Professional Documents

Culture Documents

05 - Design of Package RCTR

05 - Design of Package RCTR

Uploaded by

Faisal MumtazCopyright:

Available Formats

You might also like

- Solution Manual Chemical Engineering Fluid Mechanics 3rd Edition Ron Darby and Raj Chhabra PDF PDF FreeDocument14 pagesSolution Manual Chemical Engineering Fluid Mechanics 3rd Edition Ron Darby and Raj Chhabra PDF PDF FreeB̸̗̠̼͍̔̀͂ą̶̫̭̞̒ͅr̶̢̟͕͓͉̊̏̿̿̒̓̂̈́̎͘ũ̵̢̡̫̖͔̘̙̳̗̫͊̆͝c̷͉̘̟̹̏̅̊̂͘̚ẖ̶̢̘̦̈́̌̀̆̋̽͋ Z̸͉͕̼̪̰͂͛̒ẽ̵͙̲̱͖̣͙̬͖͓̗̄p̴͇̼̮͍̱̬͕̩͙̾̋͋̓̿͋̂̓̂͘ͅṗ̶̡̢̱̻̭̅̒̽̚͠ȩ̷̛̹̺̘͕͎̲̩͎͊̃͛̎̈́̔͆l̴͍̖̞̙͉̟̣̠̻̳͂̍̈́̏̑̈́̽́̇͝i̷͍̫̜͎̖̮͂̎̄̽͛̚No ratings yet

- Me 313a - m3 412 Heat Transfer Weeks 10-12Document59 pagesMe 313a - m3 412 Heat Transfer Weeks 10-12Solayao, Jan Marvin J.No ratings yet

- 426-Anaerobic Digester DesignDocument36 pages426-Anaerobic Digester DesignmullanaNo ratings yet

- WWT Secondary Clarifier PDFDocument15 pagesWWT Secondary Clarifier PDFdzari6738No ratings yet

- Sample WW QuestionsDocument10 pagesSample WW QuestionsKrishna Kumar MeenaNo ratings yet

- Objectives: Chapter 4 Sludge Treatment and DisposalDocument37 pagesObjectives: Chapter 4 Sludge Treatment and Disposalashe zinabNo ratings yet

- Worked ExamplesDocument9 pagesWorked ExamplesDzung Pham0% (1)

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationFrom EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationRating: 3 out of 5 stars3/5 (1)

- Anaerobic Digestor DesignDocument36 pagesAnaerobic Digestor DesignChanelNo ratings yet

- Anaerobic Digester - QasimDocument35 pagesAnaerobic Digester - Qasimawaluddin nurmiyantoNo ratings yet

- Process Loading Evaluation & Sludge Accountability: - Step Through The Performance EvaluationDocument55 pagesProcess Loading Evaluation & Sludge Accountability: - Step Through The Performance EvaluationNiong DavidNo ratings yet

- Design of Each Process of ETPDocument9 pagesDesign of Each Process of ETPFaisal Sr. ExecutiveNo ratings yet

- Design ExamplesDocument5 pagesDesign Examplesnaba1577No ratings yet

- Anaerobic Digester DesignsDocument6 pagesAnaerobic Digester DesignsaminmominNo ratings yet

- SBR Design PDFDocument7 pagesSBR Design PDFmkdholkiya100% (1)

- Calculation Memory Sheet - Pre TreatmentDocument6 pagesCalculation Memory Sheet - Pre TreatmentDiego DiazNo ratings yet

- 128 Basic Aeration Design CalculationsxDocument4 pages128 Basic Aeration Design CalculationsxErno RuzsaNo ratings yet

- Tutorial 1-CH2402 - 2019Document4 pagesTutorial 1-CH2402 - 2019Naduni RanasingheNo ratings yet

- Example: 230 MG/L BODDocument7 pagesExample: 230 MG/L BODajali1957No ratings yet

- Wastewater Math FormulasDocument17 pagesWastewater Math FormulasPratiwi Natsir PutriNo ratings yet

- Design of Biogas DigestersDocument22 pagesDesign of Biogas DigestersSharath Chandra100% (5)

- CT4485 Exam 31-01-2012 With AnswersDocument7 pagesCT4485 Exam 31-01-2012 With AnswersVali100% (1)

- Algae ConceptDocument9 pagesAlgae ConceptAnand RSNo ratings yet

- Tasarım Soruları PDFDocument2 pagesTasarım Soruları PDFAkbey ApaydınNo ratings yet

- Secondary ClarifierDocument29 pagesSecondary ClarifierNoureddine MerahNo ratings yet

- 3 Lecture Wastewater Characteristic AnalysisDocument41 pages3 Lecture Wastewater Characteristic AnalysiszeyadNo ratings yet

- Solid Waste Management: EKC378 DR Azam T Mohd Din School of Chemical Engineering Universiti Sains MalaysiaDocument46 pagesSolid Waste Management: EKC378 DR Azam T Mohd Din School of Chemical Engineering Universiti Sains MalaysiaKalai YooganNo ratings yet

- CEE373.2 - Spring 2023 - CEDPDocument16 pagesCEE373.2 - Spring 2023 - CEDPMd. Zawad Amin As-salek 2011847625No ratings yet

- Waste Water AssignmentDocument4 pagesWaste Water Assignmentermias100% (2)

- Convenience Store Business PlanDocument4 pagesConvenience Store Business Planrmrv valdezNo ratings yet

- Assignment - Part 1 (Final Year Project) : SupervisorDocument11 pagesAssignment - Part 1 (Final Year Project) : Supervisorannie aliNo ratings yet

- Design of Completely Mixed Activated Sludge System: Home Quiz Design ExampleDocument3 pagesDesign of Completely Mixed Activated Sludge System: Home Quiz Design Exampledanndiamond100% (1)

- Activated Sludge Design: Treatment Process F/M KG Bod /KG MLSS/day Extended Aeration Conventional High RateDocument4 pagesActivated Sludge Design: Treatment Process F/M KG Bod /KG MLSS/day Extended Aeration Conventional High RateMhelveneNo ratings yet

- Jae K. (Jim) Park, Professor Dept. of Civil and Environmental Engineering University of Wisconsin-MadisonDocument29 pagesJae K. (Jim) Park, Professor Dept. of Civil and Environmental Engineering University of Wisconsin-MadisonSuhas JadhavNo ratings yet

- Explanation - Design of AD Fixed Dome Reactor For A Vegetable MarketDocument3 pagesExplanation - Design of AD Fixed Dome Reactor For A Vegetable MarketAlexis ChicaizaNo ratings yet

- Municipal Solid Waste and Schedule Waste PDFDocument89 pagesMunicipal Solid Waste and Schedule Waste PDFdanial 96No ratings yet

- AL HURWWTPDesignCalculationsDocument16 pagesAL HURWWTPDesignCalculationsMedalson RonghangNo ratings yet

- Wastewater TreatmentDocument27 pagesWastewater Treatmentnayerashoman97No ratings yet

- UAS Rika BN - PGB 2020Document8 pagesUAS Rika BN - PGB 2020Rika Budi NoviawatiNo ratings yet

- Introduction To Dual Fuel InjectionDocument8 pagesIntroduction To Dual Fuel InjectionAbhiNo ratings yet

- S19 - Louisiana State University - LTC2013Document35 pagesS19 - Louisiana State University - LTC2013walaywanNo ratings yet

- Carbon Foot PrintDocument19 pagesCarbon Foot Printgou100% (1)

- Applied Wastewater Math Formula Sheet and Conversion FactorsDocument3 pagesApplied Wastewater Math Formula Sheet and Conversion FactorsMasoud HasanyNo ratings yet

- Contoh Perhitungan LumpurDocument9 pagesContoh Perhitungan Lumpurkhairinfuadi50% (4)

- Solid WasteDocument31 pagesSolid WasteCer No RusNo ratings yet

- Pump and Aeration Tank SizingDocument14 pagesPump and Aeration Tank SizingDavid LambertNo ratings yet

- 1.1 Palm Oil MillDocument31 pages1.1 Palm Oil MillChee Yen ChiaNo ratings yet

- Tutorial 4 SolutionsDocument2 pagesTutorial 4 SolutionsUý Đại100% (1)

- Loading S Calculations by Dr. Ghaida Abu Rumman enDocument36 pagesLoading S Calculations by Dr. Ghaida Abu Rumman ensauroNo ratings yet

- CE 40340 Homework 6Document4 pagesCE 40340 Homework 6NanoNo ratings yet

- CVL723PS1Document5 pagesCVL723PS1Ronald Ewa100% (1)

- MBBRDocument37 pagesMBBRLye Yp100% (2)

- 2512 Tutorial Sheet 01Document2 pages2512 Tutorial Sheet 01aggrey noahNo ratings yet

- Anaerobic Sludge Digester (ASD) : Ahmad Faris Bin Mohd Napi Muhd Baktiar Bin Razali Muhd Nasrun Bin Mohd RosdiDocument46 pagesAnaerobic Sludge Digester (ASD) : Ahmad Faris Bin Mohd Napi Muhd Baktiar Bin Razali Muhd Nasrun Bin Mohd RosdiAhmad FarisNo ratings yet

- Tutorial Sheet NumericalsDocument3 pagesTutorial Sheet NumericalsanubhavNo ratings yet

- Biogas TechnologyDocument35 pagesBiogas Technologyraghunath670743No ratings yet

- BiogasDocument11 pagesBiogasAnand RathiNo ratings yet

- Digestor Anaerobico PDFDocument5 pagesDigestor Anaerobico PDFAnonymous XguKEyW100% (1)

- Environmental Scenario in Indian Mining Industry - an OverviewFrom EverandEnvironmental Scenario in Indian Mining Industry - an OverviewNo ratings yet

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- Aramco Leadership Share New Economic Map at Ceraweek: Company Talks Strong FutureDocument11 pagesAramco Leadership Share New Economic Map at Ceraweek: Company Talks Strong FutureFaisal MumtazNo ratings yet

- Wer 1408Document7 pagesWer 1408Faisal MumtazNo ratings yet

- IWTP8-MFQ-ILF-21-0500-Mechanical Equipment List 23-p2mDocument10 pagesIWTP8-MFQ-ILF-21-0500-Mechanical Equipment List 23-p2mFaisal MumtazNo ratings yet

- Summary of A Conceptual Design of Low Fouling and High Recovery FO-MSF-DESKTOP-47LO0PODocument1 pageSummary of A Conceptual Design of Low Fouling and High Recovery FO-MSF-DESKTOP-47LO0POFaisal MumtazNo ratings yet

- Ajerd0201 05Document6 pagesAjerd0201 05Faisal MumtazNo ratings yet

- BQTS - WetWellCalcDocument3 pagesBQTS - WetWellCalcFaisal MumtazNo ratings yet

- EENG703 - Assignment04 (AutoRecovered)Document19 pagesEENG703 - Assignment04 (AutoRecovered)Faisal MumtazNo ratings yet

- Hydraulic SizingDocument2 pagesHydraulic SizingFaisal MumtazNo ratings yet

- Optimisation of The WWTP Performance MakiniaDocument39 pagesOptimisation of The WWTP Performance MakiniaFaisal MumtazNo ratings yet

- Summary of Development of A Steady-State Mathematical Model For MEE-TVCDocument2 pagesSummary of Development of A Steady-State Mathematical Model For MEE-TVCFaisal MumtazNo ratings yet

- Mannings MetricDocument1 pageMannings MetricFaisal MumtazNo ratings yet

- ExergyDocument10 pagesExergyFaisal MumtazNo ratings yet

- Experimental Study of Thermal and Catalytic Pyrolysis of Plastic Waste ComponentsDocument11 pagesExperimental Study of Thermal and Catalytic Pyrolysis of Plastic Waste ComponentsFaisal MumtazNo ratings yet

- Friction FactorDocument6 pagesFriction Factorrajeshsapkota123No ratings yet

- Ch8 Solved QuestionDocument4 pagesCh8 Solved QuestionFaisal MumtazNo ratings yet

- 01 - Mass & Energy Balance WWT (CHP3)Document56 pages01 - Mass & Energy Balance WWT (CHP3)Faisal MumtazNo ratings yet

- Sizing PoleniDocument87 pagesSizing PoleniFaisal MumtazNo ratings yet

- Assignment 1Document3 pagesAssignment 1Faisal MumtazNo ratings yet

- Summary of Vector and Tensor NotationDocument41 pagesSummary of Vector and Tensor NotationFaisal MumtazNo ratings yet

- 00 - WWT EngineeringDocument188 pages00 - WWT EngineeringFaisal MumtazNo ratings yet

- Pipe Driving: German Atv Rules and StandardsDocument51 pagesPipe Driving: German Atv Rules and StandardsFaisal MumtazNo ratings yet

- Notes 3: Mass TransportDocument60 pagesNotes 3: Mass TransportFaisal MumtazNo ratings yet

- 06 - STP Energy Balance (Power Consumption Calcs)Document7 pages06 - STP Energy Balance (Power Consumption Calcs)Faisal MumtazNo ratings yet

- Pyrolysis of Polypropylene Waste With Natural Zeolite As CatalystDocument10 pagesPyrolysis of Polypropylene Waste With Natural Zeolite As CatalystFaisal MumtazNo ratings yet

- 02 - Case Study - Industrial Technical QueryDocument3 pages02 - Case Study - Industrial Technical QueryFaisal MumtazNo ratings yet

- Explosion Protection in Accordance To German Law, Safety and Quality StandardsDocument1 pageExplosion Protection in Accordance To German Law, Safety and Quality StandardsFaisal MumtazNo ratings yet

- A Study On Thermo - Catalytic Degradation of PET (Polyethylene Terephthalate) Waste For Fuel Production and Chemical ProductsDocument6 pagesA Study On Thermo - Catalytic Degradation of PET (Polyethylene Terephthalate) Waste For Fuel Production and Chemical ProductsFaisal MumtazNo ratings yet

- Isoconversional Methods - Fundamentals, Meaning and ApplicationDocument11 pagesIsoconversional Methods - Fundamentals, Meaning and ApplicationFaisal MumtazNo ratings yet

- 02 Bo Leistungsprofil-Gebäudetechnik enDocument1 page02 Bo Leistungsprofil-Gebäudetechnik enFaisal MumtazNo ratings yet

- Hydraulic Dimensioning and Verification of Drainage Systems: German Atv Rules and StandardsDocument42 pagesHydraulic Dimensioning and Verification of Drainage Systems: German Atv Rules and StandardsFaisal Mumtaz100% (1)

- EXP#2 Conduction of Gases and LiquidsDocument6 pagesEXP#2 Conduction of Gases and LiquidsShahbazNo ratings yet

- Experimental Research On The Novel Process of Iron Ore Direct ReductionDocument8 pagesExperimental Research On The Novel Process of Iron Ore Direct ReductionMariaNo ratings yet

- Tutorial-10-MEP311-Sheet-7-Premixed Flames-P-1-5Document22 pagesTutorial-10-MEP311-Sheet-7-Premixed Flames-P-1-5Amr MohsenNo ratings yet

- RWO Grease TrapDocument2 pagesRWO Grease TrapMuzami ThahirNo ratings yet

- ECS002 - Calculation For The Orifice Plate On The AC Lube Oil SystemDocument9 pagesECS002 - Calculation For The Orifice Plate On The AC Lube Oil SystemPaul CarlyNo ratings yet

- 3 - MID-TD-0000-1 - Fuel Gas Spec Rev Sept 09Document14 pages3 - MID-TD-0000-1 - Fuel Gas Spec Rev Sept 09talebNo ratings yet

- Installation Practices For Pressure Relief ValvesDocument5 pagesInstallation Practices For Pressure Relief ValvesSevda KonakNo ratings yet

- Wet Air Oxidation and Catalytic Wet Air Oxidation For Refinery Spent Caustic DegradationDocument7 pagesWet Air Oxidation and Catalytic Wet Air Oxidation For Refinery Spent Caustic DegradationSudeep MukherjeeNo ratings yet

- Fluent Input RationaleDocument5 pagesFluent Input RationaleAsaad iqbalNo ratings yet

- Uou-5.3 SRPDocument106 pagesUou-5.3 SRPDalibor SimicNo ratings yet

- Fischer Tropsch CatalystsDocument93 pagesFischer Tropsch CatalystschuertaNo ratings yet

- Guidelines For The Avoidance of Vibration Induced Fatigue Failure in Process PDocument5 pagesGuidelines For The Avoidance of Vibration Induced Fatigue Failure in Process PFSAAVEDRAFNo ratings yet

- Unit - Iv Heat Transfer AnalysisDocument36 pagesUnit - Iv Heat Transfer AnalysisAkhil SriramNo ratings yet

- CHNG 3014 - Safety Project (Ammonia Plant - Group 2) (5536)Document146 pagesCHNG 3014 - Safety Project (Ammonia Plant - Group 2) (5536)Alex LochaiNo ratings yet

- Enhance Naphtha Value and Gasoline Reformer Performance Using UOP's MaxEneTMProcessEnhanceDocument25 pagesEnhance Naphtha Value and Gasoline Reformer Performance Using UOP's MaxEneTMProcessEnhanceAhmad DaoodNo ratings yet

- Fluid Mechanics: 7 SessionDocument9 pagesFluid Mechanics: 7 SessionAmir MehrNo ratings yet

- Solvolysis LabDocument5 pagesSolvolysis LabAriesNo ratings yet

- Steam Reforming Carbon FormationDocument26 pagesSteam Reforming Carbon FormationBilalNo ratings yet

- 5 UOP. Honeywell Egypt - Olefins - Mike BanachDocument17 pages5 UOP. Honeywell Egypt - Olefins - Mike Banachharaldno1No ratings yet

- CHM111 - Chemical Equilibrium NoteDocument22 pagesCHM111 - Chemical Equilibrium NoteolufemisongNo ratings yet

- Sewage Treatment PlantDocument33 pagesSewage Treatment PlantTanish Bhansali100% (1)

- PMS Chapter5ADocument80 pagesPMS Chapter5AmoulitechNo ratings yet

- Jurnal TA Lean SIx SigmaDocument7 pagesJurnal TA Lean SIx SigmaManuel AllenNo ratings yet

- Mtu Engine Model12V4000G63 A. LT CIRCUIT (260 KW at 29 M /HR) Heat Exchanger: Gl-13Lx24 Duty RequirementsDocument4 pagesMtu Engine Model12V4000G63 A. LT CIRCUIT (260 KW at 29 M /HR) Heat Exchanger: Gl-13Lx24 Duty RequirementsbaljeetjatNo ratings yet

- 13 Reaction Kinetics (S)Document32 pages13 Reaction Kinetics (S)Mr TanNo ratings yet

- 5113Document4 pages5113jineesha p jNo ratings yet

- Introduction To Convection: Flow and Thermal ConsiderationsDocument11 pagesIntroduction To Convection: Flow and Thermal ConsiderationsJT RobertoNo ratings yet

- Mechanisms of Heat TransferDocument5 pagesMechanisms of Heat TransferIsabel RamosNo ratings yet

05 - Design of Package RCTR

05 - Design of Package RCTR

Uploaded by

Faisal MumtazOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05 - Design of Package RCTR

05 - Design of Package RCTR

Uploaded by

Faisal MumtazCopyright:

Available Formats

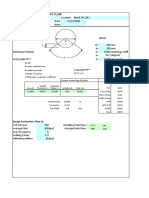

Design Example of Extended - Aeration Activated Sludge Process (Package Plant)

A prefabricated package modular plant is to be used to treat the wastewater from a newly developed housing area

consisting of X individual family residences villas as part of Ministry of Housing Projects.

The average occupancy has been estimated to be 2.9 persons per residence villa.

Use a flow of 230 L/person.day and a daily peaking factor of 2.5 for flow, BOD5 and SS.

Use an hourly peaking factor of 4 for sizing the sedimentation facilities. It is suggested to use Package-modular;

Extended Aeration Activated Sludge Process type of treatment plant and size the principal components of the plant.

Effluent BOD5 concentration of the process must be or lower than 30 mg/L.

Sample Solution for 550 villas...

1. The total number of person : No. of homes* no. of persons living per home:

(550 home)(2.9 person/home-given) = 1,595 person

2. The corresponding average flowrate :No. of persons* assumed/given usage (m3/d)

(1,595 person)(0.230 m3/person.day-given) = 366.85 m3/day

3. The corresponding peak daily flowrate : Average flowrate(m3/d)*Peak factor

(366.85 m3/day)(2.5-given) = 917.13 m3/day

4. The average BOD5 load : No. of people*Assumed BOD produced per person(g/person/day)

(1,595 persons)(80 g BOD5/person.day) = 127,600 g BOD5/day

5. The corresponding BOD5 concentration : Average BOD load(g/d)/Flowrate(m3/d)

(127,600 g/day) / (366.85 m3/day) = 348 g/m3 (mg/L)

6. The average SS load : No. of people*Assumed SS produced per person per day(g/person/day)

(1,595 persons)(90 g SS/person.day) = 143,550 g SS/day

7. The corresponding SS concentration: Average SS load(g/d)/Flowrate(m3/d)

(143,550 g/day) / (366.85 m3/day) = 391 g/m3 (mg/L)

8. The peak daily BOD5 load: Average BOD produced(kg/d)*peak factor

(127.60 kg BOD5/day)(2.5-given) = 319.00 kg BOD5/day

9. The peak daily SS load : Average SS produced(kg/d)*peak factor

(143.55 kg SS/day)(2.5-given) = 358.88 kg SS/day

10. An extended aeration activated sludge process package plant is selected (given)

11. The aeration time : 1.0 day/24hrs assume

12. The aeration tank volume: Average flow rate (m3/d)*aeration time(d)

(366.85 m3/day)(1.0 day) = 366.85 m3

13. The oxygen transfer efficiency : 6 % assume (assumed)

14. The specific weight of air : 1.26 kg/m3

15. The oxygen content : 23.2 %

16. The air requirement : Peak daily BOD load (kg/d)/Specific weight of air(kg/m3)*oxygen content*oxygen

transfer

(319.00 kg BOD5/day) / (1.26 kg/m3)(0.232)(0.06) = 18,187.83 m3/day

17. The peak hour factor for the settling tank : 4 (given)

18. The overflow rate for settling tank : 24 m3/m2.day (assumed)

19. The surface area of settling tank : Average flow rate (m3/d)*peak hour factor/overflow rate(m3/m2.day)

(366.85 m3/day)(4) / 24 m3/m2.day = 61.14 m2

20. The hydraulic detention time for settling tank : 0.5 h (assumed)

21. The volume of the settling tank : Average flow rate (m3/d)*peak hour factor*hydraulic detention time(d)

(366.85 m3/day)(4)(0.5 h) / 24 h/day = 30.57 m3

Design of STP (Sanitary treatment Plant;Package-modular; Extended - Aeration Activated Sludge Process type)

for East-Hidd housing project comprising of 4,545 Villas.

Design of STP (Sanitary treatment Plant;Package-modular; Extended - Aeration Activated Sludge Process type)

for Salman City housing project comprising of 15,519 Villas corresponding to 98,935 estimated population of

residents.

You might also like

- Solution Manual Chemical Engineering Fluid Mechanics 3rd Edition Ron Darby and Raj Chhabra PDF PDF FreeDocument14 pagesSolution Manual Chemical Engineering Fluid Mechanics 3rd Edition Ron Darby and Raj Chhabra PDF PDF FreeB̸̗̠̼͍̔̀͂ą̶̫̭̞̒ͅr̶̢̟͕͓͉̊̏̿̿̒̓̂̈́̎͘ũ̵̢̡̫̖͔̘̙̳̗̫͊̆͝c̷͉̘̟̹̏̅̊̂͘̚ẖ̶̢̘̦̈́̌̀̆̋̽͋ Z̸͉͕̼̪̰͂͛̒ẽ̵͙̲̱͖̣͙̬͖͓̗̄p̴͇̼̮͍̱̬͕̩͙̾̋͋̓̿͋̂̓̂͘ͅṗ̶̡̢̱̻̭̅̒̽̚͠ȩ̷̛̹̺̘͕͎̲̩͎͊̃͛̎̈́̔͆l̴͍̖̞̙͉̟̣̠̻̳͂̍̈́̏̑̈́̽́̇͝i̷͍̫̜͎̖̮͂̎̄̽͛̚No ratings yet

- Me 313a - m3 412 Heat Transfer Weeks 10-12Document59 pagesMe 313a - m3 412 Heat Transfer Weeks 10-12Solayao, Jan Marvin J.No ratings yet

- 426-Anaerobic Digester DesignDocument36 pages426-Anaerobic Digester DesignmullanaNo ratings yet

- WWT Secondary Clarifier PDFDocument15 pagesWWT Secondary Clarifier PDFdzari6738No ratings yet

- Sample WW QuestionsDocument10 pagesSample WW QuestionsKrishna Kumar MeenaNo ratings yet

- Objectives: Chapter 4 Sludge Treatment and DisposalDocument37 pagesObjectives: Chapter 4 Sludge Treatment and Disposalashe zinabNo ratings yet

- Worked ExamplesDocument9 pagesWorked ExamplesDzung Pham0% (1)

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationFrom EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationRating: 3 out of 5 stars3/5 (1)

- Anaerobic Digestor DesignDocument36 pagesAnaerobic Digestor DesignChanelNo ratings yet

- Anaerobic Digester - QasimDocument35 pagesAnaerobic Digester - Qasimawaluddin nurmiyantoNo ratings yet

- Process Loading Evaluation & Sludge Accountability: - Step Through The Performance EvaluationDocument55 pagesProcess Loading Evaluation & Sludge Accountability: - Step Through The Performance EvaluationNiong DavidNo ratings yet

- Design of Each Process of ETPDocument9 pagesDesign of Each Process of ETPFaisal Sr. ExecutiveNo ratings yet

- Design ExamplesDocument5 pagesDesign Examplesnaba1577No ratings yet

- Anaerobic Digester DesignsDocument6 pagesAnaerobic Digester DesignsaminmominNo ratings yet

- SBR Design PDFDocument7 pagesSBR Design PDFmkdholkiya100% (1)

- Calculation Memory Sheet - Pre TreatmentDocument6 pagesCalculation Memory Sheet - Pre TreatmentDiego DiazNo ratings yet

- 128 Basic Aeration Design CalculationsxDocument4 pages128 Basic Aeration Design CalculationsxErno RuzsaNo ratings yet

- Tutorial 1-CH2402 - 2019Document4 pagesTutorial 1-CH2402 - 2019Naduni RanasingheNo ratings yet

- Example: 230 MG/L BODDocument7 pagesExample: 230 MG/L BODajali1957No ratings yet

- Wastewater Math FormulasDocument17 pagesWastewater Math FormulasPratiwi Natsir PutriNo ratings yet

- Design of Biogas DigestersDocument22 pagesDesign of Biogas DigestersSharath Chandra100% (5)

- CT4485 Exam 31-01-2012 With AnswersDocument7 pagesCT4485 Exam 31-01-2012 With AnswersVali100% (1)

- Algae ConceptDocument9 pagesAlgae ConceptAnand RSNo ratings yet

- Tasarım Soruları PDFDocument2 pagesTasarım Soruları PDFAkbey ApaydınNo ratings yet

- Secondary ClarifierDocument29 pagesSecondary ClarifierNoureddine MerahNo ratings yet

- 3 Lecture Wastewater Characteristic AnalysisDocument41 pages3 Lecture Wastewater Characteristic AnalysiszeyadNo ratings yet

- Solid Waste Management: EKC378 DR Azam T Mohd Din School of Chemical Engineering Universiti Sains MalaysiaDocument46 pagesSolid Waste Management: EKC378 DR Azam T Mohd Din School of Chemical Engineering Universiti Sains MalaysiaKalai YooganNo ratings yet

- CEE373.2 - Spring 2023 - CEDPDocument16 pagesCEE373.2 - Spring 2023 - CEDPMd. Zawad Amin As-salek 2011847625No ratings yet

- Waste Water AssignmentDocument4 pagesWaste Water Assignmentermias100% (2)

- Convenience Store Business PlanDocument4 pagesConvenience Store Business Planrmrv valdezNo ratings yet

- Assignment - Part 1 (Final Year Project) : SupervisorDocument11 pagesAssignment - Part 1 (Final Year Project) : Supervisorannie aliNo ratings yet

- Design of Completely Mixed Activated Sludge System: Home Quiz Design ExampleDocument3 pagesDesign of Completely Mixed Activated Sludge System: Home Quiz Design Exampledanndiamond100% (1)

- Activated Sludge Design: Treatment Process F/M KG Bod /KG MLSS/day Extended Aeration Conventional High RateDocument4 pagesActivated Sludge Design: Treatment Process F/M KG Bod /KG MLSS/day Extended Aeration Conventional High RateMhelveneNo ratings yet

- Jae K. (Jim) Park, Professor Dept. of Civil and Environmental Engineering University of Wisconsin-MadisonDocument29 pagesJae K. (Jim) Park, Professor Dept. of Civil and Environmental Engineering University of Wisconsin-MadisonSuhas JadhavNo ratings yet

- Explanation - Design of AD Fixed Dome Reactor For A Vegetable MarketDocument3 pagesExplanation - Design of AD Fixed Dome Reactor For A Vegetable MarketAlexis ChicaizaNo ratings yet

- Municipal Solid Waste and Schedule Waste PDFDocument89 pagesMunicipal Solid Waste and Schedule Waste PDFdanial 96No ratings yet

- AL HURWWTPDesignCalculationsDocument16 pagesAL HURWWTPDesignCalculationsMedalson RonghangNo ratings yet

- Wastewater TreatmentDocument27 pagesWastewater Treatmentnayerashoman97No ratings yet

- UAS Rika BN - PGB 2020Document8 pagesUAS Rika BN - PGB 2020Rika Budi NoviawatiNo ratings yet

- Introduction To Dual Fuel InjectionDocument8 pagesIntroduction To Dual Fuel InjectionAbhiNo ratings yet

- S19 - Louisiana State University - LTC2013Document35 pagesS19 - Louisiana State University - LTC2013walaywanNo ratings yet

- Carbon Foot PrintDocument19 pagesCarbon Foot Printgou100% (1)

- Applied Wastewater Math Formula Sheet and Conversion FactorsDocument3 pagesApplied Wastewater Math Formula Sheet and Conversion FactorsMasoud HasanyNo ratings yet

- Contoh Perhitungan LumpurDocument9 pagesContoh Perhitungan Lumpurkhairinfuadi50% (4)

- Solid WasteDocument31 pagesSolid WasteCer No RusNo ratings yet

- Pump and Aeration Tank SizingDocument14 pagesPump and Aeration Tank SizingDavid LambertNo ratings yet

- 1.1 Palm Oil MillDocument31 pages1.1 Palm Oil MillChee Yen ChiaNo ratings yet

- Tutorial 4 SolutionsDocument2 pagesTutorial 4 SolutionsUý Đại100% (1)

- Loading S Calculations by Dr. Ghaida Abu Rumman enDocument36 pagesLoading S Calculations by Dr. Ghaida Abu Rumman ensauroNo ratings yet

- CE 40340 Homework 6Document4 pagesCE 40340 Homework 6NanoNo ratings yet

- CVL723PS1Document5 pagesCVL723PS1Ronald Ewa100% (1)

- MBBRDocument37 pagesMBBRLye Yp100% (2)

- 2512 Tutorial Sheet 01Document2 pages2512 Tutorial Sheet 01aggrey noahNo ratings yet

- Anaerobic Sludge Digester (ASD) : Ahmad Faris Bin Mohd Napi Muhd Baktiar Bin Razali Muhd Nasrun Bin Mohd RosdiDocument46 pagesAnaerobic Sludge Digester (ASD) : Ahmad Faris Bin Mohd Napi Muhd Baktiar Bin Razali Muhd Nasrun Bin Mohd RosdiAhmad FarisNo ratings yet

- Tutorial Sheet NumericalsDocument3 pagesTutorial Sheet NumericalsanubhavNo ratings yet

- Biogas TechnologyDocument35 pagesBiogas Technologyraghunath670743No ratings yet

- BiogasDocument11 pagesBiogasAnand RathiNo ratings yet

- Digestor Anaerobico PDFDocument5 pagesDigestor Anaerobico PDFAnonymous XguKEyW100% (1)

- Environmental Scenario in Indian Mining Industry - an OverviewFrom EverandEnvironmental Scenario in Indian Mining Industry - an OverviewNo ratings yet

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- Aramco Leadership Share New Economic Map at Ceraweek: Company Talks Strong FutureDocument11 pagesAramco Leadership Share New Economic Map at Ceraweek: Company Talks Strong FutureFaisal MumtazNo ratings yet

- Wer 1408Document7 pagesWer 1408Faisal MumtazNo ratings yet

- IWTP8-MFQ-ILF-21-0500-Mechanical Equipment List 23-p2mDocument10 pagesIWTP8-MFQ-ILF-21-0500-Mechanical Equipment List 23-p2mFaisal MumtazNo ratings yet

- Summary of A Conceptual Design of Low Fouling and High Recovery FO-MSF-DESKTOP-47LO0PODocument1 pageSummary of A Conceptual Design of Low Fouling and High Recovery FO-MSF-DESKTOP-47LO0POFaisal MumtazNo ratings yet

- Ajerd0201 05Document6 pagesAjerd0201 05Faisal MumtazNo ratings yet

- BQTS - WetWellCalcDocument3 pagesBQTS - WetWellCalcFaisal MumtazNo ratings yet

- EENG703 - Assignment04 (AutoRecovered)Document19 pagesEENG703 - Assignment04 (AutoRecovered)Faisal MumtazNo ratings yet

- Hydraulic SizingDocument2 pagesHydraulic SizingFaisal MumtazNo ratings yet

- Optimisation of The WWTP Performance MakiniaDocument39 pagesOptimisation of The WWTP Performance MakiniaFaisal MumtazNo ratings yet

- Summary of Development of A Steady-State Mathematical Model For MEE-TVCDocument2 pagesSummary of Development of A Steady-State Mathematical Model For MEE-TVCFaisal MumtazNo ratings yet

- Mannings MetricDocument1 pageMannings MetricFaisal MumtazNo ratings yet

- ExergyDocument10 pagesExergyFaisal MumtazNo ratings yet

- Experimental Study of Thermal and Catalytic Pyrolysis of Plastic Waste ComponentsDocument11 pagesExperimental Study of Thermal and Catalytic Pyrolysis of Plastic Waste ComponentsFaisal MumtazNo ratings yet

- Friction FactorDocument6 pagesFriction Factorrajeshsapkota123No ratings yet

- Ch8 Solved QuestionDocument4 pagesCh8 Solved QuestionFaisal MumtazNo ratings yet

- 01 - Mass & Energy Balance WWT (CHP3)Document56 pages01 - Mass & Energy Balance WWT (CHP3)Faisal MumtazNo ratings yet

- Sizing PoleniDocument87 pagesSizing PoleniFaisal MumtazNo ratings yet

- Assignment 1Document3 pagesAssignment 1Faisal MumtazNo ratings yet

- Summary of Vector and Tensor NotationDocument41 pagesSummary of Vector and Tensor NotationFaisal MumtazNo ratings yet

- 00 - WWT EngineeringDocument188 pages00 - WWT EngineeringFaisal MumtazNo ratings yet

- Pipe Driving: German Atv Rules and StandardsDocument51 pagesPipe Driving: German Atv Rules and StandardsFaisal MumtazNo ratings yet

- Notes 3: Mass TransportDocument60 pagesNotes 3: Mass TransportFaisal MumtazNo ratings yet

- 06 - STP Energy Balance (Power Consumption Calcs)Document7 pages06 - STP Energy Balance (Power Consumption Calcs)Faisal MumtazNo ratings yet

- Pyrolysis of Polypropylene Waste With Natural Zeolite As CatalystDocument10 pagesPyrolysis of Polypropylene Waste With Natural Zeolite As CatalystFaisal MumtazNo ratings yet

- 02 - Case Study - Industrial Technical QueryDocument3 pages02 - Case Study - Industrial Technical QueryFaisal MumtazNo ratings yet

- Explosion Protection in Accordance To German Law, Safety and Quality StandardsDocument1 pageExplosion Protection in Accordance To German Law, Safety and Quality StandardsFaisal MumtazNo ratings yet

- A Study On Thermo - Catalytic Degradation of PET (Polyethylene Terephthalate) Waste For Fuel Production and Chemical ProductsDocument6 pagesA Study On Thermo - Catalytic Degradation of PET (Polyethylene Terephthalate) Waste For Fuel Production and Chemical ProductsFaisal MumtazNo ratings yet

- Isoconversional Methods - Fundamentals, Meaning and ApplicationDocument11 pagesIsoconversional Methods - Fundamentals, Meaning and ApplicationFaisal MumtazNo ratings yet

- 02 Bo Leistungsprofil-Gebäudetechnik enDocument1 page02 Bo Leistungsprofil-Gebäudetechnik enFaisal MumtazNo ratings yet

- Hydraulic Dimensioning and Verification of Drainage Systems: German Atv Rules and StandardsDocument42 pagesHydraulic Dimensioning and Verification of Drainage Systems: German Atv Rules and StandardsFaisal Mumtaz100% (1)

- EXP#2 Conduction of Gases and LiquidsDocument6 pagesEXP#2 Conduction of Gases and LiquidsShahbazNo ratings yet

- Experimental Research On The Novel Process of Iron Ore Direct ReductionDocument8 pagesExperimental Research On The Novel Process of Iron Ore Direct ReductionMariaNo ratings yet

- Tutorial-10-MEP311-Sheet-7-Premixed Flames-P-1-5Document22 pagesTutorial-10-MEP311-Sheet-7-Premixed Flames-P-1-5Amr MohsenNo ratings yet

- RWO Grease TrapDocument2 pagesRWO Grease TrapMuzami ThahirNo ratings yet

- ECS002 - Calculation For The Orifice Plate On The AC Lube Oil SystemDocument9 pagesECS002 - Calculation For The Orifice Plate On The AC Lube Oil SystemPaul CarlyNo ratings yet

- 3 - MID-TD-0000-1 - Fuel Gas Spec Rev Sept 09Document14 pages3 - MID-TD-0000-1 - Fuel Gas Spec Rev Sept 09talebNo ratings yet

- Installation Practices For Pressure Relief ValvesDocument5 pagesInstallation Practices For Pressure Relief ValvesSevda KonakNo ratings yet

- Wet Air Oxidation and Catalytic Wet Air Oxidation For Refinery Spent Caustic DegradationDocument7 pagesWet Air Oxidation and Catalytic Wet Air Oxidation For Refinery Spent Caustic DegradationSudeep MukherjeeNo ratings yet

- Fluent Input RationaleDocument5 pagesFluent Input RationaleAsaad iqbalNo ratings yet

- Uou-5.3 SRPDocument106 pagesUou-5.3 SRPDalibor SimicNo ratings yet

- Fischer Tropsch CatalystsDocument93 pagesFischer Tropsch CatalystschuertaNo ratings yet

- Guidelines For The Avoidance of Vibration Induced Fatigue Failure in Process PDocument5 pagesGuidelines For The Avoidance of Vibration Induced Fatigue Failure in Process PFSAAVEDRAFNo ratings yet

- Unit - Iv Heat Transfer AnalysisDocument36 pagesUnit - Iv Heat Transfer AnalysisAkhil SriramNo ratings yet

- CHNG 3014 - Safety Project (Ammonia Plant - Group 2) (5536)Document146 pagesCHNG 3014 - Safety Project (Ammonia Plant - Group 2) (5536)Alex LochaiNo ratings yet

- Enhance Naphtha Value and Gasoline Reformer Performance Using UOP's MaxEneTMProcessEnhanceDocument25 pagesEnhance Naphtha Value and Gasoline Reformer Performance Using UOP's MaxEneTMProcessEnhanceAhmad DaoodNo ratings yet

- Fluid Mechanics: 7 SessionDocument9 pagesFluid Mechanics: 7 SessionAmir MehrNo ratings yet

- Solvolysis LabDocument5 pagesSolvolysis LabAriesNo ratings yet

- Steam Reforming Carbon FormationDocument26 pagesSteam Reforming Carbon FormationBilalNo ratings yet

- 5 UOP. Honeywell Egypt - Olefins - Mike BanachDocument17 pages5 UOP. Honeywell Egypt - Olefins - Mike Banachharaldno1No ratings yet

- CHM111 - Chemical Equilibrium NoteDocument22 pagesCHM111 - Chemical Equilibrium NoteolufemisongNo ratings yet

- Sewage Treatment PlantDocument33 pagesSewage Treatment PlantTanish Bhansali100% (1)

- PMS Chapter5ADocument80 pagesPMS Chapter5AmoulitechNo ratings yet

- Jurnal TA Lean SIx SigmaDocument7 pagesJurnal TA Lean SIx SigmaManuel AllenNo ratings yet

- Mtu Engine Model12V4000G63 A. LT CIRCUIT (260 KW at 29 M /HR) Heat Exchanger: Gl-13Lx24 Duty RequirementsDocument4 pagesMtu Engine Model12V4000G63 A. LT CIRCUIT (260 KW at 29 M /HR) Heat Exchanger: Gl-13Lx24 Duty RequirementsbaljeetjatNo ratings yet

- 13 Reaction Kinetics (S)Document32 pages13 Reaction Kinetics (S)Mr TanNo ratings yet

- 5113Document4 pages5113jineesha p jNo ratings yet

- Introduction To Convection: Flow and Thermal ConsiderationsDocument11 pagesIntroduction To Convection: Flow and Thermal ConsiderationsJT RobertoNo ratings yet

- Mechanisms of Heat TransferDocument5 pagesMechanisms of Heat TransferIsabel RamosNo ratings yet