Professional Documents

Culture Documents

NDT Matrix 12-99-90-1710 - Rev.2 PDF

NDT Matrix 12-99-90-1710 - Rev.2 PDF

Uploaded by

EPC NCCOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NDT Matrix 12-99-90-1710 - Rev.2 PDF

NDT Matrix 12-99-90-1710 - Rev.2 PDF

Uploaded by

EPC NCCCopyright:

Available Formats

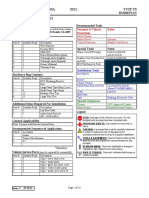

Attachment-1

Bu Hasa Integrated Field Development Project

NDE Matrix for Piping

Contractor : Tecnicas Reunidas Company Adnoc Onshore

DEP 31.38.01.31, Appendix-D

Project No : 80057 Reference

12-99-00-1601 (Rev 2)

Extent of NDT (Note-1)

Piping Class Material Rating Service Category Inspection Class RT MT/PT Remarks

VT PWHT HT PMI FT

(Note-7) (Note-2)

011412 Nitrogen, Utility Drain, Utility Water / Raw Water Category D 4d 100% 5% 0% NA NA NA NA

CS

011432 Glycol, Diesel Fuel, Drain Category D 4d 100% 5% 0% NA NA NA NA

150

018011 CS FBE Coated Fire Water (AG) Category D 4d 100% 5% 0% NA NA NA NA

018011 CS- GALV Instrument Air, Plant Air, Potable Water Category D 4d 100% 5% 0% NA NA NA NA

011422 Blanketing Gas, Motive Gas Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

011437 Produced Water Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

011440 150 Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

Process Oil, Process Gas (Dehydrated), Drain, Vent Gas, Produced Water Drain, Fuel Gas

011441 Vent Gas, Process Oil, Process Gas, Blowdown Drain, Wash Water, Process Gas (Wet), Fuel Gas (Wet), Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

031422 Blanketing Gas, Motive Gas Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

031437 Produced Water Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

031440 300 Process Oil, Process Gas (Dehydrated), Drain, Vent Gas, Produced Water Drain, Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

031441 Vent Gas, Process Oil, Process Gas, Blowdown Drain, Wash Water, Process Gas (Wet), Fuel Gas (Wet), Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

CS + NACE

061437 Aquifer Water, Injection Water, Produced Water Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

600

061440 Produced Water Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

Process Oil, Process Gas (Dehydrated), Drain, Vent Gas, Produced Water Drain, Fuel Gas , Vent Gas, Process Oil,

091441 900 Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

Process Gas, Blowdown Drain, Wash Water, Process Gas (Wet), Fuel Gas (Wet),

151437 Aquifer Water, Injection Water Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

1500

151441 Process Oil, Process Gas (wet) Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

251437 Aquifer Water, Injection Water Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

2500

251441 Process Oil, Process Gas (wet) Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

011502 Vent Gas (Dry), Process Gas (Dry), Lift Gas, Fuel Gas (Dry/Dehydrated) Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

150

011503 Vent Gas (Wet) Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

031502 Vent Gas (Dry), Process Gas (Dry), Lift Gas, Fuel Gas (Dry/Dehydrated) Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

300

031503 Vent Gas (Wet) Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

061502 LTCS + NACE 600 Vent Gas (Dry), Process Gas (Dry), Lift Gas, Fuel Gas (Dry/Dehydrated) Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

091502 Vent Gas (Dry), Process Gas (Dry), Lift Gas, Fuel Gas (Dry/Dehydrated) Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

900

091503 Vent Gas (Wet), Process Gas (wet) Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

151482 Dry Lean Gas, Lift Gas Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

1500

151502 Vent Gas (Dry), Process Gas (Dry), Lift Gas, Fuel Gas (Dry/Dehydrated) Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

LTCS + NACE

101482 10000(API) Lean gas Compressor Discharge Pipeline (Sour Service) Category M 1b 100% 20% 20% 100% 10% (Note-3) NA NA

(API-6A)

013410 Chemical Injection Category M 1b 100% 20% 20% NA NA 100% 10%

150

013411 Chemical Injection Category M 1b 100% 20% 20% NA NA 100% 10%

033411 300 Chemical Injection Category M 1b 100% 20% 20% NA NA 100% 10%

063410 Chemical Injection Category M 1b 100% 20% 20% NA NA 100% 10%

316 SS 600

063411 Chemical Injection Category M 1b 100% 20% 20% NA NA 100% 10%

093411 900 Chemical Injection Category M 1b 100% 20% 20% NA NA 100% 10%

153411 1500 Chemical Injection Category M 1a 100% 100% 100% NA 100% 100% 10%

253411 2500 Process Oil, Process Gas (wet) Category M 1a 100% 100% 100% NA 100% 100% 10%

80057-AC-198-B, Rev 0 Page 1 of 2

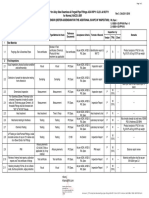

Attachment-1

Bu Hasa Integrated Field Development Project

NDE Matrix for Piping

Contractor : Tecnicas Reunidas Company Adnoc Onshore

DEP 31.38.01.31, Appendix-D

Project No : 80057 Reference

12-99-00-1601 (Rev 2)

Extent of NDT (Note-1)

Piping Class Material Rating Service Category Inspection Class RT MT/PT Remarks

VT PWHT HT PMI FT

(Note-7) (Note-2)

013421 Vent Gas, Glycol Category M 1b 100% 20% 20% NA NA 100% 10%

CS 150

013461 Vent Gas-LT Category M 1b 100% 20% 20% NA NA 100% 10%

150

063421 316 SS + NACE 600 Vent Gas, Glycol Category M 1b 100% 20% 20% NA NA 100% 10%

153461 1500 Vent Gas-LT Category M 1a 100% 100% 100% NA 100% 100% 10%

253461 2500 Lift Gas (Sour) Category M 1a 100% 100% 100% NA 100% 100% 10%

013842 HC Condensate, Closed Drain, Produced Water, Process Gas, Vent Gas Category M 1b 100% 20% 20% NA NA 100% 100%

150

013844 HC Condesnate Category M 1b 100% 20% 20% NA NA 100% 100%

033842 HC Condensate, Closed Drain, Produced Water, Process Gas, Vent Gas Category M 1b 100% 20% 20% NA NA 100% 100%

300

033844 DSS + NACE Process Gas-LT Category M 1b 100% 20% 20% NA NA 100% 100%

063842 600 HC Condensate, Closed Drain, Produced Water, Process Gas, Vent Gas, Water Disposal Category M 1b 100% 20% 20% NA NA 100% 100%

093842 900 HC Condensate, Closed Drain, Produced Water, Process Gas, Vent Gas, Water Disposal Category M 1b 100% 20% 20% NA NA 100% 100%

153842 1500 HC Condensate, Closed Drain, Produced Water, Process Gas, Vent Gas, Water Disposal Category M 1a 100% 100% 100% NA 100% 100% 100%

016620 150 Procees oil, Stagnant Drain, Closed Drain, Process gas, Disposal water, Produced Water Category M 1b 100% 20% 20% Note-4 Note-5 100% NA

018220 150 Produced Water Category M 1b 100% 20% 20% Note-4 Note-5 100% NA

036620 300 Procees oil, Stagnant Drain, Closed Drain, Process gas, Disposal water, Produced Water Category M 1b 100% 20% 20% Note-4 Note-5 100% NA

Alloy 825/ Alloy 825

038220 300 Produced Water Category M 1b 100% 20% 20% Note-4 Note-5 100% NA

cladded/LTCS + NACE

066620 600 Procees oil, Stagnant Drain, Closed Drain, Process gas, Disposal water, Produced Water Category M 1b 100% 20% 20% Note-4 Note-5 100% NA

096620 900 Procees oil, Stagnant Drain, Closed Drain, Process gas, Disposal water, Produced Water Category M 1b 100% 20% 20% Note-4 Note-5 100% NA

156620 1500 Procees oil, Stagnant Drain, Closed Drain, Process gas, Disposal water, Produced Water Category M 1a 100% 100% 100% Note-4 Note-6 100% NA

Abbreviations : VT-Visual Testing, RT-Radiography Testing, MT-Magnetic Particle Testing, PT-Penetrant Testing, PWHT-Post Weld Heat Treatment, HT-Hardness Testing, PMI-Psitive Material Identification, FT-Ferrite Testing

Notes

Note-1 : VT applies for all types of welds. RT applies only for Butt welds. MT/PT applies only to branch/R-Pad/Olet/Attachment welds. PWHT,HT,PMI,FT applies to all type of joints except attachment welds

Note-2 : PT applies for Stainless steel and Nickel welds. MT applies for Carbon steel welds

Note-3 : Joints which are locally post weld heat-treated shall be 100% hardness tested . Furnace post weld heat treated joints shall be 10% hardness tested

Note-4 : 100% PWHT required for Alloy Cladded-LTCS material if thickness >20 mm. No PWHT required for solid Alloy 825 (Inconel) material

Note-5 : Joints which are locally post weld heat-treated shall be 100% hardness tested . Furnace post weld heat treated joints shall be 10% hardness tested. No Hardness test required for solid Alloy 825 piping

Note-6 : Joints which are locally post weld heat-treated shall be 100% hardness tested . Furnace post weld heat treated joints shall be 10% hardness tested. 100% Hardness test required for solid Alloy 825 piping

Note-7 : 5% of the branch to run pipe welds of branch connections with a size of the run pipe equal to less than DN 150 (NPS 6) shall be examined by Radiography to verify geometry and weld penetration of branch joint.

80057-AC-198-B, Rev 0 Page 2 of 2

You might also like

- TS-2000 (B510-01-005) UT-20 InstallationDocument6 pagesTS-2000 (B510-01-005) UT-20 Installationbackup mailNo ratings yet

- Toyota Tacoma 2012 - Tvip V5 Part Number: PT398-35121: PreparationDocument22 pagesToyota Tacoma 2012 - Tvip V5 Part Number: PT398-35121: PreparationTomas OrozcoNo ratings yet

- RJTTDocument103 pagesRJTTJerryNo ratings yet

- Instrument Diagram W20V32 WartsilaDocument24 pagesInstrument Diagram W20V32 WartsilaMuhammad IkramNo ratings yet

- KG98 2 ONT OMF in 7861 DW 178 R0 Pressure Transmitter GA Drawing (Code 1)Document5 pagesKG98 2 ONT OMF in 7861 DW 178 R0 Pressure Transmitter GA Drawing (Code 1)Madheswaran DharmapuriNo ratings yet

- NDT SpecsDocument3 pagesNDT SpecsRam Shankar SahuNo ratings yet

- Piping DetailsDocument16 pagesPiping DetailsSasi MesthiriNo ratings yet

- 11-3-16 Set Points Alarms & Problems GvaDocument8 pages11-3-16 Set Points Alarms & Problems Gvanicu hNo ratings yet

- Consequence Development and Safeguards Exercise.02Document8 pagesConsequence Development and Safeguards Exercise.02samNo ratings yet

- Balraj Ab38 PDFDocument6 pagesBalraj Ab38 PDFbjrock123No ratings yet

- Low SupportDocument1 pageLow SupportMDhana SekarNo ratings yet

- Helliptical Head Design Calculation ASMEVIII-DIV I-141F Rev1Document2 pagesHelliptical Head Design Calculation ASMEVIII-DIV I-141F Rev1Hicham SaadiNo ratings yet

- Gas Development Project For Unitization of The Jambaran - Tiung Biru FieldDocument2 pagesGas Development Project For Unitization of The Jambaran - Tiung Biru FieldBintang AtdiNo ratings yet

- Single Line Drawing S2100-15-220-220 220VAC, 15kVA @40°C: Manufacturing VersionDocument6 pagesSingle Line Drawing S2100-15-220-220 220VAC, 15kVA @40°C: Manufacturing VersionLinh TrầnNo ratings yet

- Esquema Eletrico-Ir BoardDocument2 pagesEsquema Eletrico-Ir BoardNelson Luís MarquesNo ratings yet

- MTO Calculation Sheet R1 3Document4 pagesMTO Calculation Sheet R1 3levinhha190594No ratings yet

- 01 25284124-8230-26-000-0008 REV.02 Piping List Tie-InDocument2 pages01 25284124-8230-26-000-0008 REV.02 Piping List Tie-InRajeev KumarNo ratings yet

- Ddta114Ylp: 50V PNP Pre-Biased Small Signal Transistor in Dfn1006Document5 pagesDdta114Ylp: 50V PNP Pre-Biased Small Signal Transistor in Dfn1006alemão limaNo ratings yet

- 0108 118T0351 General Painting SpecificationDocument20 pages0108 118T0351 General Painting SpecificationfaisalnadimNo ratings yet

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDocument1 pageThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataShubham kgc100% (1)

- 2924-B200-13C67-DWG-0003 - R1.0 Electrical Cable Routing and Cable Tray Layout LYE Storage AreaDocument2 pages2924-B200-13C67-DWG-0003 - R1.0 Electrical Cable Routing and Cable Tray Layout LYE Storage AreaRonti ChanyangNo ratings yet

- Data Sheet For Automatic Tank Gauging (Atg)Document2 pagesData Sheet For Automatic Tank Gauging (Atg)Indra SUdirmanNo ratings yet

- Th32a400g PDFDocument11 pagesTh32a400g PDFManage Don GnanathilakaNo ratings yet

- Doc. No.: TitleDocument11 pagesDoc. No.: TitlePrakash RajNo ratings yet

- 112T2395 D Device Summary AlarmDocument236 pages112T2395 D Device Summary AlarmJavier Cruz VargasNo ratings yet

- Lemon Yellow: Paint Material Details: F - 2 0821D1053 Paint Material System: 6.2Document3 pagesLemon Yellow: Paint Material Details: F - 2 0821D1053 Paint Material System: 6.2susantasaha2004No ratings yet

- Tyco 1-2310224-1Document3 pagesTyco 1-2310224-1frncs.dimaioNo ratings yet

- P27-1040 Switch - Eaton PNsDocument3 pagesP27-1040 Switch - Eaton PNsDiego LiraNo ratings yet

- 01 - 25284124-8230-26-000-0010 - REV.01 - Line List - C4 ImportDocument1 page01 - 25284124-8230-26-000-0010 - REV.01 - Line List - C4 ImportRajeev KumarNo ratings yet

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDocument1 pageThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationKorneliusNo ratings yet

- Canon PC Boklet Trimmer d1Document67 pagesCanon PC Boklet Trimmer d1ralf1k1hlerNo ratings yet

- Agitator Vendor QAP Revised Code-1Document1 pageAgitator Vendor QAP Revised Code-1PRASHANTNo ratings yet

- Weld Book - Test Pack Sec 08..Document30 pagesWeld Book - Test Pack Sec 08..AslaouiNo ratings yet

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDocument1 pageThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNo ratings yet

- 01 25284124-8230-26-013-0001 REV.03 Piping List DHDTDocument7 pages01 25284124-8230-26-013-0001 REV.03 Piping List DHDTRajeev KumarNo ratings yet

- RFI Summary (April 30 2018) Rev 01Document1 pageRFI Summary (April 30 2018) Rev 01zahid1078No ratings yet

- Thermography Report of CIRCULATING WATER PUMP B 1Document2 pagesThermography Report of CIRCULATING WATER PUMP B 1sandrositohangNo ratings yet

- Thread Summary - Fire & Gas Suppression Pipe: Koc Feed Pipeline ProjectDocument1 pageThread Summary - Fire & Gas Suppression Pipe: Koc Feed Pipeline ProjectKuwait Gulf CircleNo ratings yet

- Traceability List: ProjectDocument16 pagesTraceability List: ProjectP Sandana NaraNo ratings yet

- Instruments 47: Defender (LHD) 88Document4 pagesInstruments 47: Defender (LHD) 88Osman ÇarhoğluNo ratings yet

- Ampeg PF-350 Jack Board SchematicsDocument1 pageAmpeg PF-350 Jack Board SchematicsArif SusiloNo ratings yet

- A0431-01-02 - Bio-Sea - Uv - Reactor - (Flange) - LeftDocument2 pagesA0431-01-02 - Bio-Sea - Uv - Reactor - (Flange) - Leftjavahz74No ratings yet

- Annexure 3A - ITP For Alloy Steel Seamless & Forged Pipe Fittingsa234 WP11 CL2 & A 182 F11 For Normal NACE & IBRDocument3 pagesAnnexure 3A - ITP For Alloy Steel Seamless & Forged Pipe Fittingsa234 WP11 CL2 & A 182 F11 For Normal NACE & IBRPranav JadhavNo ratings yet

- Troubleshooting Report (8Ds)Document2 pagesTroubleshooting Report (8Ds)rafael del rio de la vegaNo ratings yet

- Owner: Dangote Oil Refining Company: Consultant: Engineers India Limited Contractor: Onshore Construction FzeDocument1 pageOwner: Dangote Oil Refining Company: Consultant: Engineers India Limited Contractor: Onshore Construction Fzecrm 2No ratings yet

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDocument1 pageThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNo ratings yet

- Pioneer Pml010a DatasheetDocument1 pagePioneer Pml010a DatasheetAbdullah TaniNo ratings yet

- Memoria de Calculo Alumbrado ExteriorDocument11 pagesMemoria de Calculo Alumbrado ExteriorHernan PachecoNo ratings yet

- 01 25284124-8230-26-000-0011 REV.01 Piping List HCDSDocument1 page01 25284124-8230-26-000-0011 REV.01 Piping List HCDSRajeev KumarNo ratings yet

- Production 712906: Installation Outline Drawing, Fl500Document2 pagesProduction 712906: Installation Outline Drawing, Fl500gerardo.serco19No ratings yet

- Swing 2 DG R2F: Italiano English Français EspañolDocument28 pagesSwing 2 DG R2F: Italiano English Français EspañolEstupinan Merchan Jonathan AldemarNo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument3 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- Durabrand DBTV1901 Orion TV-1934ADocument63 pagesDurabrand DBTV1901 Orion TV-1934Aelectronicatotal100% (1)

- National Iranian Oil Company: Central Treatment and Export Plant (Ctep)Document8 pagesNational Iranian Oil Company: Central Treatment and Export Plant (Ctep)iman tabataba'iNo ratings yet

- HP - ENI - Package - ORF ENI Jangkrik - Pip Technical Specification 2015-12-03Document6 pagesHP - ENI - Package - ORF ENI Jangkrik - Pip Technical Specification 2015-12-03ANDI JAYANo ratings yet

- Witson MceDocument12 pagesWitson MceJohn SmithNo ratings yet

- Sony XS-AW200X Car Active Subwoofer SMDocument10 pagesSony XS-AW200X Car Active Subwoofer SMlasser22832165No ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Surgical Operation PDFDocument64 pagesSurgical Operation PDFshifna.latheefNo ratings yet

- Electrical and Electronic Troubleshooting For Industrial EnginesDocument25 pagesElectrical and Electronic Troubleshooting For Industrial EnginespanddyanNo ratings yet

- Cruciferous VegetablesDocument13 pagesCruciferous Vegetablesapi-271257230No ratings yet

- GRES Integrated Energy Storage SystemDocument33 pagesGRES Integrated Energy Storage SystemVadim PopovichNo ratings yet

- Mitsubishi Motors Vs Chrysler Philippines Labor UnionDocument2 pagesMitsubishi Motors Vs Chrysler Philippines Labor UnionKobe BullmastiffNo ratings yet

- IFU Acticor 439128-F EsDocument143 pagesIFU Acticor 439128-F EsMartin ArrietaNo ratings yet

- Stress and Coping Strategies Among Distance Education Students at The University of Cape Coast, GhanaDocument15 pagesStress and Coping Strategies Among Distance Education Students at The University of Cape Coast, GhanaReign EvansNo ratings yet

- Bio-Organic Chem LecturesDocument205 pagesBio-Organic Chem LecturesРаони Мессиас100% (2)

- Nanoengineered Silica-Properties PDFDocument18 pagesNanoengineered Silica-Properties PDFkevinNo ratings yet

- 1.1 - Monitor de Aterramento - 8030Document2 pages1.1 - Monitor de Aterramento - 8030Denis MarcosNo ratings yet

- Sdfsdynamic AuscultationDocument3 pagesSdfsdynamic AuscultationrichardNo ratings yet

- 7.44.session VI EHa and LTR Process Flow and Steam Gathering System v3 PDFDocument56 pages7.44.session VI EHa and LTR Process Flow and Steam Gathering System v3 PDFadityaNo ratings yet

- Normal Wash, Pigment Wash, Caustic WashDocument9 pagesNormal Wash, Pigment Wash, Caustic WashTauhidurRChowdhuryNo ratings yet

- Aisyah Fadiyah - SPEECH DRAFTDocument5 pagesAisyah Fadiyah - SPEECH DRAFTAisyah FawNo ratings yet

- Promotion Letter ShwetaDocument2 pagesPromotion Letter ShwetayogeshNo ratings yet

- Why Aws Is Even Better With CloudcheckrDocument7 pagesWhy Aws Is Even Better With CloudcheckrPardha SaradhiNo ratings yet

- ME Lab 2 LectureDocument5 pagesME Lab 2 LectureIan Paul TongolNo ratings yet

- Automatic Control Basic Course: Exercises 2021Document124 pagesAutomatic Control Basic Course: Exercises 2021Duc-Duy Pham NguyenNo ratings yet

- Inorganic Chemistry HomeworkDocument3 pagesInorganic Chemistry HomeworkAlpNo ratings yet

- Toothpaste Survey FormDocument1 pageToothpaste Survey FormBimalendu Konar50% (2)

- Wet RisersDocument3 pagesWet RisersNur Amirah Abdul JamilNo ratings yet

- Corn Growth StagesDocument33 pagesCorn Growth StagesIvan JovanovićNo ratings yet

- UO Mixing Liquid PhaseDocument2 pagesUO Mixing Liquid PhaseKumara Haekal Hafidz AmrullahNo ratings yet

- American FoodDocument10 pagesAmerican FoodEvan BanksNo ratings yet

- Sago Pudding - Recipes - Poh's KitchenDocument2 pagesSago Pudding - Recipes - Poh's KitchenXuxu TooNo ratings yet

- Use of AI in Medicinal Product Lifecycle 1689684121Document17 pagesUse of AI in Medicinal Product Lifecycle 1689684121vivek rakhaNo ratings yet

- Anthe Junior Sample Paper Class IXDocument14 pagesAnthe Junior Sample Paper Class IXMota Chashma85% (62)

- Job Hazard AnalysisDocument1 pageJob Hazard AnalysisZaul tatingNo ratings yet

- SDS Hardener 2750 EN 221004Document10 pagesSDS Hardener 2750 EN 221004juprykaNo ratings yet

- Camarines Norte - AlbayaldeDocument56 pagesCamarines Norte - AlbayaldeJChris EsguerraNo ratings yet