Professional Documents

Culture Documents

Renolit Poliplex Series - en

Renolit Poliplex Series - en

Uploaded by

Roberto Marquez MerinoCopyright:

Available Formats

You might also like

- Bel-Ray Semi-Fluid-Grease 301212 - 15 To 204 CDocument2 pagesBel-Ray Semi-Fluid-Grease 301212 - 15 To 204 CDanilo estrella ruizNo ratings yet

- Product Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDocument3 pagesProduct Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDiegoNo ratings yet

- Alathon®: ApplicationsDocument2 pagesAlathon®: ApplicationsCarlos Revilla FloresNo ratings yet

- AP Industrial Gear Oil (FVA54 Micro-Ptting)Document3 pagesAP Industrial Gear Oil (FVA54 Micro-Ptting)Yoong TanNo ratings yet

- Black Pearl EPDocument2 pagesBlack Pearl EPZaki ElsayedNo ratings yet

- 650 006+JR PS 100+PerformaSil+100+SWBE+Product+Data+Sheet+ (PDS) +08.06.2021Document2 pages650 006+JR PS 100+PerformaSil+100+SWBE+Product+Data+Sheet+ (PDS) +08.06.2021rajesh kumarNo ratings yet

- ExxonMobil LLDPE LL 1002AY BlownDocument2 pagesExxonMobil LLDPE LL 1002AY BlownOscar Tan IIINo ratings yet

- Property ASTM or UL Test Extruded NYLON 6/6 Cast Nylon Physical MechanicalDocument1 pageProperty ASTM or UL Test Extruded NYLON 6/6 Cast Nylon Physical MechanicalEktor RamirzNo ratings yet

- Bel-Ray 6 in 1 Multipurpose LubricantDocument2 pagesBel-Ray 6 in 1 Multipurpose LubricantdhowardjNo ratings yet

- Roller Bearing GreaseDocument2 pagesRoller Bearing GreaseYoong TanNo ratings yet

- PDS Caltex Delo Starplex EP 3Document3 pagesPDS Caltex Delo Starplex EP 3Juan Carlo PanchoNo ratings yet

- Molylube Extreme Pressure High Viscosity GreaseDocument4 pagesMolylube Extreme Pressure High Viscosity GreaseJaime MunozNo ratings yet

- PDSDetailPage - Black Pearl EP - EN - NEWDocument2 pagesPDSDetailPage - Black Pearl EP - EN - NEWChen LiuNo ratings yet

- Petrothene: Low Density Polyethylene Film Extrusion GradeDocument1 pagePetrothene: Low Density Polyethylene Film Extrusion GradeGabriela Lopez MunozNo ratings yet

- H.T. Brautek Lithium Moly SeriesDocument2 pagesH.T. Brautek Lithium Moly SeriesAlexo HaroNo ratings yet

- Cardolite Ultra LITE 2009: Epoxy Curing Agent Technical DatasheetDocument2 pagesCardolite Ultra LITE 2009: Epoxy Curing Agent Technical Datasheettrường phạmNo ratings yet

- Technical Datasheet: AME™ 6001 INF-135 Premium Marine Resin InfusionDocument2 pagesTechnical Datasheet: AME™ 6001 INF-135 Premium Marine Resin InfusionMarjan ArhNo ratings yet

- Exceed 3518Document2 pagesExceed 3518Amin PanNo ratings yet

- Castrol Manual EP 80W-90: DescriptionDocument1 pageCastrol Manual EP 80W-90: Descriptionvicky kNo ratings yet

- Permafil 707Document2 pagesPermafil 707Yahiko LeosNo ratings yet

- Molykote® G-1502FM Data SheetDocument2 pagesMolykote® G-1502FM Data SheetlorenzoNo ratings yet

- Product Data Sheet: 6 IN 1 Multipurpose LubricantDocument2 pagesProduct Data Sheet: 6 IN 1 Multipurpose LubricantDaniel ColinsNo ratings yet

- PEADM5372Document2 pagesPEADM5372nicolas yoris marcoglieseNo ratings yet

- No Tox Food Grade Seamer OilDocument2 pagesNo Tox Food Grade Seamer OilDon HowardNo ratings yet

- Daphne Eponex Grease SR Series: Lubricant Product InformationDocument2 pagesDaphne Eponex Grease SR Series: Lubricant Product InformationSadid ShahzadNo ratings yet

- Alpha SP Range: DescriptionDocument3 pagesAlpha SP Range: Descriptionvicky kNo ratings yet

- Daphne Super Coat TWDocument2 pagesDaphne Super Coat TWSuprastowo Bin SarinoNo ratings yet

- High Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Document2 pagesHigh Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Phung LucNo ratings yet

- TDS Molylube SF 100 Semi Synthetic Open Gear Lubricant PDFDocument3 pagesTDS Molylube SF 100 Semi Synthetic Open Gear Lubricant PDFGilmer CaceresNo ratings yet

- Derakane Momentum 411-350Document3 pagesDerakane Momentum 411-350DidikHariantoNo ratings yet

- Mobil Polyrex EMDocument2 pagesMobil Polyrex EMthe anhNo ratings yet

- Molylube Extreme Pressure High Viscosity GreaseDocument2 pagesMolylube Extreme Pressure High Viscosity GreaseGilmer Williams Cáceres BenaventeNo ratings yet

- Exceed 1012HA PDFDocument2 pagesExceed 1012HA PDFEdgar CascoNo ratings yet

- ExxonMobil Enable 20-05HHDocument2 pagesExxonMobil Enable 20-05HHHung TranNo ratings yet

- Aqualink 300F Ver2Document2 pagesAqualink 300F Ver2Georgina SuleNo ratings yet

- Castrol Axle EPX 80W-90Document1 pageCastrol Axle EPX 80W-90indeskeyNo ratings yet

- Product Data Sheet: Molylube Ultra Open Gear LubricantDocument2 pagesProduct Data Sheet: Molylube Ultra Open Gear LubricantDiegoNo ratings yet

- 423-Renolin CLP-1Document1 page423-Renolin CLP-1Moutaz IsmailNo ratings yet

- 93 Sinopec Extreme Pressure Lithium Complex GreaseDocument3 pages93 Sinopec Extreme Pressure Lithium Complex GreaseAmadeus CocaNo ratings yet

- XIAMETER™ RBB-2030-80 Base: Features & Benefits ApplicationsDocument3 pagesXIAMETER™ RBB-2030-80 Base: Features & Benefits ApplicationsDaniela Alejandra Daza LancherosNo ratings yet

- Hdpe HD 7845.30Document2 pagesHdpe HD 7845.30Cristian RodriguezNo ratings yet

- Derakane 411 Data SheetDocument3 pagesDerakane 411 Data SheetJUAN BAGNODNo ratings yet

- Technical Data: Impact Grease / TackyDocument3 pagesTechnical Data: Impact Grease / TackyRodrigo RiosNo ratings yet

- Amberlite IRC120 NaDocument3 pagesAmberlite IRC120 NaPT Deltapuro Indonesia100% (1)

- Exceed 1012MK PDFDocument2 pagesExceed 1012MK PDFEdgar CascoNo ratings yet

- Paxon™ AD60-007: High Density Polyethylene ResinDocument2 pagesPaxon™ AD60-007: High Density Polyethylene ResinLABORATORIONo ratings yet

- Royal 876 EP GreaseDocument3 pagesRoyal 876 EP GreaseVictor ZhicayNo ratings yet

- 8 21 Pure TacDocument1 page8 21 Pure TacYeison Camilo Zapata DavidNo ratings yet

- Schaeffer # 229Document3 pagesSchaeffer # 229Ingeniero aicNo ratings yet

- Molykote® SK-623Document2 pagesMolykote® SK-623If ChenNo ratings yet

- Lubricants: Unoba EPDocument2 pagesLubricants: Unoba EPQC RegianNo ratings yet

- Omega 585Document12 pagesOmega 585Vikz 4gameNo ratings yet

- Aceite Royal Purple - Synfilm - 46Document2 pagesAceite Royal Purple - Synfilm - 46micmarley2012No ratings yet

- Ap Getoel EpDocument1 pageAp Getoel EpSami KahtaniNo ratings yet

- G-Tek CSC Food Series: H1 Food Grade High Performance GreaseDocument2 pagesG-Tek CSC Food Series: H1 Food Grade High Performance GreaseInfor AdmNo ratings yet

- GL XX Mobil Polyrex EM SeriesDocument3 pagesGL XX Mobil Polyrex EM SeriesRakka HardiyantaNo ratings yet

- Product Data Sheet: No-Tox HD Food Grade GreaseDocument3 pagesProduct Data Sheet: No-Tox HD Food Grade GreaseDaniel ColinsNo ratings yet

- Ficha Técnica Castrol Syngear 75W-90Document2 pagesFicha Técnica Castrol Syngear 75W-90Victor Manuel Gonzalez PerezNo ratings yet

- GL EG Mobilfluid 424Document4 pagesGL EG Mobilfluid 424mgamal1080No ratings yet

- q1wk1 gp1 La1Document1 pageq1wk1 gp1 La1ian babiloniaNo ratings yet

- Physics 1234Document253 pagesPhysics 1234Bxhsh Hdhshssh100% (1)

- Construction Method For Pile DrivingDocument17 pagesConstruction Method For Pile DrivingsochealaoNo ratings yet

- Tube Side Velocity CalculationDocument20 pagesTube Side Velocity CalculationNitin KurupNo ratings yet

- Bardon Initiation Into Hermetics (Better Outline) : Step X Exercises SummaryDocument7 pagesBardon Initiation Into Hermetics (Better Outline) : Step X Exercises SummaryRhaxma Conspiracy100% (1)

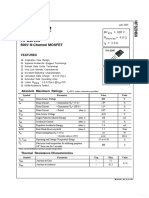

- HFS2N60: 600V N-Channel MOSFETDocument7 pagesHFS2N60: 600V N-Channel MOSFETNickol HardwayNo ratings yet

- Thermodynamics Lecture PDFDocument11 pagesThermodynamics Lecture PDFGenerale, Rey marck C.No ratings yet

- Machines For O Level Physics PDFDocument27 pagesMachines For O Level Physics PDFRwabahinda100% (1)

- Product Design Based On Discrete Particle Modeling of A Uidized Bed GranulatorDocument12 pagesProduct Design Based On Discrete Particle Modeling of A Uidized Bed Granulator권혁록No ratings yet

- Adstefan Input Data SheetDocument4 pagesAdstefan Input Data SheetMuthu KumarNo ratings yet

- IH CurveDocument8 pagesIH CurveGautam ChauhanNo ratings yet

- Moving Man SimulationDocument12 pagesMoving Man SimulationAlexa AquinoNo ratings yet

- H 1"" 1.9 Unfolding and Folding A ChainDocument4 pagesH 1"" 1.9 Unfolding and Folding A ChainAshNo ratings yet

- IB Physics Refractive Index ReportDocument5 pagesIB Physics Refractive Index ReportGiáng HươngNo ratings yet

- Reading Comprehension PracticeDocument10 pagesReading Comprehension PracticeMomi BearFruitsNo ratings yet

- Presentación Completa ArupDocument105 pagesPresentación Completa ArupCarlos Eduardo Rodriguez100% (1)

- Transparent ABS: Mabs: Toray Plastics (Malaysia) Sdn. BNDDocument6 pagesTransparent ABS: Mabs: Toray Plastics (Malaysia) Sdn. BNDTungdinh NguyenNo ratings yet

- AphiweDocument16 pagesAphiweaphiweshozi18No ratings yet

- Development of Equation of Motion For Nonlinear Vibrating SystemsDocument45 pagesDevelopment of Equation of Motion For Nonlinear Vibrating SystemsSteve KrodaNo ratings yet

- Carpe Huang - DEG I - Lab Report Kinematics 1dDocument8 pagesCarpe Huang - DEG I - Lab Report Kinematics 1dChengxiang HuangNo ratings yet

- The Ultimate Guide: For Mandala Coloring MeditationDocument17 pagesThe Ultimate Guide: For Mandala Coloring MeditationMira Nicusan100% (1)

- Channel DesignDocument5 pagesChannel DesignAaronNo ratings yet

- Universiti Teknologi Mara Mid-Term Assessment: Confidential EH/MAY 2021/CHE553Document3 pagesUniversiti Teknologi Mara Mid-Term Assessment: Confidential EH/MAY 2021/CHE553Lehbron JemsNo ratings yet

- ICT 7 Electronic Summative ExamDocument4 pagesICT 7 Electronic Summative ExamRaymond PunoNo ratings yet

- Mathematics in The Modern World: Number Sequence and SeriesDocument12 pagesMathematics in The Modern World: Number Sequence and SeriesCherrylane EdicaNo ratings yet

- Surge Arresters HubellDocument24 pagesSurge Arresters Hubellkhaldoun samiNo ratings yet

- Isometric and Orthographic ProjectionsDocument24 pagesIsometric and Orthographic ProjectionsKristian UretaNo ratings yet

- Homework Set #3: EE6412: Optimal Control January - May 2023Document2 pagesHomework Set #3: EE6412: Optimal Control January - May 2023kapali123No ratings yet

- GrammarDocument6 pagesGrammar灰谷リンエリNo ratings yet

- Mechanical Maintenance of Cement Rotary KilnDocument101 pagesMechanical Maintenance of Cement Rotary KilnVijaykumar Rugada97% (35)

Renolit Poliplex Series - en

Renolit Poliplex Series - en

Uploaded by

Roberto Marquez MerinoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Renolit Poliplex Series - en

Renolit Poliplex Series - en

Uploaded by

Roberto Marquez MerinoCopyright:

Available Formats

RENOLIT POLIPLEX SERIES

Polymer Fortified Lithium Complex Grease

Description Advantages/Benefits

Renolit Poliplex Series are lithium complex Multi-Purpose/High Temperature/Performance

thickened greases that represent the most Excellent Water Resistance

advanced lubricating technology. They are Very Shear Stable

formulated for conditions of extreme pressure

Extreme Pressure, Anti-Wear, and Corrosion

and high temperatures but are also ideal for

Protection

general purpose applications. To increase the

Polymer Fortified for Maximum Film Strength

adhesiveness and film strength of Renolit

in Shock Loaded Applications

Poliplex Series, they are manufactured with

Clean Off-White Color

state-of-the-art polymers. They also incorporate

specially selected mineral oils, extreme Tacky for Stay Put Performance/Will not

pressure, anti-wear, rust and corrosion additives Squeeze Out

that gives them the performance properties to

properly lubricate today’s modern equipment.

Application

Heavy industrial applications subject to high

heat, loads, shear, and water conditions. Ideal

for applications where shock loading is present Construction/

and the grease must resist “Squeeze Out”. Mining Polymer Fortified

Mining / Construction applications of hitch pins,

shackle pins, bushings, king pins on buckets,

excavators, shovels, and loaders.

Slack Adjuster for over the road trucks. Steel Mills Roller Bearings

Used where high temperature, high performance

and high tack grease is required. Haul Trucks Water Resistant

Gearing

Plain Bearings

1/13/2014, Page 1

Product information is based on data obtained by our own

research and is considered accurate. However, no warranty

is expressed or implied regarding the accuracy of these

data, or the results to be obtained from the use thereof.

Seller shall not be liable for any loss or damage or liability

resulting from the use of the product in the buyer’s

manufacturing processes or in combination with other

substances.

FUCHS LUBRICANTS CO. Telephone: 708-333-8900

17050 Lathrop Avenue Fax: 708-333-4470

Harvey, IL 60426 E-mail: info@fuchs.com

Web: www.fuchs.com

CHARACTERISTICS

PROPERTY VALUE UNITS METHOD

Product Name Renolit Poliplex 1 Renolit Poliplex 2

NLGI Grade 1 2

Thickener Lithium Complex Lithium Complex

Texture Tacky Tacky

Color Off-White Off-White

Penetration, Worked 323 275 0.1 mm ASTM D 217

Work Stability, 10K +9 +10 % Change ASTM D 217

Dropping Point 500+ (260) 500+ (260) ºF (ºC) ASTM D 2265

Oxidation, 100hrs 7 7 psi Drop ASTM D 942

Water Washout @175ºF 5 3 % ASTM D 1264

Rust Test Rating 1 1 Pass / Fail ASTM D 1743

Roll Stability +9 +10 % ASTM D 1831

4-Ball Wear 0.38 0.38 mm ASTM D 2266

4-Ball Weld 400 400 kgf ASTM D 2596

4-Ball LWI 45 45 kgf ASTM D 2596

Timken OK Load 60 60 lbs ASTM D 2509

Base Oil Characteristics

Viscosity @ 100ºC 15.2 15.2 cSt ASTM D 445

Viscosity @ 40ºC 196 196 cSt ASTM D 445

Viscosity Index 64 71 ASTM D 2270

Flash Point 436 (224) 436 (224) ºF (ºC) ASTM D 92

Pour Point -10 (-23) -10 (-23) ºF (ºC) ASTM D 97

1/13/2014, Page 2

Product information is based on data obtained by our own

research and is considered accurate. However, no warranty

is expressed or implied regarding the accuracy of these

data, or the results to be obtained from the use thereof.

Seller shall not be liable for any loss or damage or liability

resulting from the use of the product in the buyer’s

manufacturing processes or in combination with other

substances.

FUCHS LUBRICANTS CO. Telephone: 708-333-8900

17050 Lathrop Avenue Fax: 708-333-4470

Harvey, IL 60426 E-mail: info@fuchs.com

Web: www.fuchs.com

You might also like

- Bel-Ray Semi-Fluid-Grease 301212 - 15 To 204 CDocument2 pagesBel-Ray Semi-Fluid-Grease 301212 - 15 To 204 CDanilo estrella ruizNo ratings yet

- Product Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDocument3 pagesProduct Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDiegoNo ratings yet

- Alathon®: ApplicationsDocument2 pagesAlathon®: ApplicationsCarlos Revilla FloresNo ratings yet

- AP Industrial Gear Oil (FVA54 Micro-Ptting)Document3 pagesAP Industrial Gear Oil (FVA54 Micro-Ptting)Yoong TanNo ratings yet

- Black Pearl EPDocument2 pagesBlack Pearl EPZaki ElsayedNo ratings yet

- 650 006+JR PS 100+PerformaSil+100+SWBE+Product+Data+Sheet+ (PDS) +08.06.2021Document2 pages650 006+JR PS 100+PerformaSil+100+SWBE+Product+Data+Sheet+ (PDS) +08.06.2021rajesh kumarNo ratings yet

- ExxonMobil LLDPE LL 1002AY BlownDocument2 pagesExxonMobil LLDPE LL 1002AY BlownOscar Tan IIINo ratings yet

- Property ASTM or UL Test Extruded NYLON 6/6 Cast Nylon Physical MechanicalDocument1 pageProperty ASTM or UL Test Extruded NYLON 6/6 Cast Nylon Physical MechanicalEktor RamirzNo ratings yet

- Bel-Ray 6 in 1 Multipurpose LubricantDocument2 pagesBel-Ray 6 in 1 Multipurpose LubricantdhowardjNo ratings yet

- Roller Bearing GreaseDocument2 pagesRoller Bearing GreaseYoong TanNo ratings yet

- PDS Caltex Delo Starplex EP 3Document3 pagesPDS Caltex Delo Starplex EP 3Juan Carlo PanchoNo ratings yet

- Molylube Extreme Pressure High Viscosity GreaseDocument4 pagesMolylube Extreme Pressure High Viscosity GreaseJaime MunozNo ratings yet

- PDSDetailPage - Black Pearl EP - EN - NEWDocument2 pagesPDSDetailPage - Black Pearl EP - EN - NEWChen LiuNo ratings yet

- Petrothene: Low Density Polyethylene Film Extrusion GradeDocument1 pagePetrothene: Low Density Polyethylene Film Extrusion GradeGabriela Lopez MunozNo ratings yet

- H.T. Brautek Lithium Moly SeriesDocument2 pagesH.T. Brautek Lithium Moly SeriesAlexo HaroNo ratings yet

- Cardolite Ultra LITE 2009: Epoxy Curing Agent Technical DatasheetDocument2 pagesCardolite Ultra LITE 2009: Epoxy Curing Agent Technical Datasheettrường phạmNo ratings yet

- Technical Datasheet: AME™ 6001 INF-135 Premium Marine Resin InfusionDocument2 pagesTechnical Datasheet: AME™ 6001 INF-135 Premium Marine Resin InfusionMarjan ArhNo ratings yet

- Exceed 3518Document2 pagesExceed 3518Amin PanNo ratings yet

- Castrol Manual EP 80W-90: DescriptionDocument1 pageCastrol Manual EP 80W-90: Descriptionvicky kNo ratings yet

- Permafil 707Document2 pagesPermafil 707Yahiko LeosNo ratings yet

- Molykote® G-1502FM Data SheetDocument2 pagesMolykote® G-1502FM Data SheetlorenzoNo ratings yet

- Product Data Sheet: 6 IN 1 Multipurpose LubricantDocument2 pagesProduct Data Sheet: 6 IN 1 Multipurpose LubricantDaniel ColinsNo ratings yet

- PEADM5372Document2 pagesPEADM5372nicolas yoris marcoglieseNo ratings yet

- No Tox Food Grade Seamer OilDocument2 pagesNo Tox Food Grade Seamer OilDon HowardNo ratings yet

- Daphne Eponex Grease SR Series: Lubricant Product InformationDocument2 pagesDaphne Eponex Grease SR Series: Lubricant Product InformationSadid ShahzadNo ratings yet

- Alpha SP Range: DescriptionDocument3 pagesAlpha SP Range: Descriptionvicky kNo ratings yet

- Daphne Super Coat TWDocument2 pagesDaphne Super Coat TWSuprastowo Bin SarinoNo ratings yet

- High Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Document2 pagesHigh Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Phung LucNo ratings yet

- TDS Molylube SF 100 Semi Synthetic Open Gear Lubricant PDFDocument3 pagesTDS Molylube SF 100 Semi Synthetic Open Gear Lubricant PDFGilmer CaceresNo ratings yet

- Derakane Momentum 411-350Document3 pagesDerakane Momentum 411-350DidikHariantoNo ratings yet

- Mobil Polyrex EMDocument2 pagesMobil Polyrex EMthe anhNo ratings yet

- Molylube Extreme Pressure High Viscosity GreaseDocument2 pagesMolylube Extreme Pressure High Viscosity GreaseGilmer Williams Cáceres BenaventeNo ratings yet

- Exceed 1012HA PDFDocument2 pagesExceed 1012HA PDFEdgar CascoNo ratings yet

- ExxonMobil Enable 20-05HHDocument2 pagesExxonMobil Enable 20-05HHHung TranNo ratings yet

- Aqualink 300F Ver2Document2 pagesAqualink 300F Ver2Georgina SuleNo ratings yet

- Castrol Axle EPX 80W-90Document1 pageCastrol Axle EPX 80W-90indeskeyNo ratings yet

- Product Data Sheet: Molylube Ultra Open Gear LubricantDocument2 pagesProduct Data Sheet: Molylube Ultra Open Gear LubricantDiegoNo ratings yet

- 423-Renolin CLP-1Document1 page423-Renolin CLP-1Moutaz IsmailNo ratings yet

- 93 Sinopec Extreme Pressure Lithium Complex GreaseDocument3 pages93 Sinopec Extreme Pressure Lithium Complex GreaseAmadeus CocaNo ratings yet

- XIAMETER™ RBB-2030-80 Base: Features & Benefits ApplicationsDocument3 pagesXIAMETER™ RBB-2030-80 Base: Features & Benefits ApplicationsDaniela Alejandra Daza LancherosNo ratings yet

- Hdpe HD 7845.30Document2 pagesHdpe HD 7845.30Cristian RodriguezNo ratings yet

- Derakane 411 Data SheetDocument3 pagesDerakane 411 Data SheetJUAN BAGNODNo ratings yet

- Technical Data: Impact Grease / TackyDocument3 pagesTechnical Data: Impact Grease / TackyRodrigo RiosNo ratings yet

- Amberlite IRC120 NaDocument3 pagesAmberlite IRC120 NaPT Deltapuro Indonesia100% (1)

- Exceed 1012MK PDFDocument2 pagesExceed 1012MK PDFEdgar CascoNo ratings yet

- Paxon™ AD60-007: High Density Polyethylene ResinDocument2 pagesPaxon™ AD60-007: High Density Polyethylene ResinLABORATORIONo ratings yet

- Royal 876 EP GreaseDocument3 pagesRoyal 876 EP GreaseVictor ZhicayNo ratings yet

- 8 21 Pure TacDocument1 page8 21 Pure TacYeison Camilo Zapata DavidNo ratings yet

- Schaeffer # 229Document3 pagesSchaeffer # 229Ingeniero aicNo ratings yet

- Molykote® SK-623Document2 pagesMolykote® SK-623If ChenNo ratings yet

- Lubricants: Unoba EPDocument2 pagesLubricants: Unoba EPQC RegianNo ratings yet

- Omega 585Document12 pagesOmega 585Vikz 4gameNo ratings yet

- Aceite Royal Purple - Synfilm - 46Document2 pagesAceite Royal Purple - Synfilm - 46micmarley2012No ratings yet

- Ap Getoel EpDocument1 pageAp Getoel EpSami KahtaniNo ratings yet

- G-Tek CSC Food Series: H1 Food Grade High Performance GreaseDocument2 pagesG-Tek CSC Food Series: H1 Food Grade High Performance GreaseInfor AdmNo ratings yet

- GL XX Mobil Polyrex EM SeriesDocument3 pagesGL XX Mobil Polyrex EM SeriesRakka HardiyantaNo ratings yet

- Product Data Sheet: No-Tox HD Food Grade GreaseDocument3 pagesProduct Data Sheet: No-Tox HD Food Grade GreaseDaniel ColinsNo ratings yet

- Ficha Técnica Castrol Syngear 75W-90Document2 pagesFicha Técnica Castrol Syngear 75W-90Victor Manuel Gonzalez PerezNo ratings yet

- GL EG Mobilfluid 424Document4 pagesGL EG Mobilfluid 424mgamal1080No ratings yet

- q1wk1 gp1 La1Document1 pageq1wk1 gp1 La1ian babiloniaNo ratings yet

- Physics 1234Document253 pagesPhysics 1234Bxhsh Hdhshssh100% (1)

- Construction Method For Pile DrivingDocument17 pagesConstruction Method For Pile DrivingsochealaoNo ratings yet

- Tube Side Velocity CalculationDocument20 pagesTube Side Velocity CalculationNitin KurupNo ratings yet

- Bardon Initiation Into Hermetics (Better Outline) : Step X Exercises SummaryDocument7 pagesBardon Initiation Into Hermetics (Better Outline) : Step X Exercises SummaryRhaxma Conspiracy100% (1)

- HFS2N60: 600V N-Channel MOSFETDocument7 pagesHFS2N60: 600V N-Channel MOSFETNickol HardwayNo ratings yet

- Thermodynamics Lecture PDFDocument11 pagesThermodynamics Lecture PDFGenerale, Rey marck C.No ratings yet

- Machines For O Level Physics PDFDocument27 pagesMachines For O Level Physics PDFRwabahinda100% (1)

- Product Design Based On Discrete Particle Modeling of A Uidized Bed GranulatorDocument12 pagesProduct Design Based On Discrete Particle Modeling of A Uidized Bed Granulator권혁록No ratings yet

- Adstefan Input Data SheetDocument4 pagesAdstefan Input Data SheetMuthu KumarNo ratings yet

- IH CurveDocument8 pagesIH CurveGautam ChauhanNo ratings yet

- Moving Man SimulationDocument12 pagesMoving Man SimulationAlexa AquinoNo ratings yet

- H 1"" 1.9 Unfolding and Folding A ChainDocument4 pagesH 1"" 1.9 Unfolding and Folding A ChainAshNo ratings yet

- IB Physics Refractive Index ReportDocument5 pagesIB Physics Refractive Index ReportGiáng HươngNo ratings yet

- Reading Comprehension PracticeDocument10 pagesReading Comprehension PracticeMomi BearFruitsNo ratings yet

- Presentación Completa ArupDocument105 pagesPresentación Completa ArupCarlos Eduardo Rodriguez100% (1)

- Transparent ABS: Mabs: Toray Plastics (Malaysia) Sdn. BNDDocument6 pagesTransparent ABS: Mabs: Toray Plastics (Malaysia) Sdn. BNDTungdinh NguyenNo ratings yet

- AphiweDocument16 pagesAphiweaphiweshozi18No ratings yet

- Development of Equation of Motion For Nonlinear Vibrating SystemsDocument45 pagesDevelopment of Equation of Motion For Nonlinear Vibrating SystemsSteve KrodaNo ratings yet

- Carpe Huang - DEG I - Lab Report Kinematics 1dDocument8 pagesCarpe Huang - DEG I - Lab Report Kinematics 1dChengxiang HuangNo ratings yet

- The Ultimate Guide: For Mandala Coloring MeditationDocument17 pagesThe Ultimate Guide: For Mandala Coloring MeditationMira Nicusan100% (1)

- Channel DesignDocument5 pagesChannel DesignAaronNo ratings yet

- Universiti Teknologi Mara Mid-Term Assessment: Confidential EH/MAY 2021/CHE553Document3 pagesUniversiti Teknologi Mara Mid-Term Assessment: Confidential EH/MAY 2021/CHE553Lehbron JemsNo ratings yet

- ICT 7 Electronic Summative ExamDocument4 pagesICT 7 Electronic Summative ExamRaymond PunoNo ratings yet

- Mathematics in The Modern World: Number Sequence and SeriesDocument12 pagesMathematics in The Modern World: Number Sequence and SeriesCherrylane EdicaNo ratings yet

- Surge Arresters HubellDocument24 pagesSurge Arresters Hubellkhaldoun samiNo ratings yet

- Isometric and Orthographic ProjectionsDocument24 pagesIsometric and Orthographic ProjectionsKristian UretaNo ratings yet

- Homework Set #3: EE6412: Optimal Control January - May 2023Document2 pagesHomework Set #3: EE6412: Optimal Control January - May 2023kapali123No ratings yet

- GrammarDocument6 pagesGrammar灰谷リンエリNo ratings yet

- Mechanical Maintenance of Cement Rotary KilnDocument101 pagesMechanical Maintenance of Cement Rotary KilnVijaykumar Rugada97% (35)