Professional Documents

Culture Documents

Pages From Cooper Catalogue Issue 5

Pages From Cooper Catalogue Issue 5

Uploaded by

AntoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pages From Cooper Catalogue Issue 5

Pages From Cooper Catalogue Issue 5

Uploaded by

AntoCopyright:

Available Formats

ASPHALT / BITUMEN ASPHALT / BITUMEN

01 DESIGN AND TESTING OF BITIMINOUS MIXTURES

MARSHALL STABILITY

MARSHALL STABILITY SUPPLIED WITH PRODUCT CODE

The TAS-0055 Marshall Stability Test Machine is supplied TAS-0056 Automatic Marshall Stability Test

PRODUCT CODE complete with: Machine, 50 kN, 220-240 V 50-60 Hz

TAS-0056/110 Automatic Marshall Stability Test

TAS-0055 Marshall Stability Test Machine with • Load Cell, 50 kN

Machine, 50 kN, 110 V 60 Hz

Digital Readout Unit, 50 kN, • Linear Potentiometric Displacement Transducer with

Bracket, 25 x 0.001 mm TAS-0057 Breaking Head (Stability Mould) 4”

220-240 V 50-60 Hz

• Hand Wheel for Manual Control TAS-0058 Breaking Head (Stability Mould) 6”

TAS-0055/110 Marshall Stability Test Machine with • Breaking Head, 4”

Digital Readout Unit, 50 kN, 110 V 60 Hz TAS-0060 Linear Potentiometric Displacement

Transducer, 25x0.001 mm with bracket

TAS-0057 Breaking Head (Stability Mould) 4”

for TAS-0057 and TAS-0058

TAS-0058 Breaking Head (Stability Mould) 6”

TAS-0063 Indirect Tensile Test Jig for Compacted

TAS-0060 Linear Potentiometric Displacement Bituminous Samples 100 mm (4”).

Transducer, 25x0.001 mm with bracket

for TAS-0057 and TAS-0058

STANDARDS TAS-0056

TAS-0063 Indirect Tensile Test Jig for Compacted

Bituminous Samples 100 mm (4”) & 150

EN 12697-34, 12697-23, 12967-12 (Method A and B up to 51

mm (6”) Dia.

mm/min); ASTM D1559, D5581, D 6927; AASHTO T245

STANDARDS TAS-0055 DESCRIPTION

EN 12697-34; EN 12697-23; EN 12697-12 (Method A); The TAS-0056 50 kN Capacity Automatic Marshall Stability Test

ASTM D1559; ASTM D5581; ASTM D 6927; AASHTO T245 Machine is used to determine the maximum load and flow

values of bituminous mixtures.

DESCRIPTION The machine comprises of a robust and compact two column

frame with adjustable upper cross beam. The unit is a bench

mounting compression frame with motor and worm gear

The TAS-0055 50 kN Capacity Automatic Marshall Stability Test

housed within the base unit. The speed of the lower platen

Machine is used to determine the maximum load and flow

can be adjusted between 6 mm/min to 60 mm/min using the

values of bituminous mixtures.

BC100 Data Acquisition and Control Unit. For safety, the up KEY FEATURES

and down travel of the lower platen is limited the use of limit

The machine comprises of a robust and compact two column

switches. Rapid adjustment of the platen is controlled using • Automatically calculates flow and stability values

frame with adjustable upper cross beam. The unit is a bench

the up and down buttons on the front panel of the machine. • Can perform test with displacement control

mounted compression frame with motor and worm gear

The machine can be hand operated by a lateral hand wheel • Real time display of test graph

housed within the base unit. The mechanical jack raises the

for calibration purposes. The measuring system consists of a • CPU card with 32-bit ARM RISC architecture

lower platen at a constant speed of 50.8 mm/min as required

50 kN capacity strain gauge load cell fitted to the upper cross • Permanent storage capacity up to 10,000 test results

in the relevant standard. For safety, the up and down travel

beam to read stability values and the 25 x 0.001 mm linear • 4 analog channels, 2 channels are active for Marshall

of the lower platen is limited the use of limit switches. Rapid

potentiometric displacement transducer fitted to the Breaking • Programmable digital gain adjustment for load-cell,

adjustment of the platen is controlled using the up and down

Head. The TAS-0056 Automatic Marshall Stability Machine is pressure transducers, strain-gauge based sensors,

buttons on the front panel of the machine.

suitable for testing 6” dia. specimens (152.4 mm) conforming potentiometric sensors, voltage and current transmitters

to ASTM D5581. • 1/256000 points resolution per channel

The measuring system consists of a 50 kN capacity strain

gauge load cell fitted to the upper cross beam to read stability • 10 data per second sample rate for each channel

values, the 25 x 0.001 mm linear potentiometric displacement SPECIFICATIONS SUPPLIED WITH • Ethernet connecting for computer interface

transducer fitted to the Breaking Head and two digital readout • 800x480 resolution 65535 color TFT-LCD industrial

units (one for load and another for displacement). The Automatic Marshall Stability Test Machine touchscreen

The TAS-0056 Automatic Marshall Stability Machine is also Platen Speed 50,8 mm/min • 4 main function keys

is supplied complete with:

suitable for testing 6” dia. specimens (152.4 mm) conforming Capacity kN 50 • Multi-language support

to ASTM D5581. The machine can be hand operated by a • Load Cell, 50 kN • 3 different unit system selection; kN, Ton and lb

Dimensions mm • Linear Potentiometric Displacement Transducer with

lateral hand wheel for calibration purposes; the hand wheel is 550 x 700 x 1200 • Real-time clock and date

(W x D x H Bracket, 25 x 0.001 mm

supplied complete with the machine. • Test result visualisation and memory management

Weight (approx.) Kg 102 • PC Software interface

Power W 1100 • Connection Cable • Remote connection through ethernet and Bluetooth

• Hand wheel for manual control • USB flash disc for importing test results and for firmware

• Breaking Head, 4” • USB printer support for inkjet and laser printers (ask for

compatible models)

TAS-0058 • Camera support for real-time video recording during test

SPECIFICATIONS (ask for compatible models)

TAS-0063 TAS-0057

• Free of charge PC software for the test control and

advanced report generation

Platen Speed 6-60 mm/min

Capacity kN 50

Dimension mm

550 x 700 x 1200

(W x D x H)

ACCESSORIES

Weight Kg 103

Power W 1100

54 www.cooper.co.uk 55

You might also like

- Gagne's Conditions of LearningDocument3 pagesGagne's Conditions of LearningCza Mae ArsenalNo ratings yet

- Mg623 - Project Management PlanDocument79 pagesMg623 - Project Management PlanIBRAHIM NYIRENDANo ratings yet

- Risk Assessment - HV 11kV Cable, Joint & TerminationDocument90 pagesRisk Assessment - HV 11kV Cable, Joint & TerminationJobish PK0% (2)

- ESAB Shadow2 PDSDocument2 pagesESAB Shadow2 PDSEduardo Luis LicetNo ratings yet

- SAP 4.7 Installation TutorialDocument54 pagesSAP 4.7 Installation Tutorialrajeev.ashokan8023100% (34)

- MarshallDocument1 pageMarshallBanta SINGHNo ratings yet

- Machine D'essais de FatigueDocument8 pagesMachine D'essais de Fatiguemezioua.mohammedlamineNo ratings yet

- 4 AsphaltDocument12 pages4 AsphaltTarek KhallafNo ratings yet

- Hoja Técnica Asco 2905 - 700 KW2905Document2 pagesHoja Técnica Asco 2905 - 700 KW2905Hernán Peñafiel ReaNo ratings yet

- Creep Testing Kappa SSDocument2 pagesCreep Testing Kappa SSGustavo LealNo ratings yet

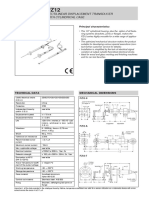

- Rectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical DimensionsDocument2 pagesRectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical Dimensionslaconte_No ratings yet

- Rectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical DimensionsDocument2 pagesRectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical Dimensionsl561926No ratings yet

- Expert 5000 Series BrochureDocument6 pagesExpert 5000 Series BrochureAde DjatnikaNo ratings yet

- Vs 100bgq04Document7 pagesVs 100bgq04P.Rajan GuruNo ratings yet

- DTS PZ12 08-2021 EngDocument2 pagesDTS PZ12 08-2021 EngOmar BarcenasNo ratings yet

- Thompson 910 SeriesDocument7 pagesThompson 910 SeriesOscar OrellanaNo ratings yet

- Microplate Shaker: MB100-2A/MB100-4A Thermo Shaker Incubator For Plates MK100-2A/MK100-4A Incubator For Plates MX100-4ADocument1 pageMicroplate Shaker: MB100-2A/MB100-4A Thermo Shaker Incubator For Plates MK100-2A/MK100-4A Incubator For Plates MX100-4AzealouseveNo ratings yet

- LWH Novotechnik LWHDocument4 pagesLWH Novotechnik LWHGerardo Espinosa EspinosaNo ratings yet

- Katalog - Ostenco - 2022Document20 pagesKatalog - Ostenco - 2022EZIO AUDITORENo ratings yet

- Series Ts 910 100 - 400 AMP: Automatic Transfer SwitchesDocument4 pagesSeries Ts 910 100 - 400 AMP: Automatic Transfer SwitchesFranco M. CaverzanNo ratings yet

- Data Sheet System TV 51140-MOSP Eng V05Document2 pagesData Sheet System TV 51140-MOSP Eng V05AekDzLaiNo ratings yet

- Automatic Compression Testers For Cylinders: SeriesDocument4 pagesAutomatic Compression Testers For Cylinders: SeriesJosé Fco. Cerda M.No ratings yet

- Fatigue Tester Brochure Rev2Document4 pagesFatigue Tester Brochure Rev2AhmedNo ratings yet

- SPETECH KammprofilesDocument2 pagesSPETECH KammprofilesabasakNo ratings yet

- Digital Automatic Universal Tester For Displacement Controlled TestsDocument4 pagesDigital Automatic Universal Tester For Displacement Controlled TestsEsmeralda MariscalNo ratings yet

- Compresión InconfinadaDocument1 pageCompresión InconfinadaJorge SanchezNo ratings yet

- Self-Supporting Linear Position Transducer With Magnetic PullingDocument2 pagesSelf-Supporting Linear Position Transducer With Magnetic PullingGopal HegdeNo ratings yet

- Alpha Single Cable Data SheetDocument1 pageAlpha Single Cable Data Sheetsaghaee.rezaNo ratings yet

- Pmi-Sl: Rectilinear Displacement Transducer With Magnetic DragDocument4 pagesPmi-Sl: Rectilinear Displacement Transducer With Magnetic DragSathish J EceNo ratings yet

- Blackbear C Hoist PDFDocument8 pagesBlackbear C Hoist PDFErich Thomas TulusNo ratings yet

- Triaxial Rock TestingDocument4 pagesTriaxial Rock TestingLizardoTalaveranoEstrellaNo ratings yet

- Active Filter Wall Mounted - 30-60-100 AmpereDocument4 pagesActive Filter Wall Mounted - 30-60-100 AmpereFreddy SuhartonoNo ratings yet

- Varistores-D V680K14 0 V680K14 VARISTOR DOCUMENTACIÓNDocument12 pagesVaristores-D V680K14 0 V680K14 VARISTOR DOCUMENTACIÓNAlberto Morillo ParelladaNo ratings yet

- Brochure CUT 6062 2021-11-008.00 ENDocument8 pagesBrochure CUT 6062 2021-11-008.00 ENHanh NguyenNo ratings yet

- Baker ZTX Brochure PUB CM-P2 13872 enDocument2 pagesBaker ZTX Brochure PUB CM-P2 13872 enPablo Marcelo Garnica TejerinaNo ratings yet

- Catalogo Equipo Dureza HR-530 - 2255Document8 pagesCatalogo Equipo Dureza HR-530 - 2255Alejandro SuntaxiNo ratings yet

- Performance and Price Effectiveness Alongside Tradition: Tipo Torque NMDocument2 pagesPerformance and Price Effectiveness Alongside Tradition: Tipo Torque NMMaheshNo ratings yet

- 1204-1204S-1205 RevCDocument2 pages1204-1204S-1205 RevCEstefany CantuNo ratings yet

- Notice of Specification Change(s)Document5 pagesNotice of Specification Change(s)Awwab ZaidiNo ratings yet

- VS-15MQ040-M3: Vishay SemiconductorsDocument6 pagesVS-15MQ040-M3: Vishay SemiconductorsVasilyNo ratings yet

- ESP200 Solid State Overload RelayDocument4 pagesESP200 Solid State Overload RelayjoseNo ratings yet

- Damping Brake RotordrumDocument8 pagesDamping Brake RotordrumAwad SalibNo ratings yet

- Annex1 - NOVA Standard MachineDocument10 pagesAnnex1 - NOVA Standard MachinePUNIT BUTANINo ratings yet

- High Precision Weld Heads: Key Features Typical ApplicationsDocument2 pagesHigh Precision Weld Heads: Key Features Typical ApplicationsAamir ZahoorNo ratings yet

- Rectilinear Displacement Transducer: Technical Data Mechanical DimensionsDocument2 pagesRectilinear Displacement Transducer: Technical Data Mechanical DimensionsJansirani SelvamNo ratings yet

- Pmi-Sle: Rectilinear Displacement Transducer With Magnetic Drag (Analog Output)Document4 pagesPmi-Sle: Rectilinear Displacement Transducer With Magnetic Drag (Analog Output)Sathish J EceNo ratings yet

- VS-6CWQ06FN-M3: Vishay SemiconductorsDocument7 pagesVS-6CWQ06FN-M3: Vishay SemiconductorsSolihin iingNo ratings yet

- Catalogue Panel MeterDocument28 pagesCatalogue Panel MeterRathnayake RmasNo ratings yet

- K575a AvtronDocument2 pagesK575a AvtronjithukshajiNo ratings yet

- BushingDocument4 pagesBushingomar_cohen_1No ratings yet

- A A H F G: MR Ad Dvantage IGH Requency Ener AtorsDocument2 pagesA A H F G: MR Ad Dvantage IGH Requency Ener AtorsJ Hernán Vázquez BenítezNo ratings yet

- SMBJ 15 Ca ComDocument5 pagesSMBJ 15 Ca ComАлексей МаренковNo ratings yet

- Magnectic Drill Pro 51 UniversalDocument1 pageMagnectic Drill Pro 51 UniversalopulitheNo ratings yet

- 105A Section6-12990Document29 pages105A Section6-12990TorretoNo ratings yet

- AX 496 Yamaha PDFDocument42 pagesAX 496 Yamaha PDFfingersoundNo ratings yet

- Megometro KyoritsuDocument1 pageMegometro KyoritsuRafael AlvarezNo ratings yet

- Anexa 19Document2 pagesAnexa 19pokemon69No ratings yet

- Ltp-A: Linear Position TransducersDocument2 pagesLtp-A: Linear Position TransducersAbhay AbhyankarNo ratings yet

- Vs Mbrs360 m3Document7 pagesVs Mbrs360 m3Gabriel DiazNo ratings yet

- PerformArc 250MDocument2 pagesPerformArc 250MLuis Gerardo Ibarra MuñozNo ratings yet

- Magazon-Series EBU SBU Aug 2020Document4 pagesMagazon-Series EBU SBU Aug 2020r rajeshNo ratings yet

- AsphaltDocument12 pagesAsphaltjitendraNo ratings yet

- Mitutoyo - Twardościomierze Rockwell HR 300, 400, 500 Seria - 2025 - 2016 ENDocument8 pagesMitutoyo - Twardościomierze Rockwell HR 300, 400, 500 Seria - 2025 - 2016 END.T.No ratings yet

- Balanced Mix Design FrameDocument3 pagesBalanced Mix Design FrameAntoNo ratings yet

- Company Profile PDFDocument37 pagesCompany Profile PDFAntoNo ratings yet

- YFD300Document4 pagesYFD300AntoNo ratings yet

- Cas Hdi IndicatorsDocument2 pagesCas Hdi IndicatorsAntoNo ratings yet

- OPTIKA-ITALY - Corporate Presentation & Product Portfolio - ENDocument24 pagesOPTIKA-ITALY - Corporate Presentation & Product Portfolio - ENAntoNo ratings yet

- OPTIKA Serie TS TSI Instruction Manual enDocument84 pagesOPTIKA Serie TS TSI Instruction Manual enAntoNo ratings yet

- OPTIKA Balances CatalogueDocument56 pagesOPTIKA Balances CatalogueAntoNo ratings yet

- BNN-Orientierungswert EN 22122021Document4 pagesBNN-Orientierungswert EN 22122021MOhamedNo ratings yet

- GREENE AaronDocument56 pagesGREENE AaronVisnja DjordjicNo ratings yet

- KH53 US EnglishDocument12 pagesKH53 US EnglishmohamedsamimorsiNo ratings yet

- Brooks Biotechnology and The Politics of Truth From The Green Revolution To An Evergreen RevolutionDocument20 pagesBrooks Biotechnology and The Politics of Truth From The Green Revolution To An Evergreen RevolutionDianaVictoriaNo ratings yet

- Wade-Kidd (2019) PDFDocument11 pagesWade-Kidd (2019) PDFJ. David Rodríguez MarinNo ratings yet

- For English CriticDocument2 pagesFor English CriticSari Sari Store VideoNo ratings yet

- Unit 0 - Friends Word of Self, Family and Friends Writing SpeakingDocument14 pagesUnit 0 - Friends Word of Self, Family and Friends Writing SpeakinglelaNo ratings yet

- Demonstration Teaching Lesson Plan On Visual Verbal RELATIONSHIP For Grade 8Document8 pagesDemonstration Teaching Lesson Plan On Visual Verbal RELATIONSHIP For Grade 8Rochelle Ann SaguirreNo ratings yet

- Carbonate ClassificationDocument5 pagesCarbonate ClassificationArpit UpadhyayNo ratings yet

- On The Ocean Floor - AltDocument2 pagesOn The Ocean Floor - AltLance0016No ratings yet

- MSC Thesis Defense Presentation - TufailDocument38 pagesMSC Thesis Defense Presentation - TufailNeerajNo ratings yet

- What's New SampleDocument19 pagesWhat's New SampleAmaanJo0No ratings yet

- Infineon IRLML2502 DataSheet v01 - 01 ENDocument10 pagesInfineon IRLML2502 DataSheet v01 - 01 ENabbaseftekhariNo ratings yet

- Overleaf Amsl Package PDFDocument44 pagesOverleaf Amsl Package PDFBruce LimNo ratings yet

- Leviton AppNote RetentionForceTechnologyDocument5 pagesLeviton AppNote RetentionForceTechnologySajeda M. Al-TalafhaNo ratings yet

- RD Sharma Jan21 Class 11 Maths Solutions Chapter 7Document25 pagesRD Sharma Jan21 Class 11 Maths Solutions Chapter 7SAIKIRANNo ratings yet

- Consumer Behavior and Sustainable MarketingDocument14 pagesConsumer Behavior and Sustainable Marketinglon choNo ratings yet

- Cryptography and Network Security: Third Edition by William Stallings Lecture Slides by Lawrie BrownDocument30 pagesCryptography and Network Security: Third Edition by William Stallings Lecture Slides by Lawrie BrownEli PriyatnaNo ratings yet

- Act 1Document5 pagesAct 1Yue YueNo ratings yet

- Rencana Pelaksanaan Pembelajaran (RPP) : School Identity Course Name Class/Semester Topic Discussion Skill Time AllocationDocument6 pagesRencana Pelaksanaan Pembelajaran (RPP) : School Identity Course Name Class/Semester Topic Discussion Skill Time AllocationNadya Septiani RahmanNo ratings yet

- MALAKIA M N CV - MDocument5 pagesMALAKIA M N CV - Mmalakiam50No ratings yet

- B. InggrisDocument2 pagesB. Inggristoko fahmiNo ratings yet

- Master in Aerospace Engineering: Ecole Centrale LyonDocument20 pagesMaster in Aerospace Engineering: Ecole Centrale LyonThangjam ShagerNo ratings yet

- Unit 1 Lessons 1 and 2Document8 pagesUnit 1 Lessons 1 and 2ivanNo ratings yet

- Emf Values of Organic CompoundsDocument34 pagesEmf Values of Organic CompoundsPrabir SahaNo ratings yet

- AWTI Calendar 23-24 - MergedDocument17 pagesAWTI Calendar 23-24 - MergedArnel MagbojosNo ratings yet