Professional Documents

Culture Documents

WPH4 51802200105 PDF

WPH4 51802200105 PDF

Uploaded by

Ayub Anwar M-SalihOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPH4 51802200105 PDF

WPH4 51802200105 PDF

Uploaded by

Ayub Anwar M-SalihCopyright:

Available Formats

OWNER’S MANUAL

14 SEER Single--Package Heat Pump System with

R--410A Refrigerant Single Phase and Three Phase

2 to 5 Nominal Tons

PHD4 Series F and WPH4 Series B

A09034

Fig. 1 -- Unit PHD4 and WPH4

NOTE TO EQUIPMENT OWNER:

For your convenience, please record the model and serial numbers of your new equipment in the spaces

provided. This information, along with the installation data and dealer contact information, will be helpful

should your system require maintenance or service.

UNIT INFORMATION INSTALLATION INFORMATION

Model # _____________________________________ Date Installed ________________________________

Serial # ______________________________________ DEALERSHIP CONTACT INFORMATION

Company Name_______________________________

ACCESSORIES (List type and model #) Address______________________________________

_____________________________________________ _____________________________________________

_____________________________________________ Phone Number _______________________________

_____________________________________________ Technician Name _____________________________

_____________________________________________

NOTE TO INSTALLER:

This manual must be left with the equipment owner.

Specifications are subject to change without notice. 51802200105 12/2015

SAFETY CONSIDERATIONS

Improper installation adjustment, alteration, service, maintenance,

! CAUTION

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury, or property CUT HAZARD

damage. Consult a qualified installer, service agency, or your Failure to follow this caution may result in personal injury.

distributor or branch for information or assistance. The qualified Sheet metal parts may have sharp edges or burrs. Use care

installer or agency must use factory--authorized kits or accessories and wear appropriate protective clothing, safety glasses and

when modifying this product Refer to the individual instructions gloves when handling parts and servicing furnaces.

packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations. OPERATING YOUR UNIT

Have a fire extinguisher available. Read these instructions The operation of your heat pump system is controlled by the

thoroughly and follow all warnings or cautions included in

indoor thermostat. You simply adjust the thermostat and it

literature and attached to the unit. Consult local building codes, the

maintains the indoor temperature at the level you select. Most

current editions of the National Electrical Code (NEC) NFPA 70. thermostats of heat pump systems have 3 controls: a temperature

In Canada refer to the current editions of the Canadian electrical control selector, a FAN control, and a SYSTEM or MODE control.

Code CSA C22.1. Refer to your thermostat owner’s manual for more information.

Recognize safety information. This is the safety--alert symbol . To better protect your investment and to eliminate unnecessary

When you see this symbol on the unit and in instructions or service calls, familiarize yourself with the following facts:

manuals, be alert to the potential for personal injury. Understand 1. During heating, increasing the desired temperature setting

these signal words; DANGER, WARNING, and CAUTION. These more than 2F (1.1C) may cause the supplemental heaters

words are used with the safety--alert symbol. DANGER identifies to be turned on for a short period of time to satisfy the

the most serious hazards which will result in severe personal injury demand. Needless use of the supplementary heat reduces

or death. WARNING signifies hazards which could result in potential energy savings.

personal injury or death. CAUTION is used to identify unsafe 2. Ice or frost tends to form on the coil during winter heating

practices which may result in minor personal injury or product and operation. Your unit is designed to automatically melt the

property damage. NOTE is used to highlight suggestions which ice. When in this defrost cycle, it is normal for steam or

will result in enhanced installation, reliability, or operation. fog to rise from the outdoor unit, and for water to drain

NOTE: Installer: This manual should be left with the equipment from the outside of unit. Do not be alarmed!

user. To start the unit:

1. Turn on the electrical power supply to unit.

! WARNING 2. Set MODE control to desired mode and select temperature.

To shut off unit:

FIRE, EXPLOSION, ELECTRICAL SHOCK

HAZARD NOTE: If the unit is being shut down because of a malfunction,

call your dealer as soon as possible.

Failure to follow this warning could result in personal

injury, death, and/or property damage. 1. Set system MODE control to OFF.

Installation and servicing of this equipment can be 2. Turn off the electrical power supply to unit.

hazardous due to mechanical and electrical components. Cooling Mode

Only trained and qualified personnel should install, repair,

or service this equipment. With the SYSTEM or MODE control set to COOL, your unit will

run in cooling mode until the indoor temperature is lowered to the

level you have selected. On extremely hot days, your unit will run

for longer periods at a time and have shorter “off” periods than on

! WARNING moderate days.

Heating Mode

FIRE, EXPLOSION, ELECTRICAL SHOCK With the SYSTEM or MODE control set to HEAT, your unit will

HAZARD run in heating mode until the room temperature is raised to the

Failure to follow this warning could result in personal level you have selected. Of course, your unit will run for longer

injury, death or property damage. periods to maintain a comfortable environment on cooler days and

Do not use this unit if any part has been under water. nights than on moderate ones.

Immediately call a qualified service technician to inspect the Supplemental Heat

unit and to replace any part of the control system which has

Your unit is your primary heating source. Your system may also be

been under water.

equipped with a supplemental heating source such as electric heat.

On cold days and nights, your system will automatically turn on

the supplemental heat, as needed, in order to maintain the level of

! WARNING comfort you have selected.

When your heat pump needs additional heat to keep you

ELECTRICAL SHOCK HAZARD comfortable your thermostat will turn on the supplemental heat (if

equipped).

Failure to follow this warning could result in personal

injury or death. Defrost Mode

Before performing recommended maintenance, be sure the When your unit is providing heat to your home or office and the

main power switch to unit is turned off and a lock--out tag is outdoor temperature drops below 45F (7.2C), moisture may

installed. There may be more than one disconnect switch. begin to freeze on the surface of the coil. If allowed to build up,

this ice would impede airflow across the coil and reduce the

amount of heat absorbed from the outside air. So, to maintain

2 Specifications are subject to change without notice. 51802200105

energy--efficient operation, your unit has an automatic defrost many applications, the installer will provide return air filter grilles

mode. mounted on the wall or ceiling of the conditioned structure. In the

The defrost mode starts at a preset time interval of 60 minutes, instance of filter grilles, the filters can simply be removed from the

although, it may be reset to 30, 90 or 120 minutes. Defrost will grille and replaced.

start at the preset time only if the ice is sufficient to interfere with The other typical application is an accessory filter rack installed

normal heating operation. inside the unit itself. The following information is given to assist in

After the ice is melted from the coil, or after a maximum of 10 changing filters used in these internal filter racks.

minutes in defrost mode, the unit automatically switches back to Filter kits are available as a purchased accessory or a factory

normal heating operation. installed option. The same filter kit is included with the accessory

Do not be alarmed if steam or fog appears at the outdoor unit economizers and factory installed economizers. See Table 1 for

during defrost mode. Water vapor from the melting ice may filter sizes supplied with accessory filter rack.

condense into a mist in the cold outside air. Table 1 – Replacement Filter Sizes

During certain weather conditions such as heavy snow and freezing Unit Size Filter Size

rain it is not uncommon for ice to build up on the unit grille. This 2 each 20 x 12 x 1

24

(508 x 305 x 25 mm)

is normal for these weather conditions. Do not attempt to remove 2 each 20 x 12 x 1

the ice from the unit grille. This condition will not affect the proper 30

(508 x 305 x 25 mm)

function of the unit and will clear within a few days. 1 each 24 x 14 x 1 (610 x 356 x 25 mm),

42--- 48

Emergency Heating Mode 24 x 16 x 1 (610 x 406 x 25 mm)

1 each 24 x 16 x 1 (610 x 406 x 25 mm),

In the event of primary unit heat failure, the emergency heat mode 36 & 60*

24 x 18 x 1 (610 x 457 x 25 mm)

allows your supplemental heating source to keep your home or *Units with bent indoor coil.

office warm until your unit can be serviced. Contact your dealer in To replace or inspect filters in accessory filter rack:

the event of primary unit heat failure.

1. Remove the filter access panel (See Fig. 3) using a 5/16--in.

MAINTENANCE AND SERVICE nut driver.

This section discusses maintenance that should be performed by 2. Remove the filter(s) by pulling it out of the unit. If the

your dealer and care you, as the owner, may wish to handle for filter(s) is dirty, clean or replace with a new one.

your new unit. When installing the new filter(s), note the direction of the airflow

Routine Maintenance arrows on the filter frame.

All routine maintenance should be handled by skilled, experienced If you have difficulty locating your air filter(s) or have questions

personnel. Your dealer can help you establish a standard procedure. concerning proper filter maintenance, contact your dealer for

To assure proper functioning of the unit, flow of condenser air instructions. When replacing filters, always use the same size and

must not be obstructed from reaching the unit. Clearance from the type of filter that was supplied originally by the installer.

top of the unit is 48 in. (1219 mm). Clearance of at least 36 in.

(914 mm) is required on sides except the power entry side (42 in.

[1067 mm] clearance) and the duct side (12 in. [305 mm]

minimum clearance).

Maintenance and Care for the Equipment Owner

Before proceeding with those things you might want to maintain

yourself, please carefully consider the following:

! WARNING

FIRE, EXPLOSION, ELECTRICAL SHOCK, CUT

HAZARD

Failure to follow this warning could result in personal

injury, death or property damage. Filter Access Panel

For Accessory Filter Rack

1. TURN OFF ELECTRICAL POWER TO YOUR UNIT

Access Panels

BEFORE SERVICING OR PERFORMING

A09044

MAINTENANCE AND INSTALL A LOCK--OUT

Fig. 2 -- Accessory Filter Rack Access Panel

TAG. THERE MAY BE MORE THAN ONE DISCON-

NECT SWITCH.

2. When removing access panels or performing

maintenance functions inside your unit, be aware of

sharp sheet metal parts and screws. Although special care

! WARNING

is taken to reduce sharp edges to a minimum, be FIRE AND UNIT OPERATION HAZARD

extremely careful when handling parts or reaching into Failure to follow this warning could result in personal

the unit. injury, death or property damage.

Never operate your unit without filters in place. An

Air Filters accumulation of dust and lint on internal parts of your unit

can cause loss of efficiency.

The air filter(s) should be checked every 3 or 4 weeks and changed

or cleaned whenever it becomes dirty. Dirty filters produce

excessive stress on the blower motor and can cause the motor to

overheat and shut down.

This unit must have an air filter in place before it can be operated.

These filters should be located in at least one of two places. In

3 Specifications are subject to change without notice. 51802200105

Units with bent indoor coils, install 24 x 18 x 1 (610 x 457 x 25

mm) filter first and then install 24 x 16 x 1 (610 x 406 x 25) filter.

When installing the new filters, note the direction of the airflow

arrows on the filter frame, which should be pointing at the indoor

coil.

3. Reinstall filter access door ensuring opening is air and

watertight.

Fans and Fan Motor

Periodically check the condition of fan wheels and housings and

fan--motor shaft bearings. Contact your dealer for the required

annual maintenance.

Indoor and Outdoor Coils

Cleaning of the coils should only be done by qualified service

personnel. Contact your dealer for the required annual

maintenance.

Condensate Drain

RETURN

The drain pan and condensate drain line should be checked and

DUCT COVER cleaned at the same time the cooling coils are checked by your

(Remove for dealer.

filter access) Compressor

SMALL CHASSIS All compressors are factory shipped with a normal charge of the

A10063 correct type and quantity of refrigeration grade oil. A compressor

Fig. 3 -- Small Chassis Filter Access should rarely require additional oil.

Condenser Fan

! WARNING

PERSONAL INJURY AND UNIT DAMAGE

HAZARD

Failure to follow this warning could result in personal

injury, death or property damage.

Do not poke sticks, screwdrivers, or any other object into

revolving fan blades.

FILTER The fan must be kept free of all obstructions to ensure proper

ACCESS cooling. Contact your dealer for any required service.

PANEL

Electrical Controls and Wiring

Electrical controls are difficult to check without proper

instrumentation. If there are any discrepancies in the operating

cycle, contact your local dealer and request service.

Refrigerant Circuit

LARGE CHASSIS

The refrigerant circuit is difficult to check for leaks without the

A10062

proper equipment. If inadequate cooling is suspected, contact your

Fig. 4 -- Large Chassis Filter Access

local dealer for service.

Replacing or inspecting filters in units with econom-

izers ! WARNING

Small Chassis (See Fig. 3)

EXPLOSION, BURN AND ENVIRONMENTAL

1. Remove return air duct cover at rear of unit using a 5/16--in. HAZARD

nut driver.

Failure to follow this warning could result in personal

2. Remove the filter(s) by pulling it out and through the unit injury, death or property damage.

duct opening. If filter is dirty, replace both filters with new

System under pressure. Relieve pressure and recover all

ones.

refrigerant before system repair or final unit disposal. Use

When installing the new filters, note the direction of the airflow all service ports and open all flow--control devices,

arrows on the filter frame, which should be pointing at the indoor including solenoid valves.

coil.

3. Reinstall duct cover ensuring opening is air and water tight.

Unit Panels

Large Chassis (See Fig. 4)

After performing any maintenance or service on the unit, be sure

1. Remove filter access door using a 5/16--in. nut driver.

all panels are fastened securely in place to prevent rain from

2. Remove the filter(s) by pulling it out and through the unit entering unit cabinet and to prevent disruption of the correct unit

filter access door. If filter is dirty, replace both filters with airflow pattern.

new ones.

4 Specifications are subject to change without notice. 51802200105

Regular Dealer Maintenance Warranty Certificate

In addition to the type of routine maintenance you might be willing Your unit has a limited warranty. Be sure to read the warranty

to perform, your unit should be inspected regularly by a properly carefully to determine the coverage for your unit.

trained service technician. An inspection (preferably each year, but Before you call for service...

at least every other year) should include the following:

...check for several easily solved problems.

1. Inspection and, if required, cleaning of the outdoor and

If insufficient heating or cooling is suspected:

indoor coils.

( ) Check for sufficient airflow. Check the air filter for dirt. Check

2. Inspection and, if required, cleaning of the indoor coil drain

for blocked return or supply air grilles. Be sure they are open and

pan.

unobstructed. If these checks do not reveal the cause, call your

3. Inspection and cleaning of blower wheel housing and servicing dealer.

motor.

If your unit is not operating at all, check the following list for

4. Inspection of all supply and return air ducts for leaks, easy solutions:

obstructions, and insulation integrity. Any problems found

( ) Check to be sure that your thermostat temperature selector is

should be resolved at this time.

set below the indoor temperature during the cooling season or

5. Inspection of the unit base to ensure that no cracks, gaps, above the indoor temperature during heating season. Be sure the

etc., exist which may cause a hazardous condition. SYSTEM switch or MODE control is in the COOL or HEAT and

6. Inspection of the unit casing for signs of deterioration. not OFF.

7. Inspection of all electrical wiring and components to assure ( ) If your unit still fails to operate, call your servicing dealer for

proper connection. troubleshooting and repairs. Specify the model and serial numbers

8. Inspection for leaks in the refrigerant circuit. Pressure and of your unit. (Record them in this manual in the space provided.) If

temperature check to determine appropriate refrigerant the dealer knows exactly which unit you have, he may be able to

charge. offer suggestions over the phone, or save valuable time through

9. Operational check of the unit to determine working knowledgeable preparation for the service call.

conditions. Repair or adjustment should be made at this In Case of Trouble

time. If you perform the steps above and unit performance is still

Your servicing dealer may offer an economical service contract that unsatisfactory, shut off the unit and call your dealer.

covers seasonal inspections. Ask for further details.

Complete service instructions can be found in the unit Installation,

Start--up and Service Instructions.

5 Specifications are subject to change without notice. 51802200105

Copyright 2015 International Comfort Products

Replaces: NEW

Lewisburg, TN 37091 USA

6 Specifications are subject to change without notice. 51802200105

You might also like

- TriPac Auxiliary Heating - Cooling Temperature Management System (53024-19-OD Original 10-05) PDFDocument118 pagesTriPac Auxiliary Heating - Cooling Temperature Management System (53024-19-OD Original 10-05) PDFRodrigo Hernandez67% (3)

- Thermoguard P-IV Multi-Temp Microprocessor Controller Revision 20xx SoftwareDocument394 pagesThermoguard P-IV Multi-Temp Microprocessor Controller Revision 20xx SoftwareMartin Malvasia100% (3)

- Iso 8528 1 2018Document11 pagesIso 8528 1 2018Ayub Anwar M-Salih67% (3)

- De Tia-Pro2 en 01 V130101Document390 pagesDe Tia-Pro2 en 01 V130101Ayub Anwar M-Salih100% (1)

- De Tia-Pro1 en 01 V130100Document433 pagesDe Tia-Pro1 en 01 V130100Ayub Anwar M-Salih100% (1)

- Carrier 52CP - TSTAT-PROGRAMMABLEINSTALLATION PDFDocument16 pagesCarrier 52CP - TSTAT-PROGRAMMABLEINSTALLATION PDFJimKNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Kinematic Exam Problem by SAM-HW-1Document1 pageKinematic Exam Problem by SAM-HW-1sahel100% (1)

- Advanced User Guide For Free McBoot 1.8Document35 pagesAdvanced User Guide For Free McBoot 1.8Anzac Matt100% (2)

- TCM-CMI-Bendix Magneto Application Guide PDFDocument68 pagesTCM-CMI-Bendix Magneto Application Guide PDFSaeed MashaqbahNo ratings yet

- HSE Legal and Other RequirementsDocument7 pagesHSE Legal and Other RequirementsAjas AjuNo ratings yet

- Wja4 42602170300 PDFDocument4 pagesWja4 42602170300 PDFAyub Anwar M-SalihNo ratings yet

- Manual de Usuario 50ZHK CPDocument6 pagesManual de Usuario 50ZHK CPProyectos Instalaciones RAVENo ratings yet

- Om50vr 04Document5 pagesOm50vr 04RAFAEL RAMÍREZ JURADONo ratings yet

- Og Acr410gen 03Document2 pagesOg Acr410gen 03Sonaina KhanNo ratings yet

- PTAC AirCollant PDFDocument24 pagesPTAC AirCollant PDFPayDro SnerlingNo ratings yet

- Og Acr410gen 02Document2 pagesOg Acr410gen 02Juan Cascante JiménezNo ratings yet

- Carrier 40mhh en UciDocument14 pagesCarrier 40mhh en UciWILLIAM CABASCANGONo ratings yet

- 50 ZPDocument4 pages50 ZPhenry peñaNo ratings yet

- Ii Ebstate 01Document20 pagesIi Ebstate 01Minh nhut LưuNo ratings yet

- 638-94837 Toc-L Ssm-5000a Um en LabsolutionstocDocument174 pages638-94837 Toc-L Ssm-5000a Um en Labsolutionstocpurin phokhunNo ratings yet

- Om 40MPHB 01Document16 pagesOm 40MPHB 01anuragsinghal1985No ratings yet

- Manual Usuario Control Remoto YXE C02UDocument20 pagesManual Usuario Control Remoto YXE C02UMaría GonzálezNo ratings yet

- Dream Inverter Owner's Manual ClassicDocument19 pagesDream Inverter Owner's Manual ClassicHemraj RamkishoreNo ratings yet

- Blanc Owner Manual (REV)Document20 pagesBlanc Owner Manual (REV)Jojo LaNo ratings yet

- XR50CX GBDocument4 pagesXR50CX GBEmilia CocioNo ratings yet

- Cylinder Unit Hydrobox FTC BoxDocument14 pagesCylinder Unit Hydrobox FTC BoxkjulenNo ratings yet

- Manual PDFDocument19 pagesManual PDFA FidNo ratings yet

- Install Tempra Trend PlusDocument68 pagesInstall Tempra Trend PlussyontechNo ratings yet

- Silhouette Dpac 120061Document41 pagesSilhouette Dpac 120061Joel StolkNo ratings yet

- WS18K57CCCI User ManualDocument20 pagesWS18K57CCCI User ManualleonardseniorNo ratings yet

- Dcs302ca61 Central ControllerDocument28 pagesDcs302ca61 Central ControllerCao Tâm VănNo ratings yet

- WHL 035Document18 pagesWHL 035Sehar KhanNo ratings yet

- AHU KIT IOM_20200731Document29 pagesAHU KIT IOM_20200731felipeNo ratings yet

- Instruction Manual: Silicone Rubber Heating BlanketsDocument8 pagesInstruction Manual: Silicone Rubber Heating BlanketsJBertrandNo ratings yet

- Packaged Terminal Air Conditioner/Heat Pump Installation/Owner'S ManualDocument27 pagesPackaged Terminal Air Conditioner/Heat Pump Installation/Owner'S ManualMichael MartinNo ratings yet

- Refrigerator ManualDocument52 pagesRefrigerator ManualAsish desaiNo ratings yet

- XR30CX: Installing and Operating InstructionsDocument4 pagesXR30CX: Installing and Operating InstructionsD GraymanNo ratings yet

- Hyc 610 Haier ManualDocument10 pagesHyc 610 Haier ManualEqui ServiciosNo ratings yet

- XR30CX: Installing and Operating InstructionsDocument4 pagesXR30CX: Installing and Operating InstructionsImmorthalNo ratings yet

- Amana Ac Unit PDFDocument20 pagesAmana Ac Unit PDFAnonymous FWoDP9j6L100% (1)

- Type F1500 Muffle Furnace: Operation Manual and Parts List Series 327Document40 pagesType F1500 Muffle Furnace: Operation Manual and Parts List Series 327Martin Oscar Pacheco AlvarezNo ratings yet

- OwnerInstallManual 2018 AlcsrcDocument48 pagesOwnerInstallManual 2018 AlcsrcpfmpiromanNo ratings yet

- Fua User ManualDocument41 pagesFua User ManualSun And youNo ratings yet

- HO2020375A-Hitachi Wired Controller HCWA21NEHH 2021050702563058Document24 pagesHO2020375A-Hitachi Wired Controller HCWA21NEHH 2021050702563058hongkai.airNo ratings yet

- Owners ManualDocument6 pagesOwners ManualRafael Ricardo Zacarias CastilloNo ratings yet

- Dixell XR20CXDocument4 pagesDixell XR20CXionut ciobanuNo ratings yet

- Applicationmanualmicro Ehv PDFDocument146 pagesApplicationmanualmicro Ehv PDFSezgin YilmazNo ratings yet

- TA DAF Test Procedures F 12 1001Document1 pageTA DAF Test Procedures F 12 1001Marcelo LeguizamonNo ratings yet

- A 2 Uq 18 GFD 0Document24 pagesA 2 Uq 18 GFD 0mohammed aderNo ratings yet

- XR20CX GBDocument4 pagesXR20CX GBเปลวเพลิง นิรนามNo ratings yet

- Service Manual For R32 Umatch-46486 PDFDocument197 pagesService Manual For R32 Umatch-46486 PDFMaria Nela PerezNo ratings yet

- AD - 001 - EN Spreader BROMADocument682 pagesAD - 001 - EN Spreader BROMAKevin Leon Izaguirre100% (2)

- Hot Plate: Operation Manual and Parts ListDocument20 pagesHot Plate: Operation Manual and Parts ListRicardo Palafox MejiaNo ratings yet

- FB4 Installation ManualDocument12 pagesFB4 Installation ManualArturo ValladaresNo ratings yet

- Fumace F62730Document36 pagesFumace F62730Diego GutierrezNo ratings yet

- KAC UserManualDocument20 pagesKAC UserManualCheryl QuaidNo ratings yet

- Shimaden SR1 8Y 1WDocument8 pagesShimaden SR1 8Y 1WmaufisanNo ratings yet

- TDE Chest ULT MD 332851H01 RevB ENGLISHDocument44 pagesTDE Chest ULT MD 332851H01 RevB ENGLISHlin.jhih.yingNo ratings yet

- Manual Ethernet InterfaceDocument124 pagesManual Ethernet InterfacebaezinoaNo ratings yet

- 12k User's ManualDocument104 pages12k User's Manualalin76usNo ratings yet

- INNOVAIR Elite 2 Owners Manual CompressedDocument23 pagesINNOVAIR Elite 2 Owners Manual CompresseddimashrnndzNo ratings yet

- USER MANUAL CompressedDocument20 pagesUSER MANUAL CompressedallenlumantaNo ratings yet

- 1.ehs Hydro Unit Eu Ib Db68-07003a-03 en 20181219Document62 pages1.ehs Hydro Unit Eu Ib Db68-07003a-03 en 20181219ion tNo ratings yet

- Mitsubishi Electric PLA-RP EA Installation Manual Eng PDFDocument20 pagesMitsubishi Electric PLA-RP EA Installation Manual Eng PDFDiogo RosaNo ratings yet

- SterlingQVSB250man PDFDocument28 pagesSterlingQVSB250man PDFsarwizNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part TwoFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part TwoNo ratings yet

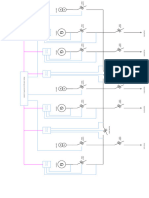

- SLDDocument1 pageSLDAyub Anwar M-SalihNo ratings yet

- Smart Home Lighting Design: Course 30 Minutes Test 20 MinutesDocument22 pagesSmart Home Lighting Design: Course 30 Minutes Test 20 MinutesAyub Anwar M-SalihNo ratings yet

- I550 PDFDocument704 pagesI550 PDFAyub Anwar M-SalihNo ratings yet

- 14 Ze 14-11-90467 001 V Thytronic Pro Nva 100 X V Iec 61850 Ed1 Server Certificate 1b0f9cb3ecDocument3 pages14 Ze 14-11-90467 001 V Thytronic Pro Nva 100 X V Iec 61850 Ed1 Server Certificate 1b0f9cb3ecAyub Anwar M-SalihNo ratings yet

- Ke-Hsr EngDocument1 pageKe-Hsr EngAyub Anwar M-SalihNo ratings yet

- Danfoss-Transmiter Za SimchemDocument7 pagesDanfoss-Transmiter Za SimchemPerc AleksandarNo ratings yet

- Ca3v 4Document119 pagesCa3v 4Ayub Anwar M-SalihNo ratings yet

- SyntheticdeoDocument2 pagesSyntheticdeoAyub Anwar M-SalihNo ratings yet

- Wja4 42602170300 PDFDocument4 pagesWja4 42602170300 PDFAyub Anwar M-SalihNo ratings yet

- Grundfosliterature 2127821Document52 pagesGrundfosliterature 2127821Ayub Anwar M-SalihNo ratings yet

- 20221113102348554Document2 pages20221113102348554Ayub Anwar M-SalihNo ratings yet

- زاد الحائر فى فهم الدوائر الجزء الاول رمضان 1441 هـ-unlockedDocument498 pagesزاد الحائر فى فهم الدوائر الجزء الاول رمضان 1441 هـ-unlockedAyub Anwar M-SalihNo ratings yet

- Vitrea VTouch Pro EnglishDocument15 pagesVitrea VTouch Pro EnglishAyub Anwar M-SalihNo ratings yet

- Qustion 1Document2 pagesQustion 1Ayub Anwar M-SalihNo ratings yet

- Iom 200 Data Sheet 4921240366 UkDocument9 pagesIom 200 Data Sheet 4921240366 UkAyub Anwar M-SalihNo ratings yet

- Yamen Kassab Hannan: ProfileDocument1 pageYamen Kassab Hannan: ProfileAyub Anwar M-SalihNo ratings yet

- Prime: Diesel Generator SetDocument6 pagesPrime: Diesel Generator SetAyub Anwar M-SalihNo ratings yet

- diacloud API文档说明v1.4.zh-CN.enDocument39 pagesdiacloud API文档说明v1.4.zh-CN.enAyub Anwar M-SalihNo ratings yet

- Understand - Ratings - TADocument5 pagesUnderstand - Ratings - TAAyub Anwar M-SalihNo ratings yet

- Dx2300Passdvwrealize Remote Monitoring Of Equipment: 【Summary】Document15 pagesDx2300Passdvwrealize Remote Monitoring Of Equipment: 【Summary】Ayub Anwar M-SalihNo ratings yet

- AGC 200 Modbus Descriptions Software Version Row Hyperlink IndexDocument42 pagesAGC 200 Modbus Descriptions Software Version Row Hyperlink IndexAyub Anwar M-SalihNo ratings yet

- Switchgear Vs SwitchboardDocument20 pagesSwitchgear Vs SwitchboardJuan MoralesNo ratings yet

- Project Report On AWCC (Afghan Wireless Communication Company) CompanyDocument82 pagesProject Report On AWCC (Afghan Wireless Communication Company) CompanyNiaz Sahil Zurmatai100% (1)

- Unbrako US Product Guide PDFDocument144 pagesUnbrako US Product Guide PDFManju KNo ratings yet

- Aquasystem Aerator Karistirici Brosur PDFDocument8 pagesAquasystem Aerator Karistirici Brosur PDFMariusCapraNo ratings yet

- Swot of EmsDocument2 pagesSwot of EmsWaleed MorsyNo ratings yet

- Objects of Conditioning Are As FollowsDocument7 pagesObjects of Conditioning Are As FollowssachinnmimsNo ratings yet

- Digam SeriesDocument14 pagesDigam SeriesNguyễn Quang TrânNo ratings yet

- 116DA Silicone SprayDocument8 pages116DA Silicone Spraykatiuska2015No ratings yet

- CFCPDocument2 pagesCFCPVaishnavi TekadeNo ratings yet

- Ejercicios PDFDocument4 pagesEjercicios PDFOrlando FernandezNo ratings yet

- TYN606 TYN1006: 6A SCRDocument6 pagesTYN606 TYN1006: 6A SCRMohammed ImranNo ratings yet

- CP-X980: DP-6860 Users ManualDocument40 pagesCP-X980: DP-6860 Users ManualRichard HollidayNo ratings yet

- Easypic2 ManualDocument17 pagesEasypic2 Manualadresa33No ratings yet

- Instruction Manual Model US1000 Digital Indicating Controller FunctionsDocument128 pagesInstruction Manual Model US1000 Digital Indicating Controller Functionsmarvin2008No ratings yet

- P21111IA-CC CNEX17ATEX0004X Issue 8 SignedDocument7 pagesP21111IA-CC CNEX17ATEX0004X Issue 8 Signedabdelrahman MohamedNo ratings yet

- Megger MIT300 Insulationtester DatasheetDocument4 pagesMegger MIT300 Insulationtester DatasheetlmendizabalNo ratings yet

- SLB - Expandable Steel PatchDocument12 pagesSLB - Expandable Steel PatchMike du PlessisNo ratings yet

- John Abercrombie - SidekicksDocument1 pageJohn Abercrombie - SidekicksСергей ЕгоровNo ratings yet

- IGS Directory 2016-SortedDocument252 pagesIGS Directory 2016-Sortedjacs127No ratings yet

- Goip Sms Interface enDocument10 pagesGoip Sms Interface enNoli Bellen RafalloNo ratings yet

- Rule: Spent Nuclear Fuel and High-Level Radioactive Waste Independent Storage Licensing Requirements: Approved Spent Fuel Storage Casks ListDocument2 pagesRule: Spent Nuclear Fuel and High-Level Radioactive Waste Independent Storage Licensing Requirements: Approved Spent Fuel Storage Casks ListJustia.comNo ratings yet

- Decanter CentrifugesDocument9 pagesDecanter CentrifugesAgnesia Afrida PasaribuNo ratings yet

- Dapped End Strengtheningof Precast Prestressed Concrete Double Tee Beamswith FRPCompositesDocument157 pagesDapped End Strengtheningof Precast Prestressed Concrete Double Tee Beamswith FRPCompositesMeganathan MegaNo ratings yet

- Lgu-Baler Ordinance No 001-2008 PDFDocument19 pagesLgu-Baler Ordinance No 001-2008 PDFhoswakihoti100% (1)

- Subject: Offer For AMW Make ACB 60 Concrete Batching Plant: To, DATE:-03/06/2021 M/S SheikhbhaiDocument5 pagesSubject: Offer For AMW Make ACB 60 Concrete Batching Plant: To, DATE:-03/06/2021 M/S SheikhbhaiHIREN PATELNo ratings yet

- Klueber Summit HySyn FG 15-100 050015 PI GB enDocument4 pagesKlueber Summit HySyn FG 15-100 050015 PI GB enOMiD QahqaieNo ratings yet