Professional Documents

Culture Documents

Saic M 1033

Saic M 1033

Uploaded by

noor mohamedazeezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic M 1033

Saic M 1033

Uploaded by

noor mohamedazeezCopyright:

Available Formats

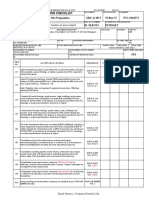

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.

00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Pre-Engineered Building - Components and Accessories

SAIC-M-1033 15-Nov-17 CIVIL-

Installation Inspection

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Pre-Engineered Building Components Installation

Roof panels shall be laid full length from ridge to eaves where possible to

minimize the possibility of water leaks at the end laps. When required, end 12-SAMSS-014

A1

lap shall be a minimum of 100 mm (4 inches nominal). Panel joints shall Sec. 6.5.1.c & d

interlock in such a way as to provide complete water tightness.

Fasteners shall be provided to secure the roof panels against wind uplift, 12-SAMSS-014

A2

mechanical movement, and to maintain water-tight panel joints Sec. 6.5.1.i

Wall panels shall be in one length from base to building eaves. Wall panel

length for above and below windows shall be as indicated on the

drawings. Wall panels shall be supported at their base by a raised curb or

grade beam that is a minimum of 150 mm above the building floor level.

12-SAMSS-014

A3 Wall panels shall extend not less than 38 mm below the concrete support,

Sec. 6.5.3.d & e

and sit in a recess in the concrete grade beam or curb to close off the

lower end of the panels. The panels shall be self-draining to the exterior.

Galvanized sill angles shall be provided to secure wall panels to the grade

beam or curb.

All roof and wall panels shall be attached to secondary framing members

by means of self-drilling or self-tapping screws. The screws shall be hex

head carbon steel screws assembled with an EPDM washer and

12-SAMSS-014

A4 mechanically zinc coating in accordance ASTM B695, Class 50. In coastal

Sec. 6.6

areas, as defined in paragraph 4.3.3(b), anaustenitic (300 series)

stainless steel fasteners shall be used. Fastener heads shall be coated

the same color as the panels.

A sealing compound shall be provided to seal ends and side laps of

panels. The material shall consist of a blend of non-toxic, synthetic resin

12-SAMSS-014

A5 base ingredients and inert extenders. Asphalt or asphalt derivatives are

Sec. 6.7.1.a & b

not permitted. The application of sealant shall be of a cross-sectional area

to provide a positive seal between adjacent surfaces.

The sealant material shall have sufficient adhesion to metal and plastic so

12-SAMSS-014

A6 as to remain in place during normal handling operations. Adhesive tensile

Sec. 6.7.1.c

strength shall be a minimum of 28 kPa (4Psi).

Flashing and/or trim shall be furnished at the rake, corners, eaves, at

framed openings, and wherever necessary to provide weather tightness

12-SAMSS-014

A7 and a finished appearance. Color will be as specified in the purchase

Sec. 6.7.2.a & c

order. A formed panel matching the slope and profile of adjoining panels

shall be provided along the building ridge.

Saudi Aramco: Company General Use

Preformed closures matching the profile of the panel shall be installed

along the eave and other locations as specified on drawings or as 12-SAMSS-014

A8

required for weather tightness, and may be made of solid or closed cell Sec. 6.7.2.d

plastic materials subject to approval

Saudi Aramco: Company General Use

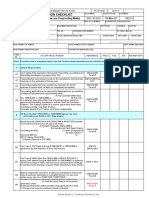

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Pre-Engineered Building - Components and Accessories

SAIC-M-1033 15-Nov-17 CIVIL-

Installation Inspection

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

B Pre-Engineered Building Accessories Installation

Windows shall be designed and constructed for integral installation with

the building system.Unless required otherwise in the contract documents,

provide building manufacturer's standard insulated double-pane window 12-SAMSS-014

B.1

(AAMA HS-C20 horizontal sliding, commercial grade) with medium natural Sec. 8.2

anodized finish (NAAMM AA-C22A31). (Alternative if selected by buyer:

fixed sash AAMA, Grade C20.)

Fasteners: Provide aluminum, stainless steel, or other material warranted

by the manufacturer to be non-corrosive and compatible with aluminum 12-SAMSS-014

B.2

window members, trim, hardware, anchors and other components of Sec. 8.2.2

window units.

Compression Glazing Strips and Weather Striping: Provide molded

EPDM, neoprene gasket complying with ASTM D2000 designation

12-SAMSS-014

B.3 2BC415 to 3BC620, molded PVC gasket complying with ASTM D2287,

Sec. 8.2.4

Grade 4, or molded expanded neoprene gasket complying with ASTM

C509.

Sealants: Provide manufacturer's standard for the joint size or aniticipated

12-SAMSS-014

B.4 movement. The sealant shall remain permanently elastic and non-

Sec. 8.2.6

shrinking and non-migrating.

Door shall comply with PIP Specification ARS08111. Door leaves shall be

of 45mm thick, full flush fabricated from Class G90 (Z275) zinc coated 12-SAMSS-014

B.5

sheets or better. Jamb extensions shall be furnished where required to Sec. 8.3.1

provide secure attachment to the wall framing.

For door assemblies required to be fire rated and exceeding limitations of

labeled assemblies, certification that each door and frame assembly is in

12-SAMSS-014

B.6 accordance with the design, materials, and construction for labeled

Sec. 8.3.1

construction in NFPA 80, NFPA 252, and UL 10B. (PIP ARS0811 Sec.

4.2.7)

Each door leaf shall be provided with a three 114mm x 114mm galvanized 12-SAMSS-014

B.7

steel, interlocking template butt hinges. Sec. 8.3.3

Door leaves shall be shop-painted with one coat of primer or finished to 12-SAMSS-014

B.8

match the walls. Sec. 8.3.4

The threshold shall be extruded aluminum shape to provide a positive 12-SAMSS-014

B.9

weather seal. Sec. 8.3.5

12-SAMSS-014

B.10 All exit doors shall be a minimum of 915 mm wide by 2035 mm high.

Sec. 8.3.6

Equipment door leaves shall be constructed of steel framing and panels

as specified for the walls. The door leaves shall be adequately flashed 12-SAMSS-014

B.11

and counter-flashed for weather tightness. Large doors may be field Sec. 8.4.1

assembled with bolted connections.

The leaves of sliding doors shall be suspended from a "C" section or other

appropriate structural member as a track header with the galvanized track

field bolted. Trolley shall be galvanized steel with dual, nylon wheels. The 12-SAMSS-014

B.12

track and trolleys shall be protected by a counter-flashed hood. When the Sec. 8.4.2

door is in the closed position the vertical gaps between the door edges

and the wall shall be automatically sealed with a closure device.

Saudi Aramco: Company General Use

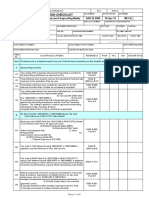

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Pre-Engineered Building - Components and Accessories

SAIC-M-1033 15-Nov-17 CIVIL-

Installation Inspection

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

12-SAMSS-014

B.13 The doors shall have inside and outside locking devices.

Sec. 8.4.3

Provide complete overhead roll-up door assemblies including door curtain,

12-SAMSS-014

B.14 guides, counterbalance, operators and installation accessories as

Sec. 8.5.1

specified herein, unless otherwise required in the contract documents.

Weather seals: At exterior doors, provide 3 mm (1/8") thick continuous

rubber or neoprene sheet weather seals on metal pressure bars secured 12-SAMSS-014

B.15

to inside of curtain coil hood. At door jambs, use 3 mm (1/8") thick Sec. 8.5.6

continuous strip secured to exterior side of jamb guide.

Eave gutters shall be box shaped 0.5 mm (26 gage) galvanized or

aluminum-zinc alloy-coated steel. The outside face of the gutter shall be 12-SAMSS-014

B.16

supported with 2.0 mm galvanized steel straps to the eave member at a Sec. 8.7.1

maximum spacing of 1000 mm.

Downspouts shall be round or rectangular 0.5mm (26 gage) galvanized or

aluminum-zinc alloy coated steel. Down spouts shall have a 45 degree 12-SAMSS-014

B.17

elbow at the bottom and shall be supported by attachment to the wall Sec. 8.7.2

covering at 3 meters maximum spacing.

Ventilators and roof openings shall be weather tight and shall be framed

12-SAMSS-014

B.18 and braced adequately to sustain the design wind and roof loads around

Sec. 8.8

the openings. Ventilators shall be furnished with bird screens.

Louver frames shall be fabricated from 1.22 mm (18 gage) galvanized

steel, and blades from 0.91mm (20 gage) galvanized steel. Louvers shall

have blades of the overlapping type providing maximum weather tightness 12-SAMSS-014

B.19

while allowing free air flow. Louver frames and blade fabricated from Sec. 8.9

extruded aluminum sheet of 1.22 mm(18 gage) thickness are also

acceptable.

Louvers are fixed sand trap type or adjustable by means of a crank, as 12-SAMSS-014

B.20

specified in the Purchase Documents. Sec. 8.9

REMARKS:

REFERENCE DOCUMENTS:

1- 12-SAMSS-014 -- Pre-Engineered Metal Buildings, 16 January 2014

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Pre-Engineered Building - Components and Accessories

SAIC-M-1033 15-Nov-17 CIVIL-

Installation Inspection

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

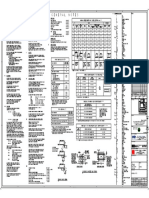

SATR NUMBER DATE APPROVED DISCIPLINE

Re-Instatement Punch List Form

SATR-A-2011 30-Apr-13 CIVIL-

PROJECT TITLE WBS/BI/JO NUMBER CONTRACTOR/SUBCONTRACTOR

Note : SATR-A-2011 forms part of SAIC-M-1033 (Pre-Engineered Buildings - Accessories & Installation Inspection)

MCC No.: Test Packs No.

System Description

Description:

ITEM Covered Originator / Completion Verified/

Description Remarks

No. Y N Agency Date Accepted

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SATR NUMBER DATE APPROVED QR NUMBER

SATR-W-2008 15-Nov-17

Attachment 3

WELD SUMMARY SHEET

Note : SATR-W-2008 forms part of SAIC-M-1033 (Pre-Engineered Buildings - Accessories & Installation Inspection)

Drawing Line Spool Matl. Joint Shop Sch. Diam- Welder's NDE PMI/MPI Hardness

Item # PWHT Remarks

Number No. Number Type No. Field Thick. eter Code ACC. REJ. ACC. REJ. Test

Saudi Aramco: Company General Use

You might also like

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saic M 1034Document2 pagesSaic M 1034noor mohamedazeezNo ratings yet

- Saic M 1034Document3 pagesSaic M 1034Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1033Document4 pagesSaic M 1033Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1031Document3 pagesSaic M 1031noor mohamedazeezNo ratings yet

- Saic M 1032Document2 pagesSaic M 1032noor mohamedazeezNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mechnisha_khan100% (1)

- Saic-Q-1066 Rev 1 (Final)Document3 pagesSaic-Q-1066 Rev 1 (Final)ryann mananquilNo ratings yet

- Saic M 1032Document3 pagesSaic M 1032Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Fireproofing Concrete Application Inspection SAIC-B-1002 1-Nov-09 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Fireproofing Concrete Application Inspection SAIC-B-1002 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Saic M 2010Document17 pagesSaic M 2010jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 25-May-05 MechDocument2 pagesSaudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 25-May-05 MechAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechDocument13 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saic B 1002Document2 pagesSaic B 1002Hussain Nasser Al- NowiesserNo ratings yet

- SAIC-D-2004 Rev 8Document3 pagesSAIC-D-2004 Rev 8Syed ImranNo ratings yet

- Saic M 1073Document6 pagesSaic M 1073Hussain Nasser Al- NowiesserNo ratings yet

- Saic e 2005Document13 pagesSaic e 2005jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Document3 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Abdul HannanNo ratings yet

- Saic M 1030Document3 pagesSaic M 1030Hussain Nasser Al- NowiesserNo ratings yet

- Saic D 2004Document1 pageSaic D 2004Muhammad Ikram QurashiNo ratings yet

- Saic-M-1012 Rev 7 (Final)Document3 pagesSaic-M-1012 Rev 7 (Final)Satheesh Rama SamyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saic Q 1011Document2 pagesSaic Q 1011Shazab NawazNo ratings yet

- SAICbDocument2 pagesSAICbAfzal HussainNo ratings yet

- Saic B 1002Document3 pagesSaic B 1002jerinNo ratings yet

- Saic D 2004Document1 pageSaic D 2004Shahzad HussainNo ratings yet

- SAIC-D-2002 Rev 8Document5 pagesSAIC-D-2002 Rev 8Syed ImranNo ratings yet

- Saudi Aramco Inspection ChecklistDocument14 pagesSaudi Aramco Inspection Checklistpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: FBE Rebar & Embedments Receiving Inspection SAIC-Q-1007 15-Nov-17 MAH-SA-CDocument3 pagesSaudi Aramco Inspection Checklist: FBE Rebar & Embedments Receiving Inspection SAIC-Q-1007 15-Nov-17 MAH-SA-CAbdul HannanNo ratings yet

- Saic D 2025Document12 pagesSaic D 2025Md ShariqueNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistAnonymous S9qBDVkyNo ratings yet

- Saic D 2025Document10 pagesSaic D 2025jerinNo ratings yet

- Saic Q 1013Document5 pagesSaic Q 1013Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Saic M 2004Document6 pagesSaic M 2004Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1012Document2 pagesSaic M 1012Hussain Nasser Al- NowiesserNo ratings yet

- SAIC-W-C014-Post Weld Visual Inspection - Offshore StructuresDocument4 pagesSAIC-W-C014-Post Weld Visual Inspection - Offshore StructuresVinu MadhavanNo ratings yet

- Saic M 1035Document4 pagesSaic M 1035noor mohamedazeezNo ratings yet

- Inspection of Support Foundation Prior To Structural or Equipment Installation SAIC-M-2006 03-Apr-22 MechDocument2 pagesInspection of Support Foundation Prior To Structural or Equipment Installation SAIC-M-2006 03-Apr-22 MechsankuNo ratings yet

- Saic M 1072Document5 pagesSaic M 1072Hussain Nasser Al- Nowiesser100% (2)

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Fencing Types I - V Installation Inspection SAIC-M-1002 30-Oct-17 CivilDocument4 pagesSaudi Aramco Inspection Checklist: Fencing Types I - V Installation Inspection SAIC-M-1002 30-Oct-17 CivilAhmad BassemNo ratings yet

- Saudi Aramco Inspection Checklist: Storm Water Drainage Systems Installation SAIC-S-4060 PlumbDocument2 pagesSaudi Aramco Inspection Checklist: Storm Water Drainage Systems Installation SAIC-S-4060 PlumbAiman RahmanNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechDocument7 pagesSaudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechmominNo ratings yet

- SAIC-B-2001 Revw Proprietary Fireproofing MaterialsDocument2 pagesSAIC-B-2001 Revw Proprietary Fireproofing MaterialsAnonymous S9qBDVkyNo ratings yet

- Saic K 4008Document3 pagesSaic K 4008Dusngi MoNo ratings yet

- SAIC-W-2085 Pre-Welding Inspection PDFDocument4 pagesSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldjahaanNo ratings yet

- SAIC-W-2006 Rev 8Document4 pagesSAIC-W-2006 Rev 8saravananmenmathiNo ratings yet

- SAIC-K-4020 Rev 08 - Chilled Water Piping Lay-OutDocument4 pagesSAIC-K-4020 Rev 08 - Chilled Water Piping Lay-Outranausman1987No ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saic M 1044Document2 pagesSaic M 1044Hussain Nasser Al- Nowiesser100% (1)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Saic L 1004Document3 pagesSaic L 1004noor mohamedazeezNo ratings yet

- Saic L 1001Document2 pagesSaic L 1001noor mohamedazeezNo ratings yet

- Saic M 1035Document4 pagesSaic M 1035noor mohamedazeezNo ratings yet

- Saic M 1034Document2 pagesSaic M 1034noor mohamedazeezNo ratings yet

- Saic M 1004Document2 pagesSaic M 1004noor mohamedazeezNo ratings yet

- Saic M 1001Document8 pagesSaic M 1001noor mohamedazeezNo ratings yet

- Saic M 1005Document4 pagesSaic M 1005noor mohamedazeezNo ratings yet

- Saic M 1032Document2 pagesSaic M 1032noor mohamedazeezNo ratings yet

- Saic M 1031Document3 pagesSaic M 1031noor mohamedazeezNo ratings yet

- General Notes PDFDocument1 pageGeneral Notes PDFnoor mohamedazeezNo ratings yet

- Markov Decision ProcessDocument11 pagesMarkov Decision ProcessHarpreet Singh BaggaNo ratings yet

- Republic of The Philippines Department of Education Pajo National High School Senior High School DepartmentDocument25 pagesRepublic of The Philippines Department of Education Pajo National High School Senior High School DepartmentBonifacio PinoNo ratings yet

- TodhunterDocument8 pagesTodhunterHilárioNo ratings yet

- Menstra - Chapter 2 Leadership Agility VUCA Nick HorneyDocument16 pagesMenstra - Chapter 2 Leadership Agility VUCA Nick HorneyanakristianaNo ratings yet

- MarineDocument16 pagesMarinehhhhhNo ratings yet

- Neighborhood and Connectivity of PixelsDocument25 pagesNeighborhood and Connectivity of Pixelswit12345No ratings yet

- Does The Media Impact Athletic PerformanceDocument2 pagesDoes The Media Impact Athletic PerformanceVaishnavi SinghNo ratings yet

- Design of Terraces 1Document2 pagesDesign of Terraces 1ᜁᜊ ᜀᜎᜆᜂNo ratings yet

- Disaster Risk Reduction and ReadinessDocument1 pageDisaster Risk Reduction and ReadinessAndrea Ericka CanawayNo ratings yet

- Lab 7b - Bilateral Transfer and Observational LearningDocument3 pagesLab 7b - Bilateral Transfer and Observational Learningapi-448989844No ratings yet

- Bira 91Document11 pagesBira 91Rishab Gupta100% (2)

- Seminar Topics NameDocument10 pagesSeminar Topics NameNilesh ThanviNo ratings yet

- Processors and Programmable Logic: Khaled Grati Grati - Khaled@Supcom - TN 2020-2021Document18 pagesProcessors and Programmable Logic: Khaled Grati Grati - Khaled@Supcom - TN 2020-2021ibrahimNo ratings yet

- Crevis Blower Control Feeding System: Scale AQ ASDocument2 pagesCrevis Blower Control Feeding System: Scale AQ ASpablo esteban jara reyesNo ratings yet

- The Work Motivation Level of Employees Working Under North Eastern Coal FieldDocument21 pagesThe Work Motivation Level of Employees Working Under North Eastern Coal FieldChayanika SaikiaNo ratings yet

- Anemia in Pregnancy by MahreeDocument53 pagesAnemia in Pregnancy by MahreesherzadmahreeNo ratings yet

- Year 12 MockDocument5 pagesYear 12 MockAlvan MmaduwubaNo ratings yet

- IS820 Computer SecurityDocument69 pagesIS820 Computer SecuritySHAHID AHMEDNo ratings yet

- Maklumat Vaksinasi: Vaccination DetailsDocument2 pagesMaklumat Vaksinasi: Vaccination DetailsNORFADHLI ARIFNo ratings yet

- ADF Health Manual Vol 20, Part8, Chp2Document18 pagesADF Health Manual Vol 20, Part8, Chp2Ahmad Usman Tahir100% (2)

- Crowley - The Crisis in FreemasonryDocument18 pagesCrowley - The Crisis in FreemasonryCelephaïs Press / Unspeakable Press (Leng)100% (4)

- (S) Topic 1 - IntroductionDocument11 pages(S) Topic 1 - IntroductionKelvin YapNo ratings yet

- Assignment 1 Victorian Poetry MA-3Document3 pagesAssignment 1 Victorian Poetry MA-3Nayyab AbidNo ratings yet

- Ancient Robbers. Reflections Behind The FactsDocument21 pagesAncient Robbers. Reflections Behind The FactspacoNo ratings yet

- A Research Project Presented To Dr. Sicily TiuDocument17 pagesA Research Project Presented To Dr. Sicily TiuGio LlanosNo ratings yet

- Appendix 4 - SSR - SG6.2-170-135mHH (1) Cel Mai ImportantDocument56 pagesAppendix 4 - SSR - SG6.2-170-135mHH (1) Cel Mai ImportantDaniel StefanNo ratings yet

- Stellar Gold Event Guide 2021Document7 pagesStellar Gold Event Guide 2021CozmynNo ratings yet

- 3 What Else Can I DoDocument1 page3 What Else Can I DoEnrico Luis BalisalisaNo ratings yet

- Methods of Manufacture of Fermented Dairy ProductsDocument25 pagesMethods of Manufacture of Fermented Dairy ProductsRonak RawatNo ratings yet

- Erasmus Presentation - 27 AbrilDocument11 pagesErasmus Presentation - 27 AbrilPaulo TavaresNo ratings yet