Professional Documents

Culture Documents

Release Bulletin PCR CosimaX Corado Reader SW v3.12 (4512 988 05313 REV AA)

Release Bulletin PCR CosimaX Corado Reader SW v3.12 (4512 988 05313 REV AA)

Uploaded by

Jose Antonio MolinsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Release Bulletin PCR CosimaX Corado Reader SW v3.12 (4512 988 05313 REV AA)

Release Bulletin PCR CosimaX Corado Reader SW v3.12 (4512 988 05313 REV AA)

Uploaded by

Jose Antonio MolinsCopyright:

Available Formats

Philips Healthcare

PCR CosimaX/Corado Rel. 3.12

Level 0 documentation

Release Bulletin

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be

reproduced, copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the

Philips Legal Department. This document is intended to be (a.) used by customers and is licensed to them as part of their Philips equipment

purchase or (b.) used to meet regulatory commitments as required by a FDA under 21 CFR 1020.30 (and any amendments to it) and other

local regulatory requirements. Use of this document by unauthorized persons is strictly prohibited.

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary. Any release or distribution of this material,

without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

4512 988 05313 REV AA

CSIP statement

Proprietary Notice:

This document and the information contained in it is proprietary and confidential information of Philips Healthcare

("Philips") and may not be reproduced, copied in whole or in part, adapted, modified, disclosed to others, or disse-

minated without the prior written permission of the Philips Legal Department. Use of this document and the infor-

mation contained in it is strictly reserved for current Philips personnel and Philips customers who have a current

and valid license from Philips for use by the customer’s designated in-house service employee on equipment lo-

cated at the customer’s designated site. Use of this document by unauthorized persons is strictly prohibited. Re-

port violation of these requirements to the Philips Legal Department. This document must be returned to Philips

when the user is no longer licensed and in any event upon Philips’ first written request.

Warranty Disclaimer Language:

Philips provides this DOCUMENT without warranty of any kind, implied or expressed, including, but not limited to,

the implied warranties of merchantability and fitness for a particular purpose.

Limitations of Liability Language:

Philips has taken care to ensure the accuracy of this document. However, Philips assumes no liability for errors or

omissions and reserves the right to make changes without further notice to any products herein to improve reliabil-

ity, function, or design. Philips may make improvements or changes in the product(s) or program(s) described in

this document at any time.

2 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Contents

Contents

1 Symbols and conventions used in this manual ............................................................ ....... 5

2 Safety ........................................................................................................................... ....... 7

2.1 General safety information .................................................................................................................... 7

2.2 Safety messages for service personnel ...................................................................................... ......... 7

2.3 Precautions against mechanical hazards ............................................................................................. 8

2.4 Precautions against electrical hazards ........................................................................................ ......... 8

2.5 Precautions against material damage .......................................................................................... ......... 9

3 Release information ..................................................................................................... ..... 11

3.1 Items supplied .............................................................................................................................. ....... 11

3.2 What's new? ................................................................................................................................ ....... 11

3.3 Known restrictions ........................................................................................................................ ....... 11

3.4 Compatibility ................................................................................................................................ ....... 12

4 Relation between the reader and the FTP server ........................................................ ..... 12

5 Systems with Eleva Workspot ...................................................................................... ..... 14

6 Software upgrade ......................................................................................................... ..... 15

6.1 Upgrade the RU PC-tool .................................................................................................................... 15

6.2 Upgrade the IPL software .................................................................................................................. 16

6.3 Upgrade the Reader software ............................................................................................................ 16

7 Initial software installation and setup ........................................................................... ..... 19

7.1 Preconditions ............................................................................................................................... ....... 19

7.2 Setting the IP addresses at the reader ............................................................................................... 19

7.3 Installing the RU PC-Tool on the PC (FTP-Server) ..................................................................... ....... 21

7.4 Installing the application software of the reader on the PC .......................................................... ....... 22

8 Configuration ................................................................................................................ ..... 27

8.1 Changing the configuration ................................................................................................................. 27

8.2 Changing IP address and IP name of the reader ......................................................................... ....... 28

8.3 Changing IP address and IP name of the FTP server ................................................................. ....... 29

8.4 Troubleshooting during configuration ........................................................................................... ....... 30

9 Backup and restore ...................................................................................................... ..... 31

4512 988 05313 REV AA CSIP Level 0 3

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Contents

9.1 Preparations ................................................................................................................................. ....... 31

9.2 Backup procedure ........................................................................................................................ ....... 31

9.3 Restore ........................................................................................................................................ ....... 31

10 Uninstalling software .................................................................................................... ..... 31

10.1 Removing the RU PC tool ............................................................................................................ ....... 31

10.2 Removing the reader application software ................................................................................... ....... 32

11 Service information ...................................................................................................... ..... 32

11.1 Local service ............................................................................................................................... ....... 32

11.2 Remote service ............................................................................................................................ ....... 32

11.3 Local service via service PC ............................................................................................................... 33

12 Sensitivity and shading adjustment .............................................................................. ..... 35

12.1 Sensitivity check with type ST and ST-BD ................................................................................... ....... 36

12.2 Sensitivity check with type HR ..................................................................................................... ....... 37

12.3 Sensitivity check with type HR-BD ...................................................................................................... 37

12.4 Shading/sensitivity adjustment for standard type ST and ST-BD ................................................ ....... 38

12.5 Sensitivity adjustment for high resolution type HR ....................................................................... ....... 39

12.6 Sensitivity adjustment for high resolution type HR-BD ................................................................ ....... 40

12.7 Shading speed correction for high resolution type HR-BD .......................................................... ....... 41

12.8 Sensitivity tolerances for type ST and ST- BD ............................................................................. ....... 41

12.9 Sensitivity tolerances for type HR ....................................................................................................... 41

12.10 Sensitivity tolerances for type HR-BD .......................................................................................... ....... 42

Glossary ....................................................................................................................... ..... 43

marker

4 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Symbols and conventions used in this manual

1 Symbols and conventions used in this manual

Safety messages

WARNING

This symbol combined with the signal word WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

If you do not obey these instructions, there is a risk of death or serious injury.

CAUTION

This symbol combined with the signal word CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

If you do not obey these instructions, there is a risk of minor or moderate injury.

The shown symbols are sometimes replaced by other symbols which indicate the concrete risk:

WARNING

Hazard of electrical shock

This symbol indicates a hazardous situation that is caused by electric current. It can result in death

or fatal injuries to service personnel or bystanders.

If you do not obey these instructions, there is a risk of death or serious injury.

WARNING

Hazard of laser beams (Class II / Class 2 laser)

This symbol indicates a hazardous situation that is caused by laser beams. It can result in damage

to your eyes and leave blind spots on your retina.

If you do not obey these instructions, there is a risk of death or serious injury.

WARNING

Hazard of radiation

This symbol indicates a situation that is caused by ionizing radiation. It can result in deadly diseas-

es.

If you do not obey these instructions, there is a risk of death or serious injury.

WARNING

Hazard of squeezing

This symbol indicates a situation that is caused by mechanical hazards related to hands and fingers.

It can result in squeezing or cutting off hands or fingers.

If you do not obey these instructions, there is a risk of death or serious injury.

4512 988 05313 REV AA CSIP Level 0 5

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Symbols and conventions used in this manual

WARNING

Hazard of severe burns

This symbol indicates a situation that is caused by hot surfaces. It can result in severe burns.

If you do not obey these instructions, there is a risk of death or serious injury.

WARNING

Hazard of biological contamination

This symbol indicates a situation that is caused by infective body fluids. It can result in deadly dis-

eases.

If you do not obey these instructions, there is a risk of death or serious injury.

Material damage

NOTICE

This symbol combined with the signal word NOTICE indicates a situation which, if not avoided,

could result in damages such as material damage. This damage is not related to personal injury.

If you do not obey these instructions, there is a risk of property damage.

Other messages

Important

This symbol combined with the signal word Important indicates an important advice that points out

that certain guidelines, parameters, conditions or restrictions must be observed.

Tip

This symbol combined with the signal word Tip indicates a helpful advice that suggests how to im-

prove the operating procedure or how to save time.

Conventions

Notation example Explanation

UI: System ➜ General ➜ Session Destination within the user interface (UI) of the

Eleva Workspot application software.

FSF: Configuration ➜ System components Destination within the Field Service Framework

(FSF).

F:\transfer\logs\ Directories and path descriptions.

[OK], [Cancel] Software keys (keys on the screen) are shown in

[square brackets].

<Enter>, <Esc>, <y> Hardware keys (keys on the keyboard) are

shown in <angle brackets>.

<Ctrl> + <c> If two or more hardware keys have to be pressed

at the same time, the “+” sign is used.

marker

6 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Safety General safety information

2 Safety

2.1 General safety information

Philips Healthcare products are designed and manufactured to meet the international safety stand-

ards for medical equipment. However, all medical electrical equipment requires proper installation,

operation and servicing, particularly with regard to human safety.

Read, note, and strictly observe all safety tags on the equipment. Strictly observe all safety direc-

tions, all warnings and all cautions that are mentioned in this chapter and throughout this service

documentation. In order to protect the personal health of service personnel, operators and patients,

ensure the safe servicing and operation of the system.

Read all information in this chapter carefully.

You are responsible to take safety precautions and to follow the safety instructions.

Thus, you can prevent harm from yourself and other persons.

• TECHNICALLY QUALIFIED PERSONNEL ONLY!

Only technically qualified Field Service Engineers (FSEs) must do the service work. The FSEs

must be appropriately and successfully trained and instructed by the Philips training center for

this specific equipment. The FSEs must be authorized to work with radiography equipment in

medical applications and they must be authorized by Philips to do maintenance work and to have

access to the appropriate documentation.

• Perform all service tasks such as installation, maintenance, or repair in strict compliance with the

provided safety instructions!

• Perform all actions as for example unpacking, installation, setting to work, testing and replace-

ment according to the sequence stated in this manual.

• Perform all service tasks in strict compliance with the local regulations concerning safety, health,

accident prevention, and medical X-ray devices!

• Never change any system parameters or components that reduce the mechanical safety, electri-

cal safety, radiation protection properties of the product!

• Do not modify this equipment without authorization of Philips.

Any unauthorized modification can cause malfunction or deterioration of performance and quality

and can therefore lead to personal injury, clinical misdiagnosis or clinical mistreatment.

• Never leave problems unsolved that may affect the safety of the product!

• Order spare parts via Philips distribution channels, only! Never use any spare parts from other

sources than spare parts supply from Philips!

• Always perform all relevant safety checks before handing the product over to the customer!

• Keep in mind that certain details or procedures changed since you previously installed or serv-

iced a similar product!

2.2 Safety messages for service personnel

Hazard of squeezing

Working with moving parts or heavy loads is very dangerous!

• Read all instructions in the subsequent chapter concerning mechanical hazards.

• Take all necessary precautions to avoid injuries.

If you do not obey these instructions, there is a risk of death or serious injury.

4512 988 05313 REV AA CSIP Level 0 7

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Precautions against mechanical hazards Safety

Hazard of electrical shock

Live electrical terminals are deadly! Incorrect handling of high-voltage cables results in death or fatal

injuries to service personnel or bystanders.

• Read all the instructions stated subsequently concerning electrical hazards.

• Take all necessary precautions to avoid electrical shock.

If you do not obey these instructions, there is a risk of death or serious injury.

Hazard of biological contamination

Infective body fluids may be present at various spots of the product and can cause deadly deseas-

es.

• Wear rubber gloves where body fluids may be present.

• Never eat, drink, or smoke with contaminated hands or gloves.

• Dispose your gloves appropriately when your work is finished.

If you do not obey these instructions, there is a risk of death or serious injury.

2.3 Precautions against mechanical hazards

Safe handling of heavy loads

• Wear appropriate protective clothing, such as safety boots and gloves.

• Take care that heavy loads are correctly lifted or carried to avoid any physical injury.

• Ask other persons for help to handle very heavy or awkwardly shaped loads.

• Use mechanical devices whenever it is possible.

• Stick to the installation instructions regarding:

– suitable tools

– lifting devices

– lifting/support points

– particular safety measures

2.4 Precautions against electrical hazards

General precautions against electrical hazards

• Switch off the mains supply.

• Make sure that nobody can switch on the system accidentally before you start.

• Make sure that all UPS-powered components are powerless.

• Use a voltmeter to verify that all line disconnects are opened.

• Remove all jewelry, such as bracelets, or rings to prevent short circuits.

Precautions concerning installation and service

Electrical installations of medically used rooms must comply with the requirements of each country.

Follow the instructions provided on the installation sheets for the specific project.

• Always use a separate conductor for ground connection. The neutral conductor is not considered as

ground connection.

• Do not use a three-to-two pin adapter to connect equipment provided with a power cord. Always con-

nect the equipment to properly grounded, three-pin power outlets.

• Connect the system to the mains as late as possible during installation.

8 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Safety Precautions against material damage

• Make sure that all protective earth conductors are installed and connected before first switching on

the system.

• Always be sure that the power is switched off when installing any parts to the equipment.

• Make sure that large internal capacitors are completely discharged. Discharging can take several mi-

nutes.

• Keep away water or other liquids from the inside of the equipment to avoid short-circuits or corrosion.

Working when connected to voltages

• Switch off the main power supply when working at the equipment. This rule does not apply for certain

measuring and adjustment procedures that are only possible when the product is switched on.

• Never measure or adjust equipment with power-on unless another person is present.

• Be very careful when working close to live contacts.

• Never perform any work on live parts (> 50 V).

• Prevent unwanted or sudden movements of the system because they are dangerous. If the proce-

dure involves mechanical movements, take every precaution especially when working with moving

and rotating parts. Use the service switch or the EMERGENCY STOP button before working within

the dangerous movement area of a product.

• Check the ground connections before touching conductive system parts.

• Use tools and measuring instruments, which are suitable for the respective procedure, only.

• Make sure that test and adjustment points are accessible without any risk of injury. If safe access is

not possible, switch off the system.

• Turn off the power supply immediately after finishing the test or adjustment procedure.

2.5 Precautions against material damage

Malfunction through electromagnetic fields

The equipment fulfills all requirements concerning electromagnetic compatibility (EMC).

Nevertheless, powerful high frequency transmitters used near the electronic components can cause

malfunction of electronic components under unusual circumstances. This malfunction causes un-

wanted risks for patients, operators, and service personnel.

• Switch off your mobile phone in designated areas.

If you do not obey these instructions, there is a risk of property damage.

Blocked air cooling

The processor can get damaged due to overheating.

• Do not block the air vents. Leave a minimum clearance of 5 cm (2 inch) to the ventilation slots.

• Do not install the computer in an enclosure that does not allow airflow.

If you do not obey these instructions, there is a risk of property damage.

Processor overheating

The processor can get damaged within a few seconds.

• Do not operate the processor without cooling.

If you do not obey these instructions, there is a risk of property damage.

4512 988 05313 REV AA CSIP Level 0 9

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Precautions against material damage Safety

Damage by electrostatic discharge (ESD)

ESD can destroy or partially damage electrostatic sensitive devices such as printed circuit boards

(PCB). The damage can lead to instant or later failures of the device.

• Read all the following instructions concerning ESD protection.

• Take all necessary precautions to protect electrostatic sensitive devices.

If you do not obey these instructions, there is a risk of property damage.

The rules concerning ESD protection apply to new devices and old devices. Old devices are re-

placed and sent back to the service depot.

This symbol identifies electrostatic sensitive devices.

• Always transport electrostatic sensitive devices (such as PCBs) in

their static shielding bags or boxes.

• Always use the ESD protection service kit when

handling electrostatic sensitive devices.

• Attach the wristband to your wrist (1) and con-

nect the ground cable of the wristband to the

conductive work surface (2).

• Connect the second ground cable (3) to the

conductive work surface (2).

• Attach the crocodile clip to a reliable ground

of the cabinet or console, where the PCB has

to be installed.

• Place the PCBs on the conductive work surface

before installing them.

• Place the PCBs on the conductive work surface

1011-46-07

for hardware settings or replacement of compo-

nents.

• Never remove or disconnect the wristband be-

fore all electrostatic sensitive devices are instal-

Fig. 1: ESD protection kit

led.

• Never remove or disconnect the wristband be-

fore all removed electrostatic sensitive devices

are safely packed in their static shielding bags or

boxes.

10 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Release information Items supplied

marker

3 Release information

3.1 Items supplied

Supplied Software Material number Fuji Material number

PCR CosimaX/ Corado Read- 4512 201 06537 -

er SW version 3.12 consisting

of:

- 1 CD 'CR-IR 362/363 APL 4512 116 06517 114Y5117002A28 (delivered in

Software Version 3.12' the accessories of the reader)

- this Release Bulletin 4512 988 05313 -

Delivery from the following S/N onwards:

– Corado: from S/N 00047 onwards (last 5 digits).

– CosimaX: from S/N 00069 onwards (last 5 digits).

Upgrades:

– Recommended for versions 3.0 ... 3.7.

– Not recommended for versions 2.x.

The application software of the reader is delivered on a CD ROM.

• Install the application software on a separate PC that is connected to the reader, for example, the

PCR Eleva Workspot.

After power-on, the reader establishes a network connection to the PC that is connected to the read-

er, for example, the Eleva Workspot. The reader gets from the PC date and time information. Refer

also to chapter Relation between the reader and the FTP server.

The machine data floppy/CD is marked with the S/N of the reader. It contains a backup of the initial

scanner data for this reader.

3.2 What's new?

The following problems are solved compared with SW version 3.9:

– A process has been added to light ON the erasure lamp during mechanical initialization. (Erasure

lamp is turned OFF when the temperature increases by up to 65℃)

– A process has been added to light ON and OFF the erasure lamp (ON when the temperature de-

creases by below 25℃, OFF when the temperature increases by up to 35℃) to make the tempera-

ture of erasure unit come within the specified range while the machine is in ready condition.

– Erasure time for single-side ST type IP has been changed; the erasure time for IP exposed with

10mR or lower dose has been changed to the time same as for IP exposed with 25mR or lower.

– Temperature to warm up erasure area at the start of erasure process has been changed (from 12℃

to 25℃.)

3.3 Known restrictions

– The FTP Server (Preview Unit or Eleva Workspot) must be booted up completely before the reader is

switched on. Otherwise the reader will hang-up after reading or before erasing an IP and will show

the error number 11499 after a reboot. In this case the IP is returned into the cassette during the

initialization of the reader. Afterwards the IP must be erased deliberately.

4512 988 05313 REV AA CSIP Level 0 11

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Compatibility Relation between the reader and the FTP server

– Some service functions of the RU PC-Tool are not supported yet. For details see service manual of

the Reader.

– Always 'A' has to be used as equipment code (Reader ID).

– During software installation the error message 'The system cannot find the file specified' is displayed

when the following four files have been written into the flash memory:

– IPH_FPMC.PRM

– IPH_SNIP.PRM

– IPH_TIME.PRM

– IPHRETRY.PRM

• During the installation of the software, especially the RU PC-Tool, a few pop-up windows may ap-

pear (see below).

• Click on [X] to close the messages.

Fig. 2

• Click on [Ignore] if the following message ap-

pears.

Fig. 3

3.4 Compatibility

Software Material number Remarks

PCR CosimaX reader 4512 201 02642 model CR-IR 363

PCR Corado reader 4512 201 02672 model CR-IR 362

PCR Eleva Workspot SW 4512 201 06383 Rel. 1.1.5

4512 201 0642x Rel. 1.2

marker

4 Relation between the reader and the FTP

server

The FTP server of the reader (= Reader Unit = RU) is a separate PC (= Console = CL).

Both communicate via a fast Ethernet connection.

A detailed description is provided in the service manual of the reader, chapter "Machine Description".

12 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Relation between the reader and the FTP server Compatibility

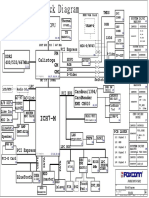

Data flow during installation:

– (1) Sets the IP addresses of both the reader

(RU) and the PC (Console CL) at the reader.

– (2) Starts the installation of the application soft-

ware.

– (3) Sets the language and the brand OEM.

– (4) Sets the configuration.

– (5) Sets the IP address of the PC.

Data flow during boot-up:

Data flow during routine processing:

4512 988 05313 REV AA CSIP Level 0 13

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Compatibility Systems with Eleva Workspot

Data flow during a backup:

Data flow during a restore:

marker

5 Systems with Eleva Workspot

DXR systems with an Eleva Workspot use the Field Service Framework (FSF) as a service program.

The FSF is a proprietary tool for PH. All the service work (local and remote) is done via this tool.

The service instructions of this manual are general ones. They do not reflect the special features of

PCR Eleva. So deviation in the use of the service functionality is possible. Further information is in-

cluded in the documentation of the Eleva Workspot.

The following service menus of FSF (PCR Eleva 1.2) are relevant:

– SW installation from CD-R:

FSF: General Functions ➜ Install software ➜ PCR reader SW

– Configuration:

FSF: Configuration ➜ PCR ➜ Start Maintenance Utility for PCR reader (PC-MUTL)

FSF: Configuration ➜ PCR ➜ Workspot status

FSF: Configuration ➜ PCR ➜ Image plate linking

– Diagnostics:

FSF: Diagnostics / Fault-finding ➜ PCR ➜ Start Maintenance Utility for PCR reader (PC-

MUTL)

– System info:

FSF: System information ➜ PCR ➜ Workspot status

FSF: System information ➜ PCR ➜ Image plate linking

Tip

Depending on the system SW version, the location of these menus in the FSF can vary.

marker

14 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Software upgrade Upgrade the RU PC-tool

6 Software upgrade

The software consists of about 21MB (compressed).

The latest software and the corresponding Release Bulletin can be downloaded from the Philips In-

tranet.

• Extract the packed software into an empty folder on your service PC.

• Mark an empty CD-R with the information given in the file "Readme.pdf".

• Remove the readme file from the software package and burn the software on the CD.

This upgrade is recommended for software versions 3.0 ... 3.7.

6.1 Upgrade the RU PC-tool

Important

This upgrade is valid for software version 3.0 ... 3.7 within Eleva systems.

Time: about 3 min.

• Switch on the system.

• Insert the CD containing the new software.

Use FSF according to chapter Systems with Eleva Workspot on page 14.

• Select [UNINSTALL] to remove the currently in-

stalled RU PC tool of the version 4.1.4 or lower.

• To install the new RU PC tool version 5.4 from CD, select [INSTALL] and then [For FTP-Server].

• Click [SET].

• During the installation of the software, especially the RU PC tool, sometimes a few pop-up windows

appear.

• To close the messages, click [X].

Fig. 4

• Click [Ignore] if the following message appears.

Fig. 5

4512 988 05313 REV AA CSIP Level 0 15

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Upgrade the IPL software Software upgrade

6.2 Upgrade the IPL software

If you have to replace the CPU91A board with version 113Y1677 P or higher, it is necessary to up-

grade the IPL software.

The IPL software is the operating system of the reader and is stored in the FLASH ROM on the IMG

board. Upgrade to version 2.3 according to the following procedure:

• Insert the CD-ROM into the drive.

The maintenance tool appears (PCR Eleva: via FSF: General Functions ➜ Install software).

• Select the batch file according to the following

figure.

• Change the default IP address of the batch file

to the actual used IP address of the reader, for

example ..._initial.bat 192.168.101.21

• Click [EXECUTE] to start the upgrade. Never

turn off the power of the reader in this situation.

• Press [Enter] when the following message ap-

pears.

It is possible to check the upgrade to 2.3 via the designer’s tag in the MUTL.

6.3 Upgrade the Reader software

Time: about 5 min.

• Insert the CD- ROM that contains the new software.

• Select FSF: General Functions ➜ Install software ➜ PCR reader SW.

• Select [START] to open the RU PC-Tool.

• Select one of the installed reader units.

16 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Software upgrade Upgrade the Reader software

• Make a backup of the CONFIGURATION, HIS-

TORY LOG and SCN ALL DATA.

• Click [EXECUTE] to start the backup.

• Click [VERSION UP].

• Click [OK].

4512 988 05313 REV AA CSIP Level 0 17

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Upgrade the Reader software Software upgrade

• Select the software version that you want to in-

stall for the reader and click [OK].

Fig. 6

• Confirm the upgrade in the next windows.

The steps of the upgrade process appear in a

command window.

During the upgrade, the LEDs of the four cas-

sette slots flash.

Fig. 7

The following windows appear.

• If the Telnet window does not appear, press

<Alt> + <Tab> to bring it into the foreground.

• Wait about 4 min. until the “Install is complete…”

message appears. After that “Connection to host

lost.” appears.

• Press <Enter> twice.

• Click [OK] to finish the installation.

• After the installation is complete, check the ver-

sion number of the software shown.

• Check the configuration and the history via their EDIT button.

• Exit the RU PC-Tool and the Set-Up PC-Tool.

18 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Initial software installation and setup Preconditions

• Remove the CD.

• Exit FSF.

• Reboot the system.

• Check the SW version displayed at the reader during the start-up.

• Check the functionality of the system.

Important

Usually there is no need to restore the data of the scanner, the configuration, and the history. During

an upgrade, all data are kept and adapted to the new software release.

marker

7 Initial software installation and setup

7.1 Preconditions

– All the network-related information is available: IP addresses, IP names, netmasks, and DICOM

AET.

– At least the operating system is installed on the PC.

– Do not connect the PCR reader and the reader server PC to the hospital network during software

installation. Link both units together via a separate Ethernet switch. A cross cable is not recommend-

ed.

• Select the appropriate reader software CD:

– For CosimaX / Corado: 'CR-IR 362/363 APL Software Version ...'

– For Eleva S Hi-res: 'CR-IR 368 APL software version ...'

Time: about 25 min.

7.2 Setting the IP addresses at the reader

• Switch on the reader and the computer.

For the CosimaX and Corado

• Start the Maintenance Utility at the reader during

the initialization phase.

For the Eleva S Hi-res

• Wait until the reader finished the startup.

• To start the Maintenance Utility at the reader,

press both upper edges of the display as shown

in the picture.

4512 988 05313 REV AA CSIP Level 0 19

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Setting the IP addresses at the reader Initial software installation and setup

• Set the IP address of the computer (FTP-Serv-

er), the netmask and the router IP address.

• Set the IP address of the computer (FTP-Server)

at the reader.

20 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Initial software installation and setup Installing the RU PC-Tool on the PC (FTP-Server)

7.3 Installing the RU PC-Tool on the PC (FTP-Server)

Tip

Sometimes a Telnet session window does not appear. Press <Alt> + <Tab> to bring it into the fore-

ground.

If the Telnet window does not close when mentioned in the text, press <Enter>.

• Insert the CD 'CR-IR 362/363 APL software version ...' into the CD/DVD drive of the PC.

Start the FSF menu General functions ➜ Install software ➜ PCR reader SW. A set-up pro-

gram is started from the CD.

• Click [INSTALL].

• Select For FTP-Server, and click [SET].

The following window appears.

• Click [Next].

4512 988 05313 REV AA CSIP Level 0 21

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Installing the application software of the reader on the PC Initial software installation and setup

• Click [Install].

• Click [Finish].

• Press any key to continue in the next few

screens.

When the RU PC-Tool is finally installed, the fol-

lowing screen appears.

7.4 Installing the application software of the reader on

the PC

• In the set- up program click [START] to install

the application software of the reader.

• Click [NEW] and enter the RU name and RU IP address of the reader.

22 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Initial software installation and setup Installing the application software of the reader on the PC

• Click [PING] to check the communication.

A window as shown appears.

• Close this window.

• Click [INSTALL].

4512 988 05313 REV AA CSIP Level 0 23

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Installing the application software of the reader on the PC Initial software installation and setup

• Click [OK].

• Select the following items and click [OK]:

– Language: The language for the display panel

of the Reader

– Brand Type: OEM

– Install Version: Select the appropriate Reader

SW release version; i.e. the highest of the list-

ed versions.

The following window appears.

The RU configuration is displayed.

Configuration item Values

EQUIPMENT CODE Use always 'A'

RANGE OF ERASE MODE Specifies the erasure mode range.

– ERASE 1: Primary erasure can be selected.

– ERASE 1, ERASE 2: Both primary and secondary erasures can

be selected.

24 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Initial software installation and setup Installing the application software of the reader on the PC

Configuration item Values

ERASE MODE TIMEOUT Automatic switch-back of the display from erasure mode into the

reading mode.

Default : 20 sec

ALARM (CASSETTE SET) Sets alarm ON/OFF when cassette is inserted.

– ON : Alarm sounds.

– OFF : Alarm does not sound

WARNING OF OVERXRAY Selects X-ray over-exposure IP warning method.

• LOG & MESSAGE: Warning by log and message.

• LOG: Warning by log.

• NONE: No warning issued.

CR-IR362 BARCODE Select NO

READER OPTION

BOARD WARMING-UP & Select OFF

CASSETTE DETECT

WARNING OF LAMP LIFE Sets the warning indication of the erasure lamp life.

• LOG ONLY (default): Only write into the error log

• LOG & MESSAGE: Write into the error log and display of the error

message.

CONDITION OF ERASE Defines whether and when a warning pops up.

LAMP CLEANING • Recommendation for customer with service contract: NO DISP

(default)

• Recommendation for customer without service contract: 90000

CONDITION OF ERASE The number of processed IPs can be entered after the customer has

LAMP CLEANING (FREE IN- gotten a warning.It is recommended that the fixed values in the row

PUT) above are used.

CONDITION OF PUMP LIFE Defines whether and when a warning pops up.

• Recommendation for customer with service contract: NO DISP

(default)

• Recommendation for customer without service contract: 18000

CONDITION OF PUMP The number of processed IPs can be entered after the customer has

CLEANING (FREE INPUT) gotten a warning. It is recommended that the fixed values in the row

above are used.

WARNING OF S VALUE Sets the warning indication of an abnormal S value deviation.

• LOG ONLY (default): Only write into the error log

• LOG & MESSAGE: Write into the error log and display of the error

message

ADDITIONAL LAMP CON- Defines whether the additional erasure lamp control is activated.

TROL Default: ON

• Enter/select the configuration data and click [SET]. The configuration is saved to hard disk and the

system returns to the main menu.

• Select the default IP address and click

[MODIFY].

4512 988 05313 REV AA CSIP Level 0 25

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Installing the application software of the reader on the PC Initial software installation and setup

• Enter the IP address and the IP name of the PC

and click [SET].

• Click [SET].

NOTICE

Reader damage

While data is written into the FLASH ROM of the reader, never turn off the power. If the power is

turned off, the program residing in the memory is corrupted, so that it is impossible to reboot the

reader.

Writing into the FLASH ROM takes a few minutes.

During the upgrade, the LEDs of the four cassettes slots flash.

If you do not obey these instructions, there is a risk of property damage.

After some seconds a Telnet session window

appears, that shows the status of the SW instal-

lation.

• If the window does not appear, press <Alt> +

<Tab> to bring it into the foreground.

• Wait about 4 min. until the “Install is complete…”

message appears. After that “Connection to host

lost.” appears.

• Press <Enter> twice.

• Click [OK] to finish the installation.

• Check the version of the Reader software. The displayed VERSION information must correspond to

the new installed release version.

26 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Configuration Changing the configuration

• To close the RU PC-tool, click [X].

• Click [EXIT] to close the set-up program.

• Remove the CD from the drive.

• Restart the reader.

• Check its functionality.

Tip

If a yellow maintenance screen blocks the use of the display of the reader, do the following:

• Touch the left-hand and right-hand upper corner of the display to close this screen.

marker

8 Configuration

The meaning of the configuration parameters are described in the service manual of the reader. See

section "Maintenance utility".

8.1 Changing the configuration

• Start up the RU PC-Tool as described in section "Service information, Local Service".

• From the LIST OF EXISTING RU, select the Reader which configuration file is to be set.

• Click [EDIT CONFIGURATION].

The RU configuration is displayed.

Configuration item Values

EQUIPMENT CODE Use always 'A'

4512 988 05313 REV AA CSIP Level 0 27

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Changing IP address and IP name of the reader Configuration

Configuration item Values

RANGE OF ERASE MODE Specifies the erasure mode range.

– ERASE 1: Primary erasure can be selected.

– ERASE 1, ERASE 2: Both primary and secondary erasures can

be selected.

ERASE MODE TIMEOUT Automatic switch-back of the display from erasure mode into the

reading mode.

Default : 20 sec

ALARM (CASSETTE SET) Sets alarm ON/OFF when cassette is inserted.

– ON : Alarm sounds.

– OFF : Alarm does not sound

WARNING OF OVERXRAY Selects X-ray over-exposure IP warning method.

• LOG & MESSAGE: Warning by log and message.

• LOG: Warning by log.

• NONE: No warning issued.

CR-IR362 BARCODE Select NO

READER OPTION

BOARD WARMING-UP & Select OFF

CASSETTE DETECT

WARNING OF LAMP LIFE Sets the warning indication of the erasure lamp life.

• LOG ONLY (default): Only write into the error log

• LOG & MESSAGE: Write into the error log and display of the error

message.

CONDITION OF ERASE Defines whether and when a warning pops up.

LAMP CLEANING • Recommendation for customer with service contract: NO DISP

(default)

• Recommendation for customer without service contract: 90000

CONDITION OF ERASE The number of processed IPs can be entered after the customer has

LAMP CLEANING (FREE IN- gotten a warning.It is recommended that the fixed values in the row

PUT) above are used.

CONDITION OF PUMP LIFE Defines whether and when a warning pops up.

• Recommendation for customer with service contract: NO DISP

(default)

• Recommendation for customer without service contract: 18000

CONDITION OF PUMP The number of processed IPs can be entered after the customer has

CLEANING (FREE INPUT) gotten a warning. It is recommended that the fixed values in the row

above are used.

WARNING OF S VALUE Sets the warning indication of an abnormal S value deviation.

• LOG ONLY (default): Only write into the error log

• LOG & MESSAGE: Write into the error log and display of the error

message

ADDITIONAL LAMP CON- Defines whether the additional erasure lamp control is activated.

TROL Default: ON

• Enter/select the configuration data and click [SET]. The configuration is saved to hard disk and the

system returns to the main menu.

8.2 Changing IP address and IP name of the reader

Be careful during a change of IP addresses. Disconnect the system from an existing hospital net-

work. Use a separate network switch temporarily.

28 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Configuration Changing IP address and IP name of the FTP server

On the reader

• Delete the old IP address.

• Enter the new one by using maintenance utility of the reader.

On the PC (FTP server)

• Delete the old registered reader unit on the PC with the RU PC tool.

• Perform a complete new installation of the reader. See Installing the PCR reader application software

on the PC.

• Restart the system.

• Check both the application and the service functionality.

8.3 Changing IP address and IP name of the FTP server

• On the reader: Delete the old IP address of the FTP server and enter the new one by using the

reader's maintenance utility.

• On the PC (FTP server): Change the IP address or the IP name via the FSF according to the doc-

umentation of the Eleva Workspot.

• Restart the PC.

• Start the RU PC tool and select the reader connected.

• Click [EDIT CL NAME].

• Select the PC and click [MODIFY].

• Enter the new IP address and/or the new IP

name of the PC and click [SET].

4512 988 05313 REV AA CSIP Level 0 29

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Troubleshooting during configuration Configuration

• Click [PING] and [FTP] to check the communi-

cation with the reader.

• Restart the system and check the normal application.

8.4 Troubleshooting during configuration

Example: "CR Console communication error".

Line error indication on the display panel of the reader.

Cause: IP name and IP address configured on the PC do not match the configuration on the reader.

Solution 1: Check the FTP server for the reader on the PC

• Start the RU PC tool.

• Select the reader.

• Click on [Edit CL Name].

• Select the configured PC for the reader.

• Click on [MODIFY] to change the data.

• Enter the matching IP address or IP name and

click [SET].

Make sure that the entered data are identical

with the ones set in the operating system.

Solution 2: Check or change the IP addresses configured on the reader

• Enter the maintenance tool on the reader.

• Select [RU IP address].

• Check the IP address of the reader.

• Select [FTP-Server].

• Check the IP addresses of the FTP server.

If the IP address of the reader is changed, uninstall the old configured reader on the PC.

After deinstallation of the old reader, install the new reader on the PC.

Solution 3: Check ‘Reader name’ and ‘Reader type’ in the configuration of the

Eleva Workspot

• Open FSF: Configuration ➜ PCR ➜ Workspot status.

marker

30 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Backup and restore Preparations

9 Backup and restore

9.1 Preparations

• Have on hand the storage medium for the backup data, for example, a USB memory stick.

• Start the RU PC tool via FSF menu Configuration ➜ PCR ➜ Start Maintenance Utility for PCR

reader (PC-MUTL).

9.2 Backup procedure

• To back up reader-specific data, select the data

you want to save from the list.

Recommended data: CONFIGURATION, SCN

ALL DATA, HISTORY LOG

• Click [EXECUTE] and follow the instruction giv-

en.

9.3 Restore

• To restore reader-specific data, select the data

you want to restore from the list.

• Click [EXECUTE] and follow the instruction giv-

en.

In the scope of delivery of each reader is a CD-R marked with machine data and the S/N of the

reader.

This medium contains the initial scanner data as adjusted by the factory.

marker

10 Uninstalling software

Two software packages of the Reader are stored at the PC, the RU PC-Tool and the application soft-

ware of the Reader unit. It is possible to uninstall them.

10.1 Removing the RU PC tool

• Insert the reader software CD into the CD/DVD drive of the PC.

• Start the set-up program via FSF: General functions ➜ Install software ➜ PCR reader SW.

The set-up program is started from CD.

• Click [Uninstall] and follow the instructions of the uninstall wizzard.

4512 988 05313 REV AA CSIP Level 0 31

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Removing the reader application software Service information

10.2 Removing the reader application software

• Insert the reader software CD into the CD/DVD drive of the PC.

• Start the set-up program via FSF: General functions ➜ Install software ➜ PCR reader SW.

The set-up program is started from CD.

• Click [Start] to open the RU PC-Tool.

• Click [Uninstall].

The application software and the configuration of all readers is removed.

marker

11 Service information

11.1 Local service

The program RU PC tool on the Eleva Workspot manages all service functions of the reader.

A subpart is the maintenance utility (MUTL) program that offers unit tests, board tests and shading

and sensitivity adjustments.

Starting the RU PC tool

• Start FSF: Diagnostics/ Fault-finding ➜ PCR ➜ Start Maintenance Utility for PCR reader (PC-

MUTL).

• Select the reader unit in the LIST OF EXISTING RU. Now all service functions are selectable.

For further explanations, refer to the service manual of the reader.

11.2 Remote service

The RU PC tool runs on the connected PC. It supports all the service functions. Because you can

start the tool only via Field Service Framework (FSF), the remote connection via FSF is described

here.

The remote access functionality depends on the software version and the software keys of the Eleva

Workspot. For details, contact the helpdesk.

• Make sure that the most actual logging and trace data are transferred from the reader to the Eleva

Workspot. The transfer happens automatically during a shutdown of the reader.

You can collect more data (configuration and scanner data) via manual backups. The target of the

backups is insignificant.

• Set up a remote connection to the Eleva Workspot via RSN or PRS (refer to the Eleva Workspot doc-

umentation for further information).

• Go to FSF: General functions ➜ Export data ➜ PCR reader data.

• Select the default transfer directory on the service partition f:\Transfer\Data\ReaderDataFilesd.zip

as the destination for the compressed reader data file.

• Use FSF: General functions ➜ Export data ➜ System data for helpdesk support to transfer the

zipped reader data together with other system information to a remote host.

Reader data of interest

Software version: version.dat

Error logs: ...\LOG\ERROR\*.* (all files)

Trace data: ...\TRACE\ *.* (all files, for factory only)

IOT data: ...\IOT\iot.log (for factory only)

32 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Service information Local service via service PC

Reader data of interest

Configuration: ...\CONFIG\Irset.cfg

History file: ...\LOG\STATISTIC\History.cfg

Scanner data: ...\MACHINE\*.* (all files, for factory or as backup)

11.3 Local service via service PC

It is also possible to maintain the reader by a service PC that is connected to the existing network.

For the connection to the service PC, install the RU PC tool as a CLIENT PC TOOL at the service

PC as follows:

• Adapt the IP address and netmask of the service PC to an address range used at the site.

• Disconnect the reader, the Eleva Workspot and the service PC from the official hospital network tem-

porarily with a separate network switch.

• Insert the CD 'CR-IR 362/363 APL Software Version ...' into the CD-ROM drive of the Service PC.

A set-up program is started from CD.

• Click [INSTALL].

• Select “For Client PC”, and click [SET].

• Click [Next].

• Click [Install].

4512 988 05313 REV AA CSIP Level 0 33

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Local service via service PC Service information

• Click [Finish].

• Click [START] to open the client PC tool.

• Click the right mouse button on [HOSPITAL].

• Create a list ...

... containing the IP addresses and names of all

the FTP servers (for example, Eleva Work-

spot) ...

... and readers (RU) according to the sequence

shown.

34 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Sensitivity and shading adjustment Local service via service PC

• Download the actual logs and settings from the

reader to the service PC.

• Select the reader that you want to work at. Select the desired service function.

It is possible to use most of the service functions in parallel to the normal application mode of both

the reader and Eleva Workspot.

This tool can also be used offline.

• The relevant files (history data, configuration, er-

ror logs) must be downloaded from the Reader

before.

• The data have to be copied into the Import path

configured in the client PC-Tool.

marker

12 Sensitivity and shading adjustment

Preconditions

– The scanning unit of the reader is cleaned before (see the unit manual of the reader).

– The image format and the leading-edge detection are well adjusted. No white blank portions are visi-

ble at the edges (see the unit manual of the reader).

– All the current scanner data are copied to a backup medium with the service program RU PC tool.

4512 988 05313 REV AA CSIP Level 0 35

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Sensitivity check with type ST and ST-BD Sensitivity and shading adjustment

– The complete system runs in the normal application mode.

Reference documents of the Reader:

Section: Checks MC Chapter: Shading/Sensitivity correction

Exposure data and applicable adjustment depending on IP type:

Adjustment procedure for: Corado CosimaX

ST= standard ST ST ST ST HR-BD

HR= high resolution HR ST-BD ST-BD

ST-BD= ST on both sides HR HR

HR-BD= HR on both sides HR-BD

ST sensitivity/shading/shad- 80 kV 80 kV 80 kV 80 kV -

ing speed 1 mR 1 mR 1 mR 1 mR

→ section 4

ST- BD sensitivity and shad- - - 80 kV 80 kV -

ing 1 mR 1 mR

→ section 4

HR sensitivity - 80 kV 80 kV - -

→ section 5 3.6 mR 3.6 mR

HR-BD sensitivity - - 25 kV 25 kV 25 kV

→ section 6 20 mR 20 mR 20 mR

HR-BD shading speed - - 80 kV 80 kV 80 kV

→ section 7 15 mR 15 mR 15 mR 1)

If not possible, then the factory data should be used.

1)

The shading speed can be corrected by using 25 kV / 20 mR but it is not recommended.

12.1 Sensitivity check with type ST and ST-BD

• Uniformly expose the largest IP of the type ST (e.g. 14” x 17” or 14” x 14”) and ST-BD (e.g. 24 x 30

cm) with a dosage of about 1 mR (8.7 µGy) at about 80 kV (≈ 0.5mAs, small focus, free exposure

technique). If necessary, use a dose value of 2 mR (17.4 µGy)

• Use a large SID (min. 1800mm).

• Do not use any filters.

• Open the shutters of the collimator completely. The green marker of the cassette shows to the

anode of the tube.

• Check the dosage with a dosimeter.

• Register (barcode) the IP under the examination SERVICE/ TEST and the view SENSITIVITY.

• Be sure that this view is programmed to EDR = 1 (semi mode) and MPM code 0900.

• Use post processing code U0000900 (GA=1, GT=A, GC=1.2, GS=0.0, RN=3, RT=F and RE=0.0).

Alternatively the examination SERVICE/ TEST/ Semi Mode/ AVE 4.0 with the MRM code 090E

can be used. The MRM code 090E with L = 4 will produce an image with a more homogeneous

gray level and lower tolerances respectively.

• 10 ... 11 minutes after the exposure has been made, enter the cassette into the Reader.

• For the result look at the image console:

For a dose value of 1mR (8.7 µGy)

S value: 170 ... 200 ... 250 S= Sdisplayed x dosemeasured[mR]

Pixel value PVraw: 1850 ... 2050 ... (12 bit, 0=white)

2250

36 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Sensitivity and shading adjustment Sensitivity check with type HR

• If there are greater deviations of S, perform the sensitivity and shading correction.

For a dose value of 2 mR (17.4 µGy)

S value: 85 ... 100 ... 125 S= Sdisplayed x dosemeasured[mR] /2

Pixel value PVraw: 2150 ... 2350 ... (12 bit, 0=white)

2550

• If there are greater deviations of S, perform the sensitivity and shading correction.

12.2 Sensitivity check with type HR

• Uniformly expose the largest available HR cassette, e.g. 24 x 30 cm, with a dosage of about 3.6 mR

(31.32 µGy) at about 80 kV (about 2mAs, small focus, free exposure technique).

• Use a large SID (min. 1800 mm).

• Do not use any filters.

• Open the shutters of the collimator completely. The chest wall side of a mammo cassette points at

the cathode of the tube. The green marker of a standard cassette 18 x 24 cm points at the anode

of the tube.

• Check the dosage with a dosimeter and write down the measured value and the time.

Now you have 10 minutes until the IP must be read out.

• Register (barcode) the IP under the examination SERVICE/ TEST and the view SENSITIVITY.

• Be sure that this view is programmed to EDR = 1 (semi mode) and MRM code 0900.

• Use post processing code U0000900 (GA=1, GT=A, GC=1.2, GS=0.0, RN=3, RT=F and RE=0.0).

Alternatively the examination SERVICE/ TEST/ Semi Mode/ AVE 4.0 with the MRM code 090E

can be used. The MRM code 090E with L = 4 will produce an image with a more homogeneous

gray level and lower tolerances respectively.

• 10 ... 11 minutes after the exposure has been made, enter the cassette into the Reader.

• For the result look at the image console:

For a dose value of 3.6 mR (31.32 µGy)

S value: 84 ... 120 ... 156 S= Sdisplayed x dosemeasured[mR] /3.6

Pixel value 1850 ... 2050 ... 2250 (12 bit, 0=white)

PVraw:

• If there are greater deviations, perform the sensitivity and shading correction.

12.3 Sensitivity check with type HR-BD

• Take the largest available size of the mammo

cassettes, e.g. 24 x 30 cm.

• Make sure the IP is aligned at the following

edges of the cassette.

• Make an exposure to measure the dosage with a dosimeter.

Exposure condition: 25 KV, 20 mR, Mo/Mo anode and filter (about 5.60 mAs, cassette in slot)

• Check the dosage with a dosimeter (20 mR = 174 µGy) at the points shown in the picture and write

down the measured dose value.

4512 988 05313 REV AA CSIP Level 0 37

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Shading/sensitivity adjustment for standard type ST and ST-BD Sensitivity and shading adjustment

• Make the reference exposure for the sensitivity check with an erased cassette using the same expo-

sure conditions.

• Wait 10 ... 11 minutes before inserting the cassette in the Reader.

• Select examination: SERVICE/ TEST and the view Sens high matrix.

• Set this view to EDR = 1 (semi mode) and MRM code 0900 and high matrix.

• For the result look at the image console:

S value: 84 ... 120 ... 156 S= Sdisplayed x dosemeasured[mR] /20

Pixel value PVraw: 2130 ... 2240 ... 2350 valid for PCR Eleva (12 bit, 0=white)

ROI of 18x24 cm IP: ≈ 120 ... 165 mm from the start line opposite to the chest wall side.

ROI of 24x30 cm IP: ≈ 150 ... 205 mm from the start line opposite to the chest wall side.

• If there are greater deviations, perform the sensitivity and shading correction.

12.4 Shading/sensitivity adjustment for standard type ST

and ST-BD

During this procedure three adjustments are performed automatically:

– Sensitivity

– Shading

– Shading speed for ST including ST- BD and HR

If also ST- BD cassettes are used by the customer, perform the sensitivity and shading adjustment

for these casettes also.

Tip

You can execute the sensitivity adjustment by using a dose in a range of 0.5 to 10 mR. Recom-

mended is a value between 1 and 2 mR.

• Uniformly expose the largest cassette with a dosage of about 1 mR (8.7 µGy) at about 80 kV.

• Use a large SID (min.1800 mm).

• Do not use any filters.

• Open the shutters of the collimator completely. The green label of the cassette points at the anode

of the tube.

38 CSIP Level 0 4512 988 05313 REV AA

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Sensitivity and shading adjustment Sensitivity adjustment for high resolution type HR

• Check the dosage with a dosimeter and write down the measured value and the time.

Now you have 10 minutes until the IP must be read out.

• Register (barcode) the IP under the examination SERVICE/ TEST and the view SENSITIVITY.

• Start the RU PC-Tool in FSF: General Functions ➜ Utilities ➜ Start Maintenance Utility for

PCR Reader (PC-MUTL).

• Select the Reader to be adjusted.

• Select MUTL.

• Close the message window 'Maintenance in progress...' at the Reader by touching the upper left and

right corner of the display if necessary.

• Select For Design/Scanner/Scanner Sensitivity Data and write down the following values:

– Sensitivity HV value/ One Side ST: ................. e.g. 508 for ST only

– Sensitivity HV Value/ Both Sides ST (Front Side): ................. e.g. 566 for ST- BD only

– Sensitivity HV Value/ Both Sides ST (Back Side): ................. e.g. 682 for ST- BD only

• Leave this screen with [CANCEL].

• Select Scanner Check/Correction.

• In Shading/Sensitivity Correction enter the measured dose in [mR], e.g. 1.05, and click [SET]

and [OK].

• 10 minutes after the IP has been exposed put the cassette into the Reader.

• Check for 'Result-OK' in the window of RU PC-Tool.

• Select For Design/Scanner/Scanner Sensitivity Data and write down the new HV value:

– Sensitivity HV value/ One Side ST: ................. for ST only

– Sensitivity HV Value/ Both Sides ST (Front Side): ................. for ST- BD only

– Sensitivity HV Value/ Both Sides ST (Back Side): ................. for ST- BD only

• Leave the RU PC-Tool.

• Repeat the sensitivity check. The S value must be in the range 180 ... 200 ... 220.

• Make a backup of the scanner data (all).

12.5 Sensitivity adjustment for high resolution type HR

• Uniformly expose the largest available HR cassette, e.g. 24 x 30 cm, with a dosage of about 3.6 mR

(31,32 µGy) at about 80 kV.

• Use a large SID (min. 1800 mm).

• Do not use any filters.

• Open the shutters of the collimator completely. The chest wall side of a mammo cassette points at

the cathode of the tube. The green marker of the applicable standard cassette 18 x 24 cm points

at the anode of the tube.

• Check the dosage with a dosimeter and write down the measured value and the time.

Now you have 10 minutes until the IP must be read out.

• Register (barcode) the IP under the examination SERVICE/ TEST and the view SENSITIVITY.

• Start the RU PC-Tool in FSF: General Functions ➜ Utilities ➜ Start Maintenance Utility for

PCR Reader (PC-MUTL).

• Select the Reader to be adjusted.

• Select MUTL.

• Close the message window 'Maintenance in progress...' at the Reader by touching the upper left and

right corner of the display if necessary.

• Select For Design/Scanner/Scanner Sensitivity Data and write down the following value:

– Sensitivity HV value/ One Side HR: .......................e.g. 491

• Leave this screen with CANCEL.

4512 988 05313 REV AA CSIP Level 0 39

ATTENTION: This page contains copyrighted materials that are confidential and/or proprietary.

Any release or distribution of this material, without permission, is a violation of law.

© 2013 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Sensitivity adjustment for high resolution type HR-BD Sensitivity and shading adjustment

• Select Scanner Check/Correction/Special Sensitivity Correction.

• Select via the X-ray Tube Selection the Tungsten tube.

• In Sensitivity Correction enter the measured dose in [mR], e.g. 3.75, and click [SET] and [OK].

• 10 minutes after the IP has been exposed put the cassette into the Reader.

• Check for 'Result-OK' in the window of RU PC-TOOL.

• Select For Design/ Scanner/ Scanner Sensitivity Data and write down the new HV value:

– Sensitivity HV value/ One Side HR: .......................

• Leave the RU PC-Tool.

• Repeat the sensitivity check. The S value must be in the range 108 ... 120 ... 132.

• Make a backup of the scanner data (all).

12.6 Sensitivity adjustment for high resolution type HR-

BD

• Expose the largest available size of the mammo cassettes, e.g. 24 x 30 cm.

• Exposure condition: 25 KV, 20 mR (174 µGy), Molybdenum anode and filter (about 5.60 mAs,

cassette in slot).

• Now you have 10 minutes for the next steps until the IP has to be read out.

• Write down the following values:

Measured dose: .................. mR , Time: ......... : ..........

• Register (barcode) the IP under the examination SERVICE/ TEST and the view SENSITIVITY.

• Set this view to EDR = 1 (semi mode) and MRM code 0900 and high matrix.

• For PCR Eleva: Create/ select the view Sens high matrix.

• Start the RU PC-Tool in FSF: General Functions ➜ Utilities ➜ Start Maintenance Utility for

PCR Reader (PC-MUTL).

• Select the Reader to be adjusted.

• Select MUTL.