Professional Documents

Culture Documents

P 55 GLR 14

P 55 GLR 14

Uploaded by

richardOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P 55 GLR 14

P 55 GLR 14

Uploaded by

richardCopyright:

Available Formats

DEPARTMENT OF TRANSPORTATION P55GL

FEDERAL AVIATION ADMINISTRATION Revision 14

Hartzell

( )HC-G3Y

TYPE CERTIFICATE DATA SHEET NO. P55GL August 25, 2014

Propellers of models described herein conforming with this data sheet (which is part of Type Certificate No. P55GL) and other

approved data on file with the Federal Aviation Administration meet the minimum standards for use in certificated aircraft in

accordance with pertinent aircraft data sheets and applicable portions of the Federal Aviation Regulations provided they are

installed, operated and maintained as prescribed by the approved manufacturer’s manuals and other approved instructions.

Type Certificate Holder Hartzell Propeller Inc.

Piqua, OH 45356

Type Constant speed; hydraulic (See Notes 3 and 4)

Engine shaft Special flange (See Note 1)

Hub material Aluminum Alloy

Blade material See Below

Number of blades Three

Hub models HC-G3YF-1, -2; EHC-G3YF-1, -2; PHC-G3YF-1, -2; HC-G3YR-4

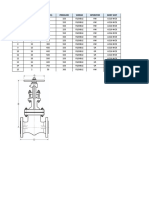

Maximum Diameter Approx. Max. Wt. Complete Blade

Blades Continuous Takeoff Limits (For Reference Only) Construction

(See Note 2) HP RPM HP RPM (See Note 2) (See Notes 3 and 7) (See Note 10)

Non-Counterweighted Propellers HC-G3YF-1, EHC-G3YF-1, PHC-G3YF-1

7392-0 350 2850 350 2850 75” to 65” 73.5 lb. Aluminum Alloy

to 7392-10 (-0 to -10)

7663-0 310 2850 310 2850 78” to 68” 70.0 lb. Aluminum Alloy

to 7663-10 (-0 to -10)

7666-0 310 2700 310 2700 78” to 68” 77.0 lb. Aluminum Alloy

to 7666-10 (-0 to -10)

7691-0 350 2850 350 2850 78” to 68” 68.0 lb. Aluminum Alloy

to 7691-10 (-0 to -10)

7693-0 350 2700 350 2700 78" to 68" 74.0 lb. Aluminum Alloy

to 7693-10 (-0 to -10)

8068+2 350 2700 350 2700 84" to 72" 78.5 lb. Aluminum Alloy

to 8068-10 (+2 to -10)

8068-2 350 2700 310 2850 80" to 72" 78.5 lb. Aluminum Alloy

to 8068-10 (-2 to -10)

8459-0 400 2700 400 2700 86” to 72” 73.0 lb. Aluminum Alloy

to 8459-14 (-0 to -14)

8465-0 400 2700 400 2700 86” to 72” 75.0 lb. Aluminum Alloy

to 8465-14 (-0 to -14)

8467-0 400 2575 400 2575 86” to 72” 79.0 lb. Aluminum Alloy

to 8467-14 (-0 to -14)

8468-0 400 2625 400 2625 86" to 72" 76.0 lb. Aluminum Alloy

to 8468-14 (-0 to -14)

8470-0 400 2700 400 2700 86” to 72” 75.0 lb. Aluminum Alloy

to 8470-14 (-0 to -14)

P55GL, Revision 14 Page 2 of 7

Maximum Diameter Approx. Max. Wt. Complete Blade

Blades Continuous Takeoff Limits (For Reference Only) Construction

(See Note 2) HP RPM HP RPM (See Note 10) (See Notes 3 and 7) (See Note 10)

8475-0 400 2575 400 2575 86” to 72” 79.0 lb. Aluminum Alloy

to 8475-14 (-0 to -14)

8477-0 400 2575 400 2575 86” to 72” 82.0 lb. Aluminum Alloy

to 8477-14 (-0 to -14)

Non-Counterweighted Propellers HC-G3YF-1

7890 400 2700 400 2700 80" 66.0 lb. Aramid Composite

Non-Counterweighted Propellers HC-G3YF-1, PHC-G3YF-1

NG8301-0 350 2700 350 2700 85" to 75” 64.0 lb. Carbon Composite

to NG8301-10 (-0 to -10)

Counterweighted Propellers HC-G3YF-2, EHC-G3YF-2, PHC-G3YF-2

C7663-0 310 2850 310 2850 78” to 68” 79.0 lb. Aluminum Alloy

to C7663-10 (-0 to -10)

C7666-0 310 2700 310 2700 78” to 68” 86.0 lb. Aluminum Alloy

to C7666-10 (-0 to -10)

C7691-0 350 2850 350 2850 78” to 68” 77.0 lb. Aluminum Alloy

to C7691-10 (-0 to -10)

C8459-0 400 2700 400 2700 86” to 72” 82.0 lb. Aluminum Alloy

to C8459-14 (-0 to -14)

C8465-0 400 2700 400 2700 86” to 72” 84.0 lb. Aluminum Alloy

to C8465-14 (-0 to -14)

C8467-0 400 2575 400 2575 86” to 72” 88.0 lb. Aluminum Alloy

to C8467-14 (-0 to -14)

C8468-0 400 2625 400 2625 86” to 72” 85.0 lb. Aluminum Alloy

to C8468-14 (-0 to -14)

C8470-0 400 2700 400 2700 86” to 72” 84.0 lb. Aluminum Alloy

to C8470-14 (-0 to -14)

C8475-0 400 2575 400 2575 86” to 72” 88.0 lb. Aluminum Alloy

to C8475-14 (-0 to -14)

C8477-0 400 2575 400 2575 86” to 72” 91.0 lb. Aluminum Alloy

to C8477-14 (-0 to -14)

Counterweighted Propellers HC-G3YR-4

NC7893-0 350 2700 350 2700 80” to 70” 69.4 lb. Carbon Composite

to NC7893-10 (-0 to -10)

Page 3 of 7 P55GL, Revision 14

Certification Basis: 14 CFR Part 35 with amendments 35-1 through 35-4 effective May 2, 1977.

Type Certificate No. P55GL issued March 31, 1978 under Delegated Option Authorization provisions

of 14 CFR Part 21 Subpart J.

Date of application for Type Certificate: January 12, 1978.

The following models were included under the original certification basis:

HC-G3YF-1; HC-G3YF-2, EHC-G3YF-2

The following models were added, updated or revised in accordance with 14 CFR Part 35 with

amendments 35-1 through 35-5 effective October 14, 1980:

HC-G3YF-(1,2); HC-G3YF-(1,2), EHC-G3YF-(1,2)

The following models were added, updated or revised in accordance with 14 CFR Part 35 with

amendments 35-1 through 35-6 effective August 1, 1990:

HC-G3YF-(1,2); HC-G3YF-(1,2), EHC-G3YF-(1,2)

The following models were added, updated or revised in accordance with 14 CFR Part 35 with

amendments 35-1 through 35-8 effective December 23, 2008:

HC-G3YR-4

The following models were added, updated or revised in accordance with 14 CFR Part 35 with

amendments 35-1 through 35-9 effective March 19, 2013:

HC-G3YF-1, PHC-G3YF-1

Production Basis: Production Certificate no. 10

Note 1: Hub Model Designation (See Notes 4 and 5)

E HC - G 3 Y F - 1 RF

F when used denotes modified pitch change system

L denotes left hand rotation

N indicates compatibility with N shank blades (See NOTE 2)

R when used denotes large piston area

U when used denotes spring kit (package) in propeller dome

Any other character denotes a minor change not affecting eligibility

Denotes specific design features

-1: non-feathering, no counterweights, governor oil pressure increases pitch

-2: feathering with counterweights, governor oil pressure decreases pitch

-4: non-feathering with counterweights, governor oil pressure decreases pitch

F denotes special flange with six 1/2” bolts and two 1/2” dowels on a 4” bolt circle

R denotes SAE #2 flange with six 1/2” bolts and five 3/4” drive bushings on a 4-3/4” bolt circle

Hartzell blade shank size

Number of blades

Identifies basic design. “G” denotes a 1.00 inch integral shaft extension

Hartzell Controllable

Indicates dowel location with respect to centerline through

blade sockets when viewing hub from flange mounting face

Dowel Pin T/C

Blank 90 & 270 deg. 30 deg. Clockwise

E: 0 & 180 deg. 240 deg. Clockwise

P: 0 & 180 deg. 120 deg. Clockwise

P55GL, Revision 14 Page 4 of 7

Note 2: Blade Model Designation (See Notes 5 and 6)

L C 76 66 D - 3R

Number when used indicates inches cut off from (or added to if +) basic diameter

Q when used denotes special 1” x 90 deg. factory-bent tip. No cutoff permitted.

R when used denotes specifically rounded tip for cutoff diameter.

Any other character in this location denotes tip shape

D or F denotes a dimensional modification from the original design

B or K denotes deicing boots

R when used denotes a rounded tip for the basic diameter

S when used denotes a square tip for the basic diameter *

Any other character denotes a minor modification not affecting eligibility

Basic blade model

Basic diameter for a two blade propeller. Add two inches for three blade propellers.

Denotes counterweighted blades

Denotes blade configuration: right-hand tractor unless otherwise noted

F denotes a large pitch change knob

H denotes right-hand pusher

J denotes left-hand tractor

L denotes left-hand pusher

N or NG denotes Carbon composite construction

No prefix is used for Aramid composite blades

* Blades may incorporate either round or square tips, yet may not be marked with an “R” or “S” in their model designation.

This character is used to distinguish between two or more tip shapes available at the same diameter. Certain blades use “S”

to denote shot peening of the exterior surface.

Note 3: Pitch Control (See Notes 4 and 10)

(a) Approved with Hartzell governors per drawings C-4770, C-4771 and C-4772. Wt.: 4.5 lb.

D-1-4 Z Governor Model Designation

L when used indicates left hand rotation

Z when used indicates drive coupling type

Any other character denotes a minor change not affecting eligibility

Minor adjustment not affecting eligibility

Minor adjustment to obtain engine/propeller/governor compatibility

Basic body and major parts modification

(b) The -2 and -4 models have counterweighted blades and use oil to decrease pitch. The -1 models do not have

counterweighted blades and use oil to increase pitch.

(c) Maximum governor output pressure: 350 psi for all propeller models

(d) All governors must be approved as part of the aircraft installation regardless of manufacturer.

Page 5 of 7 P55GL, Revision 14

Note 4: Feathering The -1 and -4 models do not feather.

The -2 models incorporate feathering and unfeathering features.

Reversing Not applicable

Note 5: Left-Hand Models (See Notes 1 and 2)

The left-hand version of an approved propeller model is approved at the same rating and diameter as listed for the

right-hand model.

Note 6: Interchangeability (See Notes 2 and 3)

(a) Governors

Hartzell governors with a “Z” suffix in their model designation may be used interchangeably with

corresponding governors without the “Z”. For example, the F-6-24Z is a replacement for the F-6-24

and the F-6-24 is a replacement for the F-6-24Z.

(b) Blades

Shot-peened blades may replace non shot-peened blades either individually or as a set

(c) Ice protection systems

Refer to Hartzell Service Letter HC-SL-30-260 for ice protection system component interchangeability.

Note 7: Accessories (See Note 10)

(a) Propeller ice protection system (weight of ice protection equipment extra)

(1) Propeller models listed in this data sheet are approved for use with propeller ice protection equipment

listed in Hartzell Manual 159( ) or in other Hartzell type design data.

(2) All propeller ice protection equipment must be approved as part of the aircraft installation regardless of

manufacturer. (See NOTE 10)

(b) Propeller spinner (weight of spinner extra)

(1) Approved with Hartzell and other manufacturers’ spinners when listed on Hartzell type design data.

(2) All propeller spinners must be approved as part of the aircraft installation regardless of manufacturer.

(See NOTE 10)

Note 8: Shank Fairings Not applicable.

P55GL, Revision 14 Page 6 of 7

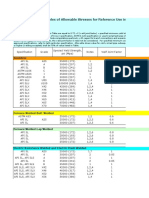

Note 9: Special Limits

Table of Propeller - Engine Combinations

Approved Vibrationwise for Use on Normal Category Single Engine Tractor Aircraft

The maximum and minimum propeller diameters that can be used from a vibration standpoint are shown below. No reduction

below the minimum diameter listed is permissible, since this figure includes the diameter reduction allowable for repair purposes.

The engine models listed below are the configurations on the engine type certificate unless specifically stated otherwise.

Modifications to the engine or airframe that alter the power of the engine models listed below during any phase of operation have

the potential to increase propeller stresses and are not approved by this list. Such modifications include, but are not limited to,

the addition of a turbocharger or turbonormalizer, increased boost pressure, increased compression ratio, increased RPM, altered

ignition timing, electronic ignition, full authority digital engine controls (FADEC), or tuned induction or exhaust. Also, any

change to the mass or stiffness of the crankshaft/counterweight assembly is not approved by this list.

Hub Blade Max. Dia. Min. Dia.

Model Model Engine Model (inches) (inches) Placards

EHC-G3YF 7663 TCM IO-520-E 77 74 none

PHC-G3YF F7691( ) TCM IO-520-D 78 77 Do not exceed 20 in. manifold

TCM IO-550-D pressure below 2200 RPM

PHC-G3YF F7691 TCM IO-520-A, -B, -BA, -BB, 78 77 Do not exceed 20 in. manifold

-C, -CB, -D, -E, -F, -J, -K, pressure below 2200 RPM

-L, -M, -MB

TCM IO-550-A, -B, -C, -D, -F,

-G, -L, -N, -P, -R

PHC-G3YF F7691( ) TCM O-470-A, -J, -K, -L, 78 77 none

-R, -S, -U

PHC-G3YF F7693F TCM IO-550-B 78 75 none

PHC-G3YF F8068 TCM IO-470-D, E, F, M, S 82 78 none

IO-520-A, J

IO-550-D, E, F, L

TSIO-520-C, H

PHC-G3YF F8068-2 TCM IO-520-D, E, F, L 80 78 none

PHC-G3YF F8468A( ) TCM O-470-K, -L 80 77 none

TCM IO-470-F

PHC-G3YF F8468A-( )R TCM O-470-A (S/N 41000 & up), 80 77 none

-J, -K, -L, -R, -S, -U

PHC-G3YF F8468A( ) TCM IO-520-D 80 77 none

TCM IO-550-D

Page 7 of 7 P55GL, Revision 14

Note 10: Propeller installation must be approved as part of the aircraft Type Certificate and demonstrate compliance with

the applicable aircraft airworthiness requirements.

Propeller models listed herein consist of basic hub and blade models. Most propeller models include additional

characters to denote minor changes and specific features as explained in Notes 1 and 2. Refer to the aircraft Type

Certificate Data Sheet for the specific propeller model applicable to the installation.

Propellers with composite blades must be evaluated for bird impact resistance prior to approval on any type

aircraft. Hartzell Propeller must perform tests and/or analyses based on aircraft configuration and operating

conditions to determine the potential hazard as a result of a bird impact.

Note 11: Retirement Time

(a) Life Limits and Mandatory Inspections

(1) Airworthiness limitations, if any, are specified in Hartzell Manuals 115N or 145.

Note 12: Special Notes

(a) Refer to Hartzell Manual no. 202( ) for overspeed and overtorque limits.

(b) Refer to Hartzell Service Letter HC-SL-61-61( ) for recommended overhaul periods.

END

You might also like

- Assignment 1Document8 pagesAssignment 1William ChinNo ratings yet

- 5 6 7 Series LPG ManualDocument31 pages5 6 7 Series LPG Manualclunkerbutt89% (9)

- SR32 - 4 MIXER Parts ListDocument23 pagesSR32 - 4 MIXER Parts Listsrinitce_meNo ratings yet

- Cast Wheel in Indian Rlys-Present StatusDocument6 pagesCast Wheel in Indian Rlys-Present StatusDevarshi GaurNo ratings yet

- BRU-61/A: Small Diameter Bomb Carriage SystemDocument2 pagesBRU-61/A: Small Diameter Bomb Carriage SystemandraxxusnephilemNo ratings yet

- P33EA Rev24Document8 pagesP33EA Rev24oftec2taasNo ratings yet

- HARTZELL P9EA - Rev17 PIPER PA30Document9 pagesHARTZELL P9EA - Rev17 PIPER PA30Enrique F. Zamalloa LeonNo ratings yet

- Department of Transportation Federal Aviation AdministrationDocument13 pagesDepartment of Transportation Federal Aviation Administrationndut ajaNo ratings yet

- Profile Rail: Mechanical PropertiesDocument17 pagesProfile Rail: Mechanical PropertiesRamadhan AdityaNo ratings yet

- Idalloy: C MN Si CR Mo V P S CuDocument1 pageIdalloy: C MN Si CR Mo V P S CuiocephNo ratings yet

- Amg RTJ Data PDFDocument8 pagesAmg RTJ Data PDFsiswoutNo ratings yet

- SERVOTECNICA-SRH SlipRingsDocument4 pagesSERVOTECNICA-SRH SlipRingsTenday Agus Setya WibawaNo ratings yet

- Row Size (NPS) Size (DN) Pressure Wedge Operator Body MatDocument3 pagesRow Size (NPS) Size (DN) Pressure Wedge Operator Body MatamirNo ratings yet

- Weld Wire SpecDocument2 pagesWeld Wire SpecRajaSekarsajjaNo ratings yet

- App B Piping Specifications PDFDocument4 pagesApp B Piping Specifications PDFirawan_epNo ratings yet

- Hydraulic HammerDocument3 pagesHydraulic Hammerbridge14No ratings yet

- Wires & Fluxes: W.E.F. 6 APRIL 2022Document16 pagesWires & Fluxes: W.E.F. 6 APRIL 2022Shivi ChaturvediNo ratings yet

- PMA Cylinder Flier 009Document2 pagesPMA Cylinder Flier 009Jonatan BernalNo ratings yet

- 2014 Hyster Yale Reference ListDocument2 pages2014 Hyster Yale Reference ListKevin Daughton100% (1)

- P15ea Rev 31Document8 pagesP15ea Rev 31api-540697339No ratings yet

- Orthodrive Lite 206-USDocument12 pagesOrthodrive Lite 206-USEsmaDergalNo ratings yet

- Flyer Turbine FMT-L Rev3 PDFDocument2 pagesFlyer Turbine FMT-L Rev3 PDFPablo CampechanoNo ratings yet

- SANDVIK Priročnik Za VarjenjeDocument354 pagesSANDVIK Priročnik Za Varjenjerisbo12No ratings yet

- GasFluxWelding PDFDocument72 pagesGasFluxWelding PDFjuandajdjNo ratings yet

- Listado Articulos PVPDocument116 pagesListado Articulos PVPfausto.ca68No ratings yet

- Midalloy ER80S B6 EB6Document1 pageMidalloy ER80S B6 EB6joel cisnerosNo ratings yet

- Accumulator MountingDocument5 pagesAccumulator MountingSean PorterNo ratings yet

- Tabel Konversi Nilai KekerasanDocument14 pagesTabel Konversi Nilai KekerasanSeptiana NugrahaNo ratings yet

- Ar70 75Document4 pagesAr70 75MarioNo ratings yet

- SFN 880Document62 pagesSFN 880lukeNo ratings yet

- Kineticsnoise@Piping & Hanger SelectionDocument2 pagesKineticsnoise@Piping & Hanger Selectioncyong7788No ratings yet

- HK 40Document2 pagesHK 40hawyegNo ratings yet

- BMW Motorcycle Engine SpecificationsDocument13 pagesBMW Motorcycle Engine Specificationspaulderekjohnson100% (1)

- Iron Grade 60 70: No Standard Grade Tensile Strength Mpa Yield Strength Mpa Elongation (%Document1 pageIron Grade 60 70: No Standard Grade Tensile Strength Mpa Yield Strength Mpa Elongation (%omar mahmoudNo ratings yet

- Final Part List CGR1213Document12 pagesFinal Part List CGR1213kkmechNo ratings yet

- HV04-07 Parts Manual IssEDocument96 pagesHV04-07 Parts Manual IssEJonathan Mercier100% (1)

- API 6A Gate ValveDocument16 pagesAPI 6A Gate ValveJuan PabloNo ratings yet

- AstmDocument29 pagesAstmMohd Zulfadli Mohamad IzaraeeNo ratings yet

- 6r 6d Bore StrokeDocument4 pages6r 6d Bore StrokeMariana ParedesNo ratings yet

- Premier Piston Pump Sales Catalog Страницы 4 6,8 9,30,34,43Document8 pagesPremier Piston Pump Sales Catalog Страницы 4 6,8 9,30,34,43Michail ArmitageNo ratings yet

- Bergen-Power Pipe SupportsDocument341 pagesBergen-Power Pipe Supportsramadan rashadNo ratings yet

- Coaxial Cable Equations-2024Document17 pagesCoaxial Cable Equations-2024RekaaNo ratings yet

- Alloytic Co. Limited - TC Rings From Project Sales CorpDocument12 pagesAlloytic Co. Limited - TC Rings From Project Sales CorpProject Sales CorpNo ratings yet

- Denison-Parker Premier SeriesDocument40 pagesDenison-Parker Premier SeriesDamNo ratings yet

- Diagrama 305Document10 pagesDiagrama 305Uriel MFNo ratings yet

- Gear Reference PDFDocument15 pagesGear Reference PDFXuan Phuong HuynhNo ratings yet

- SOW 09380SB2T SpecSheetDocument2 pagesSOW 09380SB2T SpecSheetAi NayNo ratings yet

- ADC3022L 6500 Series Cylinder RegulatorsDocument2 pagesADC3022L 6500 Series Cylinder RegulatorsWaldo ArellanoNo ratings yet

- Gas Flux WeldingDocument78 pagesGas Flux WeldingyendikesumaNo ratings yet

- Kubota Parts: Tightening TorquesDocument2 pagesKubota Parts: Tightening TorquesAlaina SousaNo ratings yet

- Installation ManualDocument4 pagesInstallation ManualALEXNo ratings yet

- Important!!!: Revised Cam Follower Installation ProcedureDocument4 pagesImportant!!!: Revised Cam Follower Installation ProcedurePratueng OnmaniNo ratings yet

- Allowable Stress in PipingDocument6 pagesAllowable Stress in PipingpelotoNo ratings yet

- TCDS Trabajo Final Motores A ReaccionDocument11 pagesTCDS Trabajo Final Motores A ReaccionRICOYUDYNo ratings yet

- Rhopoint - Flow Cups.Document4 pagesRhopoint - Flow Cups.Dinesh KumarNo ratings yet

- Rhopoint - Flow Cups PDFDocument4 pagesRhopoint - Flow Cups PDFDinesh KumarNo ratings yet

- Transactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 Final Report of Special Committee on Rail Sections, Paper No. 1177From EverandTransactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 Final Report of Special Committee on Rail Sections, Paper No. 1177No ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Anchor Dowel FixingDocument7 pagesAnchor Dowel FixingbittuchintuNo ratings yet

- DVD Audio FormatDocument17 pagesDVD Audio FormatamlNo ratings yet

- Wiring Diagram: Keyless Entry System - Power Door Locks - Super Locking SystemDocument1 pageWiring Diagram: Keyless Entry System - Power Door Locks - Super Locking SystemAlexgavgray GNo ratings yet

- Multimaus en 200614 PDFDocument36 pagesMultimaus en 200614 PDFLaur MantescuNo ratings yet

- Technical Specification: 12-SeriesDocument13 pagesTechnical Specification: 12-SeriesKhantoNo ratings yet

- American National StandardDocument52 pagesAmerican National StandardALEX ROSARIO ANGELESNo ratings yet

- A6j MB - 0103 R2.2 0118Document63 pagesA6j MB - 0103 R2.2 0118Thịnh TúNo ratings yet

- The Weave of San FranciscoDocument3 pagesThe Weave of San FranciscoyrtalienNo ratings yet

- Cics EibDocument2 pagesCics EibInvincible Sampath KumarNo ratings yet

- Professionalexperience: - Having 3 Years of Experience in IT Industry As A Java DeveloperDocument3 pagesProfessionalexperience: - Having 3 Years of Experience in IT Industry As A Java DeveloperCreeno SolutionsNo ratings yet

- Powerflex 700L Active Converter Power Module: User ManualDocument72 pagesPowerflex 700L Active Converter Power Module: User ManualThiện Lương MinhNo ratings yet

- Fireworks 43521Document10 pagesFireworks 43521m227765hNo ratings yet

- Digital Systems Design and PrototypingDocument633 pagesDigital Systems Design and PrototypingAshish Shrivastava50% (2)

- Arts 10 Quarter 3 Week 7 Las # 1Document2 pagesArts 10 Quarter 3 Week 7 Las # 1ariel velaNo ratings yet

- Autosar Memory Stack (Memstack)Document21 pagesAutosar Memory Stack (Memstack)Marute ChavanNo ratings yet

- Memo 097.7 - 101822 - Revised Pay Item Subscripts Under Item 1047 - Metal StructuresDocument2 pagesMemo 097.7 - 101822 - Revised Pay Item Subscripts Under Item 1047 - Metal StructuresAce LangNo ratings yet

- Turing TestDocument2 pagesTuring TestЕкатерина ГордееваNo ratings yet

- P1HZ X1 enDocument6 pagesP1HZ X1 enDiiani AmayaNo ratings yet

- A Bridge Device Filters Data Traffic at A Network BoundarydDocument20 pagesA Bridge Device Filters Data Traffic at A Network BoundarydShall haileNo ratings yet

- Reliance Jio Reliance Jio Head Office Contact Details: Jio's Headquarters in RCP, Navi MumbaiDocument17 pagesReliance Jio Reliance Jio Head Office Contact Details: Jio's Headquarters in RCP, Navi MumbaiMohanrajNo ratings yet

- Project Lifecycle Models - How The Differ and When To Use ThemDocument5 pagesProject Lifecycle Models - How The Differ and When To Use Themjamoris100% (1)

- ReadMe KMSpico InstallDocument1 pageReadMe KMSpico InstallWiny Wen PopeNo ratings yet

- Wagner Spring 2014 CS 161 Computer Security Final Exam: (Last) (First)Document23 pagesWagner Spring 2014 CS 161 Computer Security Final Exam: (Last) (First)Ahsan RamzanNo ratings yet

- AMDVBFLASH User Guide NDADocument12 pagesAMDVBFLASH User Guide NDADanej DoberšekNo ratings yet

- Format of Ielts General Training LettersDocument24 pagesFormat of Ielts General Training LettersmanwinderNo ratings yet

- Difference Between Adaptive and NonDocument4 pagesDifference Between Adaptive and NonTalha Mahmood ChowdhuryNo ratings yet

- Department of Electronics & Communication Engineering: VLSI Design (EEC-703)Document1 pageDepartment of Electronics & Communication Engineering: VLSI Design (EEC-703)tripathi_girishNo ratings yet

- Tips & Tricks For The Success With Azure SQL Managed InstanceDocument41 pagesTips & Tricks For The Success With Azure SQL Managed InstanceDejan Tale MarkovicNo ratings yet