Professional Documents

Culture Documents

Pipe Thickness Calculation

Pipe Thickness Calculation

Uploaded by

HarryCopyright:

Available Formats

You might also like

- Allion Manual Book EnglishDocument324 pagesAllion Manual Book EnglishMun Kit66% (53)

- ItilDocument11 pagesItilNarendar P100% (2)

- Asme B31.3Document69 pagesAsme B31.39440864459100% (4)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Capacitor Bank TestingDocument8 pagesCapacitor Bank TestingIranthaMuthuNo ratings yet

- Pipe Thickness Calculation For Internal PressureDocument12 pagesPipe Thickness Calculation For Internal PressurefsijestNo ratings yet

- Pipe DesignDocument6 pagesPipe DesignmaneeshmsanjagiriNo ratings yet

- Plate CalculationDocument7 pagesPlate CalculationminhthanhmosNo ratings yet

- ASME B31 3 Calculator V2Document11 pagesASME B31 3 Calculator V2gerrydimayuga100% (3)

- Pipe Thickness Calculation PDFDocument1 pagePipe Thickness Calculation PDFHeny Martha67% (3)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Ia Caterpillar Specifications 3304 VehicularEngine TextDocument100 pagesIa Caterpillar Specifications 3304 VehicularEngine Textkatarkivos94% (16)

- 8 Kircher 2015Document40 pages8 Kircher 2015Ahmed Ben HmidaNo ratings yet

- Pipe Thickness Calculation Internal Pressure Design Thickness As Per ASME B313Document7 pagesPipe Thickness Calculation Internal Pressure Design Thickness As Per ASME B313mohamed samy100% (1)

- Pipe Thickness Calculation (Internal Pressure Design Thickness) As Per ASME B31.3Document10 pagesPipe Thickness Calculation (Internal Pressure Design Thickness) As Per ASME B31.3Vinay Sharma100% (1)

- Traduccion ASMEDocument18 pagesTraduccion ASMEraul gonzalezNo ratings yet

- Design & Construction of Piping SystemsDocument115 pagesDesign & Construction of Piping SystemsSuresh Babu100% (13)

- Design of Piping SystemsDocument115 pagesDesign of Piping SystemsDushyant Varshney100% (2)

- Piping Wall Thickness Cal - Ver HT10.2-HTTEK FullDocument47 pagesPiping Wall Thickness Cal - Ver HT10.2-HTTEK Fullthinhvipro100% (1)

- Pipe Thickness Calculations As Per Asme B31.3Document8 pagesPipe Thickness Calculations As Per Asme B31.3JORGE DANIEL MIRANDA SIANCAS100% (2)

- ASME B31.3 CalculationDocument11 pagesASME B31.3 CalculationAnonymous wIPMQ5rhNo ratings yet

- SPREADSHEETS SERIES No. 0009S - 2Document4 pagesSPREADSHEETS SERIES No. 0009S - 2Emma DNo ratings yet

- A Comparitive Study To Find Bend Thickness Calculation Using PASS START ELEMENT TOOLDocument14 pagesA Comparitive Study To Find Bend Thickness Calculation Using PASS START ELEMENT TOOLJafer Sayed100% (1)

- SampleCalculationspipingB3132008 PDFDocument13 pagesSampleCalculationspipingB3132008 PDFsosatlantiqueNo ratings yet

- Pipe Wall Thickness CalculationDocument8 pagesPipe Wall Thickness CalculationRAGHVENDRA PRATAP SINGH0% (1)

- Pipe Thickness Calculator As Per ASME B31.3Document3 pagesPipe Thickness Calculator As Per ASME B31.3anh thoNo ratings yet

- Steel Pipe Design Calculation For SeamlessDocument4 pagesSteel Pipe Design Calculation For SeamlessA SubinNo ratings yet

- Pipe Wall Thickness Calculations As Per ASMEDocument2 pagesPipe Wall Thickness Calculations As Per ASMEErick Rodriguez ArroyoNo ratings yet

- Pipe Thickness & RF Pad Calculations As Per Asme b313Document3 pagesPipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeNo ratings yet

- Sapa Pipe and TubeTechnical Inserts June 2011Document10 pagesSapa Pipe and TubeTechnical Inserts June 2011mekag94No ratings yet

- Piping Thickness Calculation With An ExampleDocument10 pagesPiping Thickness Calculation With An ExampleMahendran KuppusamyNo ratings yet

- ASME B31.5-Refrigeration-PipingDocument11 pagesASME B31.5-Refrigeration-PipingJai100% (2)

- Design of Piping Systems by Tengku SyahdilanDocument115 pagesDesign of Piping Systems by Tengku SyahdilanRagerishcire KanaalaqNo ratings yet

- Pipe Wall Thickness Calculations: Burnex Burner HeadDocument16 pagesPipe Wall Thickness Calculations: Burnex Burner Headpramodptvpm_65797156No ratings yet

- Part-Ii: Chapter - 2. Design of Piping ComponentsDocument4 pagesPart-Ii: Chapter - 2. Design of Piping ComponentsAshish PatelNo ratings yet

- What Is The Difference Between "Required", "Nominal" and "Analysis" Pipe Wall Thickness?Document3 pagesWhat Is The Difference Between "Required", "Nominal" and "Analysis" Pipe Wall Thickness?ÅdnAn MehmOodNo ratings yet

- Sample Calculation ReportDocument9 pagesSample Calculation ReportmikimecNo ratings yet

- Pipeextp-Asme Ug 28Document1 pagePipeextp-Asme Ug 28alvinchuanNo ratings yet

- Case Study To Find Pipe Thickness Calculation Using PASS START ELEMENT TOOLDocument13 pagesCase Study To Find Pipe Thickness Calculation Using PASS START ELEMENT TOOLJafer SayedNo ratings yet

- SPREADSHEETS SERIES No. 0003S - 2Document2 pagesSPREADSHEETS SERIES No. 0003S - 2Emma DNo ratings yet

- 2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Document20 pages2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Sridhar Vijayan100% (3)

- Code Comparison ASME B31.1 Vs B31.3 Vs B31.8Document27 pagesCode Comparison ASME B31.1 Vs B31.3 Vs B31.8khaireddinNo ratings yet

- Inspection Engineer Interview Points Piping: Commonly Used Construction CodesDocument39 pagesInspection Engineer Interview Points Piping: Commonly Used Construction CodesAshat Ul Haq100% (1)

- Pipping FormulaDocument8 pagesPipping Formularajeshsabitha80No ratings yet

- A - Minimum Required Thickness or Pressure Design Thickness ASME B31.3 304.1.1 and 304.1.2Document4 pagesA - Minimum Required Thickness or Pressure Design Thickness ASME B31.3 304.1.1 and 304.1.2edisjdavNo ratings yet

- Asme B31.3 Wall THK Equation - y ValuesDocument1 pageAsme B31.3 Wall THK Equation - y Valuesjoaquin torrano veraNo ratings yet

- API 570 FormulasDocument2 pagesAPI 570 FormulasArif Mokhtar89% (9)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- Theory and Importance of Oxygen Bridge BondingDocument23 pagesTheory and Importance of Oxygen Bridge BondingHarryNo ratings yet

- Acids and Bases BronstedDocument7 pagesAcids and Bases BronstedHarryNo ratings yet

- Water Treatment Catalogue-Shandong JiulongDocument10 pagesWater Treatment Catalogue-Shandong JiulongHarryNo ratings yet

- Procedure 3M Petrifilm (Aerobic Count Plate)Document6 pagesProcedure 3M Petrifilm (Aerobic Count Plate)HarryNo ratings yet

- Marks of ESE 2023 Qualified CandidatesDocument10 pagesMarks of ESE 2023 Qualified Candidatesthunderbuddy2222No ratings yet

- 303-01 - 2.3L EcoBoost - Removal and Installation - Timing ChainDocument7 pages303-01 - 2.3L EcoBoost - Removal and Installation - Timing ChainCARLOS LIMADANo ratings yet

- A Duplex Stainless Steel With PREN 24 SPDocument2 pagesA Duplex Stainless Steel With PREN 24 SPFarhad MalikNo ratings yet

- Kitt AppaDocument90 pagesKitt AppavvvNo ratings yet

- ModularPlants 2016Document36 pagesModularPlants 2016harshad100% (1)

- US1994497 - Indicator - Winters For Gladwin, 1935Document5 pagesUS1994497 - Indicator - Winters For Gladwin, 1935devheadbotNo ratings yet

- Metalense Visible WavelengthDocument6 pagesMetalense Visible WavelengthalvinNo ratings yet

- EternityGE - Quick - Start PDFDocument48 pagesEternityGE - Quick - Start PDFkrishnamarajublrNo ratings yet

- Formula Rio Ey RMDocument3 pagesFormula Rio Ey RMDiego CarrascoNo ratings yet

- Integrity Management With S-RBI: Using The w-IMS ToolDocument28 pagesIntegrity Management With S-RBI: Using The w-IMS ToolHari ShNo ratings yet

- T 19-09 (Bulk Density (Unit Weight) and Voids in Aggregate)Document8 pagesT 19-09 (Bulk Density (Unit Weight) and Voids in Aggregate)tran_lamNo ratings yet

- Column New EC2 LastDocument81 pagesColumn New EC2 LastsuniljayaNo ratings yet

- Ram Concrete AnalysisDocument94 pagesRam Concrete AnalysisTom CurryNo ratings yet

- Thermal Power Stations: Dynamos and Engine Installed at Edison General Electric Company, New York 1895Document1 pageThermal Power Stations: Dynamos and Engine Installed at Edison General Electric Company, New York 1895trusselNo ratings yet

- Design of Column in Limit State MethodDocument7 pagesDesign of Column in Limit State MethodRicardo BermudezNo ratings yet

- Thermodyne Boiler BibleDocument144 pagesThermodyne Boiler BibleRicardas KragnysNo ratings yet

- WSTP 112ME: Metrology and Benchwork: Learning ModuleDocument54 pagesWSTP 112ME: Metrology and Benchwork: Learning ModulesheeellyyyNo ratings yet

- Hassan Ali CV AC TechDocument3 pagesHassan Ali CV AC TechMuhammad Javed BhattiNo ratings yet

- P-Cim WebDocument28 pagesP-Cim WebDamjan BabicNo ratings yet

- Pier 5Document3 pagesPier 5Want ONo ratings yet

- Renr8482-07-01-All-Power Train-SystemDocument108 pagesRenr8482-07-01-All-Power Train-Systemwilly12345120% (1)

- Prog Lang CDocument73 pagesProg Lang Ck l mandalNo ratings yet

- Civ3703 S2 2018 Final PDFDocument13 pagesCiv3703 S2 2018 Final PDFHarsha N SandrinNo ratings yet

- Van PPT WosaDocument8 pagesVan PPT WosavanajaNo ratings yet

- Bi Interview QuestionsDocument33 pagesBi Interview QuestionsRaghu KasturiNo ratings yet

Pipe Thickness Calculation

Pipe Thickness Calculation

Uploaded by

HarryOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Thickness Calculation

Pipe Thickness Calculation

Uploaded by

HarryCopyright:

Available Formats

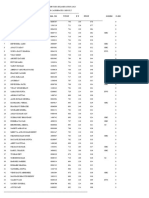

DISCUSSION 2 DATE: 17-09-2022

PIPE THICKNESS CALCULATION AND SELECTION

As per clause 304.1.2 of ASME B 31.3

Minimum required thickness, including mechanical, corrosion, and erosion allowances :

tm = t + c

The minimum thickness, T, for the pipe selected, considering manufacturer’s minus tolerance, shall be

not less than tm.

Following nomenclature is used in the equations for pressure design of straight pipe:

c = sum of the mechanical allowances (thread or groove depth) plus corrosion and erosion allowances.

For threaded components, the nominal thread depth (dimension h of ASME B1.20.1, or equivalent)

shall apply. For machined surfaces or grooves where the tolerance is not specified, the tolerance shall

be assumed to be 0.5 mm (0.02 in.) in addition to the specified depth of the cut.

D = outside diameter of pipe as listed in tables of standards or specifications or as measured

d = inside diameter of pipe. For pressure design calculation, the inside diameter of the pipe is

the maximum value allowable under the purchase specification.

E = quality factor from Table A-1A or Table A-1B

P = internal design gage pressure

S = stress value for material from Table A-1 or TableA-1M

T = pipe wall thickness (measured or minimum in accordance with the purchase specification)

t = pressure design thickness, as calculated in accordance with para. 304.1.2 for internal pressure or

as determined in accordance with para. 304.1.3 for external pressure

tm = minimum required thickness, including mechanical, corrosion, and erosion allowances

Credits1: ASME B31.3 2020 para 304.1.2 , ASME B36.10M

Credits2: Whatispiping.com

W = weld joint strength reduction factor in accordance with para. 302.3.5

Y = coefficient from Table 304.1.1, valid for t < D/6 and for materials shown. The value of Y may be

interpolated for intermediate temperatures. For t≥ D/6,

304.1.2 Straight Pipe Under Internal Pressure

(a) For t < D/6, the internal pressure design thickness for straight pipe shall be not less than that

calculated in accordance with either eq. (3a) or eq. (3b)

(b) For t ≥ D/6 or for P/SE > 0.385, calculation of pressure design thickness for straight pipe requires

special consideration of factors such as theory of failure, effects of fatigue, and thermal stress.

Credits1: ASME B31.3 2020 para 304.1.2 , ASME B36.10M

Credits2: Whatispiping.com

Sample calculation

ASME B36.10M: for ferritic steel (seamless & welded wrought steel pipes

Credits1: ASME B31.3 2020 para 304.1.2 , ASME B36.10M

Credits2: Whatispiping.com

Note:

1. Ordering thickness for seamless pipe will always be the next greater value available from

Schedule to schedule.

2. Whereas for welded pipe any next greater value will be the ordering thickness.

3. Extra thickness can be calculated by ordering thickness minus the required thickness

Use of the Extra thickness available in the pipes

for calculating the life of a pipe after 20 years.

For calculating the maximum pressure holding capacity of the pipe.

For checking extra thickness is sufficient to take care of thinning, if the same pipe is used for

manufacturing the bend.

The extra thickness also minimizes deflection and reduces the number of support.

To compare with flange pressure holding capacity, to declare pipe is stronger than the flange.

Parameters Affecting Pipe Thickness

By now you must have understood all the parameters that affect the pipe thickness. The

parameters are mentioned below for easy understanding

Design Pressure: With an increase in internal design pressure the thickness of a pipe increases.

Design Temperature: With an increase in the design temperature, the allowable stress value

reduces which, in turn, increases the pipe thickness.

Pipe Outer Diameter: With increase in piping OD the pipe thickness corresponding to same

pressure increases.

Assumptions for Pipe Thickness Calculation

For the above-mentioned pipe thickness calculation steps following ASME B31.3, the following

assumptions are made

The pipe is a thin cylinder and the value of thickness t is less than D/6.

The value of P/(SE)<0.385

The pipe is subjected to internal pressure only

Credits1: ASME B31.3 2020 para 304.1.2 , ASME B36.10M

Credits2: Whatispiping.com

You might also like

- Allion Manual Book EnglishDocument324 pagesAllion Manual Book EnglishMun Kit66% (53)

- ItilDocument11 pagesItilNarendar P100% (2)

- Asme B31.3Document69 pagesAsme B31.39440864459100% (4)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Capacitor Bank TestingDocument8 pagesCapacitor Bank TestingIranthaMuthuNo ratings yet

- Pipe Thickness Calculation For Internal PressureDocument12 pagesPipe Thickness Calculation For Internal PressurefsijestNo ratings yet

- Pipe DesignDocument6 pagesPipe DesignmaneeshmsanjagiriNo ratings yet

- Plate CalculationDocument7 pagesPlate CalculationminhthanhmosNo ratings yet

- ASME B31 3 Calculator V2Document11 pagesASME B31 3 Calculator V2gerrydimayuga100% (3)

- Pipe Thickness Calculation PDFDocument1 pagePipe Thickness Calculation PDFHeny Martha67% (3)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Ia Caterpillar Specifications 3304 VehicularEngine TextDocument100 pagesIa Caterpillar Specifications 3304 VehicularEngine Textkatarkivos94% (16)

- 8 Kircher 2015Document40 pages8 Kircher 2015Ahmed Ben HmidaNo ratings yet

- Pipe Thickness Calculation Internal Pressure Design Thickness As Per ASME B313Document7 pagesPipe Thickness Calculation Internal Pressure Design Thickness As Per ASME B313mohamed samy100% (1)

- Pipe Thickness Calculation (Internal Pressure Design Thickness) As Per ASME B31.3Document10 pagesPipe Thickness Calculation (Internal Pressure Design Thickness) As Per ASME B31.3Vinay Sharma100% (1)

- Traduccion ASMEDocument18 pagesTraduccion ASMEraul gonzalezNo ratings yet

- Design & Construction of Piping SystemsDocument115 pagesDesign & Construction of Piping SystemsSuresh Babu100% (13)

- Design of Piping SystemsDocument115 pagesDesign of Piping SystemsDushyant Varshney100% (2)

- Piping Wall Thickness Cal - Ver HT10.2-HTTEK FullDocument47 pagesPiping Wall Thickness Cal - Ver HT10.2-HTTEK Fullthinhvipro100% (1)

- Pipe Thickness Calculations As Per Asme B31.3Document8 pagesPipe Thickness Calculations As Per Asme B31.3JORGE DANIEL MIRANDA SIANCAS100% (2)

- ASME B31.3 CalculationDocument11 pagesASME B31.3 CalculationAnonymous wIPMQ5rhNo ratings yet

- SPREADSHEETS SERIES No. 0009S - 2Document4 pagesSPREADSHEETS SERIES No. 0009S - 2Emma DNo ratings yet

- A Comparitive Study To Find Bend Thickness Calculation Using PASS START ELEMENT TOOLDocument14 pagesA Comparitive Study To Find Bend Thickness Calculation Using PASS START ELEMENT TOOLJafer Sayed100% (1)

- SampleCalculationspipingB3132008 PDFDocument13 pagesSampleCalculationspipingB3132008 PDFsosatlantiqueNo ratings yet

- Pipe Wall Thickness CalculationDocument8 pagesPipe Wall Thickness CalculationRAGHVENDRA PRATAP SINGH0% (1)

- Pipe Thickness Calculator As Per ASME B31.3Document3 pagesPipe Thickness Calculator As Per ASME B31.3anh thoNo ratings yet

- Steel Pipe Design Calculation For SeamlessDocument4 pagesSteel Pipe Design Calculation For SeamlessA SubinNo ratings yet

- Pipe Wall Thickness Calculations As Per ASMEDocument2 pagesPipe Wall Thickness Calculations As Per ASMEErick Rodriguez ArroyoNo ratings yet

- Pipe Thickness & RF Pad Calculations As Per Asme b313Document3 pagesPipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeNo ratings yet

- Sapa Pipe and TubeTechnical Inserts June 2011Document10 pagesSapa Pipe and TubeTechnical Inserts June 2011mekag94No ratings yet

- Piping Thickness Calculation With An ExampleDocument10 pagesPiping Thickness Calculation With An ExampleMahendran KuppusamyNo ratings yet

- ASME B31.5-Refrigeration-PipingDocument11 pagesASME B31.5-Refrigeration-PipingJai100% (2)

- Design of Piping Systems by Tengku SyahdilanDocument115 pagesDesign of Piping Systems by Tengku SyahdilanRagerishcire KanaalaqNo ratings yet

- Pipe Wall Thickness Calculations: Burnex Burner HeadDocument16 pagesPipe Wall Thickness Calculations: Burnex Burner Headpramodptvpm_65797156No ratings yet

- Part-Ii: Chapter - 2. Design of Piping ComponentsDocument4 pagesPart-Ii: Chapter - 2. Design of Piping ComponentsAshish PatelNo ratings yet

- What Is The Difference Between "Required", "Nominal" and "Analysis" Pipe Wall Thickness?Document3 pagesWhat Is The Difference Between "Required", "Nominal" and "Analysis" Pipe Wall Thickness?ÅdnAn MehmOodNo ratings yet

- Sample Calculation ReportDocument9 pagesSample Calculation ReportmikimecNo ratings yet

- Pipeextp-Asme Ug 28Document1 pagePipeextp-Asme Ug 28alvinchuanNo ratings yet

- Case Study To Find Pipe Thickness Calculation Using PASS START ELEMENT TOOLDocument13 pagesCase Study To Find Pipe Thickness Calculation Using PASS START ELEMENT TOOLJafer SayedNo ratings yet

- SPREADSHEETS SERIES No. 0003S - 2Document2 pagesSPREADSHEETS SERIES No. 0003S - 2Emma DNo ratings yet

- 2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Document20 pages2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Sridhar Vijayan100% (3)

- Code Comparison ASME B31.1 Vs B31.3 Vs B31.8Document27 pagesCode Comparison ASME B31.1 Vs B31.3 Vs B31.8khaireddinNo ratings yet

- Inspection Engineer Interview Points Piping: Commonly Used Construction CodesDocument39 pagesInspection Engineer Interview Points Piping: Commonly Used Construction CodesAshat Ul Haq100% (1)

- Pipping FormulaDocument8 pagesPipping Formularajeshsabitha80No ratings yet

- A - Minimum Required Thickness or Pressure Design Thickness ASME B31.3 304.1.1 and 304.1.2Document4 pagesA - Minimum Required Thickness or Pressure Design Thickness ASME B31.3 304.1.1 and 304.1.2edisjdavNo ratings yet

- Asme B31.3 Wall THK Equation - y ValuesDocument1 pageAsme B31.3 Wall THK Equation - y Valuesjoaquin torrano veraNo ratings yet

- API 570 FormulasDocument2 pagesAPI 570 FormulasArif Mokhtar89% (9)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- Theory and Importance of Oxygen Bridge BondingDocument23 pagesTheory and Importance of Oxygen Bridge BondingHarryNo ratings yet

- Acids and Bases BronstedDocument7 pagesAcids and Bases BronstedHarryNo ratings yet

- Water Treatment Catalogue-Shandong JiulongDocument10 pagesWater Treatment Catalogue-Shandong JiulongHarryNo ratings yet

- Procedure 3M Petrifilm (Aerobic Count Plate)Document6 pagesProcedure 3M Petrifilm (Aerobic Count Plate)HarryNo ratings yet

- Marks of ESE 2023 Qualified CandidatesDocument10 pagesMarks of ESE 2023 Qualified Candidatesthunderbuddy2222No ratings yet

- 303-01 - 2.3L EcoBoost - Removal and Installation - Timing ChainDocument7 pages303-01 - 2.3L EcoBoost - Removal and Installation - Timing ChainCARLOS LIMADANo ratings yet

- A Duplex Stainless Steel With PREN 24 SPDocument2 pagesA Duplex Stainless Steel With PREN 24 SPFarhad MalikNo ratings yet

- Kitt AppaDocument90 pagesKitt AppavvvNo ratings yet

- ModularPlants 2016Document36 pagesModularPlants 2016harshad100% (1)

- US1994497 - Indicator - Winters For Gladwin, 1935Document5 pagesUS1994497 - Indicator - Winters For Gladwin, 1935devheadbotNo ratings yet

- Metalense Visible WavelengthDocument6 pagesMetalense Visible WavelengthalvinNo ratings yet

- EternityGE - Quick - Start PDFDocument48 pagesEternityGE - Quick - Start PDFkrishnamarajublrNo ratings yet

- Formula Rio Ey RMDocument3 pagesFormula Rio Ey RMDiego CarrascoNo ratings yet

- Integrity Management With S-RBI: Using The w-IMS ToolDocument28 pagesIntegrity Management With S-RBI: Using The w-IMS ToolHari ShNo ratings yet

- T 19-09 (Bulk Density (Unit Weight) and Voids in Aggregate)Document8 pagesT 19-09 (Bulk Density (Unit Weight) and Voids in Aggregate)tran_lamNo ratings yet

- Column New EC2 LastDocument81 pagesColumn New EC2 LastsuniljayaNo ratings yet

- Ram Concrete AnalysisDocument94 pagesRam Concrete AnalysisTom CurryNo ratings yet

- Thermal Power Stations: Dynamos and Engine Installed at Edison General Electric Company, New York 1895Document1 pageThermal Power Stations: Dynamos and Engine Installed at Edison General Electric Company, New York 1895trusselNo ratings yet

- Design of Column in Limit State MethodDocument7 pagesDesign of Column in Limit State MethodRicardo BermudezNo ratings yet

- Thermodyne Boiler BibleDocument144 pagesThermodyne Boiler BibleRicardas KragnysNo ratings yet

- WSTP 112ME: Metrology and Benchwork: Learning ModuleDocument54 pagesWSTP 112ME: Metrology and Benchwork: Learning ModulesheeellyyyNo ratings yet

- Hassan Ali CV AC TechDocument3 pagesHassan Ali CV AC TechMuhammad Javed BhattiNo ratings yet

- P-Cim WebDocument28 pagesP-Cim WebDamjan BabicNo ratings yet

- Pier 5Document3 pagesPier 5Want ONo ratings yet

- Renr8482-07-01-All-Power Train-SystemDocument108 pagesRenr8482-07-01-All-Power Train-Systemwilly12345120% (1)

- Prog Lang CDocument73 pagesProg Lang Ck l mandalNo ratings yet

- Civ3703 S2 2018 Final PDFDocument13 pagesCiv3703 S2 2018 Final PDFHarsha N SandrinNo ratings yet

- Van PPT WosaDocument8 pagesVan PPT WosavanajaNo ratings yet

- Bi Interview QuestionsDocument33 pagesBi Interview QuestionsRaghu KasturiNo ratings yet