Professional Documents

Culture Documents

mtg12 05 Forklift Pre Use Inspection PDF en PDF

mtg12 05 Forklift Pre Use Inspection PDF en PDF

Uploaded by

Kavinda BandaraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

mtg12 05 Forklift Pre Use Inspection PDF en PDF

mtg12 05 Forklift Pre Use Inspection PDF en PDF

Uploaded by

Kavinda BandaraCopyright:

Available Formats

Toolbox Meeting Guide

Forklifts: pre-use inspection

Forklifts are integral pieces of warehouse equipment and undergo rigorous use every day. As a result, frequent

inspections are required to ensure the quality of the equipment. Inspections are necessary to protect the forklift

operator because malfunctions in the equipment can potentially cause a serious or fatal injury. Before using

the forklift, the operator must conduct and document a pre-use inspection. Pre-use inspection checklists

include a visual check and an operational check.

Remember that these are general guidelines regarding forklifts. There are several different types of forklifts,

which requires attention to different components during a pre-use inspection. Please refer to the manufacturer

for details on conducting pre-use inspections for your forklift.

The visual check

The visual check involves the visual inspection

of forklift components. Generally, you are

checking to make sure that all required

components are present and in good condition.

Areas of the forklift that require checks include:

• Overall condition

• Fluids (oil, fuel, and radiator)

• Cables, wires, and connections

• Wheels and tires

• Forks

The operational check Ensure forks are in good Inspect cables for damage

working condition

The operational check involves turning the

forklift on and testing its various functions.

This is done to ensure that the forklift is

mechanically sound and able to safely perform

its function. This may involve:

• Checking engine for noises and leaks

• Checking the seat belt for damage

Check the seat belt to ensure Ensure that lights are bright

• Testing the lights, horns, and brakes good working order and working

This document is to be used for general information only. For specific details on the forklift that you are

operating, please refer to manufacturer.

MTG 12-05 WorkSafeBC Prevention Information Line: 604.276.3100 page 1 of 2

Rev. May 2017 or toll-free 1.888.621.SAFE (7233)

Record of meeting

Project

Address City Province Postal code

Employer Supervisor

Date (yyyy-mm-dd) Time Shift

Number in crew Number attending

Other safety issues or suggestions made by crew members

Record of those attending

Name (please print) Signature Company

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

Manager’s remarks

Manager’s signature Supervisor’s signature

You might also like

- Oosterhof FG - Dietrich Bonhoeffer - The Cost of Discipleship PDFDocument8 pagesOosterhof FG - Dietrich Bonhoeffer - The Cost of Discipleship PDFJoshua ChuaNo ratings yet

- Small Block Chevrolet: Stock and High-Performance RebuildsFrom EverandSmall Block Chevrolet: Stock and High-Performance RebuildsRating: 4 out of 5 stars4/5 (14)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- LF90LS Operations and Service Manual PDFDocument154 pagesLF90LS Operations and Service Manual PDFJose Vidal100% (10)

- LY38 Ops Manual PDFDocument36 pagesLY38 Ops Manual PDForlando chullo llave100% (1)

- Practica Asist Socialeintre Religios Si SecularDocument12 pagesPractica Asist Socialeintre Religios Si Seculargabriela100% (2)

- Meritor Service Manual DX195 and DX225 - MM1147Document119 pagesMeritor Service Manual DX195 and DX225 - MM1147LUKASNo ratings yet

- Chippewa Park Master Plan ReportDocument28 pagesChippewa Park Master Plan ReportinforumdocsNo ratings yet

- Massive MIMO Detection Algorithm and VLSI Architecture 2019 PDFDocument348 pagesMassive MIMO Detection Algorithm and VLSI Architecture 2019 PDFdupipiNo ratings yet

- Blood Brain Barrier PDFDocument6 pagesBlood Brain Barrier PDFmanoj_rkl_07100% (1)

- MTG12-05 Forklift Inspection ChecklistDocument3 pagesMTG12-05 Forklift Inspection ChecklistLuis De La HozNo ratings yet

- Maintenance PlanDocument7 pagesMaintenance Planmothibakgomo MoarabiNo ratings yet

- WorkSafeBC - Forklift Inspection ChecklistDocument0 pagesWorkSafeBC - Forklift Inspection ChecklistjohnzepolNo ratings yet

- Gear InspectionDocument6 pagesGear Inspectionbh hbNo ratings yet

- Daily Check & MaintenanceDocument22 pagesDaily Check & MaintenancePMV DeptNo ratings yet

- Spinning Parts 101 New 060220Document9 pagesSpinning Parts 101 New 060220rymon.engineeringNo ratings yet

- Coupling Inspection SOP GSE FinalDocument11 pagesCoupling Inspection SOP GSE FinalPravin Kangne100% (1)

- Stopemate S36IR Manual PDFDocument41 pagesStopemate S36IR Manual PDFRicardo Ramirez EstrelloNo ratings yet

- Excavator Instructors NotesDocument31 pagesExcavator Instructors NotesWALTER EMMANUEL FLORES COSCONo ratings yet

- Case Study F1111, F1118, F1119, F1139Document17 pagesCase Study F1111, F1118, F1119, F1139Muhammad IlhamNo ratings yet

- G2 Written Report - Chapter 6Document4 pagesG2 Written Report - Chapter 6John Michael BolocNo ratings yet

- Eng GB CI InspReport ART - ADocument5 pagesEng GB CI InspReport ART - AAwanNo ratings yet

- Coupling Inspection (Service Profile)Document2 pagesCoupling Inspection (Service Profile)dhavit wijayantoNo ratings yet

- Checklist - Backup Device - Petzl ASAP-LOCKDocument1 pageChecklist - Backup Device - Petzl ASAP-LOCKMax BeeksNo ratings yet

- Title Demonstrate Knowledge of Wheel Tractor Steering Systems, and Diagnose and Rectify Faults in Them Level 4 Credits 4Document4 pagesTitle Demonstrate Knowledge of Wheel Tractor Steering Systems, and Diagnose and Rectify Faults in Them Level 4 Credits 4Hassan HamdyNo ratings yet

- ARA ProPresentationto CIC July 2008Document29 pagesARA ProPresentationto CIC July 2008Yeoh KhNo ratings yet

- Microsoft Word - Tire Handler Owners Manual PDFDocument195 pagesMicrosoft Word - Tire Handler Owners Manual PDFPlanificador MantencionNo ratings yet

- HeavyFacts Steering ComponentsDocument2 pagesHeavyFacts Steering ComponentsMuazNo ratings yet

- New Era ConveyorsDocument1 pageNew Era ConveyorsgocherkeNo ratings yet

- How To Analyze Gear FailuresDocument7 pagesHow To Analyze Gear Failuresphucdc095041No ratings yet

- Root Cause Failure AnalysisDocument2 pagesRoot Cause Failure AnalysisEnaCicaaaNo ratings yet

- EVO Max 4T Maintenance ManualDocument14 pagesEVO Max 4T Maintenance Manualbubesheva10No ratings yet

- Mechanical DrivesDocument12 pagesMechanical DrivesAayush BastolaNo ratings yet

- Service General Specification: Applicable SystemsDocument2 pagesService General Specification: Applicable SystemsRizky MuhammadNo ratings yet

- A MAR WP Preventative Maintenance ENDocument8 pagesA MAR WP Preventative Maintenance ENjunkNo ratings yet

- DX175Document84 pagesDX175ВЛАДИМИРNo ratings yet

- KukaDocument18 pagesKukaSiva Manohar ChinnaNo ratings yet

- 26 Aranda GUG San Antonio GeneradoresDocument34 pages26 Aranda GUG San Antonio GeneradoresLuis EstradaNo ratings yet

- Omc Clarification Sheet: Standard(s) (Incl. Year) Sub-Clause(s) For Secretariat Use OnlyDocument2 pagesOmc Clarification Sheet: Standard(s) (Incl. Year) Sub-Clause(s) For Secretariat Use OnlyBala JiNo ratings yet

- Title Describe Tractor Braking Systems, and Diagnose and Rectify Faults in Wheel Tractor Braking Systems Level 4 Credits 7Document6 pagesTitle Describe Tractor Braking Systems, and Diagnose and Rectify Faults in Wheel Tractor Braking Systems Level 4 Credits 7Mohamad Nadzri YahayaNo ratings yet

- Module Perform-Pre-Delivery-InspectionDocument56 pagesModule Perform-Pre-Delivery-InspectionRonaldo Cruz100% (1)

- Pad Eye FailureDocument1 pagePad Eye FailuremalawanyNo ratings yet

- Std-203-Operation and Maintenance of Hoisting EquipmentDocument18 pagesStd-203-Operation and Maintenance of Hoisting EquipmentamitNo ratings yet

- Torque Wrenches - Guidelines - 0Document7 pagesTorque Wrenches - Guidelines - 0Jellyn Base100% (1)

- QA TestingDocument4 pagesQA TestingApip HilmiNo ratings yet

- Operation, Maintenance & Inspection of Hoisting EquipmentDocument20 pagesOperation, Maintenance & Inspection of Hoisting Equipmentchandra sonarNo ratings yet

- Operation, Maintenance & Inspection of Hoisting EquipmentDocument20 pagesOperation, Maintenance & Inspection of Hoisting Equipmentjamil voraNo ratings yet

- Operate An Excavator: Code OHSCER205ADocument11 pagesOperate An Excavator: Code OHSCER205APong ParrackNo ratings yet

- SECTION 10 Crane InspectionDocument17 pagesSECTION 10 Crane InspectionPramod kumar kNo ratings yet

- Drilling Rig Acceptance StandardsDocument24 pagesDrilling Rig Acceptance StandardsÖnder Büyükişcan80% (5)

- Title Describe and Operate A Bucket Wheel Excavator at An Extraction Site Level 4 Credits 15Document4 pagesTitle Describe and Operate A Bucket Wheel Excavator at An Extraction Site Level 4 Credits 15Anonymous cf6mPd3No ratings yet

- Engine Inspection (Service Profile)Document2 pagesEngine Inspection (Service Profile)dhavit wijayantoNo ratings yet

- Turbine Gearbox Inspection: Steady Work in A Shaky Wind MarketDocument6 pagesTurbine Gearbox Inspection: Steady Work in A Shaky Wind MarketmadjadNo ratings yet

- Wind Turbines ApplicationDocument4 pagesWind Turbines Applicationkumar.phanindraNo ratings yet

- Prepare Pre-Delivery InspectionDocument21 pagesPrepare Pre-Delivery InspectionAnthony GozoNo ratings yet

- Daily Maintenance Check 20141031Document6 pagesDaily Maintenance Check 20141031harish puNo ratings yet

- Girth Gear Inspection PDFDocument2 pagesGirth Gear Inspection PDFMohammed g100% (1)

- QA335 - Troca Do Rolamento Da Caixa Da PeneiraDocument52 pagesQA335 - Troca Do Rolamento Da Caixa Da PeneiraGleidson DjalmaNo ratings yet

- Checklist - Ascenders - Petzl Hand & Chest - 050717Document1 pageChecklist - Ascenders - Petzl Hand & Chest - 050717Max BeeksNo ratings yet

- Catalogo LKM - Brake - FrenosDocument84 pagesCatalogo LKM - Brake - Frenosjuan mandiolaNo ratings yet

- Lifting Inspections Man RidiingDocument8 pagesLifting Inspections Man Ridiingmac1677No ratings yet

- Testing UMTS: Assuring Conformance and Quality of UMTS User EquipmentFrom EverandTesting UMTS: Assuring Conformance and Quality of UMTS User EquipmentNo ratings yet

- 2023 TRB Annual Report CaltransDocument27 pages2023 TRB Annual Report CaltransasdfASFNo ratings yet

- Topic 02 - ILO, IsO EtcDocument49 pagesTopic 02 - ILO, IsO Etcimran_chaudhryNo ratings yet

- Energetica 09 Septembrie2020Document73 pagesEnergetica 09 Septembrie2020Ion DutescuNo ratings yet

- Training Report of IoclDocument68 pagesTraining Report of IoclAnupam SrivastavNo ratings yet

- Mathematics Course Code: 4300001: Page 1 of 10Document10 pagesMathematics Course Code: 4300001: Page 1 of 10jigarNo ratings yet

- LESSON 2 Occupational Safety and Health LawsDocument6 pagesLESSON 2 Occupational Safety and Health LawsMELCHOR CASTRONo ratings yet

- Fashion Through The Decades PowerpointDocument11 pagesFashion Through The Decades PowerpointNigar khanNo ratings yet

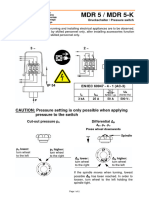

- Pressure Switch MDR5Document4 pagesPressure Switch MDR5Fidelis NdanoNo ratings yet

- Servicio y Reparación GenieDocument268 pagesServicio y Reparación Geniejonny david martinez perezNo ratings yet

- Chap 11Document3 pagesChap 11Flia Diaz ZunigaNo ratings yet

- Revised Final 2.5.2016 Entire Report 2Document117 pagesRevised Final 2.5.2016 Entire Report 2New Mexico Political ReportNo ratings yet

- Irjet V3i4441 PDFDocument5 pagesIrjet V3i4441 PDFnisaNo ratings yet

- Key AnDocument17 pagesKey Anpro techNo ratings yet

- Neptune Planet Experiment, Ariny Amos (Astronomer) - 1Document1,139 pagesNeptune Planet Experiment, Ariny Amos (Astronomer) - 1Dr. Amos ArinyNo ratings yet

- CE 1102 Fundamentals of Civil Engineering: Your LecturerDocument36 pagesCE 1102 Fundamentals of Civil Engineering: Your Lecturersaumya irugalbandaraNo ratings yet

- Group Screening Test, English 6Document4 pagesGroup Screening Test, English 6Jayson Alvarez MagnayeNo ratings yet

- Flash Notes SyndromesDocument8 pagesFlash Notes SyndromesschxzerrydawnNo ratings yet

- Synopsis Four PawsDocument7 pagesSynopsis Four PawsAnmol DubeyNo ratings yet

- A Review On Rasamanjari: It's Contribution in Pharmaceutical ScienceDocument3 pagesA Review On Rasamanjari: It's Contribution in Pharmaceutical ScienceEditor IJTSRDNo ratings yet

- أساسيات الاتصالات الرقمية PDFDocument230 pagesأساسيات الاتصالات الرقمية PDFAbdulssalam Mohammed Hussein Khako StudentNo ratings yet

- Wizard 2 BPUNIR2 PDFDocument16 pagesWizard 2 BPUNIR2 PDFalpdrNo ratings yet

- Hazardous Areas - Explosionproof Solenoids: Some HistoryDocument5 pagesHazardous Areas - Explosionproof Solenoids: Some HistoryShahram GhassemiNo ratings yet

- Mobile Division: Service Parts ListDocument20 pagesMobile Division: Service Parts Listwag008No ratings yet

- Initial Newborn AssessmentDocument14 pagesInitial Newborn Assessmentaclark831No ratings yet

- ITSDF B56-11-5-2014-Rev-12-2-14Document17 pagesITSDF B56-11-5-2014-Rev-12-2-14Fernando AguilarNo ratings yet