Professional Documents

Culture Documents

Vertical Separator Calculator Guide

Vertical Separator Calculator Guide

Uploaded by

incipit32Copyright:

Available Formats

You might also like

- COSC 2406 Outline 2023FDocument4 pagesCOSC 2406 Outline 2023Fcricket1223No ratings yet

- 2 Phase Separator Sizing Spreadsheet: Client Proj No Project Calc No Subject SheetDocument1 page2 Phase Separator Sizing Spreadsheet: Client Proj No Project Calc No Subject SheetMohammad Mehdi JafariNo ratings yet

- Activated Carbon Filter Calculation Note - Odor Control Unit - Mall of Qatar - Phase 2Document4 pagesActivated Carbon Filter Calculation Note - Odor Control Unit - Mall of Qatar - Phase 2Ahmed Labib100% (1)

- Data Sheet For WTPDocument27 pagesData Sheet For WTPrajayu20002724No ratings yet

- Gas-Liquid Vertical Separator PDFDocument2 pagesGas-Liquid Vertical Separator PDFRathish RagooNo ratings yet

- Metering Pumps Components ProMinent Product Catalogue 2020 Volume 1Document418 pagesMetering Pumps Components ProMinent Product Catalogue 2020 Volume 1Husif QedirzadeNo ratings yet

- Slug Catcher SizingDocument6 pagesSlug Catcher SizingrezaNo ratings yet

- Measurement Brochures Cam Ms Turbines Gas-Turbine BRDocument9 pagesMeasurement Brochures Cam Ms Turbines Gas-Turbine BRJhon AnguloNo ratings yet

- RT PDFDocument2 pagesRT PDFsri9987No ratings yet

- Dust CollectorDocument16 pagesDust Collectorchathura buddhikaNo ratings yet

- Metering Pumps Components Metering Systems ProMinent Product Catalogue 2017 Volume 1Document196 pagesMetering Pumps Components Metering Systems ProMinent Product Catalogue 2017 Volume 1carlosmilfontNo ratings yet

- PROMINENT Metering Pumps Components Product Catalogue 2021 Volume 1Document492 pagesPROMINENT Metering Pumps Components Product Catalogue 2021 Volume 1Bertrand LegendreNo ratings yet

- Gas Turbin Meter CatalogDocument16 pagesGas Turbin Meter CatalogAlvaro Joel Quinteros RochaNo ratings yet

- High Pressure Knock Out Drum (ALF)Document12 pagesHigh Pressure Knock Out Drum (ALF)Eng AlfNo ratings yet

- Transporte NeumáticoDocument3 pagesTransporte NeumáticoAlexander AcuñaNo ratings yet

- PT Synergy Engineering: WarningsDocument1 pagePT Synergy Engineering: Warningsokky wddNo ratings yet

- Design of Submersible PumpsDocument5 pagesDesign of Submersible PumpsNoorNo ratings yet

- PerhitunganDocument8 pagesPerhitungantsaniya.mardhiyahNo ratings yet

- A. Standard Membrane Bioreactor Computations: 2.1. Design Flowrates and Maximum Monthly Loading RatesDocument7 pagesA. Standard Membrane Bioreactor Computations: 2.1. Design Flowrates and Maximum Monthly Loading RatesshekharshindeNo ratings yet

- CatalogueforZENNER (2021)Document43 pagesCatalogueforZENNER (2021)Misbachul ChoirNo ratings yet

- Mill Performance CalculationsDocument9 pagesMill Performance Calculationssafwat hassanNo ratings yet

- CMR-Plus Combinable Magnetic Resonance ToolDocument2 pagesCMR-Plus Combinable Magnetic Resonance Toolhamed1725No ratings yet

- Sizing FLO 5WBB 20231104T101703Z003Document6 pagesSizing FLO 5WBB 20231104T101703Z003mkfe2005No ratings yet

- Softener CalculationDocument4 pagesSoftener CalculationMarcoNo ratings yet

- Knockout DesignDocument1 pageKnockout DesignHarjasa AdhiNo ratings yet

- Calculation Dilute Phase Pressure Drop Rhodes MethodDocument3 pagesCalculation Dilute Phase Pressure Drop Rhodes MethodBTENo ratings yet

- 002 - DatasheetDocument7 pages002 - Datasheetwira triswandiNo ratings yet

- Design of The Rain Pump Station-MeDocument5 pagesDesign of The Rain Pump Station-MeNoorNo ratings yet

- FGD Dual Alkali Data Sheet FilledDocument5 pagesFGD Dual Alkali Data Sheet FilledowngauravNo ratings yet

- Standard Membrane Bioreactor ComputationsDocument8 pagesStandard Membrane Bioreactor ComputationsSwaminathan ThayumanavanNo ratings yet

- Liquid Ring Vacuum Pumps: LEM 325, LEM 425Document8 pagesLiquid Ring Vacuum Pumps: LEM 325, LEM 425Margarita Rivera SegoviaNo ratings yet

- Pump Sizing Calculator GuideDocument18 pagesPump Sizing Calculator GuideK LandryNo ratings yet

- Industrial Rubber Hose CatalogDocument1 pageIndustrial Rubber Hose CatalogsudjonoNo ratings yet

- Memoria de Calculo Fefit-802Document8 pagesMemoria de Calculo Fefit-802AntonioNo ratings yet

- Filter Media JSWDocument9 pagesFilter Media JSWTimir GhoseNo ratings yet

- Turbine Meter TrainingDocument77 pagesTurbine Meter TrainingJazielNo ratings yet

- Water Treatment Plant - UPG - Specs.Document4 pagesWater Treatment Plant - UPG - Specs.ashokjj26No ratings yet

- 1.protego Flame Arrestor, Breather Valve Data SheetDocument1 page1.protego Flame Arrestor, Breather Valve Data SheetNareshNo ratings yet

- SATAM-zc17-12 24 48 80 150 250 330Document2 pagesSATAM-zc17-12 24 48 80 150 250 330Mr. AlferditomaNo ratings yet

- 03 API Bottomloading ArmsDocument8 pages03 API Bottomloading ArmsAgnel StanleyNo ratings yet

- D 3002 DesignDocument20 pagesD 3002 DesignmargaretramosNo ratings yet

- STERLINGDocument8 pagesSTERLINGHummac MagañaNo ratings yet

- Ide Progreen SW-L 5000: Key FeaturesDocument2 pagesIde Progreen SW-L 5000: Key FeaturesEric HuangNo ratings yet

- Cyclone SeparatorDocument1 pageCyclone SeparatordadNo ratings yet

- Annexure-I & II in Fovor of Anandi Specialities & Service PVT LTDDocument2 pagesAnnexure-I & II in Fovor of Anandi Specialities & Service PVT LTDLOGIN ANIMONo ratings yet

- Line SizingDocument16 pagesLine SizingAkshay bhuranNo ratings yet

- Factors Affecting Characteristic Length of The Combustion Chamber of Liquid Propellant Rocket EnginesDocument16 pagesFactors Affecting Characteristic Length of The Combustion Chamber of Liquid Propellant Rocket EnginesEndika Llano MatxinNo ratings yet

- Compressor ScrubberDocument1 pageCompressor ScrubberprocecengineerNo ratings yet

- HQFQ21P0279 - Bag Filter DatasheetDocument1 pageHQFQ21P0279 - Bag Filter Datasheetmshah222No ratings yet

- Concepts in Condenser System (Vacuum Equipment)Document7 pagesConcepts in Condenser System (Vacuum Equipment)Mustafa DemircioğluNo ratings yet

- Industrial Ro Plant 1000 LPH PDFDocument7 pagesIndustrial Ro Plant 1000 LPH PDFPurshottam AmreliyaNo ratings yet

- Industrial Ro Plant 1000 LPHDocument7 pagesIndustrial Ro Plant 1000 LPHSonu VermaNo ratings yet

- Design of Vertical Scrubber: Company Project Date Data From CustomerDocument1 pageDesign of Vertical Scrubber: Company Project Date Data From CustomerRupam sharmaNo ratings yet

- Pipe SizingDocument1 pagePipe Sizingsaurabh singhNo ratings yet

- Process Calculation-Rev0Document15 pagesProcess Calculation-Rev0kkkhattabbbNo ratings yet

- FMR 1250Document7 pagesFMR 1250Shine Water ExpertsNo ratings yet

- Technical ManualDocument12 pagesTechnical ManualMrityunjay MallikNo ratings yet

- Calculation Dilute Phase Pressure Drop Rhodes MethodDocument3 pagesCalculation Dilute Phase Pressure Drop Rhodes MethodGeorgi Mitkov SavovNo ratings yet

- Ficha Tecnica G10Document2 pagesFicha Tecnica G10SebastianNo ratings yet

- Barton 7000 PDFDocument8 pagesBarton 7000 PDFmbloexNo ratings yet

- Liquid Chromatography - Mass Spectrometry: An IntroductionFrom EverandLiquid Chromatography - Mass Spectrometry: An IntroductionNo ratings yet

- All PDF Merged Complete TocDocument755 pagesAll PDF Merged Complete TocSHIVAM GARGNo ratings yet

- Effetto Pietra: Stone LookDocument23 pagesEffetto Pietra: Stone LookClaudio AllegriNo ratings yet

- Hysys Liquid PumpingDocument8 pagesHysys Liquid PumpingEkundayo JohnNo ratings yet

- Intersil ISL9238IRTZ DatasheetDocument45 pagesIntersil ISL9238IRTZ Datasheetxingyiservice.mdy123No ratings yet

- DODO Pizza - Furniture SpecificationDocument1 pageDODO Pizza - Furniture SpecificationConstantin LeonNo ratings yet

- Spining Mill in IndiaDocument74 pagesSpining Mill in IndiaMahendra Shah100% (4)

- Exercises With Finite State Machines: CS 64: Computer Organization and Design Logic Lecture #17 Winter 2019Document17 pagesExercises With Finite State Machines: CS 64: Computer Organization and Design Logic Lecture #17 Winter 2019Gabriel CañadasNo ratings yet

- Komatsu Crawler Doozer D37pxi 23 Shop ManualDocument20 pagesKomatsu Crawler Doozer D37pxi 23 Shop Manualrodney100% (40)

- Mathematics Unit-4 - Engg.Document297 pagesMathematics Unit-4 - Engg.medwinjosemedjoNo ratings yet

- Unit V Map Design & LayoutDocument32 pagesUnit V Map Design & LayoutRashkv428 kvNo ratings yet

- Ps 1Document91 pagesPs 1Abinash ChikunNo ratings yet

- Lec 7 - Intro To CryptographyDocument38 pagesLec 7 - Intro To CryptographygNo ratings yet

- Orifice Meter: Pamantasan NG Lungsod NG MaynilaDocument20 pagesOrifice Meter: Pamantasan NG Lungsod NG MaynilaDiana Isis VelascoNo ratings yet

- Practical File: Adarsh Mahila Mahavidyalaya, BhiwaniDocument4 pagesPractical File: Adarsh Mahila Mahavidyalaya, BhiwaniShyam SainiNo ratings yet

- IOUG - Oracle-Application-Express-Administration-Francis-MignaultDocument312 pagesIOUG - Oracle-Application-Express-Administration-Francis-MignaultMaged Hamouda100% (1)

- 03 - Quality Management SystemDocument12 pages03 - Quality Management SystemCharlon Adrian RuizNo ratings yet

- UNIT-2: Flywheels and Turning Moment DiagramsDocument54 pagesUNIT-2: Flywheels and Turning Moment DiagramsPraveen KumarNo ratings yet

- Manitou Tunnelling (EN)Document8 pagesManitou Tunnelling (EN)Manitou50% (2)

- Pre-Installation FOM2 English Ver3Document19 pagesPre-Installation FOM2 English Ver3bouchaib elfatiniNo ratings yet

- BS Iso TR 08363-1997 (1999)Document16 pagesBS Iso TR 08363-1997 (1999)Олег СоловьевNo ratings yet

- What Is A Project? - Definition and Key CharacteristicsDocument6 pagesWhat Is A Project? - Definition and Key Characteristicschandan kumarNo ratings yet

- Gutters, Downpipes and Overflow: CalculatorDocument5 pagesGutters, Downpipes and Overflow: CalculatorThaiNguyenNo ratings yet

- Human or More Generally Articulated Figure Animations Have Been Seen in A Variety of Application Fields Including AdvertisingDocument6 pagesHuman or More Generally Articulated Figure Animations Have Been Seen in A Variety of Application Fields Including AdvertisingYongKang YKNo ratings yet

- Vision Executive UserGuide v633 d10 20061128 PDFDocument119 pagesVision Executive UserGuide v633 d10 20061128 PDFLina CheaNo ratings yet

- KGP-931D: Differential GPS NAVIGATORDocument2 pagesKGP-931D: Differential GPS NAVIGATORueg liepajaNo ratings yet

- Solartech PB General Solar Pumping InvertersDocument2 pagesSolartech PB General Solar Pumping InvertersYC CarieloNo ratings yet

- Ethical Use of Artificial Intelligence ADocument6 pagesEthical Use of Artificial Intelligence AGreg ChatsiosNo ratings yet

- 2-09-98-PHA DT 16.01.2002 BSNLDocument1 page2-09-98-PHA DT 16.01.2002 BSNLbsnl jamkandornaNo ratings yet

- Customer Bugs by CategoryDocument32 pagesCustomer Bugs by CategoryHarmonie AungNo ratings yet

Vertical Separator Calculator Guide

Vertical Separator Calculator Guide

Uploaded by

incipit32Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vertical Separator Calculator Guide

Vertical Separator Calculator Guide

Uploaded by

incipit32Copyright:

Available Formats

VERTICAL GAS-LIQUID SEPARATOR

CALCULATOR

Simon Learman

Blackmonk Engineering Ltd

www.blackmonk.co.uk

Copyright © 2009 Blackmonk Engineering Ltd

Blackmonk Engineering Ltd

www.blackmonk.co.uk

Contents

Contents ....................................................................................................... 2

Introduction................................................................................................... 3

System Diagram ........................................................................................... 3

Calculation Inputs ......................................................................................... 3

Calculation Outputs ...................................................................................... 4

Gas-Liquid Separator Design ....................................................................... 5

Maximum Vapour Velocity ........................................................................ 5

Separator Sizing Factor, K ........................................................................ 5

Volumetric Flow Rates .............................................................................. 6

Mixture Density ......................................................................................... 6

Separator Diameter .................................................................................. 7

Separator Inlet Nozzle Design .................................................................. 7

Liquid Hold-Up Volume ............................................................................. 8

Vapour Height ........................................................................................... 8

Separator Vessel Tan-to-Tan Height ........................................................ 8

Vessel Length:Diameter Ratio .................................................................. 9

Calculation of Vertical Gas-Liquid Separator ................................................ 9

Nomenclature ............................................................................................. 10

Example ..................................................................................................... 11

Description: ............................................................................................. 11

Requirement: .......................................................................................... 11

Solution: .................................................................................................. 11

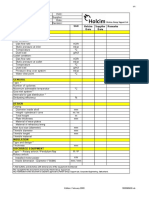

Vertical Gas-Liquid Separator Calculator Screenshot:............................ 12

Copyright © 2009 Blackmonk Engineering Ltd

Blackmonk Engineering Ltd

www.blackmonk.co.uk

Introduction

This document describes the basis and operation of the Blackmonk

Engineering Vertical Gas-Liquid Separator Calculator.

The calculation methodology is based on that described in Chapter 8 of

“Rules of Thumb for Chemical Engineers”, 3rd Edition, Carl Branan, Gulf

Publishing.

The calculator determines the vessel diameter and tan-to-tan height required

to separate liquid from gas/vapour with a specified liquid hold-up time.

The calculator determines the Souders-Brown separator sizing factor

automatically in addition to the maximum vapour velocities in the vessel and

through the inlet nozzle.

System Diagram

SEPARATOR

DIAMETER, Dsep

hvabove

INLET NOZZLE

SEPARATOR

HEIGHT, L

hvbelow

LIQUID

HEIGHT, hl

Calculation Inputs

The following parameters are user specified inputs to the calculation:

Input Description Units

Liquid flow rate Mandatory user specified liquid mass flow rate to the separator kg/hr

Mandatory user specified vapour mass flow rate to the

Vapour flow rate kg/hr

separator

3

Copyright © 2009 Blackmonk Engineering Ltd

Blackmonk Engineering Ltd

www.blackmonk.co.uk

3

Liquid density Mandatory user specified liquid density kg/m

3

Vapour density Mandatory user specified vapour density kg/m

Mandatory user specified liquid hold-up time required in the

Liquid hold-up time min

vessel

Calculation Outputs

The following parameters are calculated by the software and displayed to the

user:

Output Description Units

Volumetric flow rate of liquid

Liquid volumetric flow rate m3/hr

entering the separator vessel

Volumetric flow rate of vapour

Vapour volumetric flow rate m3/hr

entering the separator vessel

Density of the mixed liquid and

3

Mixture density vapour stream entering the kg/m

separator

Vertical gas-liquid separator

Separation factor N/A

separation factor

Vertical gas-liquid separator

Separator sizing factor Souders-Brown separator sizing m/s

factor

Maximum vapour velocity in the

Maximum vapour velocity m/s

vessel

Minimum cross sectional area of

the vessel required for separation 2

Minimum separation area required m

based on the maximum vapour

velocity

Minimum diameter of the vessel

Minimum separator diameter required for separation based on m

the maximum vapour velocity

Maximum allowable velocity in the

Maximum inlet nozzle velocity vessel inlet nozzle based on m/s

maximum momentum criteria

Minimum allowable velocity in the

Minimum inlet nozzle velocity vessel inlet nozzle based on m/s

minimum momentum criteria

Inlet nozzle diameter calculated on

Maximum inlet nozzle diameter the basis of the minimum inlet m

nozzle velocity criteria

Maximum inlet nozzle diameter

Recommended inlet nozzle size rounded up to the nearest standard inch

pipe size

Volume of liquid corresponding to

3

Liquid hold-up volume the required liquid hold-up time at m

the specified liquid flow rate

Height of liquid corresponding to

the liquid hold-up volume based on

Liquid height m

the recommended separator

diameter

Height above the inlet nozzle

Vapour height above centre line of inlet nozzle centre line to the top tan line of the m

vessel

Vapour height below centre line of inlet nozzle Height below the inlet nozzle centre m

Copyright © 2009 Blackmonk Engineering Ltd

Blackmonk Engineering Ltd

www.blackmonk.co.uk

line to the maximum liquid level

Distance between the bottom and

Vessel height tan to tan top tan lines of the vessel i.e. the m

vessel cylindrical heigh

Minimum separator diameter

Recommended separator diameter rounded up to the nearest 150 mm m

increment

The ratio of the vessel tan to tan

Vessel L:D height to the recommended N/A

separator diameter

Gas-Liquid Separator Design

The calculator sizes gas-liquid separators on the basis of maximum gas (or

vapour) velocity within the vessel as given by the Souders-Brown equation.

Maximum Vapour Velocity

The maximum gas (or vapour) velocity is given by the Souders-Brown

equation below:

Equation 1

Separator Sizing Factor, K

The Souders-Brown Separator Sizing Factor, K, is determined from the

following correlation:

Equation 2

Where:

A = -1.942936

B = -0.814894

C = -0.179390

D = -0.0123790

E = 0.000386235

F = 0.000259550

The separation factor, Sf is calculated using the following equation:

Copyright © 2009 Blackmonk Engineering Ltd

Blackmonk Engineering Ltd

www.blackmonk.co.uk

Equation 3

The Souders-Brown Separator Sizing Factor correlation is based on the data

presented in the chart below for 5% of the liquid to be entrained in the vapour

stream. This is considered adequate for normal design.

Figure 1: Separator Sizing Factor Chart

Vertical Gas-Liquid Separator Sizing Factor

0.16

0.14

0.12

0.10

K (m/s) 0.08

0.06

0.04

0.02

0.00

0.001 0.01 0.1 1 10

Separation factor, Sf

Volumetric Flow Rates

The volumetric flow rates of the liquid and vapour components of the feed

stream to the separator are calculated using the equations below:

Equation 4

Equation 5

Mixture Density

The density of the mixed feed stream is calculated using:

Copyright © 2009 Blackmonk Engineering Ltd

Blackmonk Engineering Ltd

www.blackmonk.co.uk

Equation 6

Separator Diameter

The minimum separation area required is calculated using:

Equation 7

From which the minimum required separator diameter is determined:

Equation 8

The recommended separator diameter is determined by rounding up the

calculated minimum separator diameter to the nearest 150 mm increment to

be consistent with standard rolled plate dimensions.

Equation 9

Separator Inlet Nozzle Design

The separator inlet nozzle is sized based on the following correlations for the

maximum and minimum nozzle velocities:

Equation 10

Equation 11

The maximum inlet nozzle diameter is then determined from:

Equation 12

Copyright © 2009 Blackmonk Engineering Ltd

Blackmonk Engineering Ltd

www.blackmonk.co.uk

The recommended inlet nozzle size is determined by selecting the next

largest standard pipe size based on the maximum inlet nozzle diameter.

Liquid Hold-Up Volume

Liquid hold-up volume is calculated based on the liquid flow rate to the

separator and the specified required liquid hold-up time.

Equation 13

The height of liquid corresponding to the required liquid hold-up volume is

given by:

Equation 14

Vapour Height

The vapour height above the centre line of the inlet nozzle to the top tan line

of the vessel is calculated based on the following correlation:

Equation 15

Equation 16

The vapour height below the centre line of the inlet nozzle to the maximum

liquid level is calculated based on the following correlation:

Equation 17

Equation 18

Separator Vessel Tan-to-Tan Height

The tan-to-tan height of the separator vessel is given by:

Copyright © 2009 Blackmonk Engineering Ltd

Blackmonk Engineering Ltd

www.blackmonk.co.uk

Equation 19

Vessel Length:Diameter Ratio

It is recommended that the vessel length to diameter ratio is maintained

between 3 and 5.

Equation 20

Calculation of Vertical Gas-Liquid Separator

The calculation routine is described in the following steps:

1. Calculate liquid and vapour volumetric flow rates using Equation 4 and

Equation 5

2. Calculate mixture density using Equation 6

3. Calculate Separation Factor, Sf using Equation 3

4. Calculate Separator Sizing Factor, K using Equation 2

5. Calculate maximum vapour velocity using Equation 1

6. Calculate minimum separation area required using Equation 7

7. Calculate minimum separator diameter using Equation 8

8. Calculate recommended separator diameter using Equation 9

9. Calculate maximum and minimum inlet nozzle velocities using Equation

10 and Equation 11

10. Calculate the maximum inlet nozzle diameter using Equation 12

11. Determine the recommended inlet nozzle diameter based on standard

pipe sizes

12. Calculate the liquid hold-up volume using Equation 13

13. Calculate the liquid height using Equation 14

14. Calculate the vapour height above and below the inlet nozzle using

Equation 15, Equation 16, Equation 17 and Equation 18

15. Calculate the vessel tan-to-tan height using Equation 19

16. Calculate the vessel length:diameter ratio using Equation 20

17. Generate warning if L:D < 3 or L:D > 5

Copyright © 2009 Blackmonk Engineering Ltd

Blackmonk Engineering Ltd

www.blackmonk.co.uk

Nomenclature

10

Copyright © 2009 Blackmonk Engineering Ltd

Blackmonk Engineering Ltd

www.blackmonk.co.uk

Example

The following example was adapted from the GPSA Data Book Example 7-3

page 7-8.

Description:

A vertical separator is required to handle 76320 kg/hr of gas with a density of

33.4 kg/m3. The feed to the separator also contains 2500 kg/hr of liquid with a

density of 500 kg/m3. A liquid hold-up time of 90 minutes is required.

Requirement:

Determine the separator diameter and height required.

Solution:

Calculated Separator Sizing Factor, K = 0.089 m/s (cf GPSA published value

of 0.089 m/s)

Calculated maximum vapour velocity, uvapmax = 0.33 m/s (cf GPSA published

value of 0.33 m/s)

Calculated minimum separator diameter, Dmin = 1.563 m (cf GPSA published

value of 1.560 m)

Recommended separator diameter, Dsep = 1.650 m

Calculated separator tan-to-tan height, L = 5.158 m

Calculated L:D = 3.13

11

Copyright © 2009 Blackmonk Engineering Ltd

Blackmonk Engineering Ltd

www.blackmonk.co.uk

Vertical Gas-Liquid Separator Calculator Screenshot:

INPUTS

Liquid flow rate ml 2500 kg/hr

Vapour flow rate mv 76320 kg/hr

Liquid density l 500 kg/m3

Vapour density v 33.4 kg/m3

Liquid hold-up time l 90 min

OUTPUTS

Liquid volumetric flow rate Ql 5.00 m3/hr

Vapour volumetric flow rate Qv 2285.03 m3/hr

Mixture density mix 34.42 kg/m3

Separation factor Sf 0.008

Separator sizing factor K 0.089 m/s

Maximum vapour velocity uvapmax 0.33 m/s

Minimum separation area required Amin 1.918 m2

Minimum separator diameter Dmin 1.563 m

Maximum inlet nozzle velocity unozmax 20.79 m/s

Minimum inlet nozzle velocity unozmin 12.48 m/s

Maximum inlet nozzle diameter dinlet max 0.255 m

Recommended inlet nozzle size dinlet 10 inch

Liquid hold-up volume Vl 7.500 m3

Liquid height hl 3.508 m

Vapour height above centre line of inlet

nozzle hvabove 1.200 m

Vapour height below centre line of inlet

nozzle hvbelow 0.450 m

Vessel height tan to tan L 5.158 m

Recommended separator diameter Dsep 1.650 m

Vessel L:D L:D 3.13

12

Copyright © 2009 Blackmonk Engineering Ltd

You might also like

- COSC 2406 Outline 2023FDocument4 pagesCOSC 2406 Outline 2023Fcricket1223No ratings yet

- 2 Phase Separator Sizing Spreadsheet: Client Proj No Project Calc No Subject SheetDocument1 page2 Phase Separator Sizing Spreadsheet: Client Proj No Project Calc No Subject SheetMohammad Mehdi JafariNo ratings yet

- Activated Carbon Filter Calculation Note - Odor Control Unit - Mall of Qatar - Phase 2Document4 pagesActivated Carbon Filter Calculation Note - Odor Control Unit - Mall of Qatar - Phase 2Ahmed Labib100% (1)

- Data Sheet For WTPDocument27 pagesData Sheet For WTPrajayu20002724No ratings yet

- Gas-Liquid Vertical Separator PDFDocument2 pagesGas-Liquid Vertical Separator PDFRathish RagooNo ratings yet

- Metering Pumps Components ProMinent Product Catalogue 2020 Volume 1Document418 pagesMetering Pumps Components ProMinent Product Catalogue 2020 Volume 1Husif QedirzadeNo ratings yet

- Slug Catcher SizingDocument6 pagesSlug Catcher SizingrezaNo ratings yet

- Measurement Brochures Cam Ms Turbines Gas-Turbine BRDocument9 pagesMeasurement Brochures Cam Ms Turbines Gas-Turbine BRJhon AnguloNo ratings yet

- RT PDFDocument2 pagesRT PDFsri9987No ratings yet

- Dust CollectorDocument16 pagesDust Collectorchathura buddhikaNo ratings yet

- Metering Pumps Components Metering Systems ProMinent Product Catalogue 2017 Volume 1Document196 pagesMetering Pumps Components Metering Systems ProMinent Product Catalogue 2017 Volume 1carlosmilfontNo ratings yet

- PROMINENT Metering Pumps Components Product Catalogue 2021 Volume 1Document492 pagesPROMINENT Metering Pumps Components Product Catalogue 2021 Volume 1Bertrand LegendreNo ratings yet

- Gas Turbin Meter CatalogDocument16 pagesGas Turbin Meter CatalogAlvaro Joel Quinteros RochaNo ratings yet

- High Pressure Knock Out Drum (ALF)Document12 pagesHigh Pressure Knock Out Drum (ALF)Eng AlfNo ratings yet

- Transporte NeumáticoDocument3 pagesTransporte NeumáticoAlexander AcuñaNo ratings yet

- PT Synergy Engineering: WarningsDocument1 pagePT Synergy Engineering: Warningsokky wddNo ratings yet

- Design of Submersible PumpsDocument5 pagesDesign of Submersible PumpsNoorNo ratings yet

- PerhitunganDocument8 pagesPerhitungantsaniya.mardhiyahNo ratings yet

- A. Standard Membrane Bioreactor Computations: 2.1. Design Flowrates and Maximum Monthly Loading RatesDocument7 pagesA. Standard Membrane Bioreactor Computations: 2.1. Design Flowrates and Maximum Monthly Loading RatesshekharshindeNo ratings yet

- CatalogueforZENNER (2021)Document43 pagesCatalogueforZENNER (2021)Misbachul ChoirNo ratings yet

- Mill Performance CalculationsDocument9 pagesMill Performance Calculationssafwat hassanNo ratings yet

- CMR-Plus Combinable Magnetic Resonance ToolDocument2 pagesCMR-Plus Combinable Magnetic Resonance Toolhamed1725No ratings yet

- Sizing FLO 5WBB 20231104T101703Z003Document6 pagesSizing FLO 5WBB 20231104T101703Z003mkfe2005No ratings yet

- Softener CalculationDocument4 pagesSoftener CalculationMarcoNo ratings yet

- Knockout DesignDocument1 pageKnockout DesignHarjasa AdhiNo ratings yet

- Calculation Dilute Phase Pressure Drop Rhodes MethodDocument3 pagesCalculation Dilute Phase Pressure Drop Rhodes MethodBTENo ratings yet

- 002 - DatasheetDocument7 pages002 - Datasheetwira triswandiNo ratings yet

- Design of The Rain Pump Station-MeDocument5 pagesDesign of The Rain Pump Station-MeNoorNo ratings yet

- FGD Dual Alkali Data Sheet FilledDocument5 pagesFGD Dual Alkali Data Sheet FilledowngauravNo ratings yet

- Standard Membrane Bioreactor ComputationsDocument8 pagesStandard Membrane Bioreactor ComputationsSwaminathan ThayumanavanNo ratings yet

- Liquid Ring Vacuum Pumps: LEM 325, LEM 425Document8 pagesLiquid Ring Vacuum Pumps: LEM 325, LEM 425Margarita Rivera SegoviaNo ratings yet

- Pump Sizing Calculator GuideDocument18 pagesPump Sizing Calculator GuideK LandryNo ratings yet

- Industrial Rubber Hose CatalogDocument1 pageIndustrial Rubber Hose CatalogsudjonoNo ratings yet

- Memoria de Calculo Fefit-802Document8 pagesMemoria de Calculo Fefit-802AntonioNo ratings yet

- Filter Media JSWDocument9 pagesFilter Media JSWTimir GhoseNo ratings yet

- Turbine Meter TrainingDocument77 pagesTurbine Meter TrainingJazielNo ratings yet

- Water Treatment Plant - UPG - Specs.Document4 pagesWater Treatment Plant - UPG - Specs.ashokjj26No ratings yet

- 1.protego Flame Arrestor, Breather Valve Data SheetDocument1 page1.protego Flame Arrestor, Breather Valve Data SheetNareshNo ratings yet

- SATAM-zc17-12 24 48 80 150 250 330Document2 pagesSATAM-zc17-12 24 48 80 150 250 330Mr. AlferditomaNo ratings yet

- 03 API Bottomloading ArmsDocument8 pages03 API Bottomloading ArmsAgnel StanleyNo ratings yet

- D 3002 DesignDocument20 pagesD 3002 DesignmargaretramosNo ratings yet

- STERLINGDocument8 pagesSTERLINGHummac MagañaNo ratings yet

- Ide Progreen SW-L 5000: Key FeaturesDocument2 pagesIde Progreen SW-L 5000: Key FeaturesEric HuangNo ratings yet

- Cyclone SeparatorDocument1 pageCyclone SeparatordadNo ratings yet

- Annexure-I & II in Fovor of Anandi Specialities & Service PVT LTDDocument2 pagesAnnexure-I & II in Fovor of Anandi Specialities & Service PVT LTDLOGIN ANIMONo ratings yet

- Line SizingDocument16 pagesLine SizingAkshay bhuranNo ratings yet

- Factors Affecting Characteristic Length of The Combustion Chamber of Liquid Propellant Rocket EnginesDocument16 pagesFactors Affecting Characteristic Length of The Combustion Chamber of Liquid Propellant Rocket EnginesEndika Llano MatxinNo ratings yet

- Compressor ScrubberDocument1 pageCompressor ScrubberprocecengineerNo ratings yet

- HQFQ21P0279 - Bag Filter DatasheetDocument1 pageHQFQ21P0279 - Bag Filter Datasheetmshah222No ratings yet

- Concepts in Condenser System (Vacuum Equipment)Document7 pagesConcepts in Condenser System (Vacuum Equipment)Mustafa DemircioğluNo ratings yet

- Industrial Ro Plant 1000 LPH PDFDocument7 pagesIndustrial Ro Plant 1000 LPH PDFPurshottam AmreliyaNo ratings yet

- Industrial Ro Plant 1000 LPHDocument7 pagesIndustrial Ro Plant 1000 LPHSonu VermaNo ratings yet

- Design of Vertical Scrubber: Company Project Date Data From CustomerDocument1 pageDesign of Vertical Scrubber: Company Project Date Data From CustomerRupam sharmaNo ratings yet

- Pipe SizingDocument1 pagePipe Sizingsaurabh singhNo ratings yet

- Process Calculation-Rev0Document15 pagesProcess Calculation-Rev0kkkhattabbbNo ratings yet

- FMR 1250Document7 pagesFMR 1250Shine Water ExpertsNo ratings yet

- Technical ManualDocument12 pagesTechnical ManualMrityunjay MallikNo ratings yet

- Calculation Dilute Phase Pressure Drop Rhodes MethodDocument3 pagesCalculation Dilute Phase Pressure Drop Rhodes MethodGeorgi Mitkov SavovNo ratings yet

- Ficha Tecnica G10Document2 pagesFicha Tecnica G10SebastianNo ratings yet

- Barton 7000 PDFDocument8 pagesBarton 7000 PDFmbloexNo ratings yet

- Liquid Chromatography - Mass Spectrometry: An IntroductionFrom EverandLiquid Chromatography - Mass Spectrometry: An IntroductionNo ratings yet

- All PDF Merged Complete TocDocument755 pagesAll PDF Merged Complete TocSHIVAM GARGNo ratings yet

- Effetto Pietra: Stone LookDocument23 pagesEffetto Pietra: Stone LookClaudio AllegriNo ratings yet

- Hysys Liquid PumpingDocument8 pagesHysys Liquid PumpingEkundayo JohnNo ratings yet

- Intersil ISL9238IRTZ DatasheetDocument45 pagesIntersil ISL9238IRTZ Datasheetxingyiservice.mdy123No ratings yet

- DODO Pizza - Furniture SpecificationDocument1 pageDODO Pizza - Furniture SpecificationConstantin LeonNo ratings yet

- Spining Mill in IndiaDocument74 pagesSpining Mill in IndiaMahendra Shah100% (4)

- Exercises With Finite State Machines: CS 64: Computer Organization and Design Logic Lecture #17 Winter 2019Document17 pagesExercises With Finite State Machines: CS 64: Computer Organization and Design Logic Lecture #17 Winter 2019Gabriel CañadasNo ratings yet

- Komatsu Crawler Doozer D37pxi 23 Shop ManualDocument20 pagesKomatsu Crawler Doozer D37pxi 23 Shop Manualrodney100% (40)

- Mathematics Unit-4 - Engg.Document297 pagesMathematics Unit-4 - Engg.medwinjosemedjoNo ratings yet

- Unit V Map Design & LayoutDocument32 pagesUnit V Map Design & LayoutRashkv428 kvNo ratings yet

- Ps 1Document91 pagesPs 1Abinash ChikunNo ratings yet

- Lec 7 - Intro To CryptographyDocument38 pagesLec 7 - Intro To CryptographygNo ratings yet

- Orifice Meter: Pamantasan NG Lungsod NG MaynilaDocument20 pagesOrifice Meter: Pamantasan NG Lungsod NG MaynilaDiana Isis VelascoNo ratings yet

- Practical File: Adarsh Mahila Mahavidyalaya, BhiwaniDocument4 pagesPractical File: Adarsh Mahila Mahavidyalaya, BhiwaniShyam SainiNo ratings yet

- IOUG - Oracle-Application-Express-Administration-Francis-MignaultDocument312 pagesIOUG - Oracle-Application-Express-Administration-Francis-MignaultMaged Hamouda100% (1)

- 03 - Quality Management SystemDocument12 pages03 - Quality Management SystemCharlon Adrian RuizNo ratings yet

- UNIT-2: Flywheels and Turning Moment DiagramsDocument54 pagesUNIT-2: Flywheels and Turning Moment DiagramsPraveen KumarNo ratings yet

- Manitou Tunnelling (EN)Document8 pagesManitou Tunnelling (EN)Manitou50% (2)

- Pre-Installation FOM2 English Ver3Document19 pagesPre-Installation FOM2 English Ver3bouchaib elfatiniNo ratings yet

- BS Iso TR 08363-1997 (1999)Document16 pagesBS Iso TR 08363-1997 (1999)Олег СоловьевNo ratings yet

- What Is A Project? - Definition and Key CharacteristicsDocument6 pagesWhat Is A Project? - Definition and Key Characteristicschandan kumarNo ratings yet

- Gutters, Downpipes and Overflow: CalculatorDocument5 pagesGutters, Downpipes and Overflow: CalculatorThaiNguyenNo ratings yet

- Human or More Generally Articulated Figure Animations Have Been Seen in A Variety of Application Fields Including AdvertisingDocument6 pagesHuman or More Generally Articulated Figure Animations Have Been Seen in A Variety of Application Fields Including AdvertisingYongKang YKNo ratings yet

- Vision Executive UserGuide v633 d10 20061128 PDFDocument119 pagesVision Executive UserGuide v633 d10 20061128 PDFLina CheaNo ratings yet

- KGP-931D: Differential GPS NAVIGATORDocument2 pagesKGP-931D: Differential GPS NAVIGATORueg liepajaNo ratings yet

- Solartech PB General Solar Pumping InvertersDocument2 pagesSolartech PB General Solar Pumping InvertersYC CarieloNo ratings yet

- Ethical Use of Artificial Intelligence ADocument6 pagesEthical Use of Artificial Intelligence AGreg ChatsiosNo ratings yet

- 2-09-98-PHA DT 16.01.2002 BSNLDocument1 page2-09-98-PHA DT 16.01.2002 BSNLbsnl jamkandornaNo ratings yet

- Customer Bugs by CategoryDocument32 pagesCustomer Bugs by CategoryHarmonie AungNo ratings yet