Professional Documents

Culture Documents

nc150s Isuzu 4le2x Us 200gpa0001420 - Us PDF

nc150s Isuzu 4le2x Us 200gpa0001420 - Us PDF

Uploaded by

juanpantera24Copyright:

Available Formats

You might also like

- Manual de Reparacion Motores Iveco F4GEDocument142 pagesManual de Reparacion Motores Iveco F4GELuis Antonio Vega Parangueo87% (62)

- Cummins Engine QST30-G4 PDFDocument6 pagesCummins Engine QST30-G4 PDFGermán Andrés100% (1)

- FICM Diagnosis & RepairDocument16 pagesFICM Diagnosis & RepairTrey100% (2)

- Bombardier CRJ 200-Fuel SystemDocument32 pagesBombardier CRJ 200-Fuel SystemAngelo Martinez75% (4)

- 6cta8 3-G2 PDFDocument4 pages6cta8 3-G2 PDFEstifanos AlemNo ratings yet

- Spec Oem Caterpillar 3306TDocument6 pagesSpec Oem Caterpillar 3306TAminovic MostafaNo ratings yet

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Catalogue 2015 (Oilfield Equip Parts Supplier)Document9 pagesCatalogue 2015 (Oilfield Equip Parts Supplier)Alice Mi0% (1)

- Complet Eurocamping Cylinders EngDocument52 pagesComplet Eurocamping Cylinders EngAdrianHomescuNo ratings yet

- Engineering Catalog: CD250M Dri-Prime Pump Engineering DataDocument7 pagesEngineering Catalog: CD250M Dri-Prime Pump Engineering DataNils Enrique Hansen GamarraNo ratings yet

- Catalogue Cummins 6LTAA8.9 G2Document4 pagesCatalogue Cummins 6LTAA8.9 G2akbar muslim100% (1)

- 6CTA8.3-G2 Datasheet ENGINE CUMMINSDocument4 pages6CTA8.3-G2 Datasheet ENGINE CUMMINSluis perezNo ratings yet

- FR92516 FR92996 6LTAA8.9-G2 Datasheet - 01 enDocument4 pagesFR92516 FR92996 6LTAA8.9-G2 Datasheet - 01 enmunhNo ratings yet

- Model THE: Horizontal Drilling Duty PumpDocument2 pagesModel THE: Horizontal Drilling Duty PumpzhujianglongNo ratings yet

- WATSON MARLOW SQP 500 DatenblattDocument4 pagesWATSON MARLOW SQP 500 DatenblattDicle KarabiberNo ratings yet

- Catalogue Cummins 6BT5.9 G2Document4 pagesCatalogue Cummins 6BT5.9 G2Guruh Zulianto100% (1)

- Kta50-G3 0 PDFDocument3 pagesKta50-G3 0 PDFAlisabel Muñoz de Morales0% (1)

- D232 Maintenance PlanDocument21 pagesD232 Maintenance PlanDP100% (1)

- Gross Engine Power Output: Chongqing Cummins Engine Company Ltd. Engine Performance CurveDocument6 pagesGross Engine Power Output: Chongqing Cummins Engine Company Ltd. Engine Performance CurveIvanchocdNo ratings yet

- Bentec Mud Pump T-1600-Ac - 130209Document2 pagesBentec Mud Pump T-1600-Ac - 130209leo100% (2)

- Catalogue Cummins 6BTA5.9 G2Document4 pagesCatalogue Cummins 6BTA5.9 G2MarilynNo ratings yet

- Atlas Copco: DC 17B A Heavy-Duty Articulated, Diesel Driven Carrier For Medium Sized Mining and Tunnelling EquipmentDocument2 pagesAtlas Copco: DC 17B A Heavy-Duty Articulated, Diesel Driven Carrier For Medium Sized Mining and Tunnelling EquipmentErick AlarconNo ratings yet

- BMR Orbit Hydraulic Motor With Spool ValveDocument10 pagesBMR Orbit Hydraulic Motor With Spool ValveHai VanNo ratings yet

- Pump VFD ES EstimatorDocument2 pagesPump VFD ES EstimatorVeeresh MustapureNo ratings yet

- Cummins QSB 5.9 SheetDocument2 pagesCummins QSB 5.9 SheetDaniel Perez100% (1)

- DRAIN TYPE FLUID COUPLING For Internal Combustion Engines KPTODocument4 pagesDRAIN TYPE FLUID COUPLING For Internal Combustion Engines KPTOberkahharianNo ratings yet

- Transmision Trituradora TesabDocument4 pagesTransmision Trituradora Tesabjorge alfonsoNo ratings yet

- Cummins 6BTA5.9-G2 PDFDocument5 pagesCummins 6BTA5.9-G2 PDFAlejandro LopezNo ratings yet

- Cummins Engine Datasheet: Engine Model 6Bta5.9-G2 Performance Curve FR 92306Document5 pagesCummins Engine Datasheet: Engine Model 6Bta5.9-G2 Performance Curve FR 92306Víctor zamoraNo ratings yet

- Sabroe SMC: Reciprocating Compressor UnitsDocument2 pagesSabroe SMC: Reciprocating Compressor UnitsArtur Altermann PolletNo ratings yet

- Denison Gold Cup PDFDocument64 pagesDenison Gold Cup PDFOleg080100% (3)

- Catalogue Cummins 6BTAA5.9 G2 163kVADocument4 pagesCatalogue Cummins 6BTAA5.9 G2 163kVATarek Farouk100% (1)

- Motor Charlyn5Document16 pagesMotor Charlyn5gleisongg86No ratings yet

- Technical Data SheetDocument3 pagesTechnical Data SheetAhmad RobbyNo ratings yet

- 6BT5 9-G2Document4 pages6BT5 9-G2Jusril A Hidayat100% (2)

- Non-Regulated: Specification SheetDocument3 pagesNon-Regulated: Specification SheetSon DangNo ratings yet

- Mtu 8v&12v&16v4000m70Document2 pagesMtu 8v&12v&16v4000m70bakhouche100% (1)

- 4BTA3.9-G2 CumminsDocument3 pages4BTA3.9-G2 CumminsmnezamiNo ratings yet

- Waukehsa P9390GSI - EspecificaçõesDocument2 pagesWaukehsa P9390GSI - EspecificaçõesAlan SantosNo ratings yet

- LOCO ComparisonDocument2 pagesLOCO ComparisonPrateekSinghBaghelNo ratings yet

- 6BTAA5.9-G2 Datasheet - 01 enDocument4 pages6BTAA5.9-G2 Datasheet - 01 enEncep Zaenal MNo ratings yet

- TAD880-882GE: 7.7 Liter, In-Line 6 CylinderDocument2 pagesTAD880-882GE: 7.7 Liter, In-Line 6 CylinderjamesNo ratings yet

- The Engine For Construction Equipment.: 60 - 155 KW at 1500 - 2500 RPMDocument6 pagesThe Engine For Construction Equipment.: 60 - 155 KW at 1500 - 2500 RPMSiding BarroNo ratings yet

- 4BTA3.9-G2 Datasheet - 68 KvaDocument5 pages4BTA3.9-G2 Datasheet - 68 Kvaاحمد عبدالعزيزNo ratings yet

- 6170 SpesDocument3 pages6170 SpesAmin GuiNo ratings yet

- Hydraulic Tech InfoDocument200 pagesHydraulic Tech InfoBurik8No ratings yet

- Catalogue Yanmar 4TNV106T GGEDocument17 pagesCatalogue Yanmar 4TNV106T GGEMikh MIKH100% (1)

- 116 SpecDocument2 pages116 SpecesvwestNo ratings yet

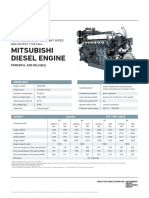

- Mitsubishi Diesel Engine - S16R-PTADocument2 pagesMitsubishi Diesel Engine - S16R-PTAfendynovapamelaNo ratings yet

- Marine Propulsion Engine: Fast VesselDocument4 pagesMarine Propulsion Engine: Fast VesselSiding BarroNo ratings yet

- Diesel Generator Set KTA50 Series Engine: 1000 kVA - 1675 kVA 50 HZ 1120 KW - 1545 KW 60 HZDocument4 pagesDiesel Generator Set KTA50 Series Engine: 1000 kVA - 1675 kVA 50 HZ 1120 KW - 1545 KW 60 HZengelton2006yahooNo ratings yet

- Main Engine 3516C 1920 BKW 1600 RPM SpecDocument6 pagesMain Engine 3516C 1920 BKW 1600 RPM SpecCarlos Luis Esquerdo Marcano100% (1)

- WD10Document3 pagesWD10service alatberatNo ratings yet

- Himsen H46 60VDocument4 pagesHimsen H46 60VairtupasNo ratings yet

- Mtu 12V 16V4000M90 1DSDocument2 pagesMtu 12V 16V4000M90 1DSzaki100% (1)

- Mtu 16v4000m60Document2 pagesMtu 16v4000m60Juan Diego Sarango100% (1)

- Technical Spec 3516C - 2575 BHP at 1600 RPM PDFDocument4 pagesTechnical Spec 3516C - 2575 BHP at 1600 RPM PDFiw100% (1)

- Full Line Brochure 7-2021Document32 pagesFull Line Brochure 7-2021PrudzNo ratings yet

- MWM D234Document4 pagesMWM D234Riki AkbarNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Boiler Question Paper Format PowerPoint PresentationDocument12 pagesBoiler Question Paper Format PowerPoint PresentationPagan jatarNo ratings yet

- VIT Fuel PumpDocument16 pagesVIT Fuel PumpAayush AgrawalNo ratings yet

- 1060 M Hydraulic Operated Concrete Block Making MachineDocument6 pages1060 M Hydraulic Operated Concrete Block Making MachineTejas T S TejasNo ratings yet

- Worley Parsons - Balikpapan Project Overview - 2020Document4 pagesWorley Parsons - Balikpapan Project Overview - 2020Vraja DasiNo ratings yet

- Energy-Related GHG Emissions of The Textile Industry in ChinaDocument9 pagesEnergy-Related GHG Emissions of The Textile Industry in ChinaFanilo RazafindralamboNo ratings yet

- Erf 1988-94 PDFDocument20 pagesErf 1988-94 PDFAlejandro Gonzalez BenitezNo ratings yet

- 3503 Brochure SoftDocument2 pages3503 Brochure SoftMike NgNo ratings yet

- 4-Electric Power GenerationDocument31 pages4-Electric Power GenerationCaribNo ratings yet

- Alternative Drive Systems and Environmen PDFDocument9 pagesAlternative Drive Systems and Environmen PDFceciliagaitanNo ratings yet

- 7b Kobelco CKE800-1F - SpecDocument16 pages7b Kobelco CKE800-1F - SpecLim Lion Yee100% (1)

- Catalogues$lpt 809 Ex2 Ex Bs-Ii PDFDocument282 pagesCatalogues$lpt 809 Ex2 Ex Bs-Ii PDFveereshNo ratings yet

- Steam TurbineDocument16 pagesSteam TurbineUtkarsh Verma100% (1)

- Maintenance Program For EquipmentsDocument793 pagesMaintenance Program For EquipmentsJoel AlcantaraNo ratings yet

- Process Description of MtbeDocument3 pagesProcess Description of Mtbeiszhani11No ratings yet

- Trojan Prill: Prilled Ammonium NitrateDocument2 pagesTrojan Prill: Prilled Ammonium NitrateSUCIATINo ratings yet

- British Emerald Bridge Systems & Equipment Operating ManualDocument307 pagesBritish Emerald Bridge Systems & Equipment Operating ManualMullah FassudinNo ratings yet

- Cilindru Bomag BW 75 H 2019Document2 pagesCilindru Bomag BW 75 H 2019Adrian DumescuNo ratings yet

- DLW Training Report, VaranasiDocument93 pagesDLW Training Report, VaranasiDigvijay Singh40% (5)

- b2201 B PDFDocument29 pagesb2201 B PDFRaj_SheetaNo ratings yet

- NGE LPG SamplingDocument17 pagesNGE LPG SamplingAsim MemonNo ratings yet

- A9000 Prod. IntroductionDocument26 pagesA9000 Prod. IntroductionSugeng AriyadiNo ratings yet

- ABG8820-En Service ManualDocument103 pagesABG8820-En Service ManualCui100% (6)

- Extra Light Fuel Oil (LFO)Document2 pagesExtra Light Fuel Oil (LFO)Sarbast H. SaeedNo ratings yet

- Technical Documentation - Regulation (EU) N. 2281 - 2016 - NECS 1314 - 3218 SEERDocument59 pagesTechnical Documentation - Regulation (EU) N. 2281 - 2016 - NECS 1314 - 3218 SEERAlexandru GNo ratings yet

- Fronius Pv-Genset Solution: / Solar EnergyDocument4 pagesFronius Pv-Genset Solution: / Solar EnergyDiana Maria Martinez OlivaNo ratings yet

nc150s Isuzu 4le2x Us 200gpa0001420 - Us PDF

nc150s Isuzu 4le2x Us 200gpa0001420 - Us PDF

Uploaded by

juanpantera24Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

nc150s Isuzu 4le2x Us 200gpa0001420 - Us PDF

nc150s Isuzu 4le2x Us 200gpa0001420 - Us PDF

Uploaded by

juanpantera24Copyright:

Available Formats

Godwin NC150S Dri-Prime®

Pump

The Godwin NC150S Dri-Prime pump is designed for use

in municipal wastewater applications that contain stringy,

modern waste. This unique self-cleaning, non-clog pump is

recommended for sewer, lift station, and bypass applications,

and is ideal for permanent installations where reliability is

absolutely critical, e.g. Diesel Backup Systems (DBS).

This is the first in a series of Godwin S Series ‘Smart’ pumps,

with significantly improved pumping efficiency, greater fuel

economy, easier operation, and reduced maintenance. Field

Smart Technology (FST) is available for remote monitoring

and control, and diesel engines that meet local regulations.

Features and benefits Specifications

• Flygt ‘non-clog’ N-Technology to avoid ragging and Suction conection 150 mm (6 in) flange

downtime caused by modern waste.

Delivery connection 150 mm (6 in) flange

• Field Smart Technology (FST) allows the user to monitor

& control the pump from anywhere in the world. Max capacity 300 m³/hr (1320 USGPM)

• New compressor belt tensioner reduces time to change Max impeller diameter 286 mm (11.3 in)

and adjust belt to approximately 30 minutes.

Max operating temp 80°C (176 °F)*

• New sight glass and measuring stick added to monitor

level and quality of mechanical seal oil. Max working pressure 6 bar (87 psi)

• Improved hydraulic design reduces vibration, maximizes Max suction pressure 4 bar (58 psi)

efficiency and fuel economy. Max casing pressure 7.5 bar (109 psi)

• Diesel Oxidative Catalyst (DOC) technology maximizes

Max operating speed 2200 rpm

available power from diesel engine, and reduces

* Please contact our office for applications in excess of 80°C (176 °F).

maintenance and downtime. † Larger diameter pipes may be required for maximum flows.

• Fully automatic priming from dry to 8.5 metres (28 ft). Materials

• Venturi priming requires no adjustment or control. Pump casing Cast Iron BS EN 1561 / EN-JL1030

• Available as open set or Sound Attenuated Enclosure.

• Standard build engine Isuzu 4LE2X (EPA Final Tier 4). Wearplates Front - Hard Iron EN12513:2000

Rear - Cast Iron BS1561:1997

• Other engine options available.

Pump Shaft Carbon steel BS970:1991 817M40T

Impeller Hard Iron EN12513:2000

Mechanical Seal Faces Silicon carbide Vs Silicon carbide

Reference number : 200GPA0001420

Date of issue: September 8, 2017

Issue : - Please contact the factory or office for further details. A typical picture of the pump is shown.

Americas All information is approximate and for general guidance only.

Performance curve Suction lift table

Flow (m³/hr) Total Total Delivery Head (feet)

0 25 50 75 100 125 150 175 200 225 250 275 300 325 suction

70 26 49 66 92 98

Head

220

(feet) Output (USGPM)

200 2200 rpm 28% 60

180 37% 10 1321 1233 1101 660 528

50%

2000 rpm 55% 60% 50

160 15 1233 1145 1013 572 440

65% 20 1065 1013 925 484 -

140 66%

1800 rpm 40

66% 25 771 748 660 352 -

Head (meters)

Head (feet)

120

65%

1600 rpm Pump curve is engine specific and based on 10ft

100 30

1400 rpm (3.0m) dynamic suction lift.

80

1200 rpm 20

60

40

10

20

0 0

0 200 400 600 800 1000 1200 1400

Flow (USGPM)

Open skidbase Sound attenuated enclosure

Engine Isuzu 4LE2X Engine Isuzu 4LE2X

Engine power 46.2 kW (62 hp) max engine rating Engine power 46.2 kW (62 hp) max engine rating

Emissions standard EPA Final Tier 4 Emissions standard EPA Final Tier 4

Noise @ 7m (23 ft) 66 db(A)

Impeller diameter 286 mm (11.3 in) Impeller diameter 286 mm (11.3 in)

Pump speed 2200 Pump speed 2200

Fuel capacity 227 liters (60 US Gal) Fuel capacity 303 liters (80 US Gal)

Fuel consumption @ 1800 rpm 10 l/hr (2.6 USGal/hr) Fuel consumption @ 1800 rpm 10 l/hr (2.6 USGal/hr)

Weight dry 1250 kg (2750 lb) Weight dry 1410 kg (3100 lb)

Weight wet 1440 kg (3170 lb) Weight wet 1670 kg (3680 lb)

Dimensions L 3023 mm x W 1676 mm x H 2210 mm Dimensions L 2565 mm x W 1092 mm x H 1778 mm

(L 119 in x W 66 in x H 87 in) (L 101 in x W 43 in x H 70 in)

Performance data provided in tables is based on water tests at sea level and 20°C (68°F) Performance data provided in tables is based on water tests at sea level and 20°C (68°F)

ambient. All information is approximate and for general guidance only. Please contact the ambient. All information is approximate and for general guidance only. Please contact the

factory or office for further details. factory or office for further details.

Reference number : 200GPA0001420

Xylem Dewatering Solutions

Date of issue: September 8, 2017

84 Floodgate Road

Issue : -

Bridgeport, NJ 08014 USA

www.xylem.com/smart

(856) 467-3636 . Fax (856) 467-4841

© 2017 Xylem, Inc. All rights reserved. Godwin is a trademark of Xylem Dewatering Solutions, Inc., a wholly-owned subsidiary of Xylem Inc. Specifications and illustrations are subject to revision

without notice. Xylem makes no representation regarding the completeness or accuracy of this information and is not liable for any direct or indirect damages arising from or relating to this

information or its use.

You might also like

- Manual de Reparacion Motores Iveco F4GEDocument142 pagesManual de Reparacion Motores Iveco F4GELuis Antonio Vega Parangueo87% (62)

- Cummins Engine QST30-G4 PDFDocument6 pagesCummins Engine QST30-G4 PDFGermán Andrés100% (1)

- FICM Diagnosis & RepairDocument16 pagesFICM Diagnosis & RepairTrey100% (2)

- Bombardier CRJ 200-Fuel SystemDocument32 pagesBombardier CRJ 200-Fuel SystemAngelo Martinez75% (4)

- 6cta8 3-G2 PDFDocument4 pages6cta8 3-G2 PDFEstifanos AlemNo ratings yet

- Spec Oem Caterpillar 3306TDocument6 pagesSpec Oem Caterpillar 3306TAminovic MostafaNo ratings yet

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Catalogue 2015 (Oilfield Equip Parts Supplier)Document9 pagesCatalogue 2015 (Oilfield Equip Parts Supplier)Alice Mi0% (1)

- Complet Eurocamping Cylinders EngDocument52 pagesComplet Eurocamping Cylinders EngAdrianHomescuNo ratings yet

- Engineering Catalog: CD250M Dri-Prime Pump Engineering DataDocument7 pagesEngineering Catalog: CD250M Dri-Prime Pump Engineering DataNils Enrique Hansen GamarraNo ratings yet

- Catalogue Cummins 6LTAA8.9 G2Document4 pagesCatalogue Cummins 6LTAA8.9 G2akbar muslim100% (1)

- 6CTA8.3-G2 Datasheet ENGINE CUMMINSDocument4 pages6CTA8.3-G2 Datasheet ENGINE CUMMINSluis perezNo ratings yet

- FR92516 FR92996 6LTAA8.9-G2 Datasheet - 01 enDocument4 pagesFR92516 FR92996 6LTAA8.9-G2 Datasheet - 01 enmunhNo ratings yet

- Model THE: Horizontal Drilling Duty PumpDocument2 pagesModel THE: Horizontal Drilling Duty PumpzhujianglongNo ratings yet

- WATSON MARLOW SQP 500 DatenblattDocument4 pagesWATSON MARLOW SQP 500 DatenblattDicle KarabiberNo ratings yet

- Catalogue Cummins 6BT5.9 G2Document4 pagesCatalogue Cummins 6BT5.9 G2Guruh Zulianto100% (1)

- Kta50-G3 0 PDFDocument3 pagesKta50-G3 0 PDFAlisabel Muñoz de Morales0% (1)

- D232 Maintenance PlanDocument21 pagesD232 Maintenance PlanDP100% (1)

- Gross Engine Power Output: Chongqing Cummins Engine Company Ltd. Engine Performance CurveDocument6 pagesGross Engine Power Output: Chongqing Cummins Engine Company Ltd. Engine Performance CurveIvanchocdNo ratings yet

- Bentec Mud Pump T-1600-Ac - 130209Document2 pagesBentec Mud Pump T-1600-Ac - 130209leo100% (2)

- Catalogue Cummins 6BTA5.9 G2Document4 pagesCatalogue Cummins 6BTA5.9 G2MarilynNo ratings yet

- Atlas Copco: DC 17B A Heavy-Duty Articulated, Diesel Driven Carrier For Medium Sized Mining and Tunnelling EquipmentDocument2 pagesAtlas Copco: DC 17B A Heavy-Duty Articulated, Diesel Driven Carrier For Medium Sized Mining and Tunnelling EquipmentErick AlarconNo ratings yet

- BMR Orbit Hydraulic Motor With Spool ValveDocument10 pagesBMR Orbit Hydraulic Motor With Spool ValveHai VanNo ratings yet

- Pump VFD ES EstimatorDocument2 pagesPump VFD ES EstimatorVeeresh MustapureNo ratings yet

- Cummins QSB 5.9 SheetDocument2 pagesCummins QSB 5.9 SheetDaniel Perez100% (1)

- DRAIN TYPE FLUID COUPLING For Internal Combustion Engines KPTODocument4 pagesDRAIN TYPE FLUID COUPLING For Internal Combustion Engines KPTOberkahharianNo ratings yet

- Transmision Trituradora TesabDocument4 pagesTransmision Trituradora Tesabjorge alfonsoNo ratings yet

- Cummins 6BTA5.9-G2 PDFDocument5 pagesCummins 6BTA5.9-G2 PDFAlejandro LopezNo ratings yet

- Cummins Engine Datasheet: Engine Model 6Bta5.9-G2 Performance Curve FR 92306Document5 pagesCummins Engine Datasheet: Engine Model 6Bta5.9-G2 Performance Curve FR 92306Víctor zamoraNo ratings yet

- Sabroe SMC: Reciprocating Compressor UnitsDocument2 pagesSabroe SMC: Reciprocating Compressor UnitsArtur Altermann PolletNo ratings yet

- Denison Gold Cup PDFDocument64 pagesDenison Gold Cup PDFOleg080100% (3)

- Catalogue Cummins 6BTAA5.9 G2 163kVADocument4 pagesCatalogue Cummins 6BTAA5.9 G2 163kVATarek Farouk100% (1)

- Motor Charlyn5Document16 pagesMotor Charlyn5gleisongg86No ratings yet

- Technical Data SheetDocument3 pagesTechnical Data SheetAhmad RobbyNo ratings yet

- 6BT5 9-G2Document4 pages6BT5 9-G2Jusril A Hidayat100% (2)

- Non-Regulated: Specification SheetDocument3 pagesNon-Regulated: Specification SheetSon DangNo ratings yet

- Mtu 8v&12v&16v4000m70Document2 pagesMtu 8v&12v&16v4000m70bakhouche100% (1)

- 4BTA3.9-G2 CumminsDocument3 pages4BTA3.9-G2 CumminsmnezamiNo ratings yet

- Waukehsa P9390GSI - EspecificaçõesDocument2 pagesWaukehsa P9390GSI - EspecificaçõesAlan SantosNo ratings yet

- LOCO ComparisonDocument2 pagesLOCO ComparisonPrateekSinghBaghelNo ratings yet

- 6BTAA5.9-G2 Datasheet - 01 enDocument4 pages6BTAA5.9-G2 Datasheet - 01 enEncep Zaenal MNo ratings yet

- TAD880-882GE: 7.7 Liter, In-Line 6 CylinderDocument2 pagesTAD880-882GE: 7.7 Liter, In-Line 6 CylinderjamesNo ratings yet

- The Engine For Construction Equipment.: 60 - 155 KW at 1500 - 2500 RPMDocument6 pagesThe Engine For Construction Equipment.: 60 - 155 KW at 1500 - 2500 RPMSiding BarroNo ratings yet

- 4BTA3.9-G2 Datasheet - 68 KvaDocument5 pages4BTA3.9-G2 Datasheet - 68 Kvaاحمد عبدالعزيزNo ratings yet

- 6170 SpesDocument3 pages6170 SpesAmin GuiNo ratings yet

- Hydraulic Tech InfoDocument200 pagesHydraulic Tech InfoBurik8No ratings yet

- Catalogue Yanmar 4TNV106T GGEDocument17 pagesCatalogue Yanmar 4TNV106T GGEMikh MIKH100% (1)

- 116 SpecDocument2 pages116 SpecesvwestNo ratings yet

- Mitsubishi Diesel Engine - S16R-PTADocument2 pagesMitsubishi Diesel Engine - S16R-PTAfendynovapamelaNo ratings yet

- Marine Propulsion Engine: Fast VesselDocument4 pagesMarine Propulsion Engine: Fast VesselSiding BarroNo ratings yet

- Diesel Generator Set KTA50 Series Engine: 1000 kVA - 1675 kVA 50 HZ 1120 KW - 1545 KW 60 HZDocument4 pagesDiesel Generator Set KTA50 Series Engine: 1000 kVA - 1675 kVA 50 HZ 1120 KW - 1545 KW 60 HZengelton2006yahooNo ratings yet

- Main Engine 3516C 1920 BKW 1600 RPM SpecDocument6 pagesMain Engine 3516C 1920 BKW 1600 RPM SpecCarlos Luis Esquerdo Marcano100% (1)

- WD10Document3 pagesWD10service alatberatNo ratings yet

- Himsen H46 60VDocument4 pagesHimsen H46 60VairtupasNo ratings yet

- Mtu 12V 16V4000M90 1DSDocument2 pagesMtu 12V 16V4000M90 1DSzaki100% (1)

- Mtu 16v4000m60Document2 pagesMtu 16v4000m60Juan Diego Sarango100% (1)

- Technical Spec 3516C - 2575 BHP at 1600 RPM PDFDocument4 pagesTechnical Spec 3516C - 2575 BHP at 1600 RPM PDFiw100% (1)

- Full Line Brochure 7-2021Document32 pagesFull Line Brochure 7-2021PrudzNo ratings yet

- MWM D234Document4 pagesMWM D234Riki AkbarNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Boiler Question Paper Format PowerPoint PresentationDocument12 pagesBoiler Question Paper Format PowerPoint PresentationPagan jatarNo ratings yet

- VIT Fuel PumpDocument16 pagesVIT Fuel PumpAayush AgrawalNo ratings yet

- 1060 M Hydraulic Operated Concrete Block Making MachineDocument6 pages1060 M Hydraulic Operated Concrete Block Making MachineTejas T S TejasNo ratings yet

- Worley Parsons - Balikpapan Project Overview - 2020Document4 pagesWorley Parsons - Balikpapan Project Overview - 2020Vraja DasiNo ratings yet

- Energy-Related GHG Emissions of The Textile Industry in ChinaDocument9 pagesEnergy-Related GHG Emissions of The Textile Industry in ChinaFanilo RazafindralamboNo ratings yet

- Erf 1988-94 PDFDocument20 pagesErf 1988-94 PDFAlejandro Gonzalez BenitezNo ratings yet

- 3503 Brochure SoftDocument2 pages3503 Brochure SoftMike NgNo ratings yet

- 4-Electric Power GenerationDocument31 pages4-Electric Power GenerationCaribNo ratings yet

- Alternative Drive Systems and Environmen PDFDocument9 pagesAlternative Drive Systems and Environmen PDFceciliagaitanNo ratings yet

- 7b Kobelco CKE800-1F - SpecDocument16 pages7b Kobelco CKE800-1F - SpecLim Lion Yee100% (1)

- Catalogues$lpt 809 Ex2 Ex Bs-Ii PDFDocument282 pagesCatalogues$lpt 809 Ex2 Ex Bs-Ii PDFveereshNo ratings yet

- Steam TurbineDocument16 pagesSteam TurbineUtkarsh Verma100% (1)

- Maintenance Program For EquipmentsDocument793 pagesMaintenance Program For EquipmentsJoel AlcantaraNo ratings yet

- Process Description of MtbeDocument3 pagesProcess Description of Mtbeiszhani11No ratings yet

- Trojan Prill: Prilled Ammonium NitrateDocument2 pagesTrojan Prill: Prilled Ammonium NitrateSUCIATINo ratings yet

- British Emerald Bridge Systems & Equipment Operating ManualDocument307 pagesBritish Emerald Bridge Systems & Equipment Operating ManualMullah FassudinNo ratings yet

- Cilindru Bomag BW 75 H 2019Document2 pagesCilindru Bomag BW 75 H 2019Adrian DumescuNo ratings yet

- DLW Training Report, VaranasiDocument93 pagesDLW Training Report, VaranasiDigvijay Singh40% (5)

- b2201 B PDFDocument29 pagesb2201 B PDFRaj_SheetaNo ratings yet

- NGE LPG SamplingDocument17 pagesNGE LPG SamplingAsim MemonNo ratings yet

- A9000 Prod. IntroductionDocument26 pagesA9000 Prod. IntroductionSugeng AriyadiNo ratings yet

- ABG8820-En Service ManualDocument103 pagesABG8820-En Service ManualCui100% (6)

- Extra Light Fuel Oil (LFO)Document2 pagesExtra Light Fuel Oil (LFO)Sarbast H. SaeedNo ratings yet

- Technical Documentation - Regulation (EU) N. 2281 - 2016 - NECS 1314 - 3218 SEERDocument59 pagesTechnical Documentation - Regulation (EU) N. 2281 - 2016 - NECS 1314 - 3218 SEERAlexandru GNo ratings yet

- Fronius Pv-Genset Solution: / Solar EnergyDocument4 pagesFronius Pv-Genset Solution: / Solar EnergyDiana Maria Martinez OlivaNo ratings yet