Professional Documents

Culture Documents

10 1109icbaps 2015 7292220 PDF

10 1109icbaps 2015 7292220 PDF

Uploaded by

nike 1998Copyright:

Available Formats

You might also like

- Fieldmaster User ManualDocument40 pagesFieldmaster User ManualArun BalaNo ratings yet

- Cyber Security MIS607 - Assessment 3 Related NotesDocument12 pagesCyber Security MIS607 - Assessment 3 Related NotesShuja ur Rehman100% (1)

- Mobile Code Collection CComputriXDocument29 pagesMobile Code Collection CComputriXapi-3742938No ratings yet

- Development of An Upper Limb Exoskeleton For Rehabilitation With Feedback From EMG and IMU SensorDocument7 pagesDevelopment of An Upper Limb Exoskeleton For Rehabilitation With Feedback From EMG and IMU SensorkeerthiNo ratings yet

- Irjet V6i6362Document6 pagesIrjet V6i6362PintuNo ratings yet

- Biomechatronics Design of A Novel Artificial Arm: A. Malik Mohd Ali M. Mahadi - Abdul JamilDocument5 pagesBiomechatronics Design of A Novel Artificial Arm: A. Malik Mohd Ali M. Mahadi - Abdul JamilİTYNo ratings yet

- Design and Development of Arm Rehabilitation Monitoring DeviceDocument2 pagesDesign and Development of Arm Rehabilitation Monitoring DeviceAmanuel TilayeNo ratings yet

- Physio Arm Control For Patient Using IOT TechnologyDocument5 pagesPhysio Arm Control For Patient Using IOT TechnologyIJRASETPublicationsNo ratings yet

- Disadvantages Eeg EogDocument22 pagesDisadvantages Eeg EogSaurabh MishraNo ratings yet

- Low Cost ExoskeletonDocument16 pagesLow Cost ExoskeletonJony WalkerNo ratings yet

- Non-Invasive Brain-Computer Interface System To Operate Assistive DevicesDocument4 pagesNon-Invasive Brain-Computer Interface System To Operate Assistive DevicesSangeetha SNo ratings yet

- Development of A Single 3-Axis Accelerometer Senso PDFDocument11 pagesDevelopment of A Single 3-Axis Accelerometer Senso PDFA k goelNo ratings yet

- A Wearable, Wireless Gaze Tracker With Integrated Selection Command Source For Human-Computer InteractionDocument7 pagesA Wearable, Wireless Gaze Tracker With Integrated Selection Command Source For Human-Computer InteractionTarishi GargNo ratings yet

- The Assistive Kitchen - A Demonstration Scenario For Cognitive Technical SystemsDocument8 pagesThe Assistive Kitchen - A Demonstration Scenario For Cognitive Technical SystemspunditNo ratings yet

- A Smart-Hand Movement-Based System To Control A Wheelchair WirelesslyDocument18 pagesA Smart-Hand Movement-Based System To Control A Wheelchair WirelesslyAKHILNo ratings yet

- Review Paper On Live Eye Gaze Tracking To Control Mouse Pointer MovementDocument5 pagesReview Paper On Live Eye Gaze Tracking To Control Mouse Pointer MovementIJRASETPublicationsNo ratings yet

- (33-40) Prosthetic Arm Multi-Purpose GloveDocument8 pages(33-40) Prosthetic Arm Multi-Purpose Glovebuddi vantarige matraNo ratings yet

- Galileo Hand: An Anthropomorphic and Affordable Upper-Limb ProsthesisDocument13 pagesGalileo Hand: An Anthropomorphic and Affordable Upper-Limb Prosthesismanju.vs1546No ratings yet

- Francis Dennis C. Acquiat, Sylvester Louie B. Dumagan, Kymm Alexis S. Paña, Joniel Jansen L. Tesara, and Aylmer Ronnel L. SombillaDocument12 pagesFrancis Dennis C. Acquiat, Sylvester Louie B. Dumagan, Kymm Alexis S. Paña, Joniel Jansen L. Tesara, and Aylmer Ronnel L. Sombillamontero.baltesNo ratings yet

- Brain Gate LibreDocument3 pagesBrain Gate Libreanks1605No ratings yet

- 0chapter-1: Poly-House Is A Elongated Protected Structure Usually For Cultivation of OffDocument76 pages0chapter-1: Poly-House Is A Elongated Protected Structure Usually For Cultivation of OffAvadhani SharmaNo ratings yet

- Development of Low-Cost Portable Hand Exoskeleton For Assistive and Rehabilitation PurposesDocument14 pagesDevelopment of Low-Cost Portable Hand Exoskeleton For Assistive and Rehabilitation Purposesgil lerNo ratings yet

- Embedded Systems Application AreasDocument8 pagesEmbedded Systems Application AreasSurr LaLaNo ratings yet

- Vision Controlled Motorised WheelchairDocument13 pagesVision Controlled Motorised WheelchairIJRASETPublicationsNo ratings yet

- A Multimodal Adaptive Wireless Control Interface For People With Upper-Body DisabilitiesDocument12 pagesA Multimodal Adaptive Wireless Control Interface For People With Upper-Body DisabilitiesSantalum AlbumNo ratings yet

- Eye Movement Recognition Based Human Machine Interaction SystemDocument4 pagesEye Movement Recognition Based Human Machine Interaction SystemIJRASETPublicationsNo ratings yet

- IEEE SJ Review - 2015Document11 pagesIEEE SJ Review - 2015Manuela GomezNo ratings yet

- Ijreiss 4110 93913Document6 pagesIjreiss 4110 93913Atul GaikwadNo ratings yet

- Irjet Automated Paralysis Patient HealthDocument7 pagesIrjet Automated Paralysis Patient HealthLakshmi PriyaNo ratings yet

- IoT-Based Smart Medicine DispenserDocument8 pagesIoT-Based Smart Medicine DispenserIJRASETPublications100% (1)

- Sensors 21 06863 v3Document43 pagesSensors 21 06863 v3Anh HuyNo ratings yet

- 8 Ijmperdjun20198Document14 pages8 Ijmperdjun20198TJPRC PublicationsNo ratings yet

- Control of Robot Using Data GloveDocument6 pagesControl of Robot Using Data GloveRajeswari MuruganNo ratings yet

- Hybrid Control of A Vision-Guided Robot Arm by EOG EMG EEG Biosignals and Head Movement Acquired Via A Consumer-Grade Wearable DeviceDocument14 pagesHybrid Control of A Vision-Guided Robot Arm by EOG EMG EEG Biosignals and Head Movement Acquired Via A Consumer-Grade Wearable DeviceShizraNo ratings yet

- Shortened PointsDocument4 pagesShortened PointsREDWAN AHMED MIAZEENo ratings yet

- Haptic TechnologyDocument5 pagesHaptic TechnologyIJRASETPublicationsNo ratings yet

- RoboticDocument6 pagesRoboticShahid HasanNo ratings yet

- IOT Based Paralysis Patient Healthcare System: Dr.S. S. Thakare Sahil Tekam, Nikita Agrawal, Swapnil PandhareDocument4 pagesIOT Based Paralysis Patient Healthcare System: Dr.S. S. Thakare Sahil Tekam, Nikita Agrawal, Swapnil PandhareNikita AgrawalNo ratings yet

- V4i10201540 PDFDocument6 pagesV4i10201540 PDFRaja TamilanNo ratings yet

- Biomechatronic Design and Control of An Anthropomorphic Artificial Hand For Prosthetic ApplicationsDocument19 pagesBiomechatronic Design and Control of An Anthropomorphic Artificial Hand For Prosthetic ApplicationsGiang TruongNo ratings yet

- Research PaperDocument4 pagesResearch PapersunilNo ratings yet

- Huat - 2022 - Soft Gripper For Food HandlingDocument12 pagesHuat - 2022 - Soft Gripper For Food HandlingmikelaxnNo ratings yet

- Implementation of UI Based On Gesture Recognition For Hospital Enquiry SystemDocument10 pagesImplementation of UI Based On Gesture Recognition For Hospital Enquiry SystemIJRASETPublicationsNo ratings yet

- An Ambient Assisted Living FrameworkDocument11 pagesAn Ambient Assisted Living FrameworkTimóteo SilvaNo ratings yet

- Human Activity Recogniton Using Machine Learning IJERTV10IS040236Document5 pagesHuman Activity Recogniton Using Machine Learning IJERTV10IS040236APS PlacementsNo ratings yet

- IJSRET V7 Issue1 145Document8 pagesIJSRET V7 Issue1 145Sachin RathodNo ratings yet

- GestureDocument6 pagesGestureKelappan NairNo ratings yet

- Seminar TopicDocument9 pagesSeminar TopicSreesha Vittal K PNo ratings yet

- Sanitization RobotDocument5 pagesSanitization Robotramya adariNo ratings yet

- A Portable Wireless Head Movement Controlled Human-Computer Interface For People With DisabilitiesDocument9 pagesA Portable Wireless Head Movement Controlled Human-Computer Interface For People With DisabilitiesIJRASETPublicationsNo ratings yet

- 10 1108 - Aa 12 2021 0174Document7 pages10 1108 - Aa 12 2021 0174walla'a yusufNo ratings yet

- MIPRO2018 Martin ModifiedDocument7 pagesMIPRO2018 Martin ModifiedFajar NuswantoroNo ratings yet

- Smart Farm Computing Systems For Animal Welfare MonitoringDocument6 pagesSmart Farm Computing Systems For Animal Welfare MonitoringSREELAKSHMI K.K.No ratings yet

- A 3D Printed Soft Robotic Hand With Embedded SoftDocument9 pagesA 3D Printed Soft Robotic Hand With Embedded SoftSwathi HsNo ratings yet

- Human Activity Recognition With SmartphoneDocument8 pagesHuman Activity Recognition With SmartphoneIJRASETPublicationsNo ratings yet

- Script On Report Ai and RobboticsDocument4 pagesScript On Report Ai and RobboticsPam ElaNo ratings yet

- The Teach'Wear - Healthcare Wearable DeviceDocument6 pagesThe Teach'Wear - Healthcare Wearable Devicedjole07No ratings yet

- Article Sensors1Document10 pagesArticle Sensors1kouacheanfal2No ratings yet

- SM3315Document19 pagesSM3315Riky Tri YunardiNo ratings yet

- Design and Implementation of Haptic Prosthetic Hand For Realization of Intuitive OperationDocument9 pagesDesign and Implementation of Haptic Prosthetic Hand For Realization of Intuitive OperationIJRASETPublicationsNo ratings yet

- Sensors And Μcontrollers In The Use Of Wearables For Recording Biometric DataDocument5 pagesSensors And Μcontrollers In The Use Of Wearables For Recording Biometric DataTria Nurmar'atinNo ratings yet

- Robotics: Deep Reinforcement Learning For The Control of Robotic Manipulation: A Focussed Mini-ReviewDocument13 pagesRobotics: Deep Reinforcement Learning For The Control of Robotic Manipulation: A Focussed Mini-ReviewHien Bui XuanNo ratings yet

- Tactile Sensing and Displays: Haptic Feedback for Minimally Invasive Surgery and RoboticsFrom EverandTactile Sensing and Displays: Haptic Feedback for Minimally Invasive Surgery and RoboticsNo ratings yet

- Bateria Laptop Sony Vaio LodiDocument24 pagesBateria Laptop Sony Vaio Lodirammstein4445No ratings yet

- DM ModeDocument1 pageDM ModeshailzworldNo ratings yet

- Hometaxial-Base Medium Power Silicon NPN Transistor: FeaturesDocument2 pagesHometaxial-Base Medium Power Silicon NPN Transistor: Featuresovidiu ovidiusNo ratings yet

- Apxvbll26ex 43-C-I20 PreDocument4 pagesApxvbll26ex 43-C-I20 Precmsd01No ratings yet

- Session 01 PDFDocument53 pagesSession 01 PDFLIVE WIRENo ratings yet

- Addl Guidelines Digital BillboardDocument7 pagesAddl Guidelines Digital BillboardrxNo ratings yet

- Week 5Document31 pagesWeek 5HadeedAhmedSherNo ratings yet

- App Module 2,3,4 NotesDocument38 pagesApp Module 2,3,4 NotesNikhil SekharanNo ratings yet

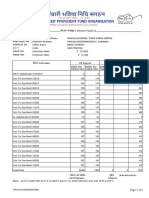

- LNL Iklcqd /: Grand Total 10,496 3,208 0 0 7,212Document2 pagesLNL Iklcqd /: Grand Total 10,496 3,208 0 0 7,212Naveen SinghNo ratings yet

- RGPV Syllabus PDFDocument44 pagesRGPV Syllabus PDFAshutosh TripathiNo ratings yet

- IFS Portal Hunt - Expert Decoder TemplateDocument14 pagesIFS Portal Hunt - Expert Decoder TemplateDeependra SinghNo ratings yet

- Hearth Book 1 - Heart - Earth Syncretism (121 Page 4Document12 pagesHearth Book 1 - Heart - Earth Syncretism (121 Page 4ADAM FOX (A FOX IN THE CITY)No ratings yet

- Brochure - LMS Virtual - Lab Noise and VibrationDocument12 pagesBrochure - LMS Virtual - Lab Noise and Vibrationsantosh_ramuNo ratings yet

- IT Chapter 11Document6 pagesIT Chapter 11Elyani RamliNo ratings yet

- Trends and Challenges in Soc Design v3Document32 pagesTrends and Challenges in Soc Design v3Nitheesh Kumar100% (1)

- Loop Length of Plain Single Weft Knitted Structure With ElastaneDocument11 pagesLoop Length of Plain Single Weft Knitted Structure With ElastaneNobodyNo ratings yet

- 2-Phase Stepping Motor Driver: Thick-Film Hybrid ICDocument23 pages2-Phase Stepping Motor Driver: Thick-Film Hybrid ICKaland RoboNo ratings yet

- RmantroublrshootingDocument28 pagesRmantroublrshootingapi-3730388No ratings yet

- Citation 28 - On-The-Combination-Of-Naive-Bayes-And-Decision-Trees-For-IntrusiDocument6 pagesCitation 28 - On-The-Combination-Of-Naive-Bayes-And-Decision-Trees-For-IntrusiZahedi AzamNo ratings yet

- Programmable Money: Next Generation Blockchain Based Conditional PaymentsDocument17 pagesProgrammable Money: Next Generation Blockchain Based Conditional PaymentsAhmad RazaNo ratings yet

- Electronic EvidenceDocument4 pagesElectronic EvidenceRandal's CaseNo ratings yet

- Case Study Should Companies Embrace Social BusinessDocument5 pagesCase Study Should Companies Embrace Social Businessdeviskipyegen3No ratings yet

- The Shellcoder's HandbookDocument12 pagesThe Shellcoder's HandbookjackienessNo ratings yet

- Manual WM Security Routers V2.04 enDocument127 pagesManual WM Security Routers V2.04 enOscar TamayoNo ratings yet

- How To Write Big Application in ExtjsDocument17 pagesHow To Write Big Application in ExtjsPrabhu Patil100% (1)

- Diwali Greeting CodeDocument4 pagesDiwali Greeting CodeVaneet Kumar NagpalNo ratings yet

- L6 - Information Systems SecurityDocument17 pagesL6 - Information Systems Securityhieubot1111No ratings yet

10 1109icbaps 2015 7292220 PDF

10 1109icbaps 2015 7292220 PDF

Uploaded by

nike 1998Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10 1109icbaps 2015 7292220 PDF

10 1109icbaps 2015 7292220 PDF

Uploaded by

nike 1998Copyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/308851389

Development of Smart Glove system for therapy treatment

Conference Paper · May 2015

DOI: 10.1109/ICBAPS.2015.7292220

CITATIONS READS

5 2,505

5 authors, including:

Abdul Malik Mohd Ali Zulkhairi Mohd Yusof

University Kuala Lumpur -UNIKLMSI University of Kuala Lumpur

42 PUBLICATIONS 132 CITATIONS 28 PUBLICATIONS 74 CITATIONS

SEE PROFILE SEE PROFILE

Azman Ismail

University of Kuala Lumpur

68 PUBLICATIONS 104 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Orbital Friction Stir Welding View project

Critical Success Factor of Trusted Elements for Mobile Health Records Management: A Review of Conceptual Models View project

All content following this page was uploaded by Azman Ismail on 30 July 2017.

The user has requested enhancement of the downloaded file.

2015 International Conference on BioSignal Analysis, Processing and Systems (ICBAPS)

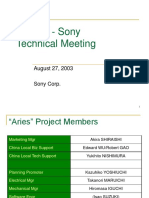

Development of Smart Glove System for Therapy Treatment

Abdul Malik. M. Ali1, Zulkhairi MD.Yusof2, Kushairy A.K1, F. Zaharah H1, Azman Ismail.

Universiti Kuala Lumpur British Malaysian Institute,

Electrical Technology1 Section and Electronic Technology2

Batu 8, Jln Sg Pusu, 53100, Gombak Selangor.

amalik@unikl.edu.my

Abstract

Arm rehabilitation activities require continuous monitoring process in care. This later concept will be followed as in this study for

order to provide information on rehabilitation results to be analyzed by the development of an artificial hand gripper [8-10].

therapist. The purpose of monitoring is to help them to improve and Teleoperation is the controlling of a robot or system over a

customize the rehabilitation process. Moreover, a portable and simple home- distance where a human and a robot collaborate to perform

based rehabilitation device can help patients to improve daily rehabilitation

activity. Some previous studies regarding home-based rehabilitation process tasks and to achieve common goal. The operator is the human

have shown improvement promoting human movement recovery. But controlling entity, whereas the teleoperator refers to the

existing rehabilitation devices are expensive and need to be supervised by a system or robot being controlled. Traditional literature divides

physical therapist, which are complicated to be used at home. Some devices tele-operation into two fields: direct teleoperation, with the

are not so efficient to be used at home due to the large size and complex

system. In this current work, flex sensor, force sensitive resistors and operator closing all control loops and supervisory control, if

accelerometer were assessed in order to be implemented as a sensory unit the teleoperator (a robot) exhibits some degree of control itself

for a portable arm rehabilitation device. The analog signal from the sensors [1]. Tele-presence means that the operator receives sufficient

will be conveyed to an Arduino microcontroller for data processing and information about the tele-operator and the task environment,

logging. The device is equipped with online or portable data logging

capabilities which can store daily activity results. The results of displayed in a sufficiently natural way, that the operator feels

rehabilitation activity can be used for further monitoring and analysis. physically present at a remote site [1]. The feeling of presence

Experiments were carried out to determine the feasibility of each sensor plays a crucial role in teleoperation, the better he can

towards the design of the new device (Figure 1). The experiments

accomplish a task. One method type of communication system

demonstrate the capabilities of the sensors to produce extended information

regarding arm movement activities which can be implemented in the design. that can embed into the robots peripheral is via using

Bluetooth technology. The aim of this research is to assist

Keyword: Microcontroller, master system and therapy handicapped individual in providing them with an enhanced

version prosthetics that is economical and affordable.

I. INTRODUCTION

II. METHOD

In science, the definition of “gripper” is subsystems of

handling mechanisms which provide temporary contact with The development of this project involves the designing of a

the object to be grasped. They ensure the position and Smart Glove and an artificial multi-finger hand gripper (refer

orientation when carrying and joining the object to the figure 1). The concept of this research is to design, develop,

handling equipment. Prehension is achieved by force assists and measure a device which can continuously monitor

producing and form matching elements. The term “gripper” is the upper arms. The device is fully functioning of smart glove

also used in cases where no actual grasping, but rather holding by using microcontroller system. This system can collected the

of the object as in vacuum suction where the retention force data, process and save in the computer monitoring system.

can act on a point, line or surface [1]. In another study, a new

prosthetic hand is being tested at the Orthopedic University

Hospital in Heidelberg Grip which functions almost like a

natural hand. It can hold a credit card, use a keyboard with the

index finger, and lift a bag weighing up to 20 kg. It's the

world's first commercially available prosthetic hand that can

move each finger separately and has an outstanding range of

grip configurations. The “i-LIMB Hand” is controlled by a

unique, highly intuitive control system that uses a traditional

two input “Myoelectric” (muscle signal) to open and close the

hand’s [2]. The construction of the artificial hand gripper

which is each individual powered finger can be quickly

removed by simply removing one screw. Thus, the developed

prosthetics can easily swap out fingers which require servicing

and therefore patients can return to their everyday lives after a

short visit to the clinic [3-4]. A three fingered, multi jointed

robot gripper for experimental use is presented. Fig. 1. Shows the proposed Smart Glove and artificial hand

This artificial limb looks and acts like a real human hand gripper.

and represents a generational advance in bionics and patient

978-1-4799-6879-4/15/$31.00 ©2015 IEEE 67

2015 International Conference on BioSignal Analysis, Processing and Systems (ICBAPS)

The microcontroller allows the control of the activity of the

smart glove in an easy and effective way. The smart glove is

connected to a computer for controlling and alerting the user

to error condition arising. In order to perform manipulation

task a multi finger system consisting of the five-finger robotic

hand gripper and data glove have been develop.

The usage of a universal gripper allows for operation in highly

variable, unstructured, unknown or dynamic working

environments. As part of telemanipulation (wire or wireless)

system the gripper is controlled by a human operation (smart

glove). On this account human hand and finger motions are

measured using the flex sensor and transfer data to the

microcontroller. Sensed interaction forces are fed back to the

operation and displayed through an LCD monitor. Since

Fig 2. Smart Glove (a) Setup for four set Flex sensor

human hand and gripper have different kinematic structure,

appropriate mapping for forces and motion between the finger

and gripper. Above is a block diagram for all operation in this

project. In simple word, data of each fingers from Master part

should be the same with Slave finger parts. Disturbance error

will be corrected by comparing value between Master and

Slave same finger parts until the both be equilibrium state. If

equilibrium state is achieved, it means that everything operates

at optimum condition.

III. HARDWARE SYSTEM

The Arduino (UNO) microcontroller used in this application

has an Analogue /Digital (A/D) converter built on the chip and

a sampling rate of 20 sec/sample. In Figure 1, the flowcharts

of the programs running on the first (root) microcontroller and

the second (slave) are shown. The root microcontroller is

connected through the Atmega 328 which is the brain of the Fig 3. HyperTerminal Channel Analysis for Master

Arduino microcontroller. Arduino board is made of an

Atmel328 AVR microprocessor, a crystal or oscillator A Smart Glove system is developed in order to effectively

(basically a crude clock that sends time pulses to the demonstrate the grasping of objects for a certain tasks. The

microcontroller to enable it to operate at the correct speed) and process involving transmitting electrical signals from the

a 5-volt linear regulator. Arduino board has a USB connector smart glove (master) to Artificial Hand Gripper (slave) is the

to enable it to be connected to a PC or Mac to upload or most challenging task in the circuit design. As shown in figure

retrieve data. The board exposes the microcontrollers I/O 2, the Flex sensors is attached on the back of the Smart Glove.

(Input/output) pins to enable it to connect those pins to other The hand glove incorporates a sensory system which can

circuits or to sensors, etc. One of the main advantage of this detect finger flexion. The sensors are connected to an Arduino

board is it does not use the USB-to-serial driver chip. Instead, microcontroller for analog signal detection via Ribbon Cable.

it features the Atmega8U2 programmed as a USB-to-serial The Ribbon cable has 10 interconnected line, each line consist

converter. The microcontrollers share the same transmitting of 5 core. Each core allows 5 Volt Direct Current. To read the

bus, which is the serial transmit (TX) to the PC. At the end of sensor, its variable resistance is converted to a variable voltage

the sampling procedure, the root microcontroller opens the and amplified with an op-amp. Then, the analog signal is

communication channel, sending the data package (8 bytes) transmitted to the A/D converter in the microcontroller side

and at the completion issues a command (Port C bit 1) to the for data processing. Each of the multi-finger gripper’s finger

next (slave) microcontroller to take over the transmitting bus will move according to the flexion of flex sensor attached on

and transmit its own data package. The slave microcontroller’s the Smart Glove. The system designed finger angle, direction

flowchart has one more subroutine, sending the end of data and speed as similar as the master’s motion. Referring

package transmission to the PC. A program running on the PC illustration in figure 2, The Arduino (UNO) microcontroller

decodes the incoming data to finger position. On the PC, there has been used in this device to process and control signals

is also a calibration program, requesting the user to position generated from sensors. The Arduino microcontroller needs to

the fingers in a fully extended position and in a fully closed be connect USB to a personal computer’s COM port.

position as a fist. Movement from master will provide raw data signals from

each five of flex sensors to be processed in Arduino board.

978-1-4799-6879-4/15/$31.00 ©2015 IEEE 68

2015 International Conference on BioSignal Analysis, Processing and Systems (ICBAPS)

Arduino will process the raw data collected and transmit the

data to the computer screen as shown in figure 3.

.

(a)

Fig 4. Bluetooth Channel Analysis for master and slave

(b)

V. RESULT & DISCUSSION Fig 5 : Picture a and b, above showing the activity of Artificial

hand Gripper (1) Initial position (2) bend 30° (3) bend

60°(4) bend 90°

The characteristic of flex sensor as shown in figure 5 been

recorded. The flex sensor is a resistance-varying strip that Table 1: Arrow finger activity

increases its total electrical resistance when the strip is flexed Position Arrow finger Angle vs Resistant

in one direction (in the other direction the resistance does not

vary significantly). This angle is measured between the two 0 ° degree 14.0 K Ohm

tangent lines at the ends of the flex sensor’s body. The flex

sensor has a typical electrical resistance variation when flexed 30 ° degree 19.03 K Ohm

or bent. From the experiment, resistance value against the flex 60 ° degree 22.01 K Ohm

sensor bending angle can be plotted as shown on graph 1 and

2. The experiment shows that when flex sensor is bend 90 ° degree 24.891 K Ohm

inward, resistance value increased significantly as the angle of

flex sensor is bend further. However, when it is bent outward,

the resistance value decreased gradually. These preliminary

finding suggest that flex sensor is clearly suitable to detect Graph 1, 2, 3 and 4 shows the results of experiment done on

finger bending angle by utilizing inward bend of the flex the flex sensor. We applied bending on the flexi sensor active

sensor. surface 5 times, and the graph shows 5 peaks which suggest

that the sensor can be used to detect bend when the glove

bending 90°, 60°,45° and 30° . By attaching this sensor to the

gripper fingertips, the flex sensor will act as a detector which

sends data to the microcontroller to inform about the gripper is

grasping an object. We expected to be able to control the

amount of deferent object generated on the grasped object

based on the resistant value generated from the flex sensors.

978-1-4799-6879-4/15/$31.00 ©2015 IEEE 69

2015 International Conference on BioSignal Analysis, Processing and Systems (ICBAPS)

Graph 1: Flex sensor bending angle during experiment

Degree vs Voltage

Graph 4: Flex sensor bending angle during experiment

Analog Data and Time

30 ° 60 ° 90 °

The result from the Graph 3 shows that, the different

respond signal during standing and sitting, so in next

experiment is to investigate the detail analogue digital

converter raw data for each fingertip when the subject in

sitting position. The Graph 4 show detail experiment of the

each fingertip during gripping the polymer for mapping the

smart glove and artificial hand gripper. Four force tension

sensors which are F2, F3 and F4 with two tactile sensors of the

F1 and F5 index fingers are plotted. The outcome was fully

satisfying and sufficiently fulfils the requirement of smart

glove if compared with the other variety of flexi force sensors

that were experienced. The result shows that the flexi force

sensor can measure the performed of each finger.

Graph 2: Flex sensor bending angle during experiment V. CONCLUSION

Degree vs Resistance

The mechanical were analyzed and finalized for designing a

workable device. A new approach with four fingers and a

Force sensor 1 & Force sensor 2

4.5 thumb gripper had been developed and controlled to ensure

Force sensor 1

Force sensor 2

optimum finger gripping and positioning was applied in the

4

Smart Glove (Master). The variable grip force feature permits

3.5 grasping and lifting of fragile objects without crushing them.

3

The characteristics of several kinematics arrangements,

including level mechanisms, and direct linear drives were

2.5

discussed to choose a satisfactory finger mechanism. The

v o lt

2 direct linear drive was chosen because it poses a linear

relationship between actuator input and finger position and the

1.5

independence of gripping force from gripper opening. A

1 useful objective index, the gripper ratio which is the maximum

0.5

weight of the object lifted divided by highest gripper weight

was applied in the artificial hand gripper design. This ratio

0

1 11 21 31 41 51 61 71 81 91 101 111 121 131 141 151 161 171 ensures the artificial hand gripper was flexible to be operated

time (200ms/unit) with different kinematics structure and source of power

especially on comparing the payload carrying capacity of the

Graph 3: Flexi Force sensor bending angle during experiment gripper. This flexibility offered in flexi-force allows it to be

Volt vs Time retrofitted in the smart glove. The optimum result was

obtained when consuming the responsive flexi-force sensor

978-1-4799-6879-4/15/$31.00 ©2015 IEEE 70

2015 International Conference on BioSignal Analysis, Processing and Systems (ICBAPS)

into the smart glove. The high sensitivity of the flexi force [7] A. Malik .Mohd Ali1, 2, A.Jalaludin M.Wahi, Radzi Bin Ambar 1, 2, M.

Mahadi .Abdul Jamil1, 2 , Journal – International Journal of Integrated

sensor was monitored with the great change of its resistances

Engineering (IJIE) Development of Artificial Hand Gripper by using

with small degree of finger kinematics. This enables the Microcontroller. Volume 3 No 3, December 2011.

Arduino microprocessor to generate significant analogue

digital converter result for mapping the servo motors

[8] R. Vinet, Y. Lozac’h, N. Beaundry, G. Drouin, Design methodology for a

positions. The advantage of the Arduino microprocessor was

multifunctional hand prosthesis, J. Rehab.Res. Dev. 32, 316–324. (1995).

used to develop stand-alone interactive object to be interfaced

to a computer. Instead of collecting data from the wearable

sensor, it also fulfils the objective requirement as a hyper [9] Rajiv, Doshi; Yeh, Clement; LeBlanc, Maurice. The design and

terminal data logging system. Upon a serial data transmission development of a gloveless endoskeletal prosthetic hand. Journal of

from the Arduino, the acquired data of five flexi force sensors Rehabilitation Research and Development. Vol. 35 No. 4, Pages 388-395.

for each finger were sent and logged into the computer. The October (1998)

research work has found that the developed application has a [10] Ludovic Dovat, Olivier Lambercy, Roger Gassert, Thomas Maeder, Ted

significant purpose in artificial hand gripper system and Milner, Teo Chee Leong and Etiene Burdet.”HandCare: A Cable-Actuated

rehabilitation treatment. In addition to that, the smart glove Rehabilitation System to Train Hand Function After Stroke”. IEEE

Transactions on Neural Systems and Rehabilitation Engineering, Vol. 16,

and the Arduino based data logging system can be utilized in

No.6, December 2008.

monitoring and evaluation of patient who suffers from mini

stroke, Parkinson and sport related injuries. [11] N.Dechev, W.L.Cleghorn,S.Naumann.”Multiple finger, passive adaptive

. grasp prosthetic hand”. Mechanism and Machine Theory 36(2001) 1157-1173.

[5] H.Kawasaki and T.Komatsu,”Development of Anthropomorphic Robot

ACKNOWLEDGMENT Hand: Gifu HandI”. J. of Robot and Mechatronics, Vol. 11, No.4, pp. 269-

273, 199.

The author would like to take opportunity to express his [12] Peter S.Lum, Charles G. Burgar , Peggy C. Shor, Matra Majmundar,

heartfelt appreciation to his respectful supervisor Dr. Zulkhairi Machiel Van der Loos.” Robot Assisted Movement Training Compared With

Mohd Yusof for his supervision, encouragement, contradictive Conventional Therapy

ideas patience, guidance and invaluable advice enabling the Techniques for the Rehabilitation of Upper-Limb Motor Function After

Stroke”. Arch. Phys. Med. Rehabil. Vol. 83, July 2002.

author to produce this paper.

[13] Ramachandran V.S. “Plasticity and functional recovery in

neurology”.Clin Med 2005; 5; 368-73.

REFERENCE

[14] Ramachandran V.S., Hirstein W., “The perception of phantom limbs”.

The D.O.Hebb lecture. Brain 1998; 121; 1603-30.

[1] A. Malik Mohd Ali, M. Yusof Ismail, M. Mahadi Abdul Jamil,

proceeding paper: “Development of Artificial Hand Gripper for [15] Ramachandran V.S.,”Touching the phantom limb”. Nature 1995; 377;

th

Rehabilitation Process”. The 5 Asian Pacific Conference on Biomedical

Engineering 2011 (Biomed 2011), Kuala Lumpur, Malaysia. 489-90.

[2] Radzi Bin Ambar, Muhammad Shukri Bin Ahmad and Muhammad

Mahadi Bin Abdul Jamil, Proceeding paper:“Design and development of arm

rehabilitation monitoring device”,5th Asian Pacific Conference on Biomedical

Engineering 2011(Biomed2011), Kuala Lumpur, Malaysia .

[3] Oliver Amft et al, “Sensing Muscle Activities with Body-Worn

Sensors”, International Workshop on Wearable and Implantable Body

Sensor Networks,IEEE Computer society. 2006.

[4] A. Malik Mohd Ali, M. Yusof Ismail, M. Mahadi, "Microcontroller

Base on Artificial Hand Gripper Control by Smart Glove for Rehabilitation

Process (136-40104)” has been received by the Technical Committee of

ICoBE-2012.(Accepted ).

[5] A. Malik Mohd Ali, M. Yusof Ismail, M. Mahadi , J. Sharif“ Development

of Artificial Hand Gripper” ASQED 2011 (Number 51) .The 4th Asia

Symposium on Quality Electronic Design (ASQED 2012) Kuala Lumpur,

Malaysia.(Submit)

[6]. A. Malik .Mohd Ali1, 2,3,4, Radzi Bin Ambar 1, 2 A. Jalaludin M. Wahi3, M.

Mahadi Abdul Jamil1,2 . Journal of Engineering Packaging , Development of

Master-Slave Robotic Hand for Mirror Visual Feedback (MVF) Therapy,

Copyright- 2011 by UNIKL BMI – November 2011,Vol.1,pp 1-6.

978-1-4799-6879-4/15/$31.00 ©2015 IEEE

View publication stats

71

You might also like

- Fieldmaster User ManualDocument40 pagesFieldmaster User ManualArun BalaNo ratings yet

- Cyber Security MIS607 - Assessment 3 Related NotesDocument12 pagesCyber Security MIS607 - Assessment 3 Related NotesShuja ur Rehman100% (1)

- Mobile Code Collection CComputriXDocument29 pagesMobile Code Collection CComputriXapi-3742938No ratings yet

- Development of An Upper Limb Exoskeleton For Rehabilitation With Feedback From EMG and IMU SensorDocument7 pagesDevelopment of An Upper Limb Exoskeleton For Rehabilitation With Feedback From EMG and IMU SensorkeerthiNo ratings yet

- Irjet V6i6362Document6 pagesIrjet V6i6362PintuNo ratings yet

- Biomechatronics Design of A Novel Artificial Arm: A. Malik Mohd Ali M. Mahadi - Abdul JamilDocument5 pagesBiomechatronics Design of A Novel Artificial Arm: A. Malik Mohd Ali M. Mahadi - Abdul JamilİTYNo ratings yet

- Design and Development of Arm Rehabilitation Monitoring DeviceDocument2 pagesDesign and Development of Arm Rehabilitation Monitoring DeviceAmanuel TilayeNo ratings yet

- Physio Arm Control For Patient Using IOT TechnologyDocument5 pagesPhysio Arm Control For Patient Using IOT TechnologyIJRASETPublicationsNo ratings yet

- Disadvantages Eeg EogDocument22 pagesDisadvantages Eeg EogSaurabh MishraNo ratings yet

- Low Cost ExoskeletonDocument16 pagesLow Cost ExoskeletonJony WalkerNo ratings yet

- Non-Invasive Brain-Computer Interface System To Operate Assistive DevicesDocument4 pagesNon-Invasive Brain-Computer Interface System To Operate Assistive DevicesSangeetha SNo ratings yet

- Development of A Single 3-Axis Accelerometer Senso PDFDocument11 pagesDevelopment of A Single 3-Axis Accelerometer Senso PDFA k goelNo ratings yet

- A Wearable, Wireless Gaze Tracker With Integrated Selection Command Source For Human-Computer InteractionDocument7 pagesA Wearable, Wireless Gaze Tracker With Integrated Selection Command Source For Human-Computer InteractionTarishi GargNo ratings yet

- The Assistive Kitchen - A Demonstration Scenario For Cognitive Technical SystemsDocument8 pagesThe Assistive Kitchen - A Demonstration Scenario For Cognitive Technical SystemspunditNo ratings yet

- A Smart-Hand Movement-Based System To Control A Wheelchair WirelesslyDocument18 pagesA Smart-Hand Movement-Based System To Control A Wheelchair WirelesslyAKHILNo ratings yet

- Review Paper On Live Eye Gaze Tracking To Control Mouse Pointer MovementDocument5 pagesReview Paper On Live Eye Gaze Tracking To Control Mouse Pointer MovementIJRASETPublicationsNo ratings yet

- (33-40) Prosthetic Arm Multi-Purpose GloveDocument8 pages(33-40) Prosthetic Arm Multi-Purpose Glovebuddi vantarige matraNo ratings yet

- Galileo Hand: An Anthropomorphic and Affordable Upper-Limb ProsthesisDocument13 pagesGalileo Hand: An Anthropomorphic and Affordable Upper-Limb Prosthesismanju.vs1546No ratings yet

- Francis Dennis C. Acquiat, Sylvester Louie B. Dumagan, Kymm Alexis S. Paña, Joniel Jansen L. Tesara, and Aylmer Ronnel L. SombillaDocument12 pagesFrancis Dennis C. Acquiat, Sylvester Louie B. Dumagan, Kymm Alexis S. Paña, Joniel Jansen L. Tesara, and Aylmer Ronnel L. Sombillamontero.baltesNo ratings yet

- Brain Gate LibreDocument3 pagesBrain Gate Libreanks1605No ratings yet

- 0chapter-1: Poly-House Is A Elongated Protected Structure Usually For Cultivation of OffDocument76 pages0chapter-1: Poly-House Is A Elongated Protected Structure Usually For Cultivation of OffAvadhani SharmaNo ratings yet

- Development of Low-Cost Portable Hand Exoskeleton For Assistive and Rehabilitation PurposesDocument14 pagesDevelopment of Low-Cost Portable Hand Exoskeleton For Assistive and Rehabilitation Purposesgil lerNo ratings yet

- Embedded Systems Application AreasDocument8 pagesEmbedded Systems Application AreasSurr LaLaNo ratings yet

- Vision Controlled Motorised WheelchairDocument13 pagesVision Controlled Motorised WheelchairIJRASETPublicationsNo ratings yet

- A Multimodal Adaptive Wireless Control Interface For People With Upper-Body DisabilitiesDocument12 pagesA Multimodal Adaptive Wireless Control Interface For People With Upper-Body DisabilitiesSantalum AlbumNo ratings yet

- Eye Movement Recognition Based Human Machine Interaction SystemDocument4 pagesEye Movement Recognition Based Human Machine Interaction SystemIJRASETPublicationsNo ratings yet

- IEEE SJ Review - 2015Document11 pagesIEEE SJ Review - 2015Manuela GomezNo ratings yet

- Ijreiss 4110 93913Document6 pagesIjreiss 4110 93913Atul GaikwadNo ratings yet

- Irjet Automated Paralysis Patient HealthDocument7 pagesIrjet Automated Paralysis Patient HealthLakshmi PriyaNo ratings yet

- IoT-Based Smart Medicine DispenserDocument8 pagesIoT-Based Smart Medicine DispenserIJRASETPublications100% (1)

- Sensors 21 06863 v3Document43 pagesSensors 21 06863 v3Anh HuyNo ratings yet

- 8 Ijmperdjun20198Document14 pages8 Ijmperdjun20198TJPRC PublicationsNo ratings yet

- Control of Robot Using Data GloveDocument6 pagesControl of Robot Using Data GloveRajeswari MuruganNo ratings yet

- Hybrid Control of A Vision-Guided Robot Arm by EOG EMG EEG Biosignals and Head Movement Acquired Via A Consumer-Grade Wearable DeviceDocument14 pagesHybrid Control of A Vision-Guided Robot Arm by EOG EMG EEG Biosignals and Head Movement Acquired Via A Consumer-Grade Wearable DeviceShizraNo ratings yet

- Shortened PointsDocument4 pagesShortened PointsREDWAN AHMED MIAZEENo ratings yet

- Haptic TechnologyDocument5 pagesHaptic TechnologyIJRASETPublicationsNo ratings yet

- RoboticDocument6 pagesRoboticShahid HasanNo ratings yet

- IOT Based Paralysis Patient Healthcare System: Dr.S. S. Thakare Sahil Tekam, Nikita Agrawal, Swapnil PandhareDocument4 pagesIOT Based Paralysis Patient Healthcare System: Dr.S. S. Thakare Sahil Tekam, Nikita Agrawal, Swapnil PandhareNikita AgrawalNo ratings yet

- V4i10201540 PDFDocument6 pagesV4i10201540 PDFRaja TamilanNo ratings yet

- Biomechatronic Design and Control of An Anthropomorphic Artificial Hand For Prosthetic ApplicationsDocument19 pagesBiomechatronic Design and Control of An Anthropomorphic Artificial Hand For Prosthetic ApplicationsGiang TruongNo ratings yet

- Research PaperDocument4 pagesResearch PapersunilNo ratings yet

- Huat - 2022 - Soft Gripper For Food HandlingDocument12 pagesHuat - 2022 - Soft Gripper For Food HandlingmikelaxnNo ratings yet

- Implementation of UI Based On Gesture Recognition For Hospital Enquiry SystemDocument10 pagesImplementation of UI Based On Gesture Recognition For Hospital Enquiry SystemIJRASETPublicationsNo ratings yet

- An Ambient Assisted Living FrameworkDocument11 pagesAn Ambient Assisted Living FrameworkTimóteo SilvaNo ratings yet

- Human Activity Recogniton Using Machine Learning IJERTV10IS040236Document5 pagesHuman Activity Recogniton Using Machine Learning IJERTV10IS040236APS PlacementsNo ratings yet

- IJSRET V7 Issue1 145Document8 pagesIJSRET V7 Issue1 145Sachin RathodNo ratings yet

- GestureDocument6 pagesGestureKelappan NairNo ratings yet

- Seminar TopicDocument9 pagesSeminar TopicSreesha Vittal K PNo ratings yet

- Sanitization RobotDocument5 pagesSanitization Robotramya adariNo ratings yet

- A Portable Wireless Head Movement Controlled Human-Computer Interface For People With DisabilitiesDocument9 pagesA Portable Wireless Head Movement Controlled Human-Computer Interface For People With DisabilitiesIJRASETPublicationsNo ratings yet

- 10 1108 - Aa 12 2021 0174Document7 pages10 1108 - Aa 12 2021 0174walla'a yusufNo ratings yet

- MIPRO2018 Martin ModifiedDocument7 pagesMIPRO2018 Martin ModifiedFajar NuswantoroNo ratings yet

- Smart Farm Computing Systems For Animal Welfare MonitoringDocument6 pagesSmart Farm Computing Systems For Animal Welfare MonitoringSREELAKSHMI K.K.No ratings yet

- A 3D Printed Soft Robotic Hand With Embedded SoftDocument9 pagesA 3D Printed Soft Robotic Hand With Embedded SoftSwathi HsNo ratings yet

- Human Activity Recognition With SmartphoneDocument8 pagesHuman Activity Recognition With SmartphoneIJRASETPublicationsNo ratings yet

- Script On Report Ai and RobboticsDocument4 pagesScript On Report Ai and RobboticsPam ElaNo ratings yet

- The Teach'Wear - Healthcare Wearable DeviceDocument6 pagesThe Teach'Wear - Healthcare Wearable Devicedjole07No ratings yet

- Article Sensors1Document10 pagesArticle Sensors1kouacheanfal2No ratings yet

- SM3315Document19 pagesSM3315Riky Tri YunardiNo ratings yet

- Design and Implementation of Haptic Prosthetic Hand For Realization of Intuitive OperationDocument9 pagesDesign and Implementation of Haptic Prosthetic Hand For Realization of Intuitive OperationIJRASETPublicationsNo ratings yet

- Sensors And Μcontrollers In The Use Of Wearables For Recording Biometric DataDocument5 pagesSensors And Μcontrollers In The Use Of Wearables For Recording Biometric DataTria Nurmar'atinNo ratings yet

- Robotics: Deep Reinforcement Learning For The Control of Robotic Manipulation: A Focussed Mini-ReviewDocument13 pagesRobotics: Deep Reinforcement Learning For The Control of Robotic Manipulation: A Focussed Mini-ReviewHien Bui XuanNo ratings yet

- Tactile Sensing and Displays: Haptic Feedback for Minimally Invasive Surgery and RoboticsFrom EverandTactile Sensing and Displays: Haptic Feedback for Minimally Invasive Surgery and RoboticsNo ratings yet

- Bateria Laptop Sony Vaio LodiDocument24 pagesBateria Laptop Sony Vaio Lodirammstein4445No ratings yet

- DM ModeDocument1 pageDM ModeshailzworldNo ratings yet

- Hometaxial-Base Medium Power Silicon NPN Transistor: FeaturesDocument2 pagesHometaxial-Base Medium Power Silicon NPN Transistor: Featuresovidiu ovidiusNo ratings yet

- Apxvbll26ex 43-C-I20 PreDocument4 pagesApxvbll26ex 43-C-I20 Precmsd01No ratings yet

- Session 01 PDFDocument53 pagesSession 01 PDFLIVE WIRENo ratings yet

- Addl Guidelines Digital BillboardDocument7 pagesAddl Guidelines Digital BillboardrxNo ratings yet

- Week 5Document31 pagesWeek 5HadeedAhmedSherNo ratings yet

- App Module 2,3,4 NotesDocument38 pagesApp Module 2,3,4 NotesNikhil SekharanNo ratings yet

- LNL Iklcqd /: Grand Total 10,496 3,208 0 0 7,212Document2 pagesLNL Iklcqd /: Grand Total 10,496 3,208 0 0 7,212Naveen SinghNo ratings yet

- RGPV Syllabus PDFDocument44 pagesRGPV Syllabus PDFAshutosh TripathiNo ratings yet

- IFS Portal Hunt - Expert Decoder TemplateDocument14 pagesIFS Portal Hunt - Expert Decoder TemplateDeependra SinghNo ratings yet

- Hearth Book 1 - Heart - Earth Syncretism (121 Page 4Document12 pagesHearth Book 1 - Heart - Earth Syncretism (121 Page 4ADAM FOX (A FOX IN THE CITY)No ratings yet

- Brochure - LMS Virtual - Lab Noise and VibrationDocument12 pagesBrochure - LMS Virtual - Lab Noise and Vibrationsantosh_ramuNo ratings yet

- IT Chapter 11Document6 pagesIT Chapter 11Elyani RamliNo ratings yet

- Trends and Challenges in Soc Design v3Document32 pagesTrends and Challenges in Soc Design v3Nitheesh Kumar100% (1)

- Loop Length of Plain Single Weft Knitted Structure With ElastaneDocument11 pagesLoop Length of Plain Single Weft Knitted Structure With ElastaneNobodyNo ratings yet

- 2-Phase Stepping Motor Driver: Thick-Film Hybrid ICDocument23 pages2-Phase Stepping Motor Driver: Thick-Film Hybrid ICKaland RoboNo ratings yet

- RmantroublrshootingDocument28 pagesRmantroublrshootingapi-3730388No ratings yet

- Citation 28 - On-The-Combination-Of-Naive-Bayes-And-Decision-Trees-For-IntrusiDocument6 pagesCitation 28 - On-The-Combination-Of-Naive-Bayes-And-Decision-Trees-For-IntrusiZahedi AzamNo ratings yet

- Programmable Money: Next Generation Blockchain Based Conditional PaymentsDocument17 pagesProgrammable Money: Next Generation Blockchain Based Conditional PaymentsAhmad RazaNo ratings yet

- Electronic EvidenceDocument4 pagesElectronic EvidenceRandal's CaseNo ratings yet

- Case Study Should Companies Embrace Social BusinessDocument5 pagesCase Study Should Companies Embrace Social Businessdeviskipyegen3No ratings yet

- The Shellcoder's HandbookDocument12 pagesThe Shellcoder's HandbookjackienessNo ratings yet

- Manual WM Security Routers V2.04 enDocument127 pagesManual WM Security Routers V2.04 enOscar TamayoNo ratings yet

- How To Write Big Application in ExtjsDocument17 pagesHow To Write Big Application in ExtjsPrabhu Patil100% (1)

- Diwali Greeting CodeDocument4 pagesDiwali Greeting CodeVaneet Kumar NagpalNo ratings yet

- L6 - Information Systems SecurityDocument17 pagesL6 - Information Systems Securityhieubot1111No ratings yet