Professional Documents

Culture Documents

5570 White

5570 White

Uploaded by

sasidharkanthetiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5570 White

5570 White

Uploaded by

sasidharkanthetiCopyright:

Available Formats

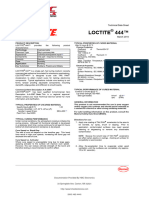

Technical Data Sheet

LOCTITE® 5570™ WHITE

February-2013

PRODUCT DESCRIPTION

LOCTITE® 5570™ WHITE provides the following product 3.0

characteristics:

2.5

Technology Flextec™ Polymer

Strength, N/mm²

Chemical Type Modified silane polymer 2.0

Appearance (uncured) White pasteLMS

Components One part - requires no mixing 1.5

Viscosity Paste

Cure Atmospheric moisture 1.0

Service Temperature -30 to 80°C

0.5

Maximum Intermittent 100°C

Exposure Temperature 0

Application Sealing or Bonding 0 1 2 3 4 5 6 7

Cure Time, days

LOCTITE® 5570™ WHITE is a high strength, high elongation Depth of Cure

The depth of cure depends on temperature and humidity.

adhesive used for elastic bonding and sealing on various

Depth of cure was determined by filling a 12 mm deep cup

substrates. It is a one component adhesive based on a and removing the cured film of material. The cured section of

Flextec™ polymer, which cures by reaction with moisture to an product is measured to determine depth of cure.

elastomeric thermoset product. The skin formation and curing

times are dependent on humidity, temperature, and joint depth.

By increasing the exposure to moisture these times can be Depth of Cure

Depth of cure, mm/d 1 to 6LMS

reduced. LOCTITE® 5570™ WHITE is sag resistant and has a

high initial tack. It is non-corrosive, free of solvents,

TYPICAL PROPERTIES OF CURED MATERIAL

isocyanates, silicones, PVC, and is odorless. LOCTITE®

Cured for 21 days @ 22 °C / 50±5 % RH

5570™ WHITE demonstrates good adhesion to a wide variety Physical Properties:

of substrates and is compatible with suitable paint systems. It Elongation, at break, ISO 527-3, % 230

also demonstrates good UV resistance and can therefore be Tensile Strength, ISO 527-3 N/mm² 2.4

used for interior and exterior applications. (psi) (380)

TYPICAL PROPERTIES OF UNCURED MATERIAL Glass Transition Temperature (Tg) -64

, ISO 11357-2, °C

Density, ISO 2811-1 @ 22 °C, g/ml 1.28 to 1.44LMS

Non-Volatile Content, ASTM D 2369, % 98

Extrusion Rate, g/min 200 to 900LMS Shore Hardness, ISO 868, Durometer A 53

Flow, ISO 7390, mm 0 to 3LMS

Flash Point - See MSDS Electrical Properties:

Dielectric Constant , IEC 60250:

1kHz 6.6

TYPICAL CURING PERFORMANCE 100-kHz 6.4

Under normal conditions, the atmospheric moisture initiates the 1-MHz 6.3

curing process. The product develops functional strength in 24 Surface Resistivity, IEC 60093, Ω 3.0×1014

hours and fully cures in 7 days. Volume Resistivity, IEC 60093, Ω·cm 4.8×1010

Skin Over Time TYPICAL PERFORMANCE OF CURED MATERIAL

Skin over time is the time the surface of the adhesive forms a Adhesive Properties

skin upon exposure to atmospheric moisture at 25 ± 2 °C, 50 ±

5% RH. Cured for 21 days @ 22 °C

Skin Over Time, minutes 10 to 60LMS Lap Shear Strength, ISO 4587:

Steel (grit blasted) N/mm² 2.8

(psi) (400)

Cure Speed vs. Time Stainless Steel N/mm² 2.8

The graph below shows the shear strength developed over (psi) (410)

time at 22 °C / 50 % RH on mild steel (grit blasted) and tested

according to ISO 4587.

TDS LOCTITE® 5570™ WHITE, February-2013

Galvanized Steel N/mm² 2.6 Storage

(psi) (380) Store product in the unopened container in a dry location.

Aluminum N/mm² 1.9 Storage information may be indicated on the product container

(psi) (270) labeling.

Zinc dichromate N/mm² 2.7 Optimal Storage: 8 °C to 21 °C. Storage below 8 °C or

(psi) (390) greater than 28 °C can adversely affect product properties.

Wood (Pine) N/mm² 1.2 Material removed from containers may be contaminated during

(psi) (170) use. Do not return product to the original container. Henkel

Glass N/mm² 2.6 Corporation cannot assume responsibility for product which

(psi) (370)

has been contaminated or stored under conditions other than

Fiberglass N/mm² 1.7

those previously indicated. If additional information is required,

(psi) (240)

please contact your local Technical Service Center or

EPDM N/mm² 0.2

(psi) (25) Customer Service Representative.

Buna-N N/mm² 0.5

(psi) (70) Conversions

(°C x 1.8) + 32 = °F

Block Shear Strength, ISO 13445: kV/mm x 25.4 = V/mil

Polycarbonate N/mm² 0.3 mm / 25.4 = inches

(psi) (40)

µm / 25.4 = mil

PVC N/mm² 2.9

N x 0.225 = lb

(psi) (420)

N/mm x 5.71 = lb/in

ABS N/mm² 1.9

(psi) (270) N/mm² x 145 = psi

Nylon N/mm² 3.2

MPa x 145 = psi

(psi) (470) N·m x 8.851 = lb·in

Polypropylene N/mm² 0.2 N·m x 0.738 = lb·ft

(psi) (30) N·mm x 0.142 = oz·in

mPa·s = cP

"T" Peel Strength, ISO 11339:

Aluminum N/mm 0.5 Note

(lb/in) (2.8) The data contained herein are furnished for information only

Impact Strength, ISO 9653, J: and are believed to be reliable. We cannot assume

Aluminum 3.4 responsibility for the results obtained by others over whose

methods we have no control. It is the user's responsibility to

determine suitability for the user's purpose of any production

methods mentioned herein and to adopt such precautions as

GENERAL INFORMATION may be advisable for the protection of property and of persons

This product is not recommended for use in pure oxygen against any hazards that may be involved in the handling and

and/or oxygen rich systems and should not be selected as use thereof. In light of the foregoing, Henkel Corporation

a sealant for chlorine or other strong oxidizing materials. specifically disclaims all warranties expressed or implied,

including warranties of merchantability or fitness for a

For safe handling information on this product, consult the particular purpose, arising from sale or use of Henkel

Material Safety Data Sheet (MSDS). Corporation’s products. Henkel Corporation specifically

disclaims any liability for consequential or incidental

damages of any kind, including lost profits. The discussion

Directions for use:

herein of various processes or compositions is not to be

1. For best performance bond surfaces should be clean and interpreted as representation that they are free from

free from grease. domination of patents owned by others or as a license under

2. Moisture curing begins immediately after the product is any Henkel Corporation patents that may cover such

exposed to the atmosphere, therefore parts to be processes or compositions. We recommend that each

assembled should be mated within a few minutes after the prospective user test his proposed application before repetitive

product is dispensed. use, using this data as a guide. This product may be covered

3. The bond should be allowed to cure (e.g. seven days), by one or more United States or foreign patents or patent

before subjecting to heavy service loads. applications.

4. Excess material can be easily wiped away with non-polar

solvents. Trademark usage

Except as otherwise noted, all trademarks in this document

Loctite Material SpecificationLMS are trademarks of Henkel Corporation in the U.S. and

LMS dated August-16, 2007. Test reports for each batch are elsewhere. ® denotes a trademark registered in the U.S.

available for the indicated properties. LMS test reports include

selected QC test parameters considered appropriate to Patent and Trademark Office.

specifications for customer use. Additionally, comprehensive

controls are in place to assure product quality and

consistency. Special customer specification requirements may Reference 0.2

be coordinated through Henkel Quality.

Henkel Americas Henkel Europe Henkel Asia Pacific

+860.571.5100 +49.89.320800.1800 +86.21.2891.8863

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

You might also like

- BS en 1706-2020Document40 pagesBS en 1706-2020marjan banoo100% (9)

- Glassfibre Reinforced Concrete Principles, Production, Properties and Applications by Professor Peter J. M. BartosDocument209 pagesGlassfibre Reinforced Concrete Principles, Production, Properties and Applications by Professor Peter J. M. Bartoscelso100% (1)

- Estimate For Grouted RiprapDocument6 pagesEstimate For Grouted RiprapTing Pipx80% (5)

- Astm A767-09Document5 pagesAstm A767-09poulmackNo ratings yet

- Si 5970-EnDocument4 pagesSi 5970-EnphairyNo ratings yet

- 5510 Adhesive Sealant WhiteDocument3 pages5510 Adhesive Sealant WhitesasidharkanthetiNo ratings yet

- Loctite SI 5970-EnDocument3 pagesLoctite SI 5970-EnAshishNo ratings yet

- LOctite SI 5900Document3 pagesLOctite SI 5900Giovanni HernandezNo ratings yet

- Loctite 576 TDSDocument2 pagesLoctite 576 TDSlijun245No ratings yet

- 5660 enDocument3 pages5660 enסטניסלב טלשבסקיNo ratings yet

- LOCTITE 383 en - GLDocument2 pagesLOCTITE 383 en - GLerayNo ratings yet

- Si 596 Red-EnDocument3 pagesSi 596 Red-EnkabiriscNo ratings yet

- Loctite SI 5060™: Product DescriptionDocument3 pagesLoctite SI 5060™: Product DescriptionSanthosh Kumar RavichandranNo ratings yet

- Loctite 577™: Technical Data SheetDocument4 pagesLoctite 577™: Technical Data SheetCristian SerbovNo ratings yet

- LOCTITE HY 4080 en - GL Tren de LoctiteDocument4 pagesLOCTITE HY 4080 en - GL Tren de Loctitedamelysevelyn02No ratings yet

- Loctite SI 5366™: Technical Data SheetDocument2 pagesLoctite SI 5366™: Technical Data SheetSanthosh Kumar RavichandranNo ratings yet

- Loctite SI 5900: Technical Data SheetDocument3 pagesLoctite SI 5900: Technical Data SheetSanthosh Kumar RavichandranNo ratings yet

- Loctite 577 en UsDocument4 pagesLoctite 577 en Uschittaranjan routNo ratings yet

- LOCTITE SI 5927 RED en - GLDocument2 pagesLOCTITE SI 5927 RED en - GLOmer IkhlasNo ratings yet

- Loctite EA 9466™: Product Description Typical Curing Performance Fixture TimeDocument4 pagesLoctite EA 9466™: Product Description Typical Curing Performance Fixture TimeVesna NikolicNo ratings yet

- LOCTITE 315 en - GLDocument2 pagesLOCTITE 315 en - GLinigo.bretonNo ratings yet

- Loctite302 TdsDocument3 pagesLoctite302 TdsM. Fikri HidayatNo ratings yet

- LOCTITE SI 5910 en - GLDocument3 pagesLOCTITE SI 5910 en - GLChandra Budhi RizkyNo ratings yet

- Zalac 002Document4 pagesZalac 002Stevie Herman TDNo ratings yet

- Loctite 403Document3 pagesLoctite 403Layeeq Ahmed PallikondaNo ratings yet

- Si 5699-EnDocument3 pagesSi 5699-EnWahyu Riz AmblakadarrNo ratings yet

- Loctite EA 907™: Technical Data SheetDocument2 pagesLoctite EA 907™: Technical Data Sheetuzzy2No ratings yet

- Loctite 5699 - enDocument3 pagesLoctite 5699 - enRider OaklandNo ratings yet

- Loctite 403Document4 pagesLoctite 403AunKrubNo ratings yet

- Loctite Fixmaster Metal Magic Steel™: Technical Data SheetDocument3 pagesLoctite Fixmaster Metal Magic Steel™: Technical Data SheetHamzaNoumanNo ratings yet

- LOCTITEDocument2 pagesLOCTITEHrNo ratings yet

- Ea 3463 New-EnDocument2 pagesEa 3463 New-EnRonald Mario Quiroz SerrateNo ratings yet

- 3463 Magic SteelDocument2 pages3463 Magic Steelmahmouddiaa554No ratings yet

- Henk Loctite Superflex Red TdsDocument2 pagesHenk Loctite Superflex Red TdsMariano DomenechNo ratings yet

- Loctite 401 enDocument3 pagesLoctite 401 enPham Van DungNo ratings yet

- HMC Loctite 444Document2 pagesHMC Loctite 444sengottNo ratings yet

- Loctite Hysol 891-60 TNDocument2 pagesLoctite Hysol 891-60 TNSebas TianNo ratings yet

- LOCTITE PC 7227 en - GLDocument4 pagesLOCTITE PC 7227 en - GLLuhur BudiNo ratings yet

- Loctite 3568 TDSDocument3 pagesLoctite 3568 TDSShareduwan SannosiNo ratings yet

- Loctite 384Document2 pagesLoctite 384A DamiánNo ratings yet

- Loctitie Fix Master Ea 3463-Na-EnDocument3 pagesLoctitie Fix Master Ea 3463-Na-EnImran KhanNo ratings yet

- PC 7337-EnDocument3 pagesPC 7337-EnJuan LondonoNo ratings yet

- 587 enDocument2 pages587 enabhayundaleNo ratings yet

- LOCTITE SI 5331 en - GLDocument2 pagesLOCTITE SI 5331 en - GLkaplanuygarNo ratings yet

- 190017-EN - Explosive Charge BonderDocument2 pages190017-EN - Explosive Charge BonderdatkoloNo ratings yet

- Loctite 573 - Tech - Info - Sheet - ENDocument3 pagesLoctite 573 - Tech - Info - Sheet - ENChristopherNo ratings yet

- Elring Sealing Compound Dirko Beige: Technical DatasheetDocument7 pagesElring Sealing Compound Dirko Beige: Technical Datasheetperico_No ratings yet

- TDS PC 7218-EnDocument3 pagesTDS PC 7218-Enangga alvianNo ratings yet

- DION IMPACT 9102 SeriesDocument5 pagesDION IMPACT 9102 SeriesLENEEVERSONNo ratings yet

- Loctite 401Document3 pagesLoctite 401Asrizal Tri WinaryoNo ratings yet

- Loctite 460™: Technical Data SheetDocument3 pagesLoctite 460™: Technical Data Sheetdantewow1No ratings yet

- Dow Corning: 734 Flowable Adhesive SealantDocument3 pagesDow Corning: 734 Flowable Adhesive SealantAbdellah AbdouNo ratings yet

- Loctite 554 TDSDocument2 pagesLoctite 554 TDSlijun245No ratings yet

- 3M™ Tape # 2228 TdsDocument3 pages3M™ Tape # 2228 TdsKishan MohtaNo ratings yet

- Loctite 596™: SurfacesDocument2 pagesLoctite 596™: Surfaces楼淼森No ratings yet

- Loctite 3478 enDocument2 pagesLoctite 3478 enMohsin ModiNo ratings yet

- Loctite 380 Black - Ficha TecnicaDocument3 pagesLoctite 380 Black - Ficha TecnicamonsepackNo ratings yet

- LOCTITE 404 en - GLDocument3 pagesLOCTITE 404 en - GLSii PindiNo ratings yet

- Loctite 495 (OLD) : Technical Data SheetDocument3 pagesLoctite 495 (OLD) : Technical Data SheetRahul GargNo ratings yet

- Aa 324-EnDocument3 pagesAa 324-EnManiNo ratings yet

- Polylite 441 800 eDocument3 pagesPolylite 441 800 echetanNo ratings yet

- Loctite Stycast 2762: Technical Data SheetDocument3 pagesLoctite Stycast 2762: Technical Data SheetankitaNo ratings yet

- 01 SpanSet Indo HSE Catalogue 2011Document3 pages01 SpanSet Indo HSE Catalogue 2011Raza AidanNo ratings yet

- Clear EpoxyDocument9 pagesClear EpoxysasidharkanthetiNo ratings yet

- Pu Sealant Mccoy Soudal Soudaflex 611 Pu SealantDocument2 pagesPu Sealant Mccoy Soudal Soudaflex 611 Pu SealantsasidharkanthetiNo ratings yet

- TDS - Zettex MS Polymer 72 - ENDocument2 pagesTDS - Zettex MS Polymer 72 - ENsasidharkanthetiNo ratings yet

- 3M™ OEM Polyurethane Glass Adhesive Sealant 590 - 20230302Document6 pages3M™ OEM Polyurethane Glass Adhesive Sealant 590 - 20230302sasidharkanthetiNo ratings yet

- 5510 Adhesive Sealant WhiteDocument3 pages5510 Adhesive Sealant WhitesasidharkanthetiNo ratings yet

- 19-0034 ECKART BR STAPA Zinc GB V1 WEB 1SDocument6 pages19-0034 ECKART BR STAPA Zinc GB V1 WEB 1SsasidharkanthetiNo ratings yet

- Chapter-1 Ishida2011Document79 pagesChapter-1 Ishida2011sasidharkanthetiNo ratings yet

- Setal 169 SS 67 - en - A4Document2 pagesSetal 169 SS 67 - en - A4sasidharkanthetiNo ratings yet

- Molins: Technical Data SheetDocument2 pagesMolins: Technical Data SheetsasidharkanthetiNo ratings yet

- Molins: Technical Data SheetDocument2 pagesMolins: Technical Data SheetsasidharkanthetiNo ratings yet

- Refractory Technology: Fundamentals and Applications: October 2016Document2 pagesRefractory Technology: Fundamentals and Applications: October 2016sasidharkanthetiNo ratings yet

- PLEXUS Product-CatalogDocument44 pagesPLEXUS Product-CatalogsasidharkanthetiNo ratings yet

- Section 407 - Hot Mix Asphalt: 407.01 GENERALDocument25 pagesSection 407 - Hot Mix Asphalt: 407.01 GENERALDaiNo ratings yet

- Fireproofing - QIDDIYADocument2 pagesFireproofing - QIDDIYAOsama KheadryNo ratings yet

- Industrial Valve Cross Ref - Vickers VS Rexroth For Primary Metal Applications0309Document60 pagesIndustrial Valve Cross Ref - Vickers VS Rexroth For Primary Metal Applications0309Abelio TavaresNo ratings yet

- Kinangay Sur BAckupDocument5 pagesKinangay Sur BAckupDJabNo ratings yet

- BHEL SPEC Section D2 PDFDocument249 pagesBHEL SPEC Section D2 PDFelangorengaNo ratings yet

- LABOUR and MATERIAL RATES Fot The Year 2019-20Document43 pagesLABOUR and MATERIAL RATES Fot The Year 2019-20pwdcd1No ratings yet

- Research PaperDocument7 pagesResearch PaperShrwan GyawaliNo ratings yet

- China Standard PDFDocument1 pageChina Standard PDFgaminNo ratings yet

- C4 Sieve Analysis Aggregate Grading For Fine and Coarse AggregateDocument6 pagesC4 Sieve Analysis Aggregate Grading For Fine and Coarse AggregateKyle MoolmanNo ratings yet

- Product Information: Fo Outdoor WBKWT HP / A-Dq (ZN) (SR) 2YDocument2 pagesProduct Information: Fo Outdoor WBKWT HP / A-Dq (ZN) (SR) 2YLe HiepNo ratings yet

- FireFre-88 Data SheetDocument4 pagesFireFre-88 Data SheetMojamethNo ratings yet

- Explosive Welding: - Mechanical Department - R.D. Eng. College, GZB - 3 YrDocument18 pagesExplosive Welding: - Mechanical Department - R.D. Eng. College, GZB - 3 YrShivam SharmaNo ratings yet

- Galvanized Steel Inspection GuideDocument20 pagesGalvanized Steel Inspection GuidePham Ngoc Khan100% (2)

- Casting Material Gray Iron in ASTM A48Document5 pagesCasting Material Gray Iron in ASTM A48Novaldi Andryoga 1707122616No ratings yet

- BS en 10028 2 2017 PDFDocument34 pagesBS en 10028 2 2017 PDFQuang Vu100% (2)

- Nas1352 Rev 11Document6 pagesNas1352 Rev 11staedtlerpNo ratings yet

- Republic of The Philippines Office of The Building Official Municipality of Panglao, BoholDocument1 pageRepublic of The Philippines Office of The Building Official Municipality of Panglao, BoholChristian AL Tac-anNo ratings yet

- Laser Welding On GTD-111Document5 pagesLaser Welding On GTD-111juneeNo ratings yet

- SPECIFICATIONS For Sanesh PDFDocument259 pagesSPECIFICATIONS For Sanesh PDFshabenoorNo ratings yet

- Reinforced Concrete Desigh IIDocument140 pagesReinforced Concrete Desigh IIMahmoud DarwishNo ratings yet

- Solder & Accessories Solder & AccessoriesDocument21 pagesSolder & Accessories Solder & Accessoriesbububu66No ratings yet

- 18256544880Document9 pages18256544880Mahnaz KarimNo ratings yet

- Structural Steel-Microalloyed (Medium and High Strength Qualities) - Specification (Document16 pagesStructural Steel-Microalloyed (Medium and High Strength Qualities) - Specification (Achuthan Kannankutty100% (2)

- J-DMS: Project HarmonyDocument1 pageJ-DMS: Project HarmonyMary DenizeNo ratings yet

- Project: Job No: ClientDocument6 pagesProject: Job No: ClientLintang Dana RayaNo ratings yet

- Compressive Strength Testing of PlasticsDocument2 pagesCompressive Strength Testing of Plasticsmohammad norooziNo ratings yet