Professional Documents

Culture Documents

ELAFLEX Information 5.09

ELAFLEX Information 5.09

Uploaded by

Bernardo Campos PereiraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ELAFLEX Information 5.09

ELAFLEX Information 5.09

Uploaded by

Bernardo Campos PereiraCopyright:

Available Formats

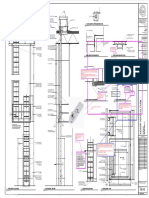

Aircraft Refuelling Hoses:

Assembling and Testing

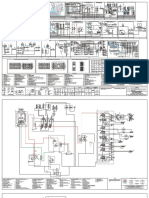

SPANNLOC hose clamps acc. to EN 14420-3

TECHNISCHE ÄNDERUNGEN VORBEHALTEN · NACHDRUCK UND KOPIEN NUR MIT UNSEREM EINVERSTÄNDNIS · Specifications subject to change without notice · Copyright ELAFLEX

SC [DN ...]

Hose tail acc. to EN 14420-2

2 3

Clamp hose straight in a smooth vice. Position SPANNLOC hose clamps.

Cut with a sharp knife straight, at a right angle.

Safety collar

4 5

Grease all bolt threads prior to assembly. First use two long After removing the long assembly bolts firmly tighten the

assembly bolts*), tighten evenly / crosswise. Spannloc screws crosswise.

Assembly bolts

A remaining space

between the clamps

should be parallel.

*) see catalogue page 297

October 2009 Information 5.09

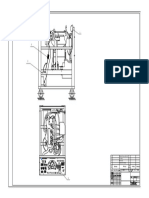

Hydrostatic Testing of Aircraft Refuelling Hoses

Prior to commissioning, aviation hose assemblies should

be pressure tested.

Our hoses are tested twice before delivery: at ContiTech

hose production and after assembly by ELAFLEX, with

test pressure of 40 bar.

The test procedures for used aircraft refuelling hoses

are described in the JIG Guidelines.

ELAFLEX test according to EN 1361 / API 1529:

l New aviation hose assemblies are tested by twice

the highest permitted working pressure (working

pressure 20 bar = test pressure 40 bar).

l The hose assembly ideally lays in a straight line

l Before testing all air is bled off

l During testing we check for hose or coupling leaks,

bubbles, deformations, twist / torsion, undue hose

elongation, coupling attachment

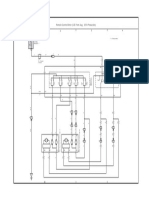

Hydrostatic testing, water / at 40 bar

Measuring Electrical Continuity

Aircraft refuelling hose assemblies are designed for safe

electrostatic dissipation.

Aviation hoses are differentiated by 'Ohm' hoses (type

C and F) and 'M'-hoses (e.g. type B, for army use only).

The resistance shall not exceed

Ohmmeter: used for Insulation Tester (500 V d.c.):

- 106 Ω for 'Ohm' hose assemblies measuring 'M' hoses used for measuring 'Ohm' hoses

(EN ISO 8031)

- 102 Ω for 'M' hose assemblies

between hose couplings.

ELAFLEX test according to EN ISO 1361 / 8031:

l Electrical continuity testing is done after hydrostatic

testing

l The hose assembly should be completely empty

(no medium within the hose)

l Measuring is only done on dry and non conducting

ground (e.g. no metal, no wet surface)

l Contact between hose covers is avoided

(not reeled up)

l Measuring is only done from coupling to coupling

l Electrodes of testing instrument must not be touched

during measuring

l ELAFLEX only deliver aircraft refuelling hose

assemblies with an electrical continuity between

103 and 106 Ω for 'Ohm' hoses and < 102 Ω for

'M' hoses Electrical continuity testing

You might also like

- Usp 1665Document12 pagesUsp 1665Adriana100% (1)

- Aisin AW TF-80SCDocument1 pageAisin AW TF-80SCJesus Alejandro Miranda Palacios100% (1)

- Quick Reference Guide To ASME Section VIII, Div. 1: Asme Boiler & Pressure Vessel Code (BPVC)Document1 pageQuick Reference Guide To ASME Section VIII, Div. 1: Asme Boiler & Pressure Vessel Code (BPVC)Amit Dama100% (1)

- S001Document1 pageS001Yong Hui OngNo ratings yet

- EN5254 8 10 20 - MobileValvesDocument5 pagesEN5254 8 10 20 - MobileValvesAmit GuptaNo ratings yet

- 6 75122 Linked PDFDocument6 pages6 75122 Linked PDFNikNo ratings yet

- CAP-1901-EM-02 - AC Switchboard-1Document1 pageCAP-1901-EM-02 - AC Switchboard-1Nindy FebrianiNo ratings yet

- TE415 Machine Tool Probe CalibrationDocument6 pagesTE415 Machine Tool Probe CalibrationAlexander Binyamin Marquez Rodriguez100% (1)

- RENR2118Document2 pagesRENR2118Barzola Soto OmarNo ratings yet

- Tainted Grail RulebookDocument24 pagesTainted Grail Rulebooknerid1973No ratings yet

- 001Document1 page001Ibrahim SahinNo ratings yet

- 83 Vios / Yaris: Remote Controlmirror (S/D From Aug. 2018 Production)Document1 page83 Vios / Yaris: Remote Controlmirror (S/D From Aug. 2018 Production)VôĐốiNo ratings yet

- Manual Azbil 25&26Document4 pagesManual Azbil 25&26Albert KristianNo ratings yet

- KSS 80 ZV-2 - Elektri̇kDocument5 pagesKSS 80 ZV-2 - Elektri̇kBerat DeğirmenciNo ratings yet

- 2216 pdf7 PDFDocument6 pages2216 pdf7 PDFRobert Blake DesignsNo ratings yet

- MS-AJ1 MS-AJ2: Universal Sensor Mounting StandDocument2 pagesMS-AJ1 MS-AJ2: Universal Sensor Mounting StandAjay MayalNo ratings yet

- Solenoid Valves 2/2 210: Pilot Operated, Hung Diaphragm For Vacuum Service 3/8 To 3/4Document2 pagesSolenoid Valves 2/2 210: Pilot Operated, Hung Diaphragm For Vacuum Service 3/8 To 3/4Evgeny DedashkoNo ratings yet

- Specifications 注意事項: Safety WiringDocument2 pagesSpecifications 注意事項: Safety WiringMalik MayNo ratings yet

- Sharp Runtka611wjqz psd-0698 Psu SCHDocument2 pagesSharp Runtka611wjqz psd-0698 Psu SCHMarko VujinovićNo ratings yet

- Features: NC FunctionDocument4 pagesFeatures: NC FunctionSachin MoreNo ratings yet

- MS 13 66Document2 pagesMS 13 66nurockNo ratings yet

- Electrical Drawing Package: LoadersDocument24 pagesElectrical Drawing Package: LoadersHebert Sozinyu100% (1)

- Asco E398a005Document2 pagesAsco E398a005ersanjeeb_456No ratings yet

- 966H 972H Hydraulic Schematic RENR8828Document2 pages966H 972H Hydraulic Schematic RENR8828Freddy Quispe100% (1)

- Cepex Electric Butterfly Valve ExtremeDocument2 pagesCepex Electric Butterfly Valve ExtremegastonNo ratings yet

- 45F RCF 04GR3Document14 pages45F RCF 04GR3porter1980No ratings yet

- Mattel 6 Lane RacewayDocument1 pageMattel 6 Lane RacewayYegor OliynykNo ratings yet

- 60F RCP 03BR0Document14 pages60F RCP 03BR0bayu.agungnugroho96No ratings yet

- LT - Bruno SchilligDocument8 pagesLT - Bruno Schilligdownload02No ratings yet

- DS Control-Arch D DSC21Document1 pageDS Control-Arch D DSC21sreeagile.esNo ratings yet

- 83 Plano Elec PDFDocument6 pages83 Plano Elec PDFManuel CanazaNo ratings yet

- Schéma Électrique 923043Document1 pageSchéma Électrique 923043ChriskvaNo ratings yet

- Cascade Roller ClamDocument14 pagesCascade Roller ClamKevinNo ratings yet

- Tog Aeneas Mk7 Light Grav TankDocument1 pageTog Aeneas Mk7 Light Grav TankScott ClintonNo ratings yet

- Parts Manual: CascadeDocument14 pagesParts Manual: CascadeAlvaro PradaNo ratings yet

- Manual Stop - PetzlDocument21 pagesManual Stop - PetzlAlan AraujoNo ratings yet

- Technical Notice STOP 1Document21 pagesTechnical Notice STOP 1Rodrigo GlückNo ratings yet

- WM 2 Inch Drain LineDocument2 pagesWM 2 Inch Drain LineMark Darrel AranasNo ratings yet

- Transformer /175W Line Safety Line: MotorDocument1 pageTransformer /175W Line Safety Line: Motororo plataNo ratings yet

- Cascade 100F-RCF-119Document14 pagesCascade 100F-RCF-119alesker.alekperov71No ratings yet

- Fluidics 5800Document1 pageFluidics 5800Héctor GarcíaNo ratings yet

- Ground Floor Lighting Layout Ground Floor Power Layout Electrical NotesDocument1 pageGround Floor Lighting Layout Ground Floor Power Layout Electrical NotesRachelle Ann NotoNo ratings yet

- Adagio From Concerto in D Minor BWV 974 by A. Marcello-J.S. Bach For Violin and PianoDocument4 pagesAdagio From Concerto in D Minor BWV 974 by A. Marcello-J.S. Bach For Violin and Pianojuicedspy66554No ratings yet

- 100F RCP 03CR2Document14 pages100F RCP 03CR2Jorge Cortés RubianoNo ratings yet

- đông cơ sau khi cải tạoDocument1 pageđông cơ sau khi cải tạothanhlocpt2205No ratings yet

- Ach-Car ConnectionsDocument1 pageAch-Car ConnectionsFidan LatifiNo ratings yet

- Tp5-Manual Fuel Supply-Plan: TP-5 Pipe Cut List Tag No Size QTY LENGTH (MM)Document1 pageTp5-Manual Fuel Supply-Plan: TP-5 Pipe Cut List Tag No Size QTY LENGTH (MM)pawanNo ratings yet

- Parts Manual: CascadeDocument16 pagesParts Manual: CascadeNizar BrahamNo ratings yet

- C15 and C18 Electrical System Industrial and Petroleum EngineDocument2 pagesC15 and C18 Electrical System Industrial and Petroleum EngineOsvaldo UrbanoNo ratings yet

- Adagio From Concerto in D Minor BWV 974 by A. Marcello-J.S. Bach For Violin and PianoDocument4 pagesAdagio From Concerto in D Minor BWV 974 by A. Marcello-J.S. Bach For Violin and PianoMarusa KotnikNo ratings yet

- A6.140 - Roof Access Ladder - 04!11!2022 - Issue For PermitDocument1 pageA6.140 - Roof Access Ladder - 04!11!2022 - Issue For PermitIMPRESIONESNo ratings yet

- EcosDocument9 pagesEcosEduarda da Luz AlmeidaNo ratings yet

- Celerra NX4 Parts GuideDocument10 pagesCelerra NX4 Parts GuideramarnehNo ratings yet

- Act A3 Fujilift Safety Line 220V PDFDocument1 pageAct A3 Fujilift Safety Line 220V PDFGhjNo ratings yet

- P&ID CWP Rev 2Document1 pageP&ID CWP Rev 2Ajeng OctaviaNo ratings yet

- A330 Test PDFDocument1 pageA330 Test PDFGeorge ArizaNo ratings yet

- ALUMERO Installation Instruction RoofHook EnglishDocument18 pagesALUMERO Installation Instruction RoofHook EnglishIsaac Torres LoretoNo ratings yet

- FM638 & FM639: Fully Lugged Butterfly Valve PN25Document1 pageFM638 & FM639: Fully Lugged Butterfly Valve PN25RonaldNo ratings yet

- Bdstde01 16 PDFDocument1 pageBdstde01 16 PDFAhmed HadeeNo ratings yet

- 3 DrawingsDocument4 pages3 DrawingsardipangulihiNo ratings yet

- It's So Easy Going Green: An Interactive, Scientific Look at Protecting Our EnvironmentFrom EverandIt's So Easy Going Green: An Interactive, Scientific Look at Protecting Our EnvironmentNo ratings yet

- Ansul N2 MSDSDocument8 pagesAnsul N2 MSDSBernardo Campos PereiraNo ratings yet

- Ansul CO2 MSDSDocument8 pagesAnsul CO2 MSDSBernardo Campos PereiraNo ratings yet

- Q5 UQnc GIn GGNJVDocument5 pagesQ5 UQnc GIn GGNJVBernardo Campos PereiraNo ratings yet

- Wel 3 H JHKC OM3 W3Document10 pagesWel 3 H JHKC OM3 W3Bernardo Campos PereiraNo ratings yet

- WEo DEa SiDocument12 pagesWEo DEa SiBernardo Campos PereiraNo ratings yet

- Performance Objectives For Light Sources Used in Emergency Notification AppliancesDocument41 pagesPerformance Objectives For Light Sources Used in Emergency Notification AppliancesBernardo Campos PereiraNo ratings yet

- Ansul Sentry Hydrostatic Test ProcedureDocument16 pagesAnsul Sentry Hydrostatic Test ProcedureBernardo Campos PereiraNo ratings yet

- FB 1200Document110 pagesFB 1200Bernardo Campos PereiraNo ratings yet

- RedLine ManualDocument2 pagesRedLine ManualBernardo Campos PereiraNo ratings yet

- XXXXXXXXXXXXXXXXXXXDocument2 pagesXXXXXXXXXXXXXXXXXXXBernardo Campos PereiraNo ratings yet

- 8C-16M B3 CatalogDocument27 pages8C-16M B3 CatalogBernardo Campos PereiraNo ratings yet

- Restaurant Fire Suppression Systems: AnsulDocument8 pagesRestaurant Fire Suppression Systems: AnsulBernardo Campos PereiraNo ratings yet

- Chemical Kinetics - LectureDocument37 pagesChemical Kinetics - LectureEsmira Melić ŠutkovićNo ratings yet

- Can We Achieve Ultra-Low Resistivity in Carbon Nanotube-Based Metal Composites?Document5 pagesCan We Achieve Ultra-Low Resistivity in Carbon Nanotube-Based Metal Composites?tao fanNo ratings yet

- Mis 7th Edition Bidgoli Test BankDocument35 pagesMis 7th Edition Bidgoli Test Bankepulotictomaleyrakqbs100% (19)

- Document 1Document3 pagesDocument 1rauff ridwan akmadNo ratings yet

- CHEE311 Lecture 25 2010Document9 pagesCHEE311 Lecture 25 2010Gaurav SinghalNo ratings yet

- NotesDocument36 pagesNotesULTRA College of Engineering & Technology for WomenNo ratings yet

- Lecture 15Document42 pagesLecture 15amitNo ratings yet

- Iec 60287-1-1Document44 pagesIec 60287-1-1Jose Giraldo100% (1)

- DLP - Final-Demo - Weld DefectsDocument11 pagesDLP - Final-Demo - Weld DefectsTrecita BacoNo ratings yet

- Chemistry MCQs PPSCDocument92 pagesChemistry MCQs PPSCMuhammad Zain Kaleem100% (1)

- Beacon Ep 2Document9 pagesBeacon Ep 2David Lie0% (1)

- Bingham Reiner EquationDocument6 pagesBingham Reiner EquationSaad Ahmed100% (2)

- 4 Adet Cümle Analizi PDFDocument2 pages4 Adet Cümle Analizi PDFferhat500No ratings yet

- ASU - Double Column ProcessDocument5 pagesASU - Double Column ProcessMH CNo ratings yet

- Heat Treatment For 16 MNCR Material: Harichand, Krishan Kumar and S.K. JhaDocument5 pagesHeat Treatment For 16 MNCR Material: Harichand, Krishan Kumar and S.K. JhaMurali KrishnaNo ratings yet

- 6.1 Aircraft Materials - Ferrous LP-1 To 18Document7 pages6.1 Aircraft Materials - Ferrous LP-1 To 18CHAITANYA SATPUTENo ratings yet

- Astm C150-C150M-22Document9 pagesAstm C150-C150M-22mustafa97a141No ratings yet

- Swastik JainDocument13 pagesSwastik JainShoaib KhanNo ratings yet

- FL4000H - MSIR - Performance - Report - ENDocument8 pagesFL4000H - MSIR - Performance - Report - ENRenato RamosNo ratings yet

- Astm d1142 PDFDocument11 pagesAstm d1142 PDFwahyu haryadiNo ratings yet

- White Paper IV - William A Tiller PDFDocument18 pagesWhite Paper IV - William A Tiller PDFharrycbaungh100% (1)

- K01587 - 20200217124343 - Chapter 4 - Natural and Synthetic RubberDocument27 pagesK01587 - 20200217124343 - Chapter 4 - Natural and Synthetic RubberAbdulRahim059No ratings yet

- Chemsheets AS 1057 Group 2 Physical PrperrtiesDocument1 pageChemsheets AS 1057 Group 2 Physical PrperrtiesYusuf AhmedNo ratings yet

- Daily Lesson Plan: in Science 6Document75 pagesDaily Lesson Plan: in Science 6Bryan Bangiban100% (2)

- DCVG MethodDocument12 pagesDCVG MethodAmanSharmaNo ratings yet

- F C-Mo: C: AWS SFA 5.28 W P ER70S-A1 H, F, Vu, Oh CDocument1 pageF C-Mo: C: AWS SFA 5.28 W P ER70S-A1 H, F, Vu, Oh CAshok RajNo ratings yet

- Unit 6-Skincare - Part-3 PDFDocument6 pagesUnit 6-Skincare - Part-3 PDFAmber LugtuNo ratings yet

- Intro To Metabo (IsmDocument8 pagesIntro To Metabo (IsmManila MedNo ratings yet

- Itogon Suyoc Resources Inc. Refinery Circuit For 400 MTPDDocument1 pageItogon Suyoc Resources Inc. Refinery Circuit For 400 MTPDrewrtegamingNo ratings yet