Professional Documents

Culture Documents

Is 1865 - 2

Is 1865 - 2

Uploaded by

Svapnesh ParikhCopyright:

Available Formats

You might also like

- Wacker RT820Document204 pagesWacker RT820Luiggii BanyaiNo ratings yet

- BS en 818-6Document16 pagesBS en 818-6Wantana RattaneeNo ratings yet

- Is2062 E350Document12 pagesIs2062 E350Sowmen ChakrobortyNo ratings yet

- Is 513 PDFDocument13 pagesIs 513 PDFManeesh Bangale100% (5)

- Is 513 2016Document16 pagesIs 513 2016santosh kumar50% (14)

- SAE J434 1986 Automotive Ductile Iron Castings Nodular Iron CastingsDocument10 pagesSAE J434 1986 Automotive Ductile Iron Castings Nodular Iron Castingsvinicius_bacellarNo ratings yet

- GBTDocument16 pagesGBTTatumi SobueNo ratings yet

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocument29 pagesInsulation Resistance (IR) Values - Electrical Notes & ArticlesNikhil Chakravarthy Vatsavayi100% (1)

- BS 5834 - 2Document17 pagesBS 5834 - 2PD AWSSIESPNo ratings yet

- Is 1865Document13 pagesIs 1865RAKESH SRIVASTAVANo ratings yet

- 1865Document13 pages1865rskcadNo ratings yet

- Iron Castings With Spheroidal or Nodular Graphite - Specification (Document13 pagesIron Castings With Spheroidal or Nodular Graphite - Specification (Lipika GayenNo ratings yet

- Is 1865 1991Document16 pagesIs 1865 1991kumarkk1969No ratings yet

- Is 1865 - 3Document1 pageIs 1865 - 3Svapnesh ParikhNo ratings yet

- 1-277 Fixed.Document10 pages1-277 Fixed.Duong Phuong DuyNo ratings yet

- 7Ltwmkm - M: !V7T&TmDocument13 pages7Ltwmkm - M: !V7T&TmAshutosh RawatNo ratings yet

- Is - 9595Document55 pagesIs - 9595sanjeet_sengar100% (3)

- IS 7904 - Standard For High Carbon SteelDocument7 pagesIS 7904 - Standard For High Carbon Steelsarang.vishnuNo ratings yet

- Is 1285 PDFDocument11 pagesIs 1285 PDFswaroop87No ratings yet

- Steel wire rod for bridge cable wire 桥梁缆索钢丝用盘条: (English Translation)Document9 pagesSteel wire rod for bridge cable wire 桥梁缆索钢丝用盘条: (English Translation)Mada TetoNo ratings yet

- Is 210 PDFDocument13 pagesIs 210 PDFJagdeep DhillonNo ratings yet

- Guide To Structural Steel Selection - G-SpecificationsDocument56 pagesGuide To Structural Steel Selection - G-SpecificationsFelix RanillaNo ratings yet

- WWFMM-M: @imfrhDocument9 pagesWWFMM-M: @imfrhShreenivas ThakurNo ratings yet

- Is 1079 98Document12 pagesIs 1079 98Rakesh SrivastavaNo ratings yet

- 277 - Galvanised Steel SheetsDocument10 pages277 - Galvanised Steel SheetsKaushik SenguptaNo ratings yet

- I S 617 - 1994Document15 pagesI S 617 - 1994Muthusamy ArumugamNo ratings yet

- 2831 PDFDocument9 pages2831 PDFAlpha Test HouseNo ratings yet

- High Strength Low Alloy Structural SteelsDocument16 pagesHigh Strength Low Alloy Structural SteelsTuan DangNo ratings yet

- IS 2062 Hot Rolled Steel Specs.Document13 pagesIS 2062 Hot Rolled Steel Specs.Yasir Abbas100% (1)

- Austempered Ductile Iron Castings: Standard Specification ForDocument8 pagesAustempered Ductile Iron Castings: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- Is 2062 StandardDocument3 pagesIs 2062 StandardsatyaprakashgondNo ratings yet

- A 897 - A 897M - 03 Qtg5ny9bodk3tq - PDFDocument8 pagesA 897 - A 897M - 03 Qtg5ny9bodk3tq - PDFMung Duong XuanNo ratings yet

- IS:2002Document14 pagesIS:2002Madhavi YerurNo ratings yet

- Kineski Limovi Q PDFDocument10 pagesKineski Limovi Q PDFssteticNo ratings yet

- gb713-2008-ケッコヘムケチヲネンニテクヨー・steel plates for boilers and pressure vessels-en-ネォホトDocument13 pagesgb713-2008-ケッコヘムケチヲネンニテクヨー・steel plates for boilers and pressure vessels-en-ネォホトNguyễn Thanh TùngNo ratings yet

- Is1079 2017Document10 pagesIs1079 2017qualityNo ratings yet

- Carbon Structural Steels: National Standard of The People'S Republic of ChinaDocument8 pagesCarbon Structural Steels: National Standard of The People'S Republic of ChinaNicolás GuerreroNo ratings yet

- GB T700-2006Carbonstructuralsteels (英文版)Document11 pagesGB T700-2006Carbonstructuralsteels (英文版)yong liNo ratings yet

- High-Silicon Molybdenum Ferritic Iron Castings: Standard Specification ForDocument7 pagesHigh-Silicon Molybdenum Ferritic Iron Castings: Standard Specification Formohammed karasnehNo ratings yet

- Carbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)Document12 pagesCarbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)SreenathaNo ratings yet

- Astm A36Document4 pagesAstm A36jemorpeNo ratings yet

- Vrir Y?Kqñr Dkczu Blikr DH PKNJ, Oa Iùkh: HKKJRH EkudDocument17 pagesVrir Y?Kqñr Dkczu Blikr DH PKNJ, Oa Iùkh: HKKJRH Ekudsunil kumar sharmaNo ratings yet

- Hot Rolled Low, Medium and High Tensile Structural Steel: TR7wr)Document11 pagesHot Rolled Low, Medium and High Tensile Structural Steel: TR7wr)jbharghavNo ratings yet

- GB1499.2 2007Document5 pagesGB1499.2 2007lwin_oo243567% (3)

- GB T 700-2006-Carbon Structural Steels-En&CNDocument22 pagesGB T 700-2006-Carbon Structural Steels-En&CNNespak P&M100% (1)

- Is 12791 1989 - High Carbon-Chromium Bearing SteelDocument10 pagesIs 12791 1989 - High Carbon-Chromium Bearing SteelVismay kumar. NNo ratings yet

- Astm A351Document5 pagesAstm A351pepelefuuNo ratings yet

- 2062Document17 pages2062hswed91100% (1)

- Surface Vehicle Recommended Practice: Rev. FEB2001Document10 pagesSurface Vehicle Recommended Practice: Rev. FEB2001san moedanoNo ratings yet

- Grey Iron Castings - Specification: Indian StandardDocument1 pageGrey Iron Castings - Specification: Indian StandardSvapneshNo ratings yet

- 1285Document11 pages1285Kaushik SenguptaNo ratings yet

- Vrir Y?Kqñr Dkczu Blikr DH PKNJ, Oa Iùkh: HKKJRH EkudDocument14 pagesVrir Y?Kqñr Dkczu Blikr DH PKNJ, Oa Iùkh: HKKJRH Ekudsunil kumar sharmaNo ratings yet

- (RFRQR) : 4fu,#,ff, O,,ffi##umDocument10 pages(RFRQR) : 4fu,#,ff, O,,ffi##umradhakrishnaNo ratings yet

- Astm A351Document5 pagesAstm A351Srinivasan KrishnamoorthyNo ratings yet

- VF+ST - M: Acaimmm MigqDocument12 pagesVF+ST - M: Acaimmm MigqJainco Transmission LimitedNo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- Proceedings of the 8th International Symposium on Superalloy 718 and DerivativesFrom EverandProceedings of the 8th International Symposium on Superalloy 718 and DerivativesNo ratings yet

- Ultra-High Temperature Ceramics: Materials for Extreme Environment ApplicationsFrom EverandUltra-High Temperature Ceramics: Materials for Extreme Environment ApplicationsWilliam G. FahrenholtzNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- High Temperature Ceramic Matrix Composites 8From EverandHigh Temperature Ceramic Matrix Composites 8Litong ZhangNo ratings yet

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- Is 12308-8 - 1997 - 5Document1 pageIs 12308-8 - 1997 - 5Svapnesh ParikhNo ratings yet

- Is 12308-7 - 1991 - 5Document1 pageIs 12308-7 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 12308-9 - 1993 - 1Document1 pageIs 12308-9 - 1993 - 1Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 3Document1 pageIs 12308-5 - 1991 - 3Svapnesh ParikhNo ratings yet

- Is 12308-7 - 1991 - 3Document1 pageIs 12308-7 - 1991 - 3Svapnesh ParikhNo ratings yet

- Is 12308-6 - 1991 - 4Document1 pageIs 12308-6 - 1991 - 4Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 5Document1 pageIs 12308-5 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 1Document1 pageIs 12308-5 - 1991 - 1Svapnesh ParikhNo ratings yet

- Is 12308-8 - 1997 - 3Document1 pageIs 12308-8 - 1997 - 3Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 1Document1 pageIs 8422-3 - 1977 - 1Svapnesh ParikhNo ratings yet

- Is 12308-4 - 1988 - 4Document1 pageIs 12308-4 - 1988 - 4Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 14Document1 pageIs 10719 (Iso 1302) - 14Svapnesh ParikhNo ratings yet

- Is 12308-6 - 1991 - 5Document1 pageIs 12308-6 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 11166 - 1993 - 10Document1 pageIs 11166 - 1993 - 10Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 5Document1 pageIs 10719 (Iso 1302) - 5Svapnesh ParikhNo ratings yet

- Is 8422-8 - 1977 - 5Document1 pageIs 8422-8 - 1977 - 5Svapnesh ParikhNo ratings yet

- Is 12308-3 - 1987 - 1Document1 pageIs 12308-3 - 1987 - 1Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 11Document1 pageIs 10719 (Iso 1302) - 11Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 12Document1 pageIs 10719 (Iso 1302) - 12Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 1Document1 pageIs 10719 (Iso 1302) - 1Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 4Document1 pageIs 10719 (Iso 1302) - 4Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 8Document1 pageIs 10719 (Iso 1302) - 8Svapnesh ParikhNo ratings yet

- Is 8422-6 - 1977 - 4Document1 pageIs 8422-6 - 1977 - 4Svapnesh ParikhNo ratings yet

- Is 8422-8 - 1977 - 2Document1 pageIs 8422-8 - 1977 - 2Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 2Document1 pageIs 8422-3 - 1977 - 2Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 3Document1 pageIs 8422-3 - 1977 - 3Svapnesh ParikhNo ratings yet

- Is 8422-2 - 1977 - 3Document1 pageIs 8422-2 - 1977 - 3Svapnesh ParikhNo ratings yet

- Is 8422-1 - 1977 - 5Document1 pageIs 8422-1 - 1977 - 5Svapnesh ParikhNo ratings yet

- Is 8422-2 - 1977 - 6Document1 pageIs 8422-2 - 1977 - 6Svapnesh ParikhNo ratings yet

- Is 8422-1 - 1977 - 2Document1 pageIs 8422-1 - 1977 - 2Svapnesh ParikhNo ratings yet

- Hoffman JB Corrosion 4Document4 pagesHoffman JB Corrosion 4HJNo ratings yet

- Quantum With Unity Pro: 141 MMS 425 01, 141 MMS 535 02 SERCOS Multi-Axis Motion Controller User ManualDocument36 pagesQuantum With Unity Pro: 141 MMS 425 01, 141 MMS 535 02 SERCOS Multi-Axis Motion Controller User Manualrmorenodx4587No ratings yet

- Global MEPS Guide For Low Voltage Motors 50060049 Brochure EnglishDocument12 pagesGlobal MEPS Guide For Low Voltage Motors 50060049 Brochure Englishmiha sredNo ratings yet

- Caas - Aip - Enr (Radio Failure)Document10 pagesCaas - Aip - Enr (Radio Failure)Timoteo XieNo ratings yet

- Catalogo Drive One 161110 PDFDocument174 pagesCatalogo Drive One 161110 PDFIdiLab EmprendimientoNo ratings yet

- VideoJet X10/20/40 Video EncoderDocument6 pagesVideoJet X10/20/40 Video EncodervsuneelgNo ratings yet

- Psu LS1502049-18Document10 pagesPsu LS1502049-18Ciobanusorinflorin SorinNo ratings yet

- A. Instructions For Filling Up The Application FormDocument5 pagesA. Instructions For Filling Up The Application Formsandeep sNo ratings yet

- Psu650 Manual en BmsDocument8 pagesPsu650 Manual en Bmsمصطفى المسلمNo ratings yet

- User Manual: DTSU666-H 100 A and 250 A Smart Power SensorDocument27 pagesUser Manual: DTSU666-H 100 A and 250 A Smart Power SensorAitor LarrenNo ratings yet

- Historical at Experience Time Studies Predetermined Time Standards Work SamplingDocument2 pagesHistorical at Experience Time Studies Predetermined Time Standards Work Samplingmj alfred007No ratings yet

- Weldspec ASME PQRDocument2 pagesWeldspec ASME PQRSunil KumarNo ratings yet

- The Philippine Grid CodeDocument4 pagesThe Philippine Grid CodeAldrin cj SorianoNo ratings yet

- FAA Cape Wind - Determination of No Hazard To Air NavigationDocument9 pagesFAA Cape Wind - Determination of No Hazard To Air NavigationztowerNo ratings yet

- Section 1.1: Configure The ACME Headquarters Network (AS 12345) As Per The Following RequirementsDocument59 pagesSection 1.1: Configure The ACME Headquarters Network (AS 12345) As Per The Following Requirementsdimkatsar30No ratings yet

- Alv Tree DockingDocument8 pagesAlv Tree DockingRicky DasNo ratings yet

- Ecoserial3 - Modbus - Protocol - Eng - Ver3 - 11 - BOLDROCCHI - ITALY BFDocument32 pagesEcoserial3 - Modbus - Protocol - Eng - Ver3 - 11 - BOLDROCCHI - ITALY BFSamsung.galaxy.core DousNo ratings yet

- PTP 24100 Full - High Power: Specifications Sheet Motorola CanopyDocument1 pagePTP 24100 Full - High Power: Specifications Sheet Motorola CanopyperuingenierosNo ratings yet

- Engineering Terms 2Document4 pagesEngineering Terms 2Jigar M. UpadhyayNo ratings yet

- Hsse Competence AssurancechecklistDocument3 pagesHsse Competence Assurancechecklistzam110No ratings yet

- M7 Axa RTV2Document16 pagesM7 Axa RTV2younesNo ratings yet

- TM-81 Condenser Cleaner 5125Document6 pagesTM-81 Condenser Cleaner 5125gshdavidNo ratings yet

- Operating Manual: Air Band TransceiverDocument60 pagesOperating Manual: Air Band TransceiverDaniel GoodNo ratings yet

- 4HP16Document241 pages4HP16Anonymous LaDv2vy100% (4)

- A Meta Analytical Study On Leadership in PDFDocument24 pagesA Meta Analytical Study On Leadership in PDFalamtareqNo ratings yet

Is 1865 - 2

Is 1865 - 2

Uploaded by

Svapnesh ParikhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is 1865 - 2

Is 1865 - 2

Uploaded by

Svapnesh ParikhCopyright:

Available Formats

Pig Iron and Cast Iron.

Sectional Committee, MTD 6

FOREWORD

This Indian Standard ( Third Revision j was adopted by the Bureau of Indian Standards, after the draft

finalized by the Pig Iron and Cast Iron Sectional Committee had been approved by the Metallurgical

Engineering Division Council.

This standard was first published in 1961 and subsequently revised in 1968 and 1974. In this third

revision, the following major changes have been incorporated:

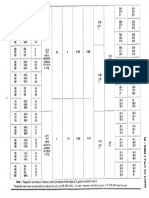

a) The classification of cpheroidal or nodular graphite cast irons has been made based on the mecha-

nical properties of the material measured on the test pieces prepared from separately-cast test

samples, and on the test pieces prepared from cast-on test samples;

b) Classification made on the basis of hardness has also been included if hardness is recognised by ~

the purchaser and the manufacturer as being essential for the application such as in automobile

industry;

cl The provisions of the standard have generally been aligned with the ISO/ : 1987 ‘Spheroidal

graphite cast iron - Classification’ issued by International Organization for Standardization.

4 For the classification as a function of mechanical properties measured on separately-cast test

samples, one new Grade SG 900/2 has been included; and

4 The two existing grades namely SG 400/12 and SG 370117 have been replaced by SG 450/10 and

SG 400/15 and SG 400/18 & SG 350/22 respectively. The grades SO 400/l 8 and 350122 are

meant for applications involving high impact loads and/or subzero service temperatures. Impact

values for these two grades have been stipulated at ambient as well as at subzero temperatures.

Spheroidal or nodular graphite cast iron or ductile iron is a casting alloy of iron and carbon, carbon

being present in the spheroidal form.

The properties of spheroidal graphite cast iron depend, particularly, on a form ( shape and size ) of

the graphite and the structure of the matrix which can be chariged or altered by suitable heat treatment.

Graphite flakes in cast iron act as discontinuities in the matrix and thus lower its mechanical proper-

ties. The sharp corners of the flakes also act as stress raisers. The weakening effect of the graphite

can be overcome by changing its form from a flake to a spheroidal form.

For the purpose of deciding whether a particular requirement of this standard is complied with, the

final value, observed or calculated, expressing the result of a test or analysis, shall be rounded off in

accordance with LS 2 : 1960 ‘Rules for rounding off numerical values ( revised )‘. The number of

significant places retained in the rounded off value should be the same as that of the specified value

in this standard.

You might also like

- Wacker RT820Document204 pagesWacker RT820Luiggii BanyaiNo ratings yet

- BS en 818-6Document16 pagesBS en 818-6Wantana RattaneeNo ratings yet

- Is2062 E350Document12 pagesIs2062 E350Sowmen ChakrobortyNo ratings yet

- Is 513 PDFDocument13 pagesIs 513 PDFManeesh Bangale100% (5)

- Is 513 2016Document16 pagesIs 513 2016santosh kumar50% (14)

- SAE J434 1986 Automotive Ductile Iron Castings Nodular Iron CastingsDocument10 pagesSAE J434 1986 Automotive Ductile Iron Castings Nodular Iron Castingsvinicius_bacellarNo ratings yet

- GBTDocument16 pagesGBTTatumi SobueNo ratings yet

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocument29 pagesInsulation Resistance (IR) Values - Electrical Notes & ArticlesNikhil Chakravarthy Vatsavayi100% (1)

- BS 5834 - 2Document17 pagesBS 5834 - 2PD AWSSIESPNo ratings yet

- Is 1865Document13 pagesIs 1865RAKESH SRIVASTAVANo ratings yet

- 1865Document13 pages1865rskcadNo ratings yet

- Iron Castings With Spheroidal or Nodular Graphite - Specification (Document13 pagesIron Castings With Spheroidal or Nodular Graphite - Specification (Lipika GayenNo ratings yet

- Is 1865 1991Document16 pagesIs 1865 1991kumarkk1969No ratings yet

- Is 1865 - 3Document1 pageIs 1865 - 3Svapnesh ParikhNo ratings yet

- 1-277 Fixed.Document10 pages1-277 Fixed.Duong Phuong DuyNo ratings yet

- 7Ltwmkm - M: !V7T&TmDocument13 pages7Ltwmkm - M: !V7T&TmAshutosh RawatNo ratings yet

- Is - 9595Document55 pagesIs - 9595sanjeet_sengar100% (3)

- IS 7904 - Standard For High Carbon SteelDocument7 pagesIS 7904 - Standard For High Carbon Steelsarang.vishnuNo ratings yet

- Is 1285 PDFDocument11 pagesIs 1285 PDFswaroop87No ratings yet

- Steel wire rod for bridge cable wire 桥梁缆索钢丝用盘条: (English Translation)Document9 pagesSteel wire rod for bridge cable wire 桥梁缆索钢丝用盘条: (English Translation)Mada TetoNo ratings yet

- Is 210 PDFDocument13 pagesIs 210 PDFJagdeep DhillonNo ratings yet

- Guide To Structural Steel Selection - G-SpecificationsDocument56 pagesGuide To Structural Steel Selection - G-SpecificationsFelix RanillaNo ratings yet

- WWFMM-M: @imfrhDocument9 pagesWWFMM-M: @imfrhShreenivas ThakurNo ratings yet

- Is 1079 98Document12 pagesIs 1079 98Rakesh SrivastavaNo ratings yet

- 277 - Galvanised Steel SheetsDocument10 pages277 - Galvanised Steel SheetsKaushik SenguptaNo ratings yet

- I S 617 - 1994Document15 pagesI S 617 - 1994Muthusamy ArumugamNo ratings yet

- 2831 PDFDocument9 pages2831 PDFAlpha Test HouseNo ratings yet

- High Strength Low Alloy Structural SteelsDocument16 pagesHigh Strength Low Alloy Structural SteelsTuan DangNo ratings yet

- IS 2062 Hot Rolled Steel Specs.Document13 pagesIS 2062 Hot Rolled Steel Specs.Yasir Abbas100% (1)

- Austempered Ductile Iron Castings: Standard Specification ForDocument8 pagesAustempered Ductile Iron Castings: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- Is 2062 StandardDocument3 pagesIs 2062 StandardsatyaprakashgondNo ratings yet

- A 897 - A 897M - 03 Qtg5ny9bodk3tq - PDFDocument8 pagesA 897 - A 897M - 03 Qtg5ny9bodk3tq - PDFMung Duong XuanNo ratings yet

- IS:2002Document14 pagesIS:2002Madhavi YerurNo ratings yet

- Kineski Limovi Q PDFDocument10 pagesKineski Limovi Q PDFssteticNo ratings yet

- gb713-2008-ケッコヘムケチヲネンニテクヨー・steel plates for boilers and pressure vessels-en-ネォホトDocument13 pagesgb713-2008-ケッコヘムケチヲネンニテクヨー・steel plates for boilers and pressure vessels-en-ネォホトNguyễn Thanh TùngNo ratings yet

- Is1079 2017Document10 pagesIs1079 2017qualityNo ratings yet

- Carbon Structural Steels: National Standard of The People'S Republic of ChinaDocument8 pagesCarbon Structural Steels: National Standard of The People'S Republic of ChinaNicolás GuerreroNo ratings yet

- GB T700-2006Carbonstructuralsteels (英文版)Document11 pagesGB T700-2006Carbonstructuralsteels (英文版)yong liNo ratings yet

- High-Silicon Molybdenum Ferritic Iron Castings: Standard Specification ForDocument7 pagesHigh-Silicon Molybdenum Ferritic Iron Castings: Standard Specification Formohammed karasnehNo ratings yet

- Carbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)Document12 pagesCarbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)SreenathaNo ratings yet

- Astm A36Document4 pagesAstm A36jemorpeNo ratings yet

- Vrir Y?Kqñr Dkczu Blikr DH PKNJ, Oa Iùkh: HKKJRH EkudDocument17 pagesVrir Y?Kqñr Dkczu Blikr DH PKNJ, Oa Iùkh: HKKJRH Ekudsunil kumar sharmaNo ratings yet

- Hot Rolled Low, Medium and High Tensile Structural Steel: TR7wr)Document11 pagesHot Rolled Low, Medium and High Tensile Structural Steel: TR7wr)jbharghavNo ratings yet

- GB1499.2 2007Document5 pagesGB1499.2 2007lwin_oo243567% (3)

- GB T 700-2006-Carbon Structural Steels-En&CNDocument22 pagesGB T 700-2006-Carbon Structural Steels-En&CNNespak P&M100% (1)

- Is 12791 1989 - High Carbon-Chromium Bearing SteelDocument10 pagesIs 12791 1989 - High Carbon-Chromium Bearing SteelVismay kumar. NNo ratings yet

- Astm A351Document5 pagesAstm A351pepelefuuNo ratings yet

- 2062Document17 pages2062hswed91100% (1)

- Surface Vehicle Recommended Practice: Rev. FEB2001Document10 pagesSurface Vehicle Recommended Practice: Rev. FEB2001san moedanoNo ratings yet

- Grey Iron Castings - Specification: Indian StandardDocument1 pageGrey Iron Castings - Specification: Indian StandardSvapneshNo ratings yet

- 1285Document11 pages1285Kaushik SenguptaNo ratings yet

- Vrir Y?Kqñr Dkczu Blikr DH PKNJ, Oa Iùkh: HKKJRH EkudDocument14 pagesVrir Y?Kqñr Dkczu Blikr DH PKNJ, Oa Iùkh: HKKJRH Ekudsunil kumar sharmaNo ratings yet

- (RFRQR) : 4fu,#,ff, O,,ffi##umDocument10 pages(RFRQR) : 4fu,#,ff, O,,ffi##umradhakrishnaNo ratings yet

- Astm A351Document5 pagesAstm A351Srinivasan KrishnamoorthyNo ratings yet

- VF+ST - M: Acaimmm MigqDocument12 pagesVF+ST - M: Acaimmm MigqJainco Transmission LimitedNo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- Proceedings of the 8th International Symposium on Superalloy 718 and DerivativesFrom EverandProceedings of the 8th International Symposium on Superalloy 718 and DerivativesNo ratings yet

- Ultra-High Temperature Ceramics: Materials for Extreme Environment ApplicationsFrom EverandUltra-High Temperature Ceramics: Materials for Extreme Environment ApplicationsWilliam G. FahrenholtzNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- High Temperature Ceramic Matrix Composites 8From EverandHigh Temperature Ceramic Matrix Composites 8Litong ZhangNo ratings yet

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- Is 12308-8 - 1997 - 5Document1 pageIs 12308-8 - 1997 - 5Svapnesh ParikhNo ratings yet

- Is 12308-7 - 1991 - 5Document1 pageIs 12308-7 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 12308-9 - 1993 - 1Document1 pageIs 12308-9 - 1993 - 1Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 3Document1 pageIs 12308-5 - 1991 - 3Svapnesh ParikhNo ratings yet

- Is 12308-7 - 1991 - 3Document1 pageIs 12308-7 - 1991 - 3Svapnesh ParikhNo ratings yet

- Is 12308-6 - 1991 - 4Document1 pageIs 12308-6 - 1991 - 4Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 5Document1 pageIs 12308-5 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 1Document1 pageIs 12308-5 - 1991 - 1Svapnesh ParikhNo ratings yet

- Is 12308-8 - 1997 - 3Document1 pageIs 12308-8 - 1997 - 3Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 1Document1 pageIs 8422-3 - 1977 - 1Svapnesh ParikhNo ratings yet

- Is 12308-4 - 1988 - 4Document1 pageIs 12308-4 - 1988 - 4Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 14Document1 pageIs 10719 (Iso 1302) - 14Svapnesh ParikhNo ratings yet

- Is 12308-6 - 1991 - 5Document1 pageIs 12308-6 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 11166 - 1993 - 10Document1 pageIs 11166 - 1993 - 10Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 5Document1 pageIs 10719 (Iso 1302) - 5Svapnesh ParikhNo ratings yet

- Is 8422-8 - 1977 - 5Document1 pageIs 8422-8 - 1977 - 5Svapnesh ParikhNo ratings yet

- Is 12308-3 - 1987 - 1Document1 pageIs 12308-3 - 1987 - 1Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 11Document1 pageIs 10719 (Iso 1302) - 11Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 12Document1 pageIs 10719 (Iso 1302) - 12Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 1Document1 pageIs 10719 (Iso 1302) - 1Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 4Document1 pageIs 10719 (Iso 1302) - 4Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 8Document1 pageIs 10719 (Iso 1302) - 8Svapnesh ParikhNo ratings yet

- Is 8422-6 - 1977 - 4Document1 pageIs 8422-6 - 1977 - 4Svapnesh ParikhNo ratings yet

- Is 8422-8 - 1977 - 2Document1 pageIs 8422-8 - 1977 - 2Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 2Document1 pageIs 8422-3 - 1977 - 2Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 3Document1 pageIs 8422-3 - 1977 - 3Svapnesh ParikhNo ratings yet

- Is 8422-2 - 1977 - 3Document1 pageIs 8422-2 - 1977 - 3Svapnesh ParikhNo ratings yet

- Is 8422-1 - 1977 - 5Document1 pageIs 8422-1 - 1977 - 5Svapnesh ParikhNo ratings yet

- Is 8422-2 - 1977 - 6Document1 pageIs 8422-2 - 1977 - 6Svapnesh ParikhNo ratings yet

- Is 8422-1 - 1977 - 2Document1 pageIs 8422-1 - 1977 - 2Svapnesh ParikhNo ratings yet

- Hoffman JB Corrosion 4Document4 pagesHoffman JB Corrosion 4HJNo ratings yet

- Quantum With Unity Pro: 141 MMS 425 01, 141 MMS 535 02 SERCOS Multi-Axis Motion Controller User ManualDocument36 pagesQuantum With Unity Pro: 141 MMS 425 01, 141 MMS 535 02 SERCOS Multi-Axis Motion Controller User Manualrmorenodx4587No ratings yet

- Global MEPS Guide For Low Voltage Motors 50060049 Brochure EnglishDocument12 pagesGlobal MEPS Guide For Low Voltage Motors 50060049 Brochure Englishmiha sredNo ratings yet

- Caas - Aip - Enr (Radio Failure)Document10 pagesCaas - Aip - Enr (Radio Failure)Timoteo XieNo ratings yet

- Catalogo Drive One 161110 PDFDocument174 pagesCatalogo Drive One 161110 PDFIdiLab EmprendimientoNo ratings yet

- VideoJet X10/20/40 Video EncoderDocument6 pagesVideoJet X10/20/40 Video EncodervsuneelgNo ratings yet

- Psu LS1502049-18Document10 pagesPsu LS1502049-18Ciobanusorinflorin SorinNo ratings yet

- A. Instructions For Filling Up The Application FormDocument5 pagesA. Instructions For Filling Up The Application Formsandeep sNo ratings yet

- Psu650 Manual en BmsDocument8 pagesPsu650 Manual en Bmsمصطفى المسلمNo ratings yet

- User Manual: DTSU666-H 100 A and 250 A Smart Power SensorDocument27 pagesUser Manual: DTSU666-H 100 A and 250 A Smart Power SensorAitor LarrenNo ratings yet

- Historical at Experience Time Studies Predetermined Time Standards Work SamplingDocument2 pagesHistorical at Experience Time Studies Predetermined Time Standards Work Samplingmj alfred007No ratings yet

- Weldspec ASME PQRDocument2 pagesWeldspec ASME PQRSunil KumarNo ratings yet

- The Philippine Grid CodeDocument4 pagesThe Philippine Grid CodeAldrin cj SorianoNo ratings yet

- FAA Cape Wind - Determination of No Hazard To Air NavigationDocument9 pagesFAA Cape Wind - Determination of No Hazard To Air NavigationztowerNo ratings yet

- Section 1.1: Configure The ACME Headquarters Network (AS 12345) As Per The Following RequirementsDocument59 pagesSection 1.1: Configure The ACME Headquarters Network (AS 12345) As Per The Following Requirementsdimkatsar30No ratings yet

- Alv Tree DockingDocument8 pagesAlv Tree DockingRicky DasNo ratings yet

- Ecoserial3 - Modbus - Protocol - Eng - Ver3 - 11 - BOLDROCCHI - ITALY BFDocument32 pagesEcoserial3 - Modbus - Protocol - Eng - Ver3 - 11 - BOLDROCCHI - ITALY BFSamsung.galaxy.core DousNo ratings yet

- PTP 24100 Full - High Power: Specifications Sheet Motorola CanopyDocument1 pagePTP 24100 Full - High Power: Specifications Sheet Motorola CanopyperuingenierosNo ratings yet

- Engineering Terms 2Document4 pagesEngineering Terms 2Jigar M. UpadhyayNo ratings yet

- Hsse Competence AssurancechecklistDocument3 pagesHsse Competence Assurancechecklistzam110No ratings yet

- M7 Axa RTV2Document16 pagesM7 Axa RTV2younesNo ratings yet

- TM-81 Condenser Cleaner 5125Document6 pagesTM-81 Condenser Cleaner 5125gshdavidNo ratings yet

- Operating Manual: Air Band TransceiverDocument60 pagesOperating Manual: Air Band TransceiverDaniel GoodNo ratings yet

- 4HP16Document241 pages4HP16Anonymous LaDv2vy100% (4)

- A Meta Analytical Study On Leadership in PDFDocument24 pagesA Meta Analytical Study On Leadership in PDFalamtareqNo ratings yet