Professional Documents

Culture Documents

Exam 1 P1 A

Exam 1 P1 A

Uploaded by

CRISTIAN X ORTIZ-PERALESOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exam 1 P1 A

Exam 1 P1 A

Uploaded by

CRISTIAN X ORTIZ-PERALESCopyright:

Available Formats

Answer: The

fluctuation of the torquemaximum

and bending moment allowable torque

are synchronized. is

The material hasM

T a=

a tensile

strength of 590MPa and a yield strength of 480MPa. The shaft has been designed with safe

1

factor of 1.5, reliability of 99.9%, operates at room temperature.

Determine the life of the component.

8/13. Exam 1 – Part 1 (Total Grade 35%)

r = 1.5 mm

Consider a cannon barrel made of AISI 4340 steel with a tensile strength of TS=1.23GPa, a yield

strength of YS=1.13GP, subjected to a repetitive fire that consists of a firing pressure of 260

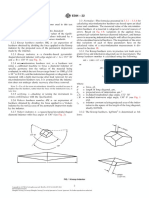

An axle has a gro

MPa.

P P

A small symmetrical indentation in the barrel inside diameter produces the following stress

according to the fig

concentrations Klongitudinal=1.3 , Kradial=1.1 , Khoop=1.1

26 30 mm

The design safety factor for the component is 1.3 and for the dynamic stress concentration at a tensile loading P

the point of analysis consider a fillet radius of 1mm for the calculation of Kf.

Data: OD=0.21m wall thickness of the barrel =0.08m , operates at 400oC, surface finish is

ground

is 1450-01 with σ U

A q =and reliability is 99.9%. Consider atmospheric pressureofasnotches

zero and

and KKsize =0.88

σ = 140 MPa and

1 implies that the material is very sensitive to the presence f = Kt , while

Determine the following:

q = 0 implies that the materials is not sensitive to notches and Kf = 1. The notch sensitivity q

The maximum

was found to depend on stresses (at thecharacteristics

the materials ID), mean and amplitude

such

FL

(use stress

as on the ductility, concentration)

grain size, preferred

Use the

The data

S-N below

diagram for the stress concentration (H=D in the drawing).Use

orientation or texture and heat treatment. H. Neubers (Theory of Notch Stresses -1946) found a

the same notch

sensitivity for normal andsensitivity

shear stresses. Use modified Goodman atcriterium.

Determine the safety factor with respect to fatigu

For

and10

The Basquin’s

relationship

3

between

cycles,

Using

Peterseon

equation

the notch (use graph

to: use the value 0.87xTS.

Marin’s approach calculate

andprovided

the notch

correction

inradius

handout

factors

later for the stresss

modified by Moore, 1000cycles)

Hardrath

Life of the component using modified Goodman criterion

mean value and the amplitude of the loading stress 1

q=

1+

q

a

⇢

where a is the Neuber’s Constant that depend on the tensile strength of the material and ⇢ is the

Note: equations:

notchsubmit

Please radius.your

In steels with ain325M

answers PDF Pfile

a <inTthree

S < 1725M

pagesPmaximum.

a the Neuber’s constant is given by the F Mb

=4 ax=) b = 32 =

expression: ⇡d2 ⇡d3

The static stress concentration factors for these type

3 2

log a = 1.079 ⇥ 10 9 (T S) + 2.740 ⇥ 10 6 (T S) 10 3 (T S)

3.740 ⇥Petersen) + equation:

the 0.6404

of the stress concentration factor. Hence, the stress concentration factor needs to be deter- 1

Kt = 1 + q

where

mined T S is

for every the tensile

individual strength

type of geometricofdiscontinuity

the material in MPa

(grooves, andchange

notches, a is inof mm.

cross Other expressions for r

A t + 2B d r

1+

the Neuber’s

section, constant

etc.) and for are:type of stresses (axial, bending, torsion, transversewhere

each di↵erent shear).

A, B, C and z are constants given in the table b

p 8

a = 0.246 2.67 ⇥ 10 T S 3 + 1.51 ⇥ 10 5

T S2 3.08 ⇥ 10 3

T S for bending/axial loading

Groove

p 8 3 5 2 3

a = 0.190 2.67 ⇥ 10 T S + 1.35 ⇥ 10 TS 2.51 ⇥ 10 T S for torsion loading

tension bending torsion tensio

and a value of q = 0.2 is recommended for cast iron material. The two above

A

expressions

0.22

are

0.2 0.7 0.62

equations: represented graphically as follows:

B 1.37 2.75 10.3 3.5

F Mb T

ax = 4 2

=) b = 32 3 =) ⌧t = 16 3 C - - - -

⇡d ⇡d ⇡d

The static stress concentration factors for these types of discontinuities are given byz (after- - - -

Petersen) the equation: ⌧max,tor

max,b

Kt,b = =) Kt,tor =

nom,b 1 ⌧nom,tor

q that the stress concentration factor has been obtained for static

Kt = 1 t+indicates

where the subscript

r r 2 z d

A calculation

loading by either a theoretical t + 2B 1 + 2ofdr finite+element

usingd principles C rt analysis

D or determined

Page 8:10

where A, B, Cthe

and

experimentally under laboratory conditions and static loading, the subscripts b and tor refer to

z are

stress typesconstants given

of bending and in loading.

torsion the tableThe below:

nominal stresses are therefore reference Chapter 8

stresses that need to be properly defined for each of the discontinuity types. In general, nominal

net stresses are used that is they are obtained using the net cross section. So for the above

example the nominal stress for bending and torsion are:

Groove 32M

Shoulder Fillet

16T

nom,b = =) ⌧nom,tor =

⇡d3 ⇡d3

And alternative

where is the diameterapproach

d = D 2t to the calculation

measured of the

between the roots relationship

of the groove. between the Kt and Kf will be

tension bending torsion tension bending torsion

given

Inglis (1913below. It is

C.E. Inglis, clear in

“Stresses that 1 6Due

a Plate Kfto 6theK t and of

Presence that forand

Cracks mild notches

Sharp Corners,”Kf ⇡ Kt and for acute

Transactions of the Institution of Naval Architects, Vol. 55, London, K1913, pp. 219–230.) carried

A outnotches Kf < Kt . The notch support factor n = Kf has been calculated using three common

t

0.22

the 0.2 treatment

first mathematical 0.7of stress concentration

0.62 0.62

factors in an elliptical hole 3.4

on an

approaches, namely, stress averaging, stress gradient and highly stress volume.

infinite wide plate. The ellipse of long axis (2a) and short axis (2b) was subjected to a tensile

B stress in the direction

Stress

1.37 averaging:perpendicular

2.75 10.3to the longindicated,

As previously axis.

3.5 there is5.8

2

a limit for the 19

maximum stress value that

b

Thecan exist

radius in a notch.

of curvature at theTherefore, thewas

tip of the ellipse stress that control

calculated as ⇢ = the

and initiation of stress

the maximum a crack is not the maximum

You might also like

- Accumulator Discharging and Charging Procedures (0738, 4263, 4264, 4331, 5077, 5077, 5081, 7474)Document24 pagesAccumulator Discharging and Charging Procedures (0738, 4263, 4264, 4331, 5077, 5077, 5081, 7474)Odai AlsaafinNo ratings yet

- Sri - FM200Document11 pagesSri - FM200undertaker550% (1)

- Duct Static Pressure CalculationsDocument7 pagesDuct Static Pressure CalculationsMirza Mohammed Yousuf Baig100% (2)

- Physics SPMDocument23 pagesPhysics SPMkamalharmoza100% (4)

- ASTM E384 (2022) - Part2Document1 pageASTM E384 (2022) - Part2david4231993No ratings yet

- Nuclear Magnetic Resonance (NMR) : 1 TheoryDocument18 pagesNuclear Magnetic Resonance (NMR) : 1 Theoryfajarsahatasitorus3935No ratings yet

- FORMULA Machine DesignDocument11 pagesFORMULA Machine Designnatalie echaviaNo ratings yet

- Liu - Fatigue Crack Propagation and Applied Stress Range - An Energy ApproachDocument7 pagesLiu - Fatigue Crack Propagation and Applied Stress Range - An Energy ApproachDavid C HouserNo ratings yet

- Problems-Part IIDocument3 pagesProblems-Part IIAisha AbuzgaiaNo ratings yet

- Torsion em 327: Mechanics of Materials LaboratoryDocument4 pagesTorsion em 327: Mechanics of Materials LaboratoryfrankjonoNo ratings yet

- Finite Element and Boundary Methods (ME 613) Assignment-1Document20 pagesFinite Element and Boundary Methods (ME 613) Assignment-1Nishant GuptaNo ratings yet

- Chapter 1 Stress and Strain PDFDocument21 pagesChapter 1 Stress and Strain PDFsanthiyaperemelNo ratings yet

- Susmel, Taylor - 2008 - The Modified Wohler Curve Method Applied Along With The Theory of Critical Distances To Estimate Finite Life ofDocument18 pagesSusmel, Taylor - 2008 - The Modified Wohler Curve Method Applied Along With The Theory of Critical Distances To Estimate Finite Life ofCaio LacerdaNo ratings yet

- Nonlinear Standingwaves in Acoustic ResonatorsDocument4 pagesNonlinear Standingwaves in Acoustic ResonatorsJmeno PrijmeniNo ratings yet

- KLA AppNote StrainRateDocument6 pagesKLA AppNote StrainRatep dNo ratings yet

- TENSION MEMBERS Yielding Shear LagDocument28 pagesTENSION MEMBERS Yielding Shear LagEhsan WasimNo ratings yet

- Is Rubber More Elastic Than Steel? The Answer Lies in The Concept of ElasticityDocument7 pagesIs Rubber More Elastic Than Steel? The Answer Lies in The Concept of ElasticityKiran YaqoobNo ratings yet

- PED I Book Part 1Document27 pagesPED I Book Part 1RADHE GRAPHICSNo ratings yet

- Microsoft Word - SOM Contents and PrefaceDocument429 pagesMicrosoft Word - SOM Contents and Prefacebrendonsithole6No ratings yet

- Charge Transport in Semiconductors 3.1 Drift Current: D NDRDocument21 pagesCharge Transport in Semiconductors 3.1 Drift Current: D NDRKesavNo ratings yet

- 1 s2.0 0921452689901075 MainDocument4 pages1 s2.0 0921452689901075 MainBiswajit AdhikaryNo ratings yet

- The Author Also Holds An Appointment As Affiliated Pro-Fessor of Physics at Montana State University, BozemanDocument6 pagesThe Author Also Holds An Appointment As Affiliated Pro-Fessor of Physics at Montana State University, BozemanVignesh RamakrishnanNo ratings yet

- Assignment 4Document2 pagesAssignment 4Manchimsetty Sri NidhiNo ratings yet

- SEC MODULE 06 SolDocument4 pagesSEC MODULE 06 Solkenji belanizoNo ratings yet

- RSE3060 Prac Class 2 - W3, S2, 2023Document1 pageRSE3060 Prac Class 2 - W3, S2, 2023NilakshiManawaduNo ratings yet

- Mechanics - Case Study Solution: Stress Transformation Equations Principal StressesDocument31 pagesMechanics - Case Study Solution: Stress Transformation Equations Principal StressesPaldexNo ratings yet

- ME 498 - 6 - Nanoindentation and NanoscratchDocument23 pagesME 498 - 6 - Nanoindentation and NanoscratchTt Ownsqq100% (1)

- Stress2_dimecDocument13 pagesStress2_dimecSamy HernándezNo ratings yet

- Pile Foundations Solved ProblemsDocument27 pagesPile Foundations Solved ProblemsSujata SarkarNo ratings yet

- b16 Exam ProblemsDocument96 pagesb16 Exam ProblemsTuanNo ratings yet

- Computer Aided Modelling of Tube DrawingDocument4 pagesComputer Aided Modelling of Tube DrawingandrreaskinzNo ratings yet

- SOMDocument431 pagesSOMPradeepvenugopalNo ratings yet

- Desing of Diagonal Cross-BracingDocument5 pagesDesing of Diagonal Cross-BracingJoseph Cristhian Lipa FloresNo ratings yet

- Beam ColumnsDocument8 pagesBeam ColumnsJohn Cedric GarganeraNo ratings yet

- Debschutz 1993Document7 pagesDebschutz 1993Hannan yusuf KhanNo ratings yet

- Strength of Materials 2018 by S K MondalDocument482 pagesStrength of Materials 2018 by S K MondalSnake BiteNo ratings yet

- Materials Processing Technology: Journal ofDocument6 pagesMaterials Processing Technology: Journal ofMatheus BarbosaNo ratings yet

- Cohesion Value For RockDocument16 pagesCohesion Value For Rockks_raghuveerNo ratings yet

- A Method For Calculating The Undrained Strength Ratio Cu P - 1981 - Soils andDocument7 pagesA Method For Calculating The Undrained Strength Ratio Cu P - 1981 - Soils andfabian valenciaNo ratings yet

- ST FFEMS 2007 RailWheelDocument14 pagesST FFEMS 2007 RailWheelPawan KishoreNo ratings yet

- 2543 33130 T5 SolutionDocument6 pages2543 33130 T5 SolutionPetrus GunturNo ratings yet

- Lattice Relaxation 1Document1 pageLattice Relaxation 1Vishwesh SNo ratings yet

- Lab 3: Use of Strain Gages To Determine The Strain in Cantilever BeamsDocument11 pagesLab 3: Use of Strain Gages To Determine The Strain in Cantilever BeamsAfghanNo ratings yet

- Topic 5 - Allowable Compressive StressesDocument18 pagesTopic 5 - Allowable Compressive StressesMohammad Taha PumbayaNo ratings yet

- Topic 5 - Allowable Compressive StressesDocument18 pagesTopic 5 - Allowable Compressive StressesMohammad Taha PumbayaNo ratings yet

- Prestressed ConcreteDocument5 pagesPrestressed ConcreteSamNo ratings yet

- Hydrodynamics and Gauge/gravity Duality: Nuclear Physics B (Proc. Suppl.) 192-193 (2009) 113-118Document6 pagesHydrodynamics and Gauge/gravity Duality: Nuclear Physics B (Proc. Suppl.) 192-193 (2009) 113-118GNo ratings yet

- Thickness Calculation of Annular Base PlateDocument2 pagesThickness Calculation of Annular Base PlateRam Chandra100% (1)

- An Analytical Solution For Time-Dependent Displacements in A Circular TunnelDocument10 pagesAn Analytical Solution For Time-Dependent Displacements in A Circular TunnelEugenio DoglioneNo ratings yet

- Module 1 - Stress, Strain & Tensile TestingsDocument21 pagesModule 1 - Stress, Strain & Tensile TestingsJuandre HerbstNo ratings yet

- Som Unit - IIIDocument32 pagesSom Unit - IIIiliyasiliyas6721No ratings yet

- Chapter 4 SensorsDocument42 pagesChapter 4 Sensorsyoyi6423No ratings yet

- The Crack Tip Strain Field of AISI 4340: Experimental MeasurementsDocument9 pagesThe Crack Tip Strain Field of AISI 4340: Experimental Measurementsfrederico wlassakNo ratings yet

- Torsion Lab Manual (Short) PDFDocument7 pagesTorsion Lab Manual (Short) PDFDonnell FrancisNo ratings yet

- MDC-II, Final Key PointsDocument6 pagesMDC-II, Final Key Pointsfahad javedNo ratings yet

- Pressure VesselDocument4 pagesPressure VesselPartha SurveNo ratings yet

- 1980 Probability Design of Prestress Concrete PolesDocument8 pages1980 Probability Design of Prestress Concrete PolesChandara KOEMNo ratings yet

- SUSMEL Et Al-2007-Fatigue & Fracture of Engineering Materials & StructuresDocument15 pagesSUSMEL Et Al-2007-Fatigue & Fracture of Engineering Materials & StructuresRafael SilvaNo ratings yet

- 1 s2.0 0017931087900457 Main PDFDocument10 pages1 s2.0 0017931087900457 Main PDFSri VatsanNo ratings yet

- Problems in Quantum Mechanics: Third EditionFrom EverandProblems in Quantum Mechanics: Third EditionRating: 3 out of 5 stars3/5 (2)

- TSFLUXUS F601V1-3-3EN LusDocument24 pagesTSFLUXUS F601V1-3-3EN LusafnanNo ratings yet

- Visvesvaraya National Institute of TechnologyDocument2 pagesVisvesvaraya National Institute of TechnologyPrabuddha GopeNo ratings yet

- Seismic Receiver and Noise Correlation Based Studies in AustraliaDocument0 pagesSeismic Receiver and Noise Correlation Based Studies in Australiaputih_138242459No ratings yet

- Practicetopics 6 Paper 1.pagesDocument13 pagesPracticetopics 6 Paper 1.pagesnadia sykesNo ratings yet

- Sena AssDocument4 pagesSena AssSena MekoninNo ratings yet

- Collision Bar Ve Jayaram AnDocument8 pagesCollision Bar Ve Jayaram AnMani VannanNo ratings yet

- Effect of Carbon Nanofibers (CNF) On The Crystallization Kinetics of Polyphenylene Sulfide (PPS)Document6 pagesEffect of Carbon Nanofibers (CNF) On The Crystallization Kinetics of Polyphenylene Sulfide (PPS)Velumani sNo ratings yet

- Tsunami Can Be Generated When The Sea Floor Abruptly Deforms and Vertically Displaces The Overlying WaterDocument2 pagesTsunami Can Be Generated When The Sea Floor Abruptly Deforms and Vertically Displaces The Overlying WaterRësürrëctêd Kärän SïnġhNo ratings yet

- HEINEBinocularLoupesandHeadlights Brochure EN GB PDFDocument8 pagesHEINEBinocularLoupesandHeadlights Brochure EN GB PDFazizNo ratings yet

- Unit & Dimension - DPPsDocument7 pagesUnit & Dimension - DPPsmt4081783No ratings yet

- MTHL-PKG2-DS-TCN-A-00-027 Rev. 1Document10 pagesMTHL-PKG2-DS-TCN-A-00-027 Rev. 1Hemant YesajiNo ratings yet

- Heat Transfer Analysis of Corrugated Plate Heat ExchangerDocument6 pagesHeat Transfer Analysis of Corrugated Plate Heat Exchangerpak1t0No ratings yet

- Praying Mantis Data SheetDocument2 pagesPraying Mantis Data SheetatswallaNo ratings yet

- Physics - F4Document25 pagesPhysics - F4Nyomenda Jamhuri WilliamNo ratings yet

- Various Type of Steam TrapsDocument46 pagesVarious Type of Steam TrapsRamesh VenugopalNo ratings yet

- Volumetric AnalysisDocument4 pagesVolumetric AnalysisSana SyedNo ratings yet

- Preventing and Correcting Rutting in Asphalt PavementsDocument5 pagesPreventing and Correcting Rutting in Asphalt PavementsJean Claude EidNo ratings yet

- Hall Effect and Hall VoltageDocument2 pagesHall Effect and Hall VoltageHimanshu TyagiNo ratings yet

- MF Uf NFDocument69 pagesMF Uf NFNguyen Huu HieuNo ratings yet

- How To Differentiate Capacitances Using Trasatti and Dunn MethodsDocument56 pagesHow To Differentiate Capacitances Using Trasatti and Dunn Methodsgopi undavalliNo ratings yet

- Data Book Solid WireDocument128 pagesData Book Solid WireRaron1No ratings yet

- 3-Days Training Course: September 26-28, 2011Document50 pages3-Days Training Course: September 26-28, 2011chibssa alemayehuNo ratings yet

- Liquid Diffusion MethodDocument5 pagesLiquid Diffusion MethodSUNDARAMAHALINGAM ANo ratings yet

- In Process Quality Control Tests (IPQC) For Solid Dosage FromDocument28 pagesIn Process Quality Control Tests (IPQC) For Solid Dosage FromSagar kishor savale75% (8)

- Clarke'S Solution Cleaning Used For Corrosion Product Removal: Effects On Carbon Steel SubstrateDocument10 pagesClarke'S Solution Cleaning Used For Corrosion Product Removal: Effects On Carbon Steel SubstrateDr. Pushkar ShuklaNo ratings yet

- Vibrational Spectroscopic and Conductimetric Studies of Lithium Battery Electrolyte SolutionsDocument4 pagesVibrational Spectroscopic and Conductimetric Studies of Lithium Battery Electrolyte Solutionspatybena20No ratings yet