure - Marine Solutions 2016Document228 pagesWartsila Brochure - Marine Solutions 2016OnceoffpleaseNo ratings yet

- Registration of SocietyDocument6 pagesRegistration of SocietyDeepak AroraNo ratings yet

- Cryoseal: Liquid Nitrogen Containers (Dewars) : Also Available 340/550 Liters Bulk Storage ContainersDocument2 pagesCryoseal: Liquid Nitrogen Containers (Dewars) : Also Available 340/550 Liters Bulk Storage ContainersDr. Awanish MishraNo ratings yet

- IMChap 011Document24 pagesIMChap 011Aaron Hamilton100% (2)

- Hashimoto'S: ProtocolDocument13 pagesHashimoto'S: ProtocolNatasa EricNo ratings yet

- Socialism in Europe & The Russian RevolutionDocument21 pagesSocialism in Europe & The Russian Revolutionthinkiit50% (2)