Professional Documents

Culture Documents

Microbial Zoning & Swab Test Schedule (138126)

Microbial Zoning & Swab Test Schedule (138126)

Uploaded by

ArunPrakash JCopyright:

Available Formats

You might also like

- QAP - Powder CoatingDocument4 pagesQAP - Powder Coatingnaveen yadavNo ratings yet

- Encyclopedia of Korean Folk BeliefsDocument167 pagesEncyclopedia of Korean Folk BeliefsAria7No ratings yet

- Mat'l Sourcing List (Saudi Aramco)Document130 pagesMat'l Sourcing List (Saudi Aramco)Pageduesca Rouel100% (2)

- Stress - The Different Kinds of StressDocument4 pagesStress - The Different Kinds of StressbogdanNo ratings yet

- Chemical Analysis: Si No. RM ParametersDocument10 pagesChemical Analysis: Si No. RM ParametersarunNo ratings yet

- Mud Report Geotermal 11.04.2024Document1 pageMud Report Geotermal 11.04.2024cristianjugaruNo ratings yet

- IPAL RTM 5 m3Document8 pagesIPAL RTM 5 m3Axl FerreraNo ratings yet

- D Pharmacy Lab InstrumentsDocument10 pagesD Pharmacy Lab InstrumentssajedNo ratings yet

- 05.chemical MEI 2019Document106 pages05.chemical MEI 2019Andhy AlfharoNo ratings yet

- Product Information Sheet: Synthite Industries Private LimitedDocument2 pagesProduct Information Sheet: Synthite Industries Private LimitedMaurice Dan GeroyNo ratings yet

- Jenis Operasi Sedang Kls.3: Bba Ok Rsu An Nisaa'Document14 pagesJenis Operasi Sedang Kls.3: Bba Ok Rsu An Nisaa'DINA NORINENo ratings yet

- Product Information Sheet: Synthite Industries Private LimitedDocument2 pagesProduct Information Sheet: Synthite Industries Private LimitedMaurice Dan GeroyNo ratings yet

- Form Daily DaehwaDocument2 pagesForm Daily DaehwarismaNo ratings yet

- IPAL RTM 10 m3Document8 pagesIPAL RTM 10 m3Axl FerreraNo ratings yet

- 1 KaveeduDocument4 pages1 KaveeduAJITH CHRISTOPHERNo ratings yet

- 1 Lab Equipment ListDocument9 pages1 Lab Equipment ListYasir Ali DharejoNo ratings yet

- COBAS 6000: C501 Reagent Inventory MONTH/YEARDocument3 pagesCOBAS 6000: C501 Reagent Inventory MONTH/YEARCharmaine Corpuz GranilNo ratings yet

- Attachement of GB #2 RO SystemDocument5 pagesAttachement of GB #2 RO SystemOunur RofiqNo ratings yet

- Presentation On Department Training Technical (SSU-4) : Presented By: Jayanth.kDocument32 pagesPresentation On Department Training Technical (SSU-4) : Presented By: Jayanth.kShweta BagdiNo ratings yet

- Rose RN: Sweet Powder Human ConsumptionDocument1 pageRose RN: Sweet Powder Human ConsumptionFransiska FitriaNo ratings yet

- Macadamia Plant Protection Guide 2020Document18 pagesMacadamia Plant Protection Guide 2020quang phamNo ratings yet

- S.NO. Quality Control and Testing of Polymer LabDocument2 pagesS.NO. Quality Control and Testing of Polymer Labaharish_iitkNo ratings yet

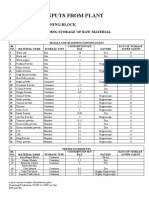

- All Inputs From Plant R2 05.09.23Document15 pagesAll Inputs From Plant R2 05.09.23Prakhar sharmaNo ratings yet

- QAP Mat and TAPE SINGHALDocument8 pagesQAP Mat and TAPE SINGHALsumit sumanNo ratings yet

- MMA CETP MAHAD by Mr. S. Pathare PDFDocument58 pagesMMA CETP MAHAD by Mr. S. Pathare PDFPrinoy DharNo ratings yet

- Green ValleyDocument4 pagesGreen ValleyRonelio Pardilla Jr.No ratings yet

- Game of Thrones and I Will Be There 6Document47 pagesGame of Thrones and I Will Be There 6MUHAMMED FUADNo ratings yet

- Material Movement TS 2201022Document1 pageMaterial Movement TS 2201022Ilyas Rangga RamadhanNo ratings yet

- Ms of TestDocument6 pagesMs of TestMhando IgnasNo ratings yet

- Manifold and ReducersDocument3 pagesManifold and Reducershendra tambunanNo ratings yet

- Lab MachinesDocument1 pageLab MachinessaidurtexNo ratings yet

- F-QAD-04 Receiving Quality Plan - RMDocument6 pagesF-QAD-04 Receiving Quality Plan - RMNavnath GulveNo ratings yet

- Ship Store ArrDocument2 pagesShip Store ArrHoài ThanhNo ratings yet

- Microbiologist Work FlowDocument10 pagesMicrobiologist Work FlowAri DanteNo ratings yet

- Boq Ipal Pasar Sukamaju2019Document3 pagesBoq Ipal Pasar Sukamaju2019tiopen5ilhamNo ratings yet

- PDF 011 Repl of Kiln Shell Under TyreDocument32 pagesPDF 011 Repl of Kiln Shell Under TyreFurqan ShabbirNo ratings yet

- Status Barang l149 (Update 14 12 2022)Document19 pagesStatus Barang l149 (Update 14 12 2022)Ance GtrgalauNo ratings yet

- KarlFischer TitrationDocument30 pagesKarlFischer TitrationSalman AbuzuhairaNo ratings yet

- Revitalization of Tsui Ping River-Plant TrialDocument9 pagesRevitalization of Tsui Ping River-Plant TrialGabriel WongNo ratings yet

- FBR2 DDR 08-06-2019Document3 pagesFBR2 DDR 08-06-2019faiadrigbfaiadrigbtpNo ratings yet

- Material Utk PEP DewaDocument2 pagesMaterial Utk PEP Dewawahyu hidayatNo ratings yet

- Conventional STP 400 KLDDocument15 pagesConventional STP 400 KLDK&K ConsultantsNo ratings yet

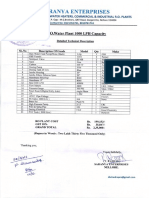

- Saranya Enterprises: 0 (T Plant LPHDocument1 pageSaranya Enterprises: 0 (T Plant LPHABDUL MATEEN MdNo ratings yet

- BoQ IPAL PASAR BONE BONE2019 - 2Document3 pagesBoQ IPAL PASAR BONE BONE2019 - 2tio7799 penNo ratings yet

- Mat'l Sourcing List (Saudi Aramco) PDFDocument130 pagesMat'l Sourcing List (Saudi Aramco) PDFPageduesca RouelNo ratings yet

- 125kld-mr - Akash.gupta JiDocument10 pages125kld-mr - Akash.gupta JiTech MongerNo ratings yet

- CETP ValayanchirangraDocument5 pagesCETP ValayanchirangraRamNo ratings yet

- Deinking Studies at TCIRDDocument49 pagesDeinking Studies at TCIRDpiyushverma78No ratings yet

- 04 Calibration of WMM PlantDocument1 page04 Calibration of WMM PlantEnd EndNo ratings yet

- Spesifikasi Ekstrak KecurDocument1 pageSpesifikasi Ekstrak KecurSindhy DewiNo ratings yet

- A) Effluent Discharge Details Type Limit Dispo ActualDocument6 pagesA) Effluent Discharge Details Type Limit Dispo Actualmukesh katarnavareNo ratings yet

- Checklist Daftar Peralatan Housekeeping GedungDocument3 pagesChecklist Daftar Peralatan Housekeeping GedungaeniNo ratings yet

- PL-2626 (39630) Reipl 0119Document2 pagesPL-2626 (39630) Reipl 0119Abhishekh DagaNo ratings yet

- OkDocument70 pagesOkRiswan RiswanNo ratings yet

- 19 - Sludge Calc OutletDocument1 page19 - Sludge Calc OutlettongaiNo ratings yet

- Gopu Venugopala Reddy Team Labs and Consultants India PDFDocument22 pagesGopu Venugopala Reddy Team Labs and Consultants India PDFHardik VavdiyaNo ratings yet

- Mudlogging Part 2Document26 pagesMudlogging Part 2Sunny ChaubeyNo ratings yet

- Microbiological Test ReportDocument7 pagesMicrobiological Test ReportJuan PesantezNo ratings yet

- Pdi Report 0091 21 For Sprayer Meseret Mekonnen Po 81093909Document2 pagesPdi Report 0091 21 For Sprayer Meseret Mekonnen Po 81093909OLIYADNo ratings yet

- Gujarat Electricity Corporation Ltd. Stack Sample AnalysisDocument1 pageGujarat Electricity Corporation Ltd. Stack Sample AnalysisAbhijeet OundhakarNo ratings yet

- Sang HiDocument44 pagesSang HiSuresh GanjiNo ratings yet

- National Seminar On Smart Broiler Production The Way Forward PDFDocument2 pagesNational Seminar On Smart Broiler Production The Way Forward PDFArunPrakash JNo ratings yet

- In Process Audit ChecklistDocument25 pagesIn Process Audit ChecklistArunPrakash JNo ratings yet

- Color Coding AllDocument1 pageColor Coding AllArunPrakash JNo ratings yet

- Idly,& Parota Sensory Checklist (138585)Document2 pagesIdly,& Parota Sensory Checklist (138585)ArunPrakash JNo ratings yet

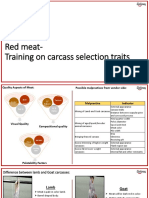

- Red Meat TrainingDocument9 pagesRed Meat TrainingArunPrakash JNo ratings yet

- Preventive Maintenace RecordDocument47 pagesPreventive Maintenace RecordArunPrakash JNo ratings yet

- Chlorine Strength VerificationDocument2 pagesChlorine Strength VerificationArunPrakash JNo ratings yet

- PCES FebDocument6 pagesPCES FebArunPrakash JNo ratings yet

- EMMPDocument19 pagesEMMPArunPrakash JNo ratings yet

- Packing Material ChecklistDocument4 pagesPacking Material ChecklistArunPrakash JNo ratings yet

- Chlorination ProcedureDocument1 pageChlorination ProcedureArunPrakash JNo ratings yet

- Dawson A J.design of Inland Wat.1950.TRANSDocument26 pagesDawson A J.design of Inland Wat.1950.TRANSKelvin XuNo ratings yet

- Blockk PDFDocument5 pagesBlockk PDFIsaias Bartolomeu SambgaNo ratings yet

- Confucianism: By: Alisha, Mandy, Michael, and PreshiaDocument15 pagesConfucianism: By: Alisha, Mandy, Michael, and PreshiaAvi Auerbach AvilaNo ratings yet

- Department of Education: Republic of The PhilippinesDocument3 pagesDepartment of Education: Republic of The PhilippinesRhenalyn Rose Obligar PasaholNo ratings yet

- Atlas FiltriDocument18 pagesAtlas FiltriCristi CicireanNo ratings yet

- 27 To 930Mhz Fsk/Fm/Ask Transceiver FeaturesDocument44 pages27 To 930Mhz Fsk/Fm/Ask Transceiver FeaturesMuhammad Amir YousufNo ratings yet

- Antares Eng Rev02Document2 pagesAntares Eng Rev02Steven BrownNo ratings yet

- Piping Info - Pipe Support Design GuidelinesDocument4 pagesPiping Info - Pipe Support Design GuidelinesSUSHANTBIJAM100% (1)

- Generalized Analysis of Quasi-Steady-State and Quasi-Transient Measurements of Carrier Lifetimes in SemiconductorsDocument4 pagesGeneralized Analysis of Quasi-Steady-State and Quasi-Transient Measurements of Carrier Lifetimes in SemiconductorsMohaimen UzzamanNo ratings yet

- By Products of Fish and PrawnDocument9 pagesBy Products of Fish and PrawnNarasimha MurthyNo ratings yet

- Indra Motion MLC - Trainning Manual PDFDocument36 pagesIndra Motion MLC - Trainning Manual PDFjorfleitasNo ratings yet

- Chemistry Practical Procedure Systematic Analysis of Salt STD: Xi & XiiDocument9 pagesChemistry Practical Procedure Systematic Analysis of Salt STD: Xi & XiivarshiniNo ratings yet

- Dit 24Document1 pageDit 24Abvolt IndiaNo ratings yet

- Log RegDocument32 pagesLog RegSIDDHARTH KUMARNo ratings yet

- Starch BasedDocument6 pagesStarch BasedBongzkie Irudistan AmanteNo ratings yet

- GEA Chapter6 Economy HiresDocument37 pagesGEA Chapter6 Economy HiresMike LassaNo ratings yet

- NE2R757GT-P6: Specifications For Red LedDocument19 pagesNE2R757GT-P6: Specifications For Red LedYiannis PapadopoulosNo ratings yet

- Crabs Hell Ms DsDocument1 pageCrabs Hell Ms DsRega Wahyu AnggrainiNo ratings yet

- Projectile MotionDocument5 pagesProjectile MotionAC CamoñasNo ratings yet

- Mathematics ECAT (Sir Nasim Zulfiqar) - 1Document134 pagesMathematics ECAT (Sir Nasim Zulfiqar) - 1AYESH qureshiNo ratings yet

- Tutorial L298N Driver MotorDocument5 pagesTutorial L298N Driver MotorHairul Anam SNo ratings yet

- Turbo Charger - ProjectDocument36 pagesTurbo Charger - ProjectSam Sams100% (2)

- Unexplained Mysteries - Mona Lisa's Eyes Reveal CodeDocument33 pagesUnexplained Mysteries - Mona Lisa's Eyes Reveal CodeFirst LastNo ratings yet

- Lesson 02 PDFDocument13 pagesLesson 02 PDFJeremy TohNo ratings yet

- Womb World Mandala Reflections of The BuDocument11 pagesWomb World Mandala Reflections of The BuLenka MladenovićNo ratings yet

- EEE40003 Digital Signal and Image Processing: LAB 3: Discrete LTI SystemsDocument13 pagesEEE40003 Digital Signal and Image Processing: LAB 3: Discrete LTI SystemsKai JieNo ratings yet

- Magic TutorialDocument3 pagesMagic TutorialGaurav SainiNo ratings yet

- DM NafithDocument5 pagesDM NafithialnabahinNo ratings yet

Microbial Zoning & Swab Test Schedule (138126)

Microbial Zoning & Swab Test Schedule (138126)

Uploaded by

ArunPrakash JOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Microbial Zoning & Swab Test Schedule (138126)

Microbial Zoning & Swab Test Schedule (138126)

Uploaded by

ArunPrakash JCopyright:

Available Formats

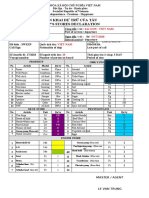

Internal lab analysis schedule

Chemical Analysis

Si No. RM Parameters Frequency

1 Rice

2 Dal

3 Methi

4 Maida Moisture, Ash, Water absorption

percentage, viscosity, Free fatty when ever new lot arrives

5 Atta acid,Solubility, Gluten,Alcoholic acidity

6 Salt

7 Rice bran oil

8 Vanaspati

Si No. Water Parameters Frequency

1 RO and Rawwater Ph and TDS Daily

Si No. FG Parameters Frequency

1 Parotta Moisture, Ash, Ph Daily 1 Sample

Si No. PM Parameters Frequency

1 Batter PM Height, Width, side gusset, thickness,

bottom gusset, leak test, drop test , seal whenever a new batch arrives

2 Parotta PM integrity

Micro analysis

Si No. Items Parameters Frequency

1 Batter Coliforms, Yeast and Mold Weekly 5 sample

2 Parotta TPC, coliform, Yeast and mold Weekly 5 sample

3 Hand swab TPC, Coliform , Ecoli Weekly 5 sample

4 CIP TPC, Coliform , Ecoli weekly one

5 RO and Rawwater TPC, Coliform , Ecoli weekly one

6 Equipment swab TPC, Coliform Weekly 5 sample

7 Air Sampling TPC, Yeast and Mold Monthly once

MICROBIAL ZONING

Batter section

SL No. Zone Items Frequency Indicator organism Tests Limit

1 Grinding inner surface

2 Filling nozzle

3 Batter packing conveyor swab

4 Soaking tank

5 collection tank <100 cfu/g-TPC

Zone-1 TPC, Salmonella

6 Agitator tank Salmonella - Nil

7 Methi soaking vessel

8 Methi hopper

9 Hand Swab

10 RO Water

11 Grinder frame work Salmonella and EColi,

Listeria

12 Soaking tank outer surface Weekly

13 collection tank outer surface

14 Agitator tank outer surface

15 Zone-2 Sides of conveyor

16 Filling nozzle outer surface

<500cfu/g- Tpc Ecoli

TPC, Coliform

17 Methi hopper outer surface nd Listeria - Nil

Ecoli, Listeria, Y & M

Coliform - <100 cfu/g

18 crates

19 Trolleys

20 walls

21 Floors

Zone-3

22 Drains

23 Lift

Parotta section

24 Oil Dalda mixing outlet

25 Dough mixing tank

26 Master table

27 Cooking tawa <100 cfu/g-TPC

Zone-1 TPC, Salmonella

28 Cooling Conveyor Salmonella - Nil

29 Cooling and packing table

30 Weighing balance (Masters area)

31 Trays

32 Master table downsides, and legs Salmonella and

EColi,Listeria

33 Dough mixing tank outer surfaces Weekly

34 Conveyer frame work

35 Trolleys

Zone-2

36 Uniform swab

<500cfu/g- Tpc Ecoli

TPC, Coliform

37 Coneyor sides nd Listeria - Nil

Ecoli, Listeria,Y & M

Coliform - <100 cfu/g

38 Metal detector

39 Check weigher

40 walls

41 Zone-3 Floors

42 Drains

Others

43 Cafeteria

44 RM godown

45 Dispatch Area <10000 cfu/g- Tpc

TPC,Coliforms and Ecoli,

Zone-4 Monthly EColi, Listeria Listeria nd Ecoli- Nil

46 Passage Listeria,Y & M

Coliform - <100 cfu/g

47 Office

48 Toilet

High risk area

Medium risk area

Medium risk area

lower risk area

Reference: The corrective action taken for positive pathogen detection or increased colony count includes

Stop the production in the affected line

Thoroughly examine the area visually and through swabbing

Clean the affected area and collect the sample in 50 foot radius from the site and the adjacent areas

Increase in sampling frequency until get two consecutive negative results

Finished good alo should be tested before the dispatch

You might also like

- QAP - Powder CoatingDocument4 pagesQAP - Powder Coatingnaveen yadavNo ratings yet

- Encyclopedia of Korean Folk BeliefsDocument167 pagesEncyclopedia of Korean Folk BeliefsAria7No ratings yet

- Mat'l Sourcing List (Saudi Aramco)Document130 pagesMat'l Sourcing List (Saudi Aramco)Pageduesca Rouel100% (2)

- Stress - The Different Kinds of StressDocument4 pagesStress - The Different Kinds of StressbogdanNo ratings yet

- Chemical Analysis: Si No. RM ParametersDocument10 pagesChemical Analysis: Si No. RM ParametersarunNo ratings yet

- Mud Report Geotermal 11.04.2024Document1 pageMud Report Geotermal 11.04.2024cristianjugaruNo ratings yet

- IPAL RTM 5 m3Document8 pagesIPAL RTM 5 m3Axl FerreraNo ratings yet

- D Pharmacy Lab InstrumentsDocument10 pagesD Pharmacy Lab InstrumentssajedNo ratings yet

- 05.chemical MEI 2019Document106 pages05.chemical MEI 2019Andhy AlfharoNo ratings yet

- Product Information Sheet: Synthite Industries Private LimitedDocument2 pagesProduct Information Sheet: Synthite Industries Private LimitedMaurice Dan GeroyNo ratings yet

- Jenis Operasi Sedang Kls.3: Bba Ok Rsu An Nisaa'Document14 pagesJenis Operasi Sedang Kls.3: Bba Ok Rsu An Nisaa'DINA NORINENo ratings yet

- Product Information Sheet: Synthite Industries Private LimitedDocument2 pagesProduct Information Sheet: Synthite Industries Private LimitedMaurice Dan GeroyNo ratings yet

- Form Daily DaehwaDocument2 pagesForm Daily DaehwarismaNo ratings yet

- IPAL RTM 10 m3Document8 pagesIPAL RTM 10 m3Axl FerreraNo ratings yet

- 1 KaveeduDocument4 pages1 KaveeduAJITH CHRISTOPHERNo ratings yet

- 1 Lab Equipment ListDocument9 pages1 Lab Equipment ListYasir Ali DharejoNo ratings yet

- COBAS 6000: C501 Reagent Inventory MONTH/YEARDocument3 pagesCOBAS 6000: C501 Reagent Inventory MONTH/YEARCharmaine Corpuz GranilNo ratings yet

- Attachement of GB #2 RO SystemDocument5 pagesAttachement of GB #2 RO SystemOunur RofiqNo ratings yet

- Presentation On Department Training Technical (SSU-4) : Presented By: Jayanth.kDocument32 pagesPresentation On Department Training Technical (SSU-4) : Presented By: Jayanth.kShweta BagdiNo ratings yet

- Rose RN: Sweet Powder Human ConsumptionDocument1 pageRose RN: Sweet Powder Human ConsumptionFransiska FitriaNo ratings yet

- Macadamia Plant Protection Guide 2020Document18 pagesMacadamia Plant Protection Guide 2020quang phamNo ratings yet

- S.NO. Quality Control and Testing of Polymer LabDocument2 pagesS.NO. Quality Control and Testing of Polymer Labaharish_iitkNo ratings yet

- All Inputs From Plant R2 05.09.23Document15 pagesAll Inputs From Plant R2 05.09.23Prakhar sharmaNo ratings yet

- QAP Mat and TAPE SINGHALDocument8 pagesQAP Mat and TAPE SINGHALsumit sumanNo ratings yet

- MMA CETP MAHAD by Mr. S. Pathare PDFDocument58 pagesMMA CETP MAHAD by Mr. S. Pathare PDFPrinoy DharNo ratings yet

- Green ValleyDocument4 pagesGreen ValleyRonelio Pardilla Jr.No ratings yet

- Game of Thrones and I Will Be There 6Document47 pagesGame of Thrones and I Will Be There 6MUHAMMED FUADNo ratings yet

- Material Movement TS 2201022Document1 pageMaterial Movement TS 2201022Ilyas Rangga RamadhanNo ratings yet

- Ms of TestDocument6 pagesMs of TestMhando IgnasNo ratings yet

- Manifold and ReducersDocument3 pagesManifold and Reducershendra tambunanNo ratings yet

- Lab MachinesDocument1 pageLab MachinessaidurtexNo ratings yet

- F-QAD-04 Receiving Quality Plan - RMDocument6 pagesF-QAD-04 Receiving Quality Plan - RMNavnath GulveNo ratings yet

- Ship Store ArrDocument2 pagesShip Store ArrHoài ThanhNo ratings yet

- Microbiologist Work FlowDocument10 pagesMicrobiologist Work FlowAri DanteNo ratings yet

- Boq Ipal Pasar Sukamaju2019Document3 pagesBoq Ipal Pasar Sukamaju2019tiopen5ilhamNo ratings yet

- PDF 011 Repl of Kiln Shell Under TyreDocument32 pagesPDF 011 Repl of Kiln Shell Under TyreFurqan ShabbirNo ratings yet

- Status Barang l149 (Update 14 12 2022)Document19 pagesStatus Barang l149 (Update 14 12 2022)Ance GtrgalauNo ratings yet

- KarlFischer TitrationDocument30 pagesKarlFischer TitrationSalman AbuzuhairaNo ratings yet

- Revitalization of Tsui Ping River-Plant TrialDocument9 pagesRevitalization of Tsui Ping River-Plant TrialGabriel WongNo ratings yet

- FBR2 DDR 08-06-2019Document3 pagesFBR2 DDR 08-06-2019faiadrigbfaiadrigbtpNo ratings yet

- Material Utk PEP DewaDocument2 pagesMaterial Utk PEP Dewawahyu hidayatNo ratings yet

- Conventional STP 400 KLDDocument15 pagesConventional STP 400 KLDK&K ConsultantsNo ratings yet

- Saranya Enterprises: 0 (T Plant LPHDocument1 pageSaranya Enterprises: 0 (T Plant LPHABDUL MATEEN MdNo ratings yet

- BoQ IPAL PASAR BONE BONE2019 - 2Document3 pagesBoQ IPAL PASAR BONE BONE2019 - 2tio7799 penNo ratings yet

- Mat'l Sourcing List (Saudi Aramco) PDFDocument130 pagesMat'l Sourcing List (Saudi Aramco) PDFPageduesca RouelNo ratings yet

- 125kld-mr - Akash.gupta JiDocument10 pages125kld-mr - Akash.gupta JiTech MongerNo ratings yet

- CETP ValayanchirangraDocument5 pagesCETP ValayanchirangraRamNo ratings yet

- Deinking Studies at TCIRDDocument49 pagesDeinking Studies at TCIRDpiyushverma78No ratings yet

- 04 Calibration of WMM PlantDocument1 page04 Calibration of WMM PlantEnd EndNo ratings yet

- Spesifikasi Ekstrak KecurDocument1 pageSpesifikasi Ekstrak KecurSindhy DewiNo ratings yet

- A) Effluent Discharge Details Type Limit Dispo ActualDocument6 pagesA) Effluent Discharge Details Type Limit Dispo Actualmukesh katarnavareNo ratings yet

- Checklist Daftar Peralatan Housekeeping GedungDocument3 pagesChecklist Daftar Peralatan Housekeeping GedungaeniNo ratings yet

- PL-2626 (39630) Reipl 0119Document2 pagesPL-2626 (39630) Reipl 0119Abhishekh DagaNo ratings yet

- OkDocument70 pagesOkRiswan RiswanNo ratings yet

- 19 - Sludge Calc OutletDocument1 page19 - Sludge Calc OutlettongaiNo ratings yet

- Gopu Venugopala Reddy Team Labs and Consultants India PDFDocument22 pagesGopu Venugopala Reddy Team Labs and Consultants India PDFHardik VavdiyaNo ratings yet

- Mudlogging Part 2Document26 pagesMudlogging Part 2Sunny ChaubeyNo ratings yet

- Microbiological Test ReportDocument7 pagesMicrobiological Test ReportJuan PesantezNo ratings yet

- Pdi Report 0091 21 For Sprayer Meseret Mekonnen Po 81093909Document2 pagesPdi Report 0091 21 For Sprayer Meseret Mekonnen Po 81093909OLIYADNo ratings yet

- Gujarat Electricity Corporation Ltd. Stack Sample AnalysisDocument1 pageGujarat Electricity Corporation Ltd. Stack Sample AnalysisAbhijeet OundhakarNo ratings yet

- Sang HiDocument44 pagesSang HiSuresh GanjiNo ratings yet

- National Seminar On Smart Broiler Production The Way Forward PDFDocument2 pagesNational Seminar On Smart Broiler Production The Way Forward PDFArunPrakash JNo ratings yet

- In Process Audit ChecklistDocument25 pagesIn Process Audit ChecklistArunPrakash JNo ratings yet

- Color Coding AllDocument1 pageColor Coding AllArunPrakash JNo ratings yet

- Idly,& Parota Sensory Checklist (138585)Document2 pagesIdly,& Parota Sensory Checklist (138585)ArunPrakash JNo ratings yet

- Red Meat TrainingDocument9 pagesRed Meat TrainingArunPrakash JNo ratings yet

- Preventive Maintenace RecordDocument47 pagesPreventive Maintenace RecordArunPrakash JNo ratings yet

- Chlorine Strength VerificationDocument2 pagesChlorine Strength VerificationArunPrakash JNo ratings yet

- PCES FebDocument6 pagesPCES FebArunPrakash JNo ratings yet

- EMMPDocument19 pagesEMMPArunPrakash JNo ratings yet

- Packing Material ChecklistDocument4 pagesPacking Material ChecklistArunPrakash JNo ratings yet

- Chlorination ProcedureDocument1 pageChlorination ProcedureArunPrakash JNo ratings yet

- Dawson A J.design of Inland Wat.1950.TRANSDocument26 pagesDawson A J.design of Inland Wat.1950.TRANSKelvin XuNo ratings yet

- Blockk PDFDocument5 pagesBlockk PDFIsaias Bartolomeu SambgaNo ratings yet

- Confucianism: By: Alisha, Mandy, Michael, and PreshiaDocument15 pagesConfucianism: By: Alisha, Mandy, Michael, and PreshiaAvi Auerbach AvilaNo ratings yet

- Department of Education: Republic of The PhilippinesDocument3 pagesDepartment of Education: Republic of The PhilippinesRhenalyn Rose Obligar PasaholNo ratings yet

- Atlas FiltriDocument18 pagesAtlas FiltriCristi CicireanNo ratings yet

- 27 To 930Mhz Fsk/Fm/Ask Transceiver FeaturesDocument44 pages27 To 930Mhz Fsk/Fm/Ask Transceiver FeaturesMuhammad Amir YousufNo ratings yet

- Antares Eng Rev02Document2 pagesAntares Eng Rev02Steven BrownNo ratings yet

- Piping Info - Pipe Support Design GuidelinesDocument4 pagesPiping Info - Pipe Support Design GuidelinesSUSHANTBIJAM100% (1)

- Generalized Analysis of Quasi-Steady-State and Quasi-Transient Measurements of Carrier Lifetimes in SemiconductorsDocument4 pagesGeneralized Analysis of Quasi-Steady-State and Quasi-Transient Measurements of Carrier Lifetimes in SemiconductorsMohaimen UzzamanNo ratings yet

- By Products of Fish and PrawnDocument9 pagesBy Products of Fish and PrawnNarasimha MurthyNo ratings yet

- Indra Motion MLC - Trainning Manual PDFDocument36 pagesIndra Motion MLC - Trainning Manual PDFjorfleitasNo ratings yet

- Chemistry Practical Procedure Systematic Analysis of Salt STD: Xi & XiiDocument9 pagesChemistry Practical Procedure Systematic Analysis of Salt STD: Xi & XiivarshiniNo ratings yet

- Dit 24Document1 pageDit 24Abvolt IndiaNo ratings yet

- Log RegDocument32 pagesLog RegSIDDHARTH KUMARNo ratings yet

- Starch BasedDocument6 pagesStarch BasedBongzkie Irudistan AmanteNo ratings yet

- GEA Chapter6 Economy HiresDocument37 pagesGEA Chapter6 Economy HiresMike LassaNo ratings yet

- NE2R757GT-P6: Specifications For Red LedDocument19 pagesNE2R757GT-P6: Specifications For Red LedYiannis PapadopoulosNo ratings yet

- Crabs Hell Ms DsDocument1 pageCrabs Hell Ms DsRega Wahyu AnggrainiNo ratings yet

- Projectile MotionDocument5 pagesProjectile MotionAC CamoñasNo ratings yet

- Mathematics ECAT (Sir Nasim Zulfiqar) - 1Document134 pagesMathematics ECAT (Sir Nasim Zulfiqar) - 1AYESH qureshiNo ratings yet

- Tutorial L298N Driver MotorDocument5 pagesTutorial L298N Driver MotorHairul Anam SNo ratings yet

- Turbo Charger - ProjectDocument36 pagesTurbo Charger - ProjectSam Sams100% (2)

- Unexplained Mysteries - Mona Lisa's Eyes Reveal CodeDocument33 pagesUnexplained Mysteries - Mona Lisa's Eyes Reveal CodeFirst LastNo ratings yet

- Lesson 02 PDFDocument13 pagesLesson 02 PDFJeremy TohNo ratings yet

- Womb World Mandala Reflections of The BuDocument11 pagesWomb World Mandala Reflections of The BuLenka MladenovićNo ratings yet

- EEE40003 Digital Signal and Image Processing: LAB 3: Discrete LTI SystemsDocument13 pagesEEE40003 Digital Signal and Image Processing: LAB 3: Discrete LTI SystemsKai JieNo ratings yet

- Magic TutorialDocument3 pagesMagic TutorialGaurav SainiNo ratings yet

- DM NafithDocument5 pagesDM NafithialnabahinNo ratings yet