Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

28 viewsUntitled

Untitled

Uploaded by

Tarik KhanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- UntitledDocument47 pagesUntitledTarik KhanNo ratings yet

- SQUI00101 - Technical Offer R2Document17 pagesSQUI00101 - Technical Offer R2Tarik KhanNo ratings yet

- Past Supply List - ULTIMA ProductsDocument21 pagesPast Supply List - ULTIMA ProductsTarik KhanNo ratings yet

- 33kv C&R PANEL FOR FEEDER - 1 Cable ScheduleDocument1 page33kv C&R PANEL FOR FEEDER - 1 Cable ScheduleTarik KhanNo ratings yet

- Datasheet - Steel Poles MSGIDocument14 pagesDatasheet - Steel Poles MSGITarik KhanNo ratings yet

- ISO CERTIFICATE - Ultima Switchgears LimitedDocument5 pagesISO CERTIFICATE - Ultima Switchgears LimitedTarik KhanNo ratings yet

- 5.33 KV Line DP With Dog Conductor Approved Drawing For RanchiDocument4 pages5.33 KV Line DP With Dog Conductor Approved Drawing For RanchiTarik KhanNo ratings yet

- Datasheet N°2: Three Phase Transformer 33/0.415kV, 50kVA: No. Characteristics Unit Client Requirements OfferedDocument1 pageDatasheet N°2: Three Phase Transformer 33/0.415kV, 50kVA: No. Characteristics Unit Client Requirements OfferedTarik KhanNo ratings yet

- Datasheet N°3: Three Phase Transformer 33/0.415kV, 100kVA: No. Characteristics Unit Client Requirements OfferedDocument1 pageDatasheet N°3: Three Phase Transformer 33/0.415kV, 100kVA: No. Characteristics Unit Client Requirements OfferedTarik KhanNo ratings yet

Untitled

Untitled

Uploaded by

Tarik Khan0 ratings0% found this document useful (0 votes)

28 views11 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

28 views11 pagesUntitled

Untitled

Uploaded by

Tarik KhanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 11

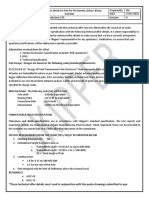

FACTORY ACCEPTANCE TEST REPORT

1, NAME OF THE PROJECT ECOWAS REGIONAL ELECTRICITY ACCESS

PROJECT (ECOWAS - REAP) (PHASE-1)-P164044,

LOT-1 THE GAMBIA

2. NAME OF PROJECT OWNER : NATIONAL WATER & ELECTRICITY COMPANY,

LTD, (NAWEC)

3. NAME OF OWNER'S ENGINEER: SOLENER TECHNOLOGIES

4, NAME OF CONTRACTOR MIS. KEI INDUSTRIES LIMITED

, 1D.90, OKHLA INDUSTRIAL AREA, PHASE-I,

NEW DELHI-110020

5, NAME OF THE SUPPLIER AKG PLASTICS PVT. LTD.

B-23, SECTOR -85, NOIDA

GAUTAM BUDDH NAGAR, (U.P)-201305

6. CONTRACT REFERENCE NO. Ne

-ECOWAS-DEM-197717-CW-RFB-LOT1-GM

DATED 12/06/2021

7.DESCRIPTION OF MATERIAL _: 1- Cyntroplast sleeve (32mm Flexible Conduit pipe)

2- Cyntroplast sleeve (40mm Flexible Conduit pipe)

8. NAME OF INSPECTING OFFICER: 1) MR. PAUL A MENDY (NAWEC)

i 2) MR. OUSMAN TOURAY (NAWEC)

3) MR. OUSSEYNOU GNING (SOLENER TECHNOLOGIES)

4) MR. ADAMA B. LY (SOLENER TECHNOLOGIES)

5) MR-TARIK KHAN (KEI INDUSTRIES LTD)

9. Date of Inspection +: 28/02/2023 (Online Inspection)

10, Item Description

Offered

& Qty Samples | Qty to be Delivered

iy Desdtiptica |, Inspected Qty Qty Accepted.

Oty

[Mtr NO’s Mtr

1 | Cymtroplast sleeve (32mm Flexible | o66ooyqy a tose

Conduit pipe) |

Cyntroplast sleeve (40mm Flexible

By Chaim ae) | 23400Mer 5 23400Mtr

11. Details of Test Conducted as per Approved GTP/Drawing and MQP.

1. Visual Examination:

‘Visual Examination of Cyntroplast sleeve (32mm and 40mm) were conducted and overall

Finish was found satisfactory

2. Verification of Dimensions:

‘The dimensioris of all the samples were measured and compared with approved GTP/drawing and

Found within Permissible limit / tolerance.

3. Verification of Mechanical Test:

‘The mechanical test of sample verified and found satisfactory and the test results are enclosed.

4, Flexing t

enclosed.

‘The Flexing test of sample verified and found satisfactory and the test results are

ENCLOSURES 1. Witnessed acceptance test Report

2. Calibration reports & status

3, Final Packing list

Conclusion: The test results of Cyntroplast sleeve (32mm and 40mm) are within the permissible

limits of approved GTPs, Drawings and Specification, The acceptance is based on the test results of

the samples collected randomly from the lot. Hence the materials are technically accepted & cleared

for dispatch.

Tested By | Witnessed By] Witnessed By | _ Witnessed By | Witnessed By | Witnessed

By

Mr. RAKESH |” Mr OUSMAN | Mr PAULA | Mr OUSSEYNOU | MR-ADAMAB. | Mi. Terk

KUMAR TOURAY MENDY GNING LY (SOLENER | — Khan

(AKG) NAWEC NAWEC - SOLENER | TECHNOLOGIES | (KEI

PIU | TECHNOLOGIES INDUSTRIE

SLTD)

CERTIFICATE OF INSPECTION/ INSPECTI

REPORT

1, NAME OF THE PROJECT ECOWAS REGIONAL ELECTRICITY ACCESS

PROJECT (ECOWAS - REAP) (PHASE-1)-P164044,

LOT-1 THE GAMBIA

2. NAME OF PROJECT OWNER NATIONAL WATER & ELECTRICITY COMPANY

LTD. (NAWEC)

3. NAME OF OWNER’S ENGINEER —_ : SOLENER TECHNOLOGIES

4, NAME OF CONTRACTOR : M/S. KEI INDUSTRIES LIMITED

D-90, OKHLA INDUSTRIAL AREA, PHASE-I,

NEW DELHI-110020

5. NAME OF THE SUPPLIER AKG PLASTICS PVT. LTD.

B-23, SECTOR -85, NOIDA

GAUTAM BUDDH NAGAR, (U.P)-201305

6. CONTRACT REFERENCE NO. : NG-ECOWAS-DEM-197717-CW-RFB-LOTI-GM

DATED 12/06/2021

7. DESCRIPTION OF MATERIAL —_: 1- Cyntroplast sleeve (32mm Flexible Conduit pipe)

2+ Cyntroplast sleeve (40mm Flexible Conduit pipe)

& NAME OF INSPECTING OFFICER: 1) MR. PAUL A MENDY (NAWEC)

2)MR. OUSMAN TOURAY (NAWEC)

3) MR. OUSSEYNOU GNING (SOLENER TECHNOLOGIES)

4) MR. ADAMA B. LY (SOLENER TECHNOLOGIES)

5) MR-TARIK KHAN (KEI INDUSTRIES LTD)

9. Date of Inspection 28/02/2023 (Online Inspection)

10, Item Description

Offered

Quy! Samples | Qty to be Delivered/

ae Description eee Qty ‘Qty Accepted

Mtr NO’s Mir

1 | Cyntroplast sleeve G2mm Flexible | pesoour ; Deu

Conduit pipe)

2 | Cyntroplast sleeve (40mm Flexible | soo yep F

Conduit pipe) |

11, Details of Test Conducted as per Approved GTP/Drawing and MQP.

1, Visual Examination:

Visual Examination of Cyntroplast sleeve (32mm and 40mm) were conducted and overall

Finish was found satisfactory

2. Verification of Dimensions:

‘The dimensions of all the samples were measured and compared with approved GTP/drawing and

Found within Permissible limit / tolerance.

3. Verification of Mechanical Test:

‘The mechanical test of sample verified and found satisfactory and the test results are enclosed.

4. Flexing test: The Flexing test of sample verified and found satisfactory and the test results are

enclosed.

ENCLOSURES 1, Witnessed acceptance test Report

2. Calibration reports & status

3, Final Packing list

Conclusion: The test results of Cyntroplast sleeve (32mm and 40mm) are within the permissible

limits of approved GTPs, Drawings and Specification. The acceptance is based on the test results of

the samples collected randomly from the lot. Hence the materials are technically accepted & cleared

for dispatch.

Tested By | Witnessed By | Witnessed By | Witnessed By | Witnessed By | Witnessed

_By

Mr RAKESH | Mr. OUSMAN | Mr. PAULA | Mr. OUSSEYNOU | MR.ADAMAB. | Mr, Tarik

K TOURAY MENDY GNING LY (SOLENER Khan

(AKG) NAWEC NAWEC - SOLENER | TECHNOLOGIES | (KEI

PIU ‘TECHNOLOGIES INDUSTRIE

SLTD)

vy A

EC. )S

HN Is,

AKG PLASTICS PVT. LTD.

AKG 223, Sta Nat

Gautam Buddh Nagar, (U.P)-201305

A Gan Grupo Conpanes Ph: +91 120 2973 706-713

Web: wwrw.akggroupindia.com

Email: electrical@akggroupindia.com

CIN No: U252090L2001PTC111552

Test Report

* Tem :Flexible Conduit Pipe(PPCP) size = 332mm

‘S.No | Characteristics RefiStandard ‘Observations Remarks

1S:9537 Part-II! (1983)

iz Construction Both the surfaces should be smooth and free | Surfaces are smooth and | Pass

From burrs free from burrs

2 Dimension (@) 0D-31.80 to 32.04mm ‘As Enclosed Pass

(2) 10:24.40mm to 24.60mm

3 Thickness 1.15mmz0.10mm ‘As Enclosed Pass

4, Length of coil 25mtr 2émtr

5. Flexing test There should be no cracks and no sign of No Cracks Pass

peeling after impact

6 Tensile strength | Force applied upto SOON. ‘As Enclosed

Qty:106600mtrs.

erm

4

AKG

Dr ACG Gop af Cores

AKG PLASTICS PVT. LTD.

8-23, Sector-85, Noida

Gautam Buddh Nagar, (U.P)-201805

Ph: +91 120 2973 706-713

Web: wwrw.akggroupindia.com

mal: electrical@akggroupindia.com

Cit No: U2s2090L2001°7C111552

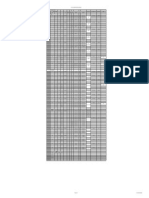

Dimension Report Date-28.02.2023

‘Size-40mm Dimension chart in mm

SampleNo [1 2 3 4 s

OD 39.9 | 4002 [40.00 | 40.01 | 39.99

LD 3184 | 31.74 [3182 | 31.77 | 31.81

Thickness [118 | 120 | 1.24 1.23 1.23

Tensile Strength

Size-40mm length (mm) Breaking load (N) Displacement(mm)

Sample No. (min SOON)

2 150) 793 171.60

2 150 78 180.90

S| 150 732 133.90

4 150 730 134.50

5 150 646 139.50

remy

ey

A

AKG

AX Gar Go Corps

AKG PLASTICS PVT. LTD.

8-23, Sector-85, Noida

Gautam Buddh Nagar, (U.)-201305

Ph: +81 120 2973 706-713

Web: wnw.akggroupindia.com

Email: electrical@akggroupindia.com

(ON No: U25209012001PTC11 1552

Come

een

Test Report

+ ITEM Flexible Conduit Pipe(PPCP) SIZE :40mm

S.No | Characteristics RefiStandard Observations Remarks

1S:9537 Part-II (1983)

1 Construction Both the surfaces should be smooth and free _| Surfaces are smooth and _| Pass

From burrs free from burrs

2 Dimension (2) 00-39.80 to 40.02mm ‘As Enclosed Pass

(2) 10:31.70mm to 31.90mm

3.__| Thickness 1.15mm20.10mm ‘As Enclosed Pass

4. Length of coil 20mtr 20.80mtr

3. Flexing test There should be no cracks and no sign of No Cracks Pass

peeling after impact

6 Tensile strength | Force applied upto SOON. ‘As Enclosed

Qty:23400mtrs.

Ce Ly

ee

es

AKG PLASTICS PVT. LTD.

8-23, Sector-85, Noida

Gautam Buddh Nagar, (U.P)-201805

Ph: +91 120 2973 706-713

ena ‘Web: www.akogroupindia.com

Emait electrical@akggroupindia com

CCN No: U252090L2001PTC111552

Dimension Report Date-28.02.2023

Size-32mm Dimension chart in mm

SampleNo | 4 2 3 a 3 6 7 8

0.0 3194 | 3204 [31.96 [32.03 | 3199 | 31.86 | 3202 | 32.01

1D 24.60 | 2455 | 2452 | 2460 | 2457 | 24.50 | 2452 | 24.55

Thickness [4.16 | a4 | 148 | 115 121 is 2 [ 423 118

Tensile Strength

‘Size-32mm length (mm) Breaking load (N) Displacement(mm)

Sample No. (min SOON)

a 150 713 125

2 150 7a 126

3 150 808 139

a 4 150 764 178

5 150 778 198.9

6 150 724 1714

7 150 678, 1393

8 150 780 206.9

Crea

Ce ane

AKG PLASTICS PVT. LTD.

8-23, Sactor-85, Noida

Gautam Budd Nagar, (U.P)-201305

Ph: +91 120 2973 706-713

Web: wwrw.akggroupindia.com

Email: electrical@akggroupindia.com

GIN No: U2s2090L2001F7C111552

(my)

¥

a

170] 234) 225) 53.805

4a] 1087] 7,710] 216.000]

(0105) | (60s) | (xa)

6900 | 04s | 04s | os: | o1o1| | 4264] 253] 5.804] 163.003

hi A

h g

In :

3 [Bb 3

ie a

HE} 8 8

Bios .

ie 3

| |fiteis Ts

7 oe

hl ef fa

senso

not | of

te)

2%

a

(ES Acumen (Measurements & Consultancy Pvt. Td.

(a): Ar. (Calibration Division)

1016, First Floor, Okhla Industrial Area, Phase-1, New Delhi -4400

CEE hs Oviatt, davonaza, 4270123" Mole: 6soess2e, 9550000895

: Info@acumendelhi.com, calibration@acumendelhi.com W: www.acumendelhi.comcc.2364

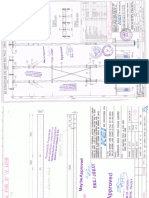

CALIBRATION CERTIFICATE

Format No.:7.8F-01 Page 1of1

UR Wo. = CC236422000000629F [Gerficate No. TAMCTOOTES

[CUSTOMER NAME & ADDRESS:- |Service Request No.&Date ++ 0590 & 02-03-2022

IM/s. AKG Plastics P. Ltd. [Date of Calibration +1 03-03-2022

1B - 23, Sector - 85, |Sug. Cal. Due Date 02-03-2023,

|Noida- 201301 (U.P) lissue Date 05-03-2022

TTEM'S DESCRIPTION & IDENTIFICATION

instrument Name+ IMPACT TESTER (WEIGHTS)

Make Range/size :0t02kg

IMode! No. Least Count N/A

serial No. Visual Inspection ox

Party 10 Mark location Laboratory

[ENVIRONMENTAL CONDITIONS Temperature 7 EZ

L Relative Humidy } (0+ 10%

Scainaion Poceduies Nest Gaisaton Foswanes Ne REPT iodo Compation wh Honda alton

Methodology of Collbrtion & _-ocedes wing susenWeahing metod ond ABBA weighing yc he repaid ase

\Velve(s) (ere) the conventionol mass vave(s)MC) related to the ve mass value(s) (A) by

the formula : MC = MT[l 1.1/4 1/8000) (Where, isn kg/m)

MAJOR EQUIPMENT USED

Nomenclature Ident. No. Traceability Cerfficate No. Valid upto

Digital Weighing Bolonce (1 kg) MMI/38 TSC/21-22/3702-4 02-07-22

Weighing Balance (5 kg.) Mami/a7 18C/21-22/3902-5 02-07-22

lWeight (S) /Set (S) SCW-O.5K/20KF1-SS 18¢/20-21/11038-2 02.0223,

[CALIBRATION RESULTS ( ABBA Method )

ens Denomination ‘Mass Value Uncertainty of

- (9) (9) Measurement (+)

1 1000 100.188 32mg

2 1200 1200.03 0.0209

3 1400 1399.99 0.020 9

4 1400 1600.02 0.020 g

5 1800 1800.14 00209

6 2000 2000.11 0.0209

REMARKS =

1. Mass valve ofall the weights are within he maximum enor permissible in per OlkAL recommendation no R.111-1:2006

2, Expanded uncertainy of measurement at approx 95% confidence level for overage factork|=2

3, Suggested next due date of caliorotion Is alven os equested by customer.

%. DUC hos been calibrated againes lab standards are racedble fo national & Intemational standars.

5. Tistesul of cobration refer to only tothe particular tem submited for calibration.

6 Cerlifcate sued 5s only scientific or industrial purposes only.

5. the result reported in ths cerfficate are valid atthe ime of and under the slated conditions of Measurement.

4, Tiécoticate sat not be reproduced, excep nul nls writen pemision fr the publication oan approved aberoc os

been obtained trom the CEO, Acumen Measurements & Consultancy Pvt. Lid., New Delhi

Tesved & Authorized By

a

sachin Kumar Bc bied ucsuter

(Coliorated By) “EAU OFReport® (1™M/QM)

& TESTNCAL LABORATORY

(A DIVISION OF TESTING & CALIBRATION INDIA (OPC) PVT. LTD)

Tacadtas Plot No-113, Pocket-A2, Sector-17, Dwarka, New Dethi-110075 (India)

Mob, +91-8882056269, 9990730550, E-mai-testncal@gmail.com; Website - ww-tnclab.com

[CertificatelULR No: _0C205522000006040F Page tof

WIS AKG PLASTICS PVT. LTD. Instrument Receipt Date | 17-Aug-2022

SRF No "TNC 1J0/22-231568

Customer Details: | 5.23, Sector- 85, Noida, Utar Pradesh [Dae of Gallbvalon 17-Aug-2022

iteratabclie, Next Calibration Date 16-Aug-2023

Certificate Iseue Date 18-Aug-2022

‘A) Identification On UUG (Unit Under Calibration)

Instrument Name Digital Tensile Testing Machine Make / Model No. MaxwellNA

Range O10 2500N Instrument Condition | OK

Teast Gount OtN Location of Calibration | at Ste

Serial No 633 Location Lab

instrument NA Parameter Force

ENVIRONMENTAL | Temperature:-2432 °G.Relative _ | Calibration Reference Standard | 1S 1828(Pani) 2015

CONDITION Homidity: - Bos10 Calibration Procedure. TNC -01-F 2.0

Details of Tost Equipments Used

Tame ID-NOSR NO. GorificatofULR No Valid upto

Taga Gai With ator *7o60oTe DRSVOTEA28 95/08/2023

(ad Cal wir indicator TRCFIGROTAT ‘GOR IOT2RO0NCOETAF TBOTIRO2A

Calibration Resulis

[Forea(Ny] Division | Division | [Observed] Observed] Average | Relative | Relative | Relative | Relate [Expended|

atid. | atroom fading | Reading | of | accuracy |Repeatabi|resolution|Zero Error|Uncer

Temp. | Temp. |(Divisions|(Divisions (Divisions| Roading |error (| tity error |Error (al%s| (fo)% | y of

zac | 2sate | yo" | )420° | 240° |(Division) (y% IMeasurem|

ent %

Too | 178s [7015s _| rors | s0186_[Torss_[torese7 |_oo1 | oor | oto] oe Poe

00 | 20808 |" 20307 |" 20308 | “20506 [20st [20808 00 | 01 —|_ao1 | 005 | 000] to

“~|_ soa" soser “| s0660 [50661 7] s08e0 “| soess_| sosee.s7|_ aot [oor | —oc2 | a0] a0

To00 ] Toros | Toro4s | Toroas | sovOso | or0st ]101060.00] 000 | 0.00 | oor | ago] 1.0

1500_| 7160s [1603 [1605 | iso | Tes | ea | Oo | 01s] oor no Pr

2500 |= 2602 | 2602 |= 2802 =| 2508 [2508 | 2503.00 [004 | 0.08 | —o00 | 000 | Tor

oo rn a o a a o 2 0

Nee:

4, The Calibration resus reported in his certicat ae valida the tie of andthe started contin of measurement

2. Ths report should not be reproduced excopt in ful nithout our prior persion in uring,

2 Calbration certificate without signature are nat vad and this cristae ntended of ony for guider.ce and no for legal purpose or for

4 Allourcontiates ate Traceable to natonalintemationl standard

5 Ths Certicaterelstes othe tem Caltrate total ably of Testncal Laboratory wile filed othe inviced amount only

P17 F03-00

Issued & Approved By

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- UntitledDocument47 pagesUntitledTarik KhanNo ratings yet

- SQUI00101 - Technical Offer R2Document17 pagesSQUI00101 - Technical Offer R2Tarik KhanNo ratings yet

- Past Supply List - ULTIMA ProductsDocument21 pagesPast Supply List - ULTIMA ProductsTarik KhanNo ratings yet

- 33kv C&R PANEL FOR FEEDER - 1 Cable ScheduleDocument1 page33kv C&R PANEL FOR FEEDER - 1 Cable ScheduleTarik KhanNo ratings yet

- Datasheet - Steel Poles MSGIDocument14 pagesDatasheet - Steel Poles MSGITarik KhanNo ratings yet

- ISO CERTIFICATE - Ultima Switchgears LimitedDocument5 pagesISO CERTIFICATE - Ultima Switchgears LimitedTarik KhanNo ratings yet

- 5.33 KV Line DP With Dog Conductor Approved Drawing For RanchiDocument4 pages5.33 KV Line DP With Dog Conductor Approved Drawing For RanchiTarik KhanNo ratings yet

- Datasheet N°2: Three Phase Transformer 33/0.415kV, 50kVA: No. Characteristics Unit Client Requirements OfferedDocument1 pageDatasheet N°2: Three Phase Transformer 33/0.415kV, 50kVA: No. Characteristics Unit Client Requirements OfferedTarik KhanNo ratings yet

- Datasheet N°3: Three Phase Transformer 33/0.415kV, 100kVA: No. Characteristics Unit Client Requirements OfferedDocument1 pageDatasheet N°3: Three Phase Transformer 33/0.415kV, 100kVA: No. Characteristics Unit Client Requirements OfferedTarik KhanNo ratings yet