Professional Documents

Culture Documents

Lecture 7 - Minor Head Loss

Lecture 7 - Minor Head Loss

Uploaded by

Percival Archer0 ratings0% found this document useful (0 votes)

12 views47 pagesMinor head losses are caused by changes in flow direction or velocity due to pipe fittings. These losses can usually be neglected for long pipelines over 1500 times the diameter, but must be considered for short pipelines where they may exceed friction losses. There are equations to calculate head losses for sudden contractions, enlargements, bends, and other fittings. Solving reservoir and pipe network problems requires applying principles of continuity and ensuring pressure drops around loops are zero.

Original Description:

Hydraulics

Minor losses are caused by the changes in direction or velocity of flow.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMinor head losses are caused by changes in flow direction or velocity due to pipe fittings. These losses can usually be neglected for long pipelines over 1500 times the diameter, but must be considered for short pipelines where they may exceed friction losses. There are equations to calculate head losses for sudden contractions, enlargements, bends, and other fittings. Solving reservoir and pipe network problems requires applying principles of continuity and ensuring pressure drops around loops are zero.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

12 views47 pagesLecture 7 - Minor Head Loss

Lecture 7 - Minor Head Loss

Uploaded by

Percival ArcherMinor head losses are caused by changes in flow direction or velocity due to pipe fittings. These losses can usually be neglected for long pipelines over 1500 times the diameter, but must be considered for short pipelines where they may exceed friction losses. There are equations to calculate head losses for sudden contractions, enlargements, bends, and other fittings. Solving reservoir and pipe network problems requires applying principles of continuity and ensuring pressure drops around loops are zero.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 47

Minor Head Loss

• Minor losses are caused by the changes in

direction or velocity of flow. These changes

may be due to sudden contraction, sudden

enlargement, valves, and bends, and any

other pipe fittings. These losses can usually be

neglected if the length of the pipeline is

greater than 1500 times the pipe's diameter.

However, in short pipelines, because these

losses may exceed the friction losses, minor

losses must be considered.

A. Sudden Enlargement

• The head loss, m, across a sudden

enlargement of pipe diameter is:

A. Sudden Enlargement

• Another equation for the head loss caused by

sudden enlargements was determined

experimentally by archer, and given as

• A special application of the equations above is

the discharge from a pipe into a reservoir. The

water in the reservoir has no velocity, so a full

velocity head is lost.

B. Gradual Enlargement

• The head loss, m, across a gradual conical

enlargement of pipe diameter is

• The approximate values of K are shown in

graph below.

C. Sudden Contraction

• The head loss, m, across a sudden contraction

of a pipe is

C. Sudden Contraction

• A special case of sudden contraction is the

entrance loss for pipes connected to a

reservoir. For this case, the values of Kc are as

follows:

D. Bends and Standard Fittings

• The approximate values of K are given in the table below. K

values vary not only for different sizes of fittings but with

different manufacturers. For these reasons, manufacturer's

data are the best source for loss coefficients.

• The head loss due to pipe fittings may also be found by

increasing the pipe length using the values of L/D in the

table below. For very smooth pipes, it is better to use the K

values when determining the loss through fittings.

Pipe Discharging from a Reservoir

• The figure shown below shows the conditions of

flow in a pipe of uniform diameter discharging

from a reservoir into open air. The velocity head

and the pressure head in the liquid surface of the

reservoir are zero. If there will be no head lost,

the velocity head could have been equal to H,

which is the distance between the water surface

in the tank and the exit end of the pipe and the

velocity of flow could have been v = √2gH , but

such is not the case due to losses.

Pipe Discharging from a Reservoir

• For pipe with constant diameter, the

difference between the water levels in the

piezometer tubes. If the pipe is horizontal and

with uniform size, the difference in pressure

head measures the head lost between the two

points.

• If the pipe is very large such that the velocity

head is very small, the total head lost HL can

be taken as equal to H.

Pipe Connecting Two Reservoir

• When one or more pipes connects two

reservoirs as in the figure shown, the total

head lost in all the pipes is equal to the

difference in elevation of the liquid surfaces of

the reservoir.

𝐻𝐻𝐻𝐻 = 𝐻𝐻 = ℎ𝐿𝐿𝐿𝐿𝐿𝐿𝐿𝐿𝐿𝐿𝐿𝐿 + ℎ𝑓𝑓

Pipe Connected in Series

• For pipes of different diameters connected in

series as shown in the figure below, the

discharge in all pipes are all equal and the

total head lost is equal to the sum of the

individual head losses.

Pipe Connected in Series

• If the pipe length in any problem is about 500

diameters, the error resulting from neglecting

minor losses will ordinarily not exceed 5%,

and if the pipe length is 1000 diameters or

more, the effect of minor losses can usually be

considered negligible. Neglecting minor

losses, the head lost becomes:

Pipes Connected in Parallel

Pipe Connected in Parallel

• In the pipe system shown, pipe 1 draws water

from reservoir A and leads to junction C which

divides the flow to pipes 2 and 3, which join

again in junction D and flows through pipe 4.

The sum of the flow in pipes 2 and 3 equals

the flow in pipes 1 and 4. Since the drop in the

energy grade line between C and D is equal to

the difference in the levels of piezometers a

and b, then the head lost in pipe 2 is therefore

equal to the head lost in pipe 3.

Equivalent Pipe

• If a pipe system (O) is to be replaced with an

equivalent single pipe (E), the equivalent pipe

must have the same discharge and head loss

as the original pipe system.

Reservoir Problems

• In the figure shown below, the three pipes 1,

2, and 3 connects the three reservoirs A, B,

and C respectively and with all pipes meeting

at a common junction D.

Types of Reservoir Problems

• Type 1: Given the discharge in one of the

pipes, or given the pressure at the junction P,

and the required is the elevation one of the

reservoirs or the diameter or length of the one

of the pipes, and

• Type 2: Given all the pipe properties and

elevation of all reservoirs, find the flow in

each pipe, which can be solved by trial and

error.

Types of Reservoir Problems

• In any of these types, the main objective is to

locate the position (elevation) of the energy at

the junction P. This position represents the

water surface of an imaginary reservoir at P.

The difference in elevation between this

surface and the surface of another reservoir is

the head lost in the pipe leading to that

reservoir (See figure above).

Procedure in Solving Reservoir

Problems

Type 1

1. With known flow in one pipe leading to or

flowing out from a reservoir of known elevation,

solve for its head lost hf.

2. Determine the elevation of the energy grade line

at the junction of the pipes (P) by adding or

subtracting (depending on the direction of flow)

the head lost in the pipe from the elevation of

the water surface in the reservoir.

Procedure in Solving Reservoir

Problems

Type 1

3. If the known value is the pressure at P, the

elevation of P' is the elevation of P + pp/γ.

4. Draw a line from P' to the surface of the other

reservoir. These lines represent the EGL's of

each pipe. The difference in elevation between

P' and the surface of the reservoir is the head

lost in the pipe. 5. Solve for the discharge.

Procedure in Solving Reservoir

Problems

Type 2

1. Given all elevation and pipe properties,

determine the direction of flow in each pipe.

Of course, the highest reservoir always have

an outflow and the lowest always have an

inflow, but the middle reservoir (B) may have

an inflow or outflow.

Procedure in Solving Reservoir

Problems

Type 2

2. To find out the direction of flow in pipe 2

assume that Q2 = 0 such that P’ is at elevation B,

then the values of hf1 and hf3 can be solved. (In

the figure shown, hf1 = 20 m and hf3 = 30 m).

With hf1 and hf3 known, solve for Q1 and Q3. If

Q1 > Q3, then Q2 is towards B and P’ is above

the reservoir B. If Q1 < Q3, then Q2 is away from

B and P’ is below reservoir B.

Procedure in Solving Reservoir

Problems

Type 2

3. After determining the direction of Q2 (say

towards reservoir B), express all the head lost

in terms the other, say in terms of hf1. Let

hf1 = x.

Procedure in Solving Reservoir

Problems

Type 2

With all head lost hf, expressed in terms of x, all

flow Q can also be expressed in terms of x

(usually in the form a√(x+b)).

Simplify the equation and solve for x. We may also use trial-and-error solution.

Procedure in Solving Reservoir

Problems

Type 2

4. Once x is determined, substitute its value to

Equations 1, 2, and 3 to solve for Q1, Q2, and

Q3, respectively.

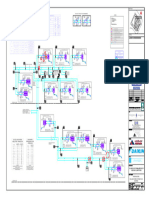

Pipe Networks

The following conditions must be satisfied in any

pipe network:

1. The algebraic sum of the pressure drops

(head loss) around any closed loop must be

zero and,

2. The flow entering a junction must be equal to

the flow leaving it.

Pipe Networks

• The first condition states that there can be no

discontinuity in pressure (the pressure drop

through any route between two junctions must

be the same). The second condition is a

statement of the law of continuity.

• Pipe network problems are usually solved by

numerical methods using computer since any

analytical solution requires the use of many

simultaneous i equations, some of which are

nonlinear.

Hardy Cross Method

• The procedure suggested by Hardy Cross

requires that the flow in each pipe be

assumed so that the principle of continuity is

satisfied at each junction. A correction to the

assumed flow is computed successively for

each pipe loop in the network until the

correction is reduced to an acceptable value.

Hardy Cross Method

• The correction a is added or subtracted from

the assumed flow in order to get the true or

corrected flow, It is added if the direction of

flow is clockwise and subtracted if

counterclockwise,

• The general formula in computing the

correction a can be expressed as:

You might also like

- Lecture 10 - HydrodynamicsDocument10 pagesLecture 10 - HydrodynamicsPercival ArcherNo ratings yet

- Civil Engineering in TUP ManilaDocument4 pagesCivil Engineering in TUP ManilaPercival ArcherNo ratings yet

- Supersonic Flow Over Naca4412 - FinalevaluationDocument65 pagesSupersonic Flow Over Naca4412 - FinalevaluationHaardikGargNo ratings yet

- Exact Solutions Navier Stokes WangDocument19 pagesExact Solutions Navier Stokes WangToddharrisNo ratings yet

- Fully Developed Flow Between Two Parallel PlatesDocument7 pagesFully Developed Flow Between Two Parallel PlatesKantharaj ChinnappaNo ratings yet

- Ch7 Steady Flow in PipeDocument35 pagesCh7 Steady Flow in PipeDany StarkNo ratings yet

- CE-UG-2018 Spring FEB-JUN 2020Document42 pagesCE-UG-2018 Spring FEB-JUN 2020SalmanNo ratings yet

- P IpesDocument15 pagesP IpesMelvin EsguerraNo ratings yet

- PlumbingDocument16 pagesPlumbingMelvin EsguerraNo ratings yet

- Steady Conduit FlowDocument13 pagesSteady Conduit FlowEyuelAdamNo ratings yet

- Flow Through PipesDocument34 pagesFlow Through PipesBrian SamendeNo ratings yet

- THERMOFLUIDSDocument23 pagesTHERMOFLUIDSareejkhanNo ratings yet

- Diaz Bendo Lipana FinalDocument73 pagesDiaz Bendo Lipana FinalAries Villegas MontabonNo ratings yet

- Pipe Systems and Networks: DR WCDK FernandoDocument29 pagesPipe Systems and Networks: DR WCDK FernandoSuranga Gayan0% (1)

- Flow Through Circular PipesDocument105 pagesFlow Through Circular PipesArchangel VenantNo ratings yet

- Steady Incompressible Flow in Pressure Conduits: Lecture - 10Document34 pagesSteady Incompressible Flow in Pressure Conduits: Lecture - 10Nawaz441No ratings yet

- MODULE 5.1-5.5 Coefficients To TubesDocument18 pagesMODULE 5.1-5.5 Coefficients To TubesFrancis HernandezNo ratings yet

- Chapter 8 Turbulent Flow in Circular PipesDocument29 pagesChapter 8 Turbulent Flow in Circular PipesSiti Nurshahira100% (1)

- Flow Through PipesDocument22 pagesFlow Through Pipestoggikumbheshwar26No ratings yet

- Internal FlowDocument41 pagesInternal FlowTusanita MapuolaNo ratings yet

- Flow in PipesDocument29 pagesFlow in PipesRafa MartínezNo ratings yet

- Chapter 3. Wells and Well Hydraulics (HWRE 6034)Document110 pagesChapter 3. Wells and Well Hydraulics (HWRE 6034)Saqalain HaiderNo ratings yet

- FM-2 Lecture Relateded To Haze William and Minor LosesDocument35 pagesFM-2 Lecture Relateded To Haze William and Minor LosesMehboob KhanNo ratings yet

- Module 3-Part3-FM&FMC - Pipe FlowDocument42 pagesModule 3-Part3-FM&FMC - Pipe FlowASHITA K BNo ratings yet

- Minor Losses & Pressure Requirements: V H K 2gDocument0 pagesMinor Losses & Pressure Requirements: V H K 2gAnastasia Monica KhunniegalshottestNo ratings yet

- Ch3 Munson BDocument31 pagesCh3 Munson BMaryam ArifNo ratings yet

- 15 HydraulicsDocument20 pages15 HydraulicsRajab RajabovNo ratings yet

- ES 65 Problem Solving Drill IIDocument2 pagesES 65 Problem Solving Drill IIedmark icalina100% (4)

- FHWA - HDS-03 - Design Charts For Open-Channel Flow - August 1961Document228 pagesFHWA - HDS-03 - Design Charts For Open-Channel Flow - August 1961FPlotasNo ratings yet

- Principle of Pipe FlowDocument30 pagesPrinciple of Pipe FlowLawal SherifNo ratings yet

- Fluid Mechanics For Mechanical Engineering: Tutorial 4Document27 pagesFluid Mechanics For Mechanical Engineering: Tutorial 4mitulkindNo ratings yet

- CH 3 2020Document62 pagesCH 3 2020Emmanuel LazoNo ratings yet

- Open Channel FlowDocument75 pagesOpen Channel FlowPrince VinceNo ratings yet

- Cve 305 - 5,6Document22 pagesCve 305 - 5,6mohammed adoNo ratings yet

- Fundamentals of Fluid FlowDocument22 pagesFundamentals of Fluid Flowmark galangNo ratings yet

- Flow Through PipesDocument31 pagesFlow Through PipesShyam Pandey50% (2)

- Partially Full Pipe Flow CalculationsDocument26 pagesPartially Full Pipe Flow CalculationsLim Han Jian100% (1)

- Head Loss in Pipe - Lab Report MannualDocument4 pagesHead Loss in Pipe - Lab Report MannualRampukar SahNo ratings yet

- HYBP 324 Part IVA Pipe System in Series and in Parallel Brancing Pipes Autosaved 6-1Document20 pagesHYBP 324 Part IVA Pipe System in Series and in Parallel Brancing Pipes Autosaved 6-1seia deirahNo ratings yet

- Water SupplyDocument5 pagesWater SupplyZahid BasharNo ratings yet

- Head Losses in Pipes: NomenclatureDocument2 pagesHead Losses in Pipes: NomenclatureAudrey Patrick KallaNo ratings yet

- Revised LabDocument18 pagesRevised LabAbu AyemanNo ratings yet

- Section 4 PIPESDocument44 pagesSection 4 PIPESgracielle joy alcantaraNo ratings yet

- Fluid Flow Measurement - 2Document51 pagesFluid Flow Measurement - 2Percival Archer100% (1)

- Chapter Three Part 1Document40 pagesChapter Three Part 1Mustafa OmerNo ratings yet

- Water Distribution System PDFDocument12 pagesWater Distribution System PDFakhilchibberNo ratings yet

- AbstractDocument6 pagesAbstractJashan MatadeenNo ratings yet

- Water System Manual EditedDocument43 pagesWater System Manual EditedFroilan Roman Vergara PineNo ratings yet

- AE December 2016 98 Civ A5Document4 pagesAE December 2016 98 Civ A5Mohammed BaderNo ratings yet

- Water Flow in Open ChannelsDocument83 pagesWater Flow in Open ChannelsShashank ShawNo ratings yet

- Hydrology For Engineers Prof Ako-9Document97 pagesHydrology For Engineers Prof Ako-9Gloria MANANLANo ratings yet

- Pipe FrictionDocument4 pagesPipe FrictionRufus ChengNo ratings yet

- Lect#2 Pipes Flow-1Document31 pagesLect#2 Pipes Flow-1Kamran AliNo ratings yet

- Pipes - : Series - ParallelDocument14 pagesPipes - : Series - ParallelDenwende HeheNo ratings yet

- Unit Iii: Flow Through Pipes 15marks 06HrsDocument27 pagesUnit Iii: Flow Through Pipes 15marks 06HrsAaditya BhatnagarNo ratings yet

- CEB707 - 7 - Water Transmission SystemDocument41 pagesCEB707 - 7 - Water Transmission SystemalexNo ratings yet

- Energy Losses in Bends Lab Report Download Full VersionDocument2 pagesEnergy Losses in Bends Lab Report Download Full VersionOBO EmmanuelNo ratings yet

- Hydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedFrom EverandHydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedNo ratings yet

- The Mechanics of Water-Wheels - A Guide to the Physics at Work in Water-Wheels with a Horizontal AxisFrom EverandThe Mechanics of Water-Wheels - A Guide to the Physics at Work in Water-Wheels with a Horizontal AxisNo ratings yet

- Irrigation Works: The Principles on Which Their Design and Working Should Be Based, with Special Details Relating to Indian Canals and Some Proposed ImprovementsFrom EverandIrrigation Works: The Principles on Which Their Design and Working Should Be Based, with Special Details Relating to Indian Canals and Some Proposed ImprovementsNo ratings yet

- Fluid Mechanics in Channel, Pipe and Aerodynamic Design Geometries 2From EverandFluid Mechanics in Channel, Pipe and Aerodynamic Design Geometries 2No ratings yet

- 11 Uncertainties PDFDocument18 pages11 Uncertainties PDFPercival ArcherNo ratings yet

- 13-Replacement AnalysisDocument12 pages13-Replacement AnalysisPercival ArcherNo ratings yet

- Types of FlowDocument15 pagesTypes of FlowPercival ArcherNo ratings yet

- 11-Uncertainties ProbDocument7 pages11-Uncertainties ProbPercival ArcherNo ratings yet

- 6-Cylindrical ComponentsDocument23 pages6-Cylindrical ComponentsPercival ArcherNo ratings yet

- 7-Analysis of Dependent MotionDocument21 pages7-Analysis of Dependent MotionPercival ArcherNo ratings yet

- Lecture 9 - Velocity Distribution in Open ChannelDocument10 pagesLecture 9 - Velocity Distribution in Open ChannelPercival ArcherNo ratings yet

- Lecture 6 - Fluid Flow in PipesDocument42 pagesLecture 6 - Fluid Flow in PipesPercival ArcherNo ratings yet

- Lecture 8 - Open ChannelDocument10 pagesLecture 8 - Open ChannelPercival ArcherNo ratings yet

- Fluid Flow MeasurementDocument27 pagesFluid Flow MeasurementPercival ArcherNo ratings yet

- HydraulicsDocument46 pagesHydraulicsPercival ArcherNo ratings yet

- Fluid Flow Measurement - 2Document51 pagesFluid Flow Measurement - 2Percival Archer100% (1)

- Group 6 - Roofing MaterialsDocument102 pagesGroup 6 - Roofing MaterialsPercival ArcherNo ratings yet

- Chapter 9 - 12 (SMBC)Document43 pagesChapter 9 - 12 (SMBC)Percival ArcherNo ratings yet

- Group 6 & 7 - Planning and SchedulingDocument122 pagesGroup 6 & 7 - Planning and SchedulingPercival ArcherNo ratings yet

- WeirsDocument34 pagesWeirsPercival ArcherNo ratings yet

- Group 5 - Construction Management OrganizationDocument94 pagesGroup 5 - Construction Management OrganizationPercival ArcherNo ratings yet

- Group 8 - Building Telecommunication SystemsDocument92 pagesGroup 8 - Building Telecommunication SystemsPercival ArcherNo ratings yet

- A Brief Guide To Engineering Management Financial CalculationsDocument23 pagesA Brief Guide To Engineering Management Financial CalculationsPercival ArcherNo ratings yet

- Chemistry Finals ReviewerDocument3 pagesChemistry Finals ReviewerPercival ArcherNo ratings yet

- Innovation and IdeasDocument22 pagesInnovation and IdeasPercival ArcherNo ratings yet

- Introduction To TechnopreneurshipDocument12 pagesIntroduction To TechnopreneurshipPercival Archer100% (1)

- Group 1 - Contract ConstructionDocument57 pagesGroup 1 - Contract ConstructionPercival ArcherNo ratings yet

- Group 5 - Construction Management Organization (Written Report)Document31 pagesGroup 5 - Construction Management Organization (Written Report)Percival ArcherNo ratings yet

- 4 Market OpportunityDocument33 pages4 Market OpportunityPercival ArcherNo ratings yet

- Group 8 - Building Telecommunication Systems (Technical Report)Document22 pagesGroup 8 - Building Telecommunication Systems (Technical Report)Percival ArcherNo ratings yet

- Group 7 - TileworksDocument93 pagesGroup 7 - TileworksPercival ArcherNo ratings yet

- Bes3 Combined Voltes 5 AwraDocument85 pagesBes3 Combined Voltes 5 AwraPercival ArcherNo ratings yet

- Experiment No. 9 Demonstration of Fluid Flow Through An Orifice I. ObjectiveDocument5 pagesExperiment No. 9 Demonstration of Fluid Flow Through An Orifice I. ObjectiveMark B. BarrogaNo ratings yet

- Aerated Drilling FormulasDocument3 pagesAerated Drilling FormulaskhansaNo ratings yet

- Supplementary Formulae SheetDocument2 pagesSupplementary Formulae SheetTony WANGNo ratings yet

- Journal of Wind Engineering and Industrial Aerodynamics: Namhun Lee, Hyungro Lee, Chung Baek, Seungsoo LeeDocument12 pagesJournal of Wind Engineering and Industrial Aerodynamics: Namhun Lee, Hyungro Lee, Chung Baek, Seungsoo LeeAlexandre AraujoNo ratings yet

- Chapter 3 Flow ComputationDocument16 pagesChapter 3 Flow ComputationRefisa Jiru100% (1)

- 16873Document2 pages16873Abdel HamidNo ratings yet

- Questions Related To Open Channel Flow.Document3 pagesQuestions Related To Open Channel Flow.Mohd AmirNo ratings yet

- ME 423 Finals Formula SheetDocument2 pagesME 423 Finals Formula SheetNicolai CeloNo ratings yet

- KKS Plant TaggingDocument6 pagesKKS Plant TaggingIshwar Alt100% (1)

- Chapter 2: Turbulent Flow in Pipes Characteristics of Turbulent Flow in PipesDocument27 pagesChapter 2: Turbulent Flow in Pipes Characteristics of Turbulent Flow in PipesNigel Joseph KabigtingNo ratings yet

- Radial ImpellerDocument10 pagesRadial ImpellernikitaNo ratings yet

- Gasmultibloc Combined Regulator and Safety Shut-Off Valves Single-Stage Function Integrated Bypass Valve MB-D (Le) 405 - 412 B07Document6 pagesGasmultibloc Combined Regulator and Safety Shut-Off Valves Single-Stage Function Integrated Bypass Valve MB-D (Le) 405 - 412 B07TobiasAngererNo ratings yet

- Intermittent Gas Lift Is An Artificial Lift Technique That Has BeenDocument4 pagesIntermittent Gas Lift Is An Artificial Lift Technique That Has Beenankit71989No ratings yet

- Ludwig PrandtlDocument4 pagesLudwig PrandtlDasika SunderNo ratings yet

- Experiment 3-1Document7 pagesExperiment 3-1Cyrus DavidNo ratings yet

- Orbital Welding of Stainless Steel TubingDocument2 pagesOrbital Welding of Stainless Steel TubingJai MurugeshNo ratings yet

- Slender Body 3Document26 pagesSlender Body 3akashsinha_2004No ratings yet

- Practical Piping CurseDocument46 pagesPractical Piping Cursemsaad2100% (1)

- Piping DesignDocument4 pagesPiping DesignTerry YongNo ratings yet

- Tip Loss Corrections For Wind Turbine Computations - Shen PDFDocument19 pagesTip Loss Corrections For Wind Turbine Computations - Shen PDFJose Da SilvaNo ratings yet

- KJ 117 o en Sac 00 Zme 0301Document1 pageKJ 117 o en Sac 00 Zme 0301Abdullah ObeidatNo ratings yet

- Itr-Pgr (GRP Piping)Document10 pagesItr-Pgr (GRP Piping)mahmoudNo ratings yet

- Fluid Friction Noncircular Ducts: E. Walker, A. Whan, R. R. RothfusDocument6 pagesFluid Friction Noncircular Ducts: E. Walker, A. Whan, R. R. RothfusRajeev PandeyNo ratings yet

- Concepts of Pipe Stress AnalysisDocument54 pagesConcepts of Pipe Stress AnalysisKavin Kumar100% (3)

- Ghulam Ishaq Khan Institute of Engineering Sciences and Technology, Topi-23460Document3 pagesGhulam Ishaq Khan Institute of Engineering Sciences and Technology, Topi-23460Saad RasheedNo ratings yet

- S127 Nestor Garcia PDFDocument198 pagesS127 Nestor Garcia PDFNicolas PironnetNo ratings yet

- Chapter 5 SolutionDocument7 pagesChapter 5 SolutionAli M AntthoNo ratings yet